Description

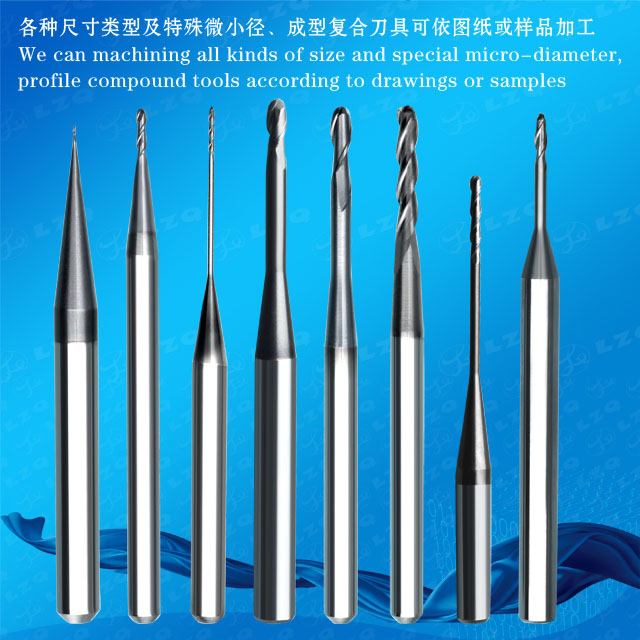

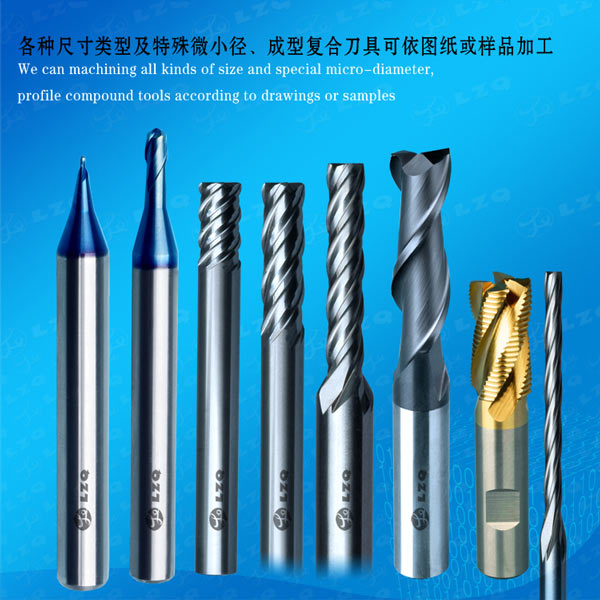

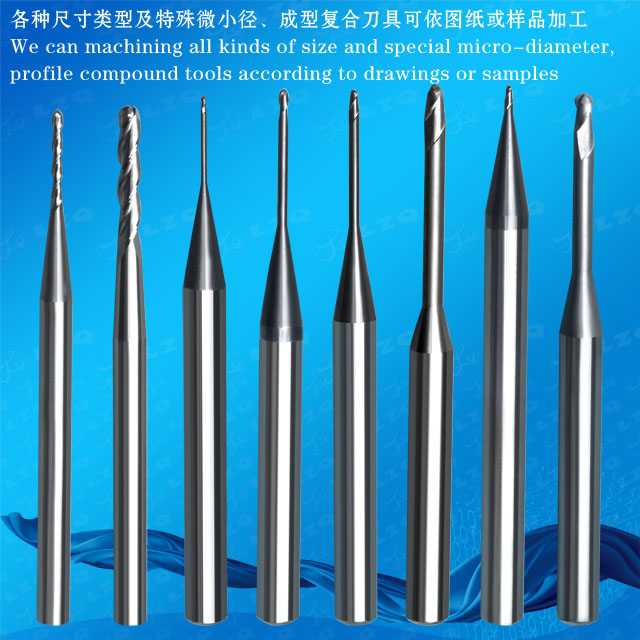

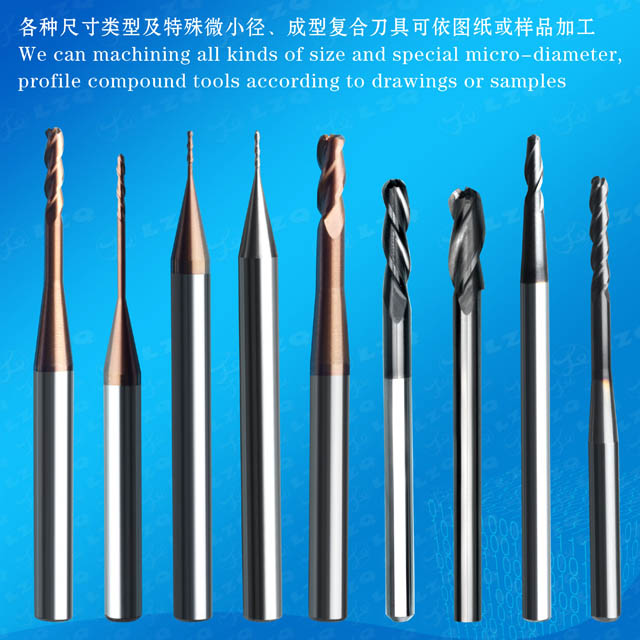

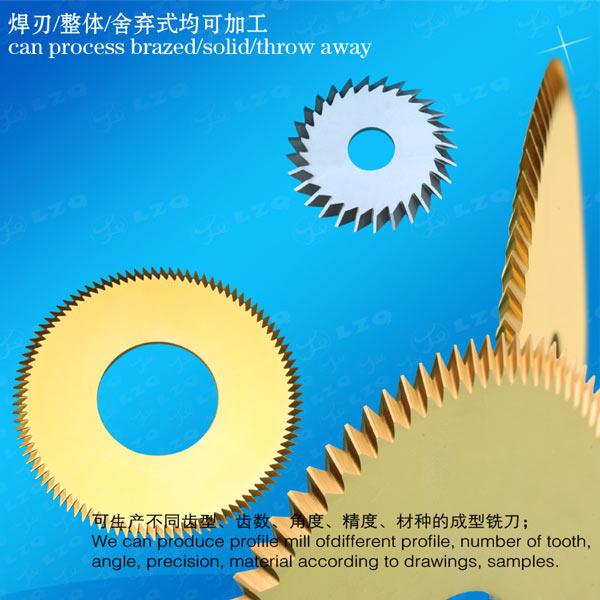

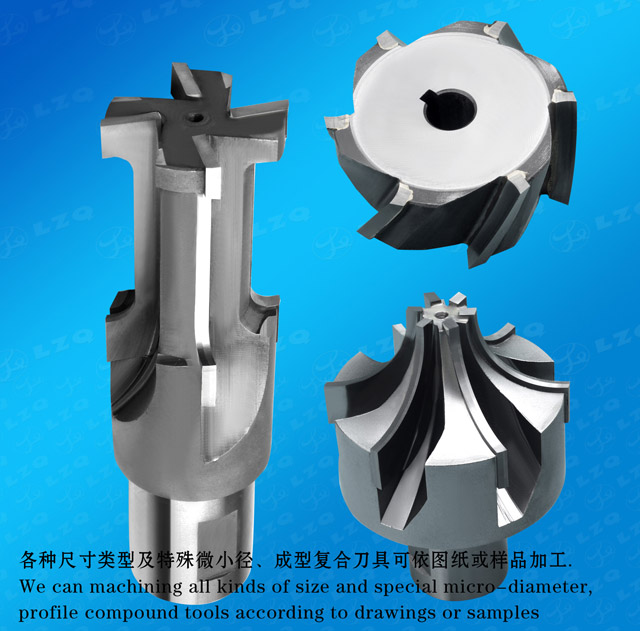

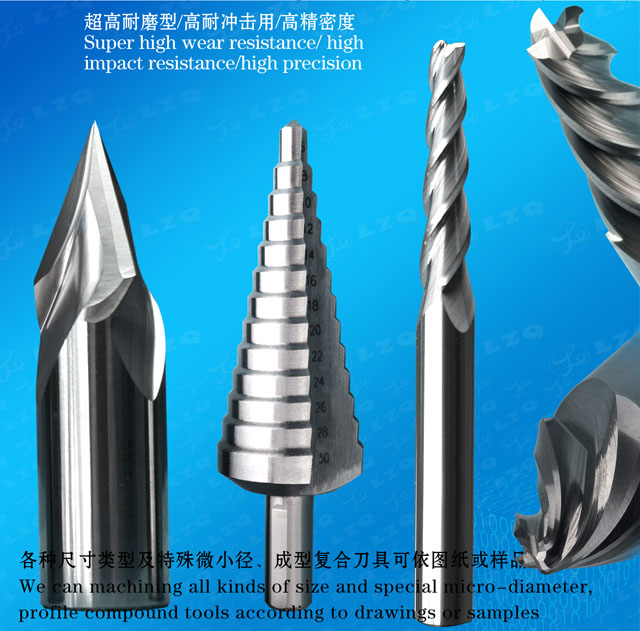

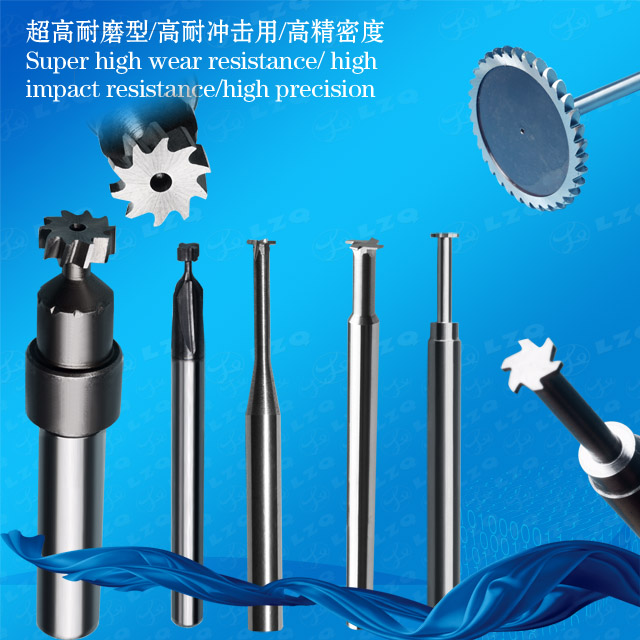

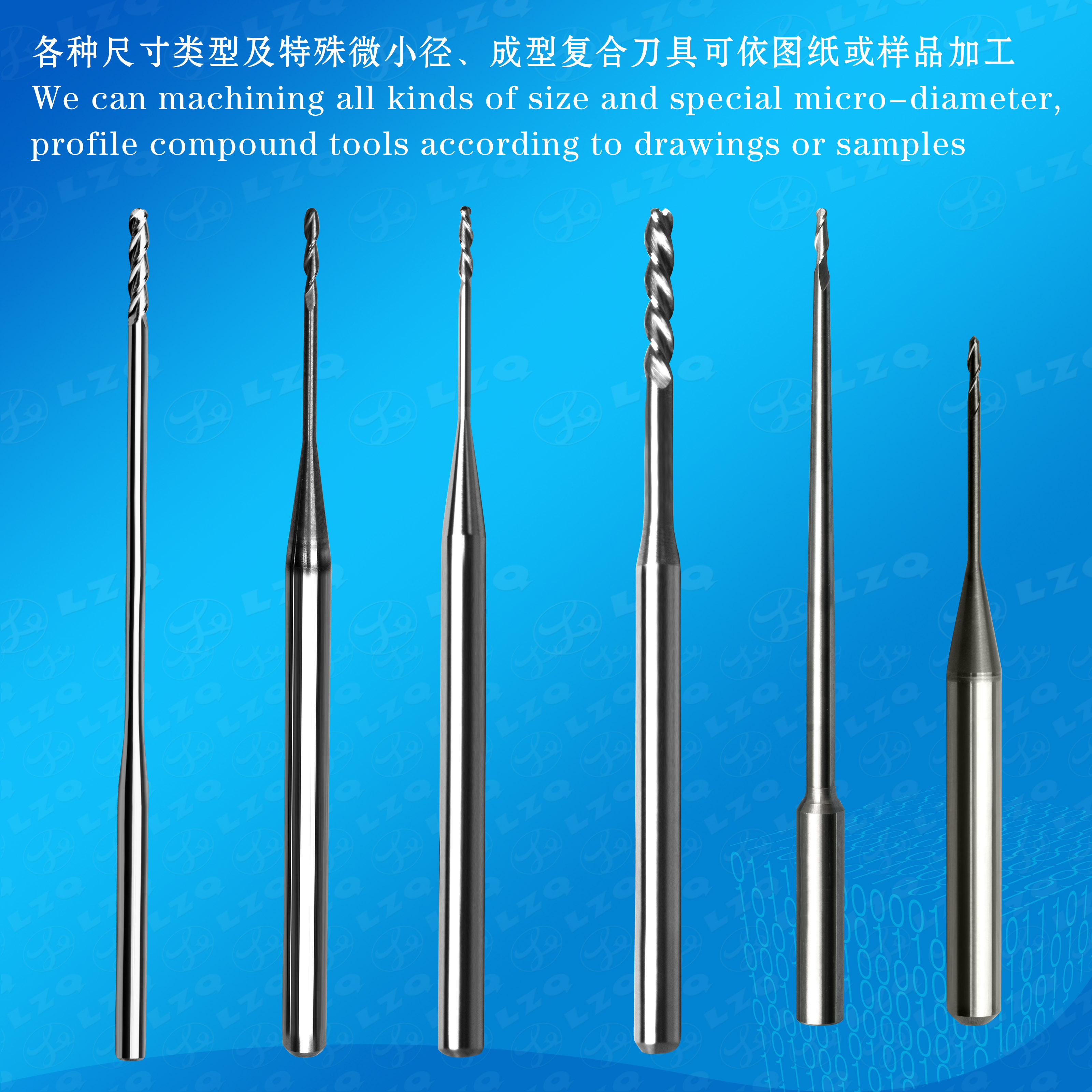

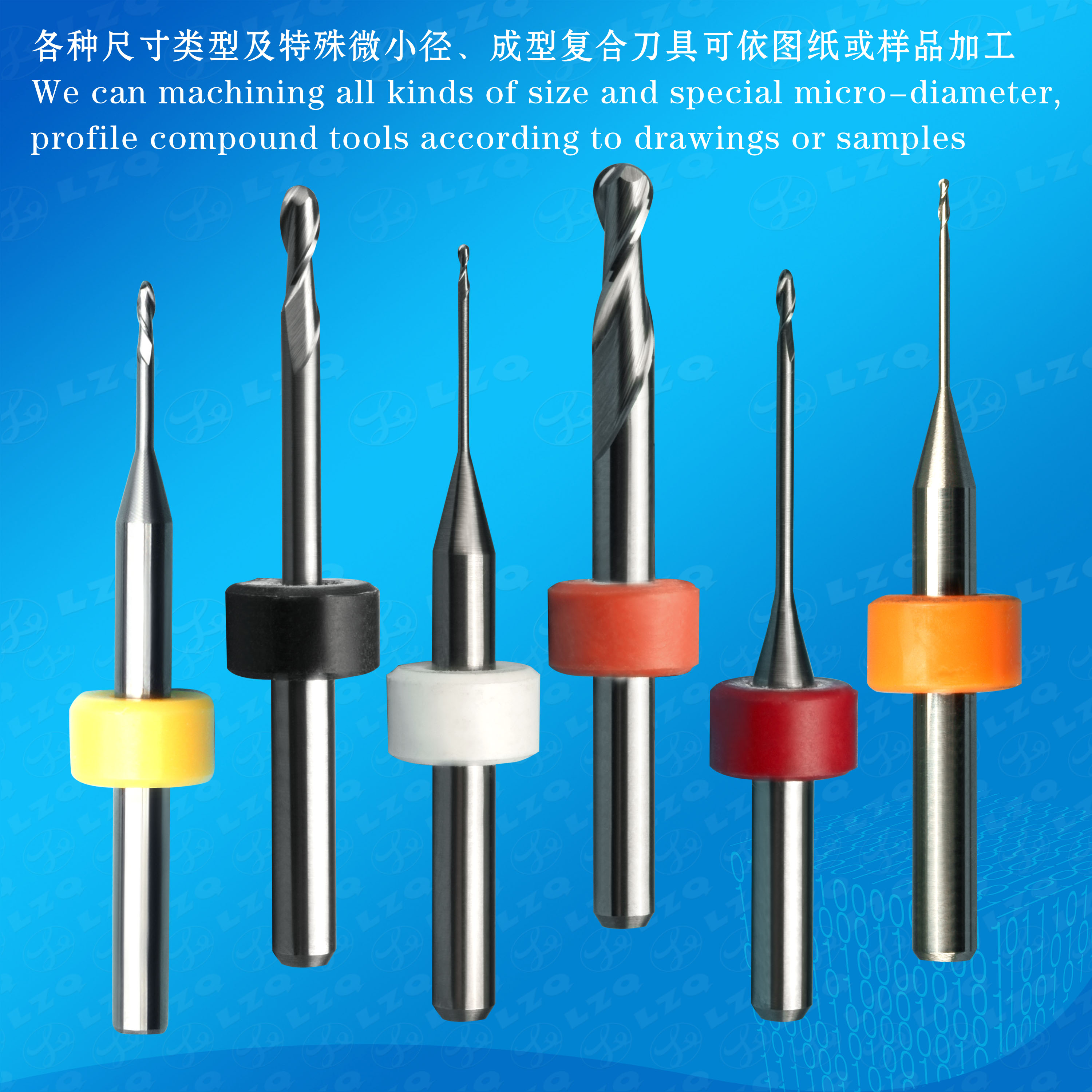

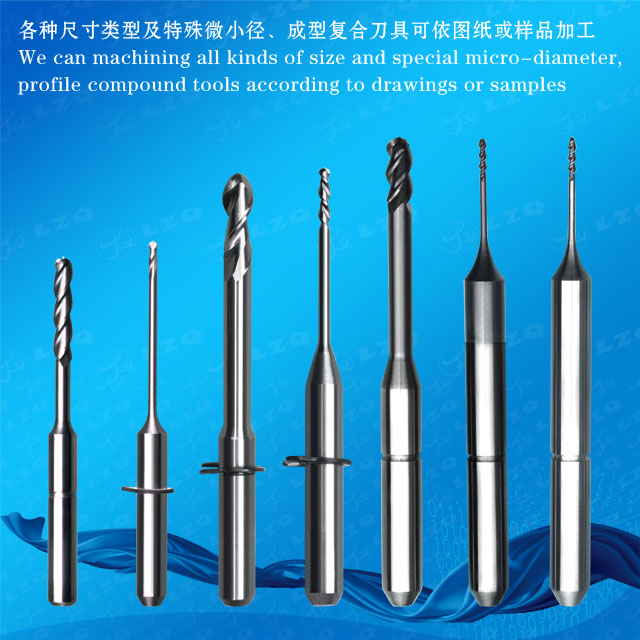

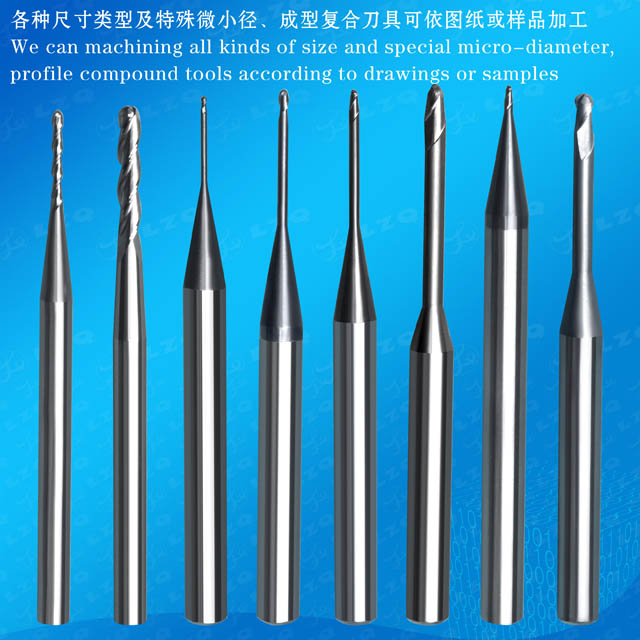

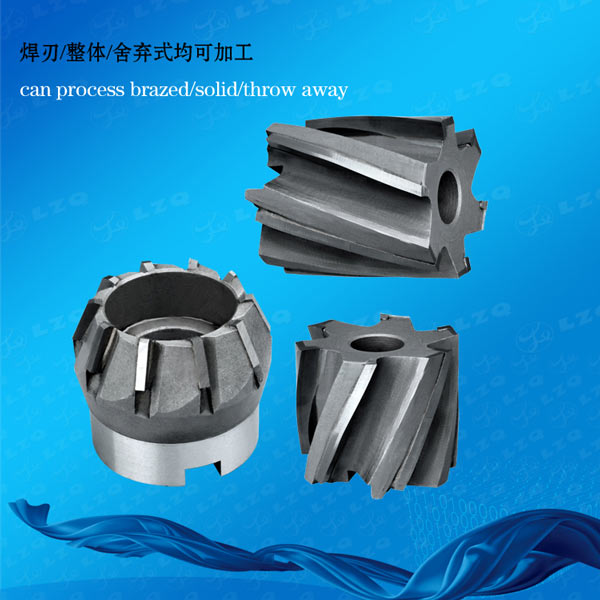

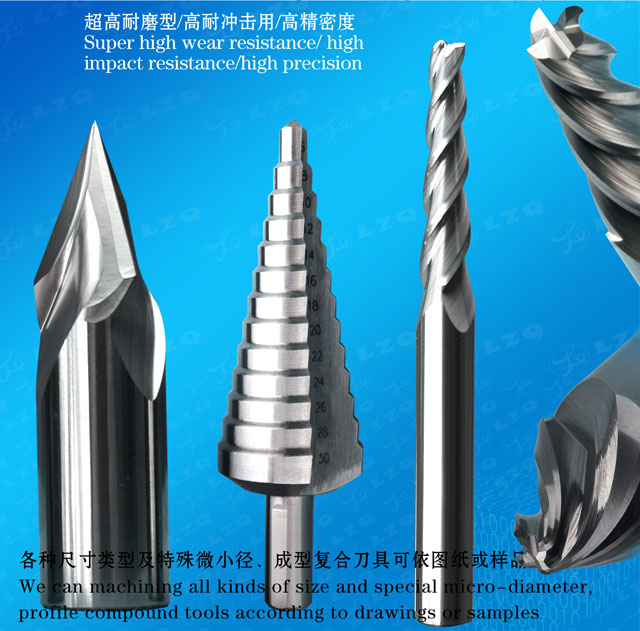

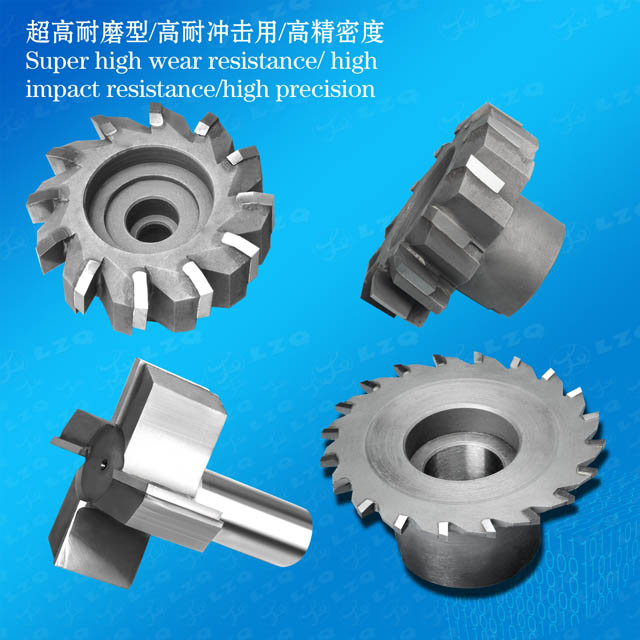

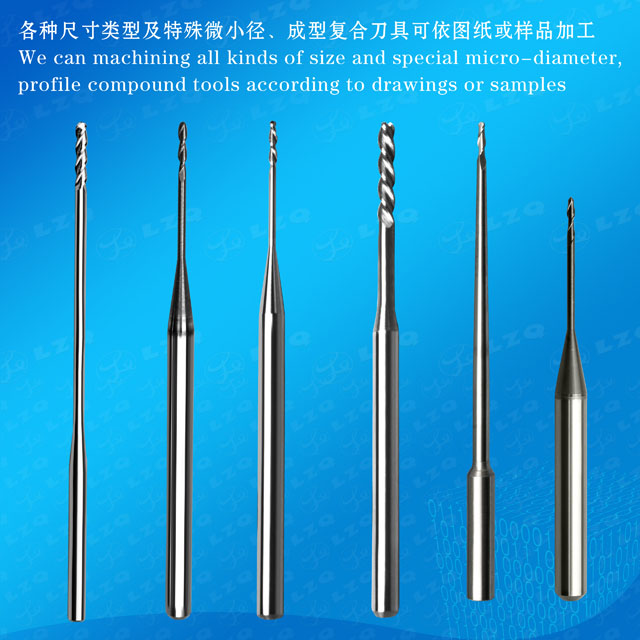

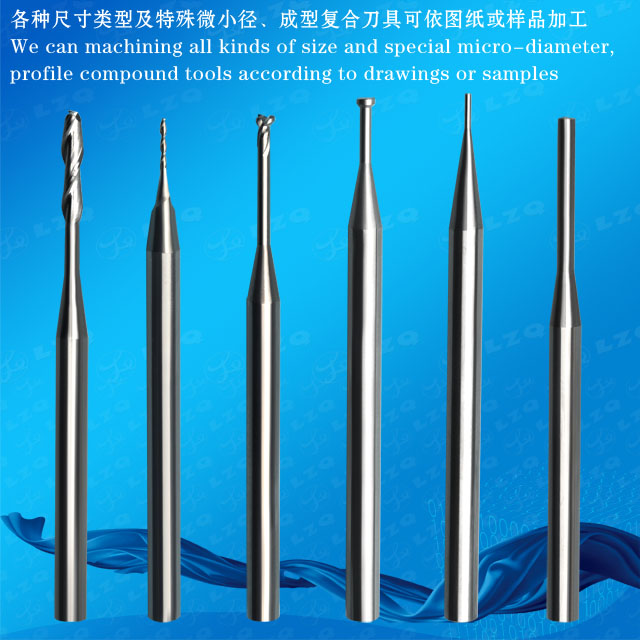

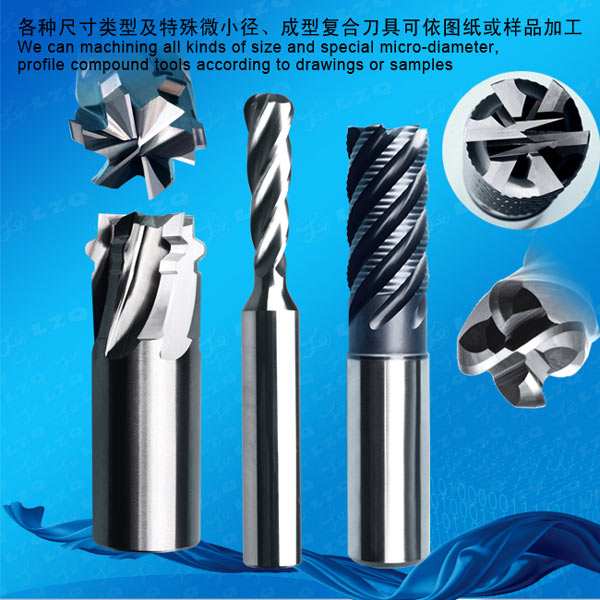

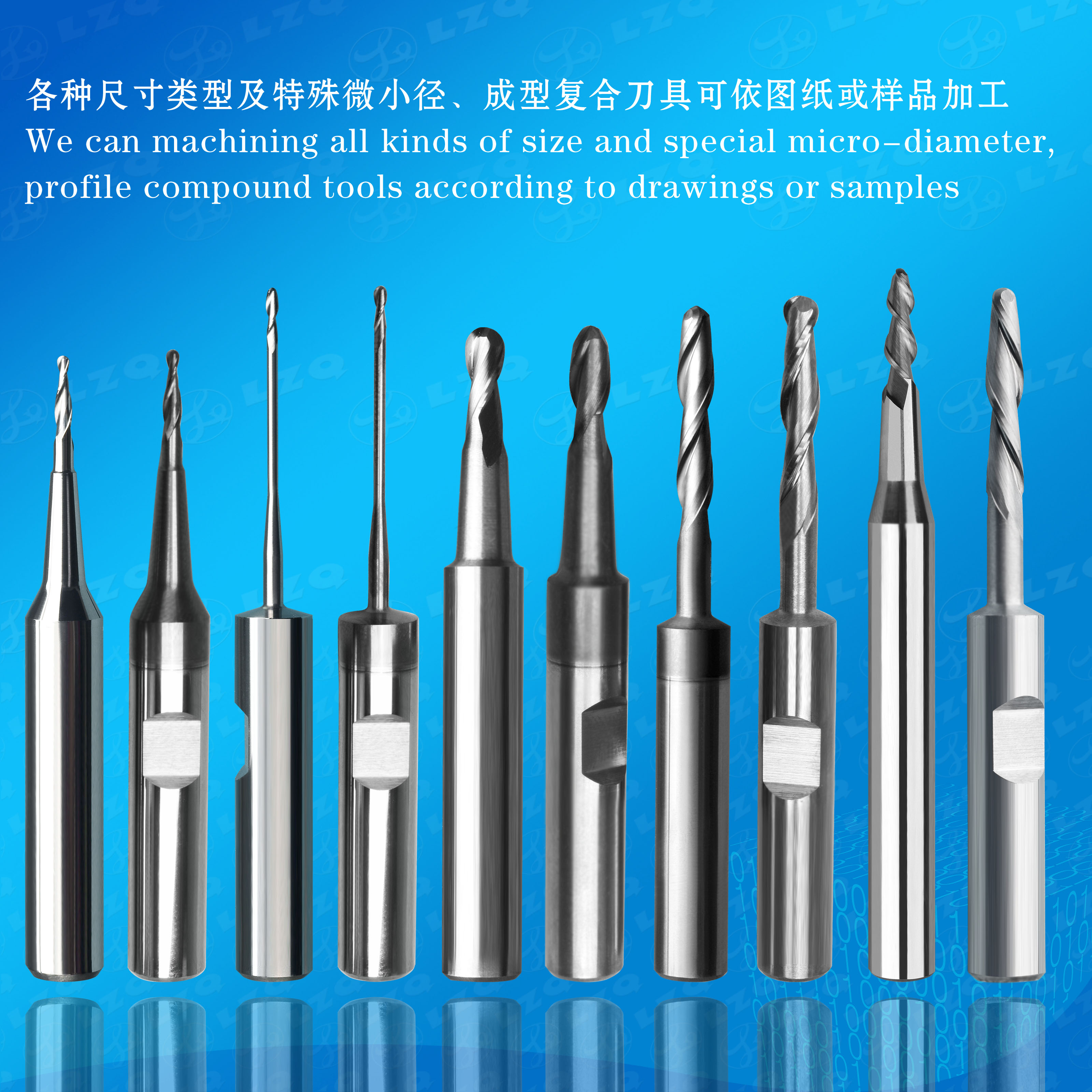

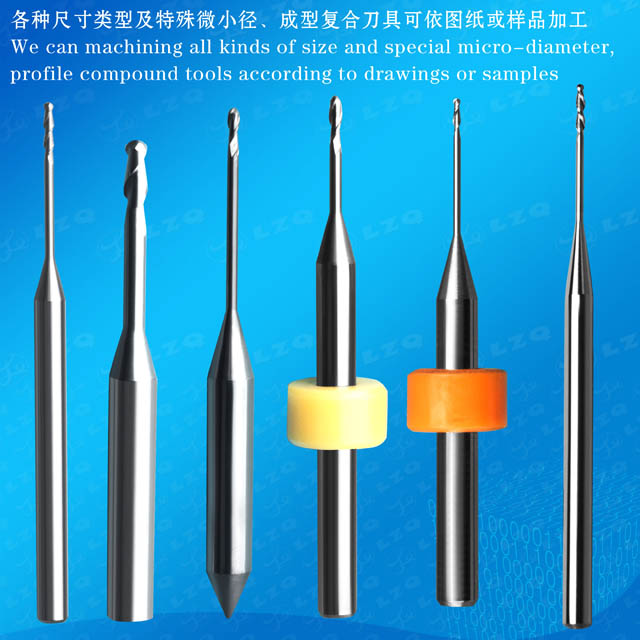

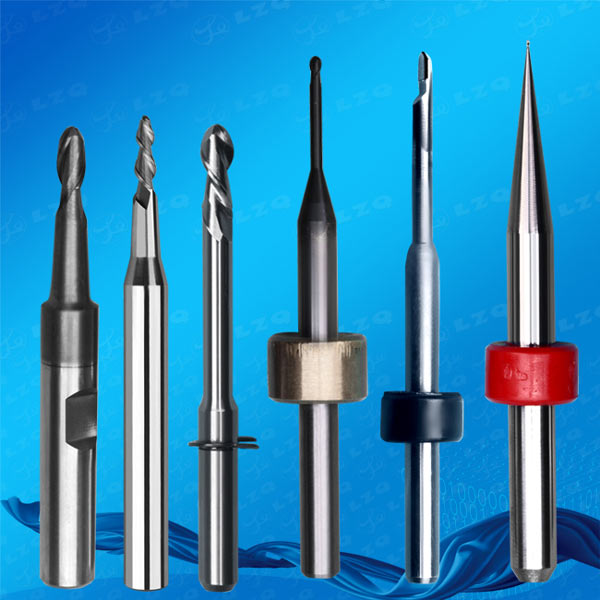

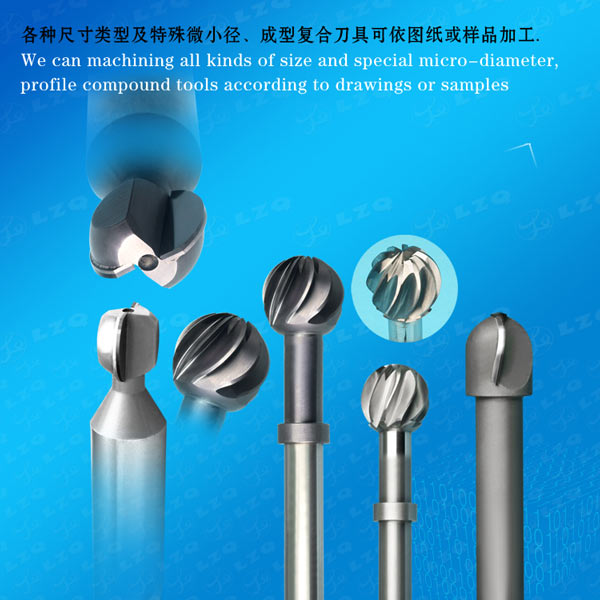

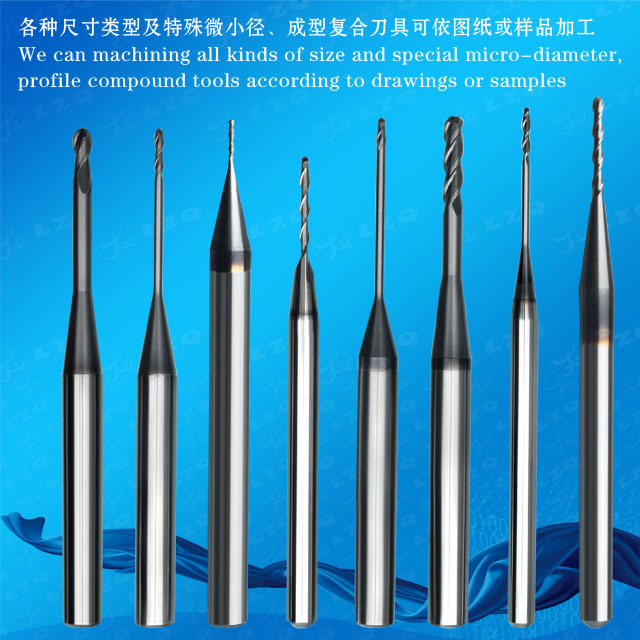

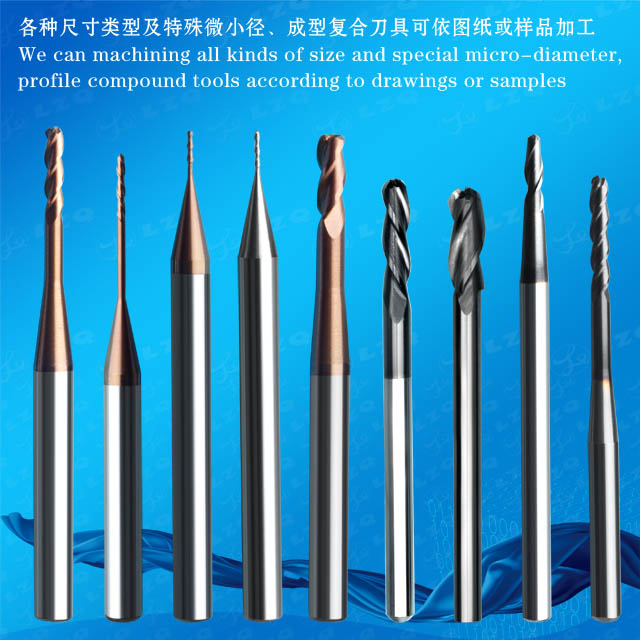

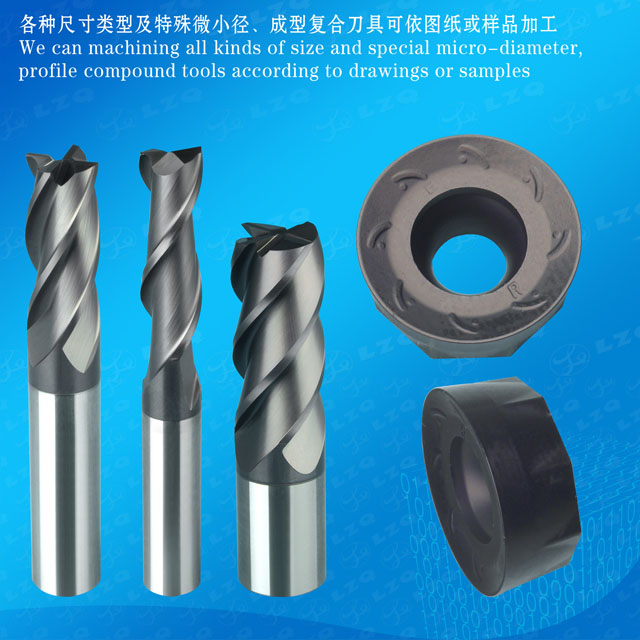

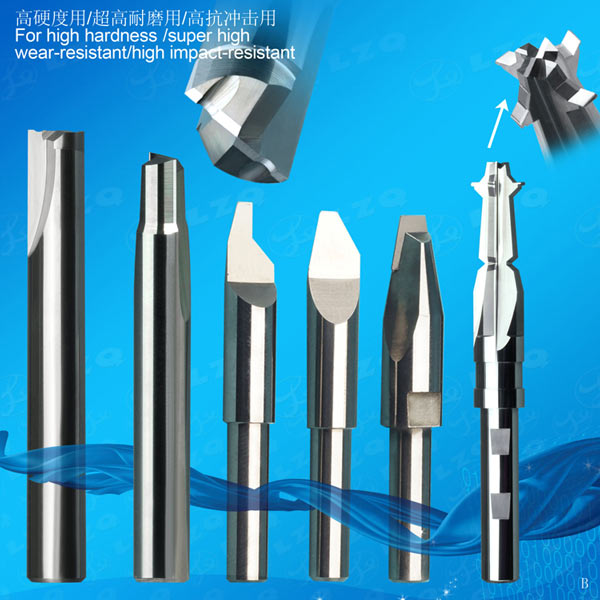

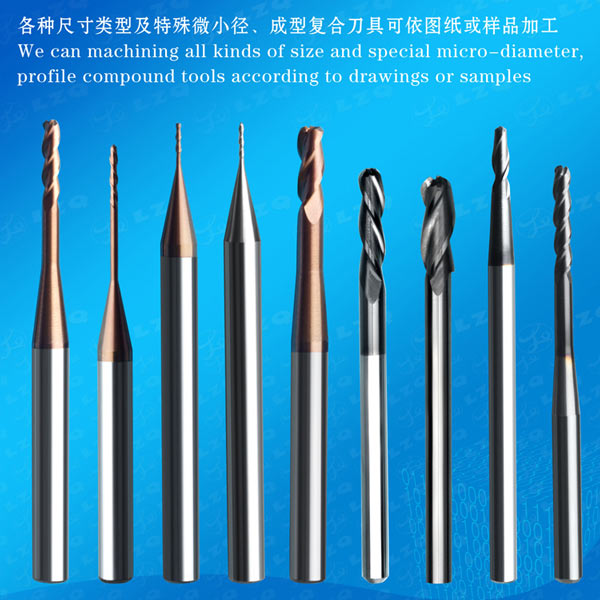

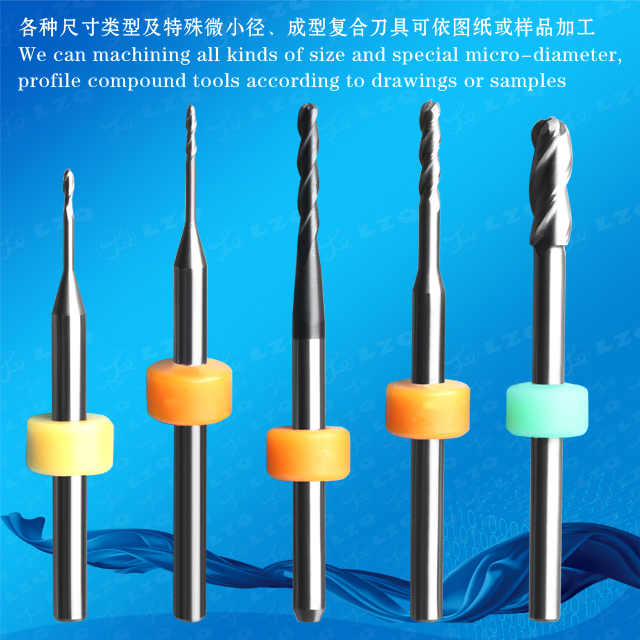

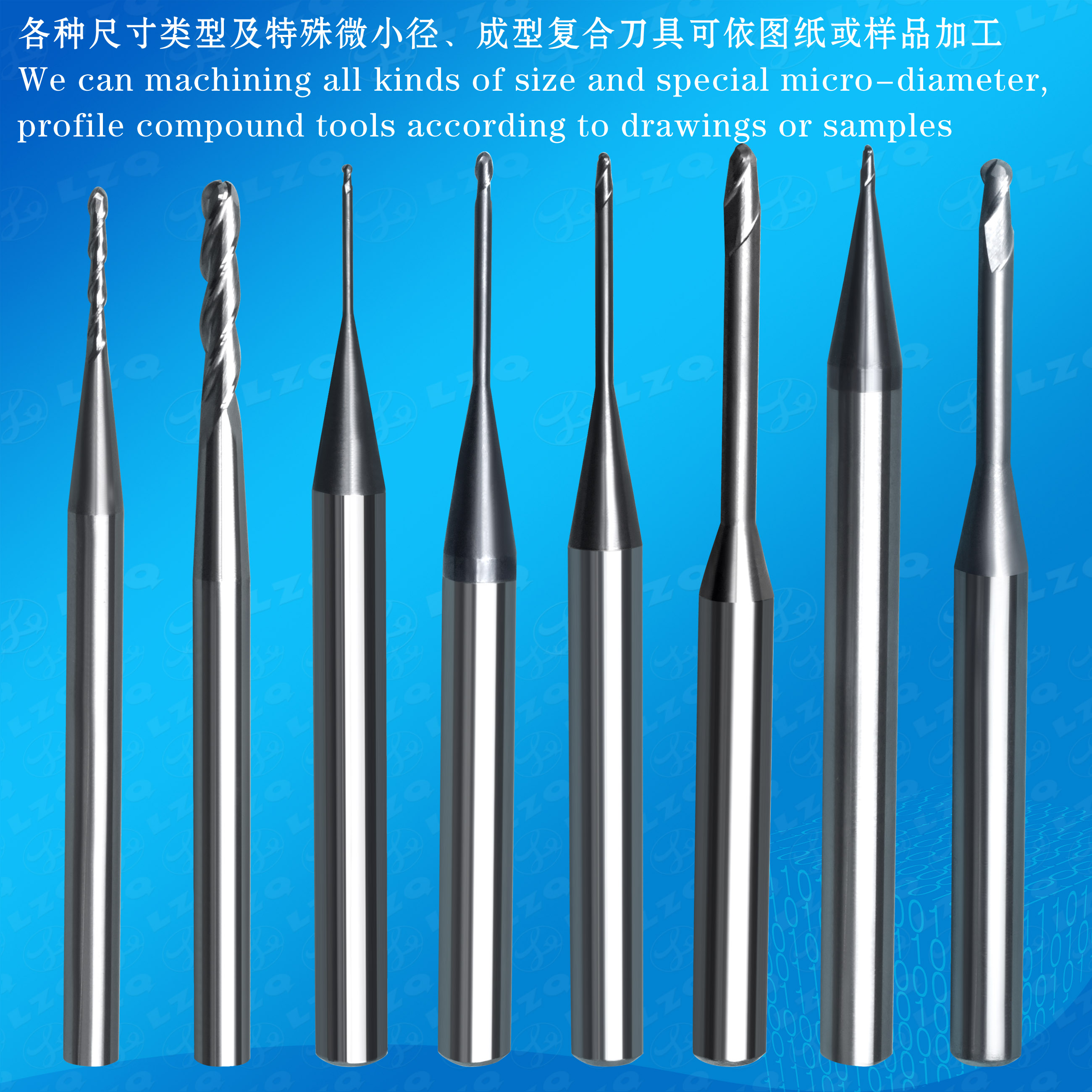

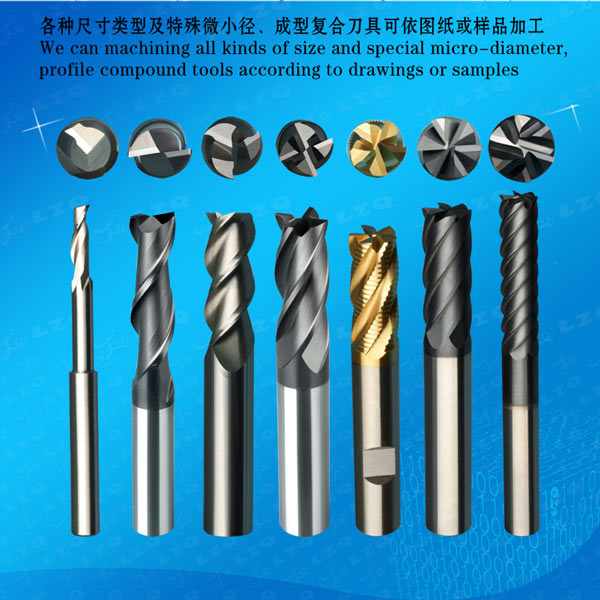

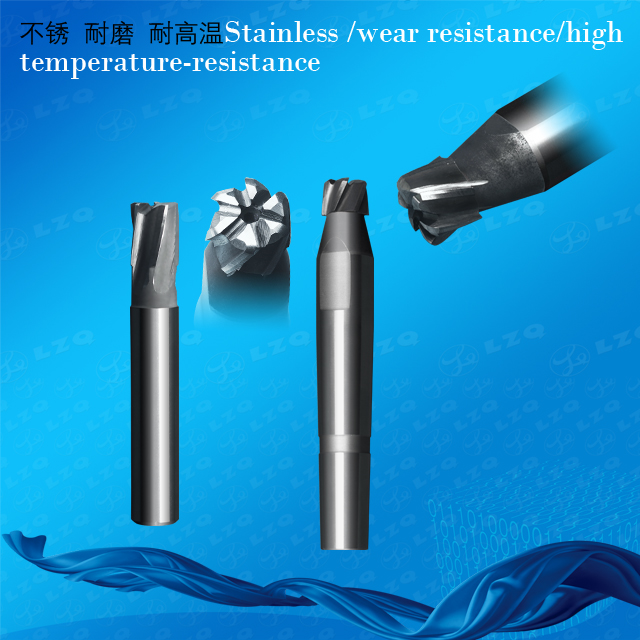

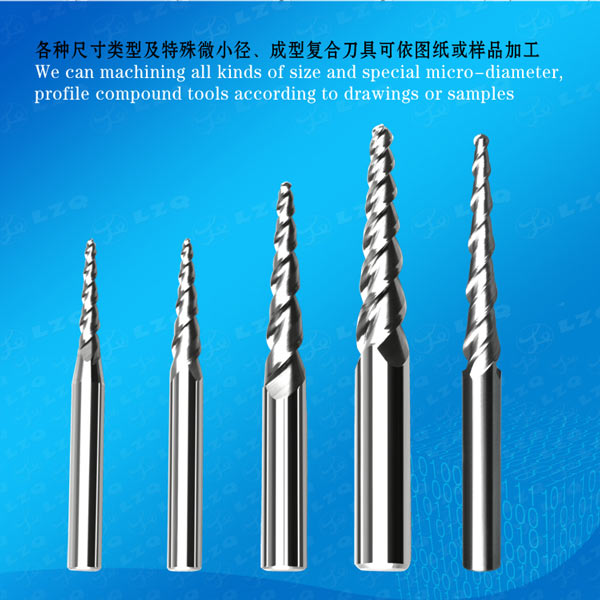

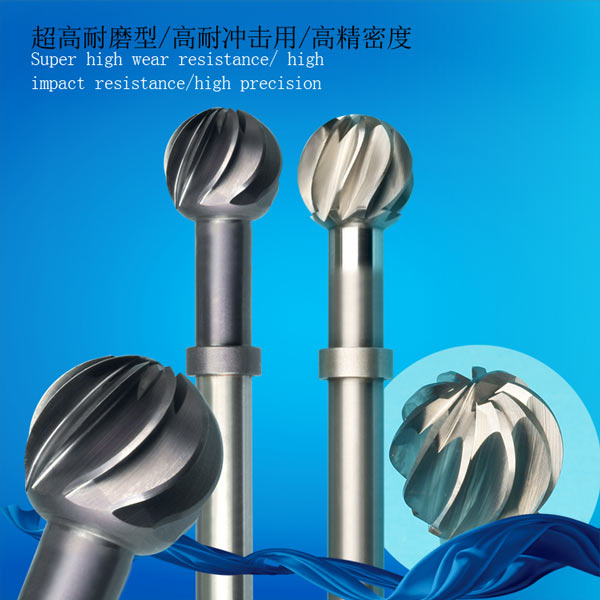

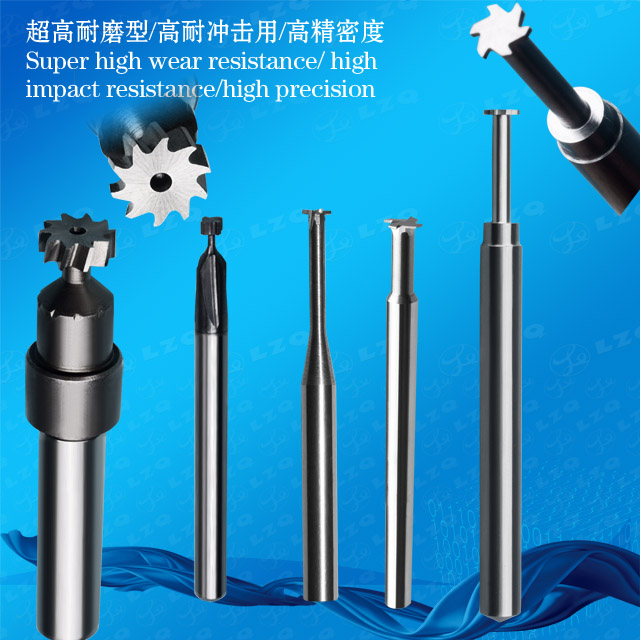

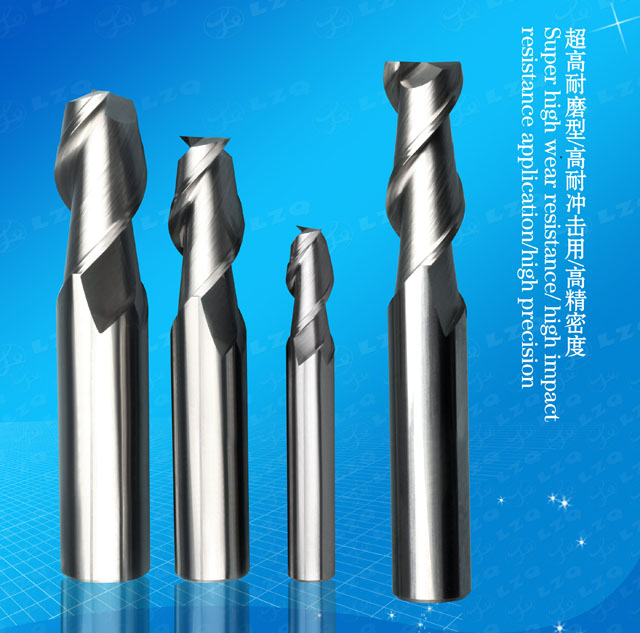

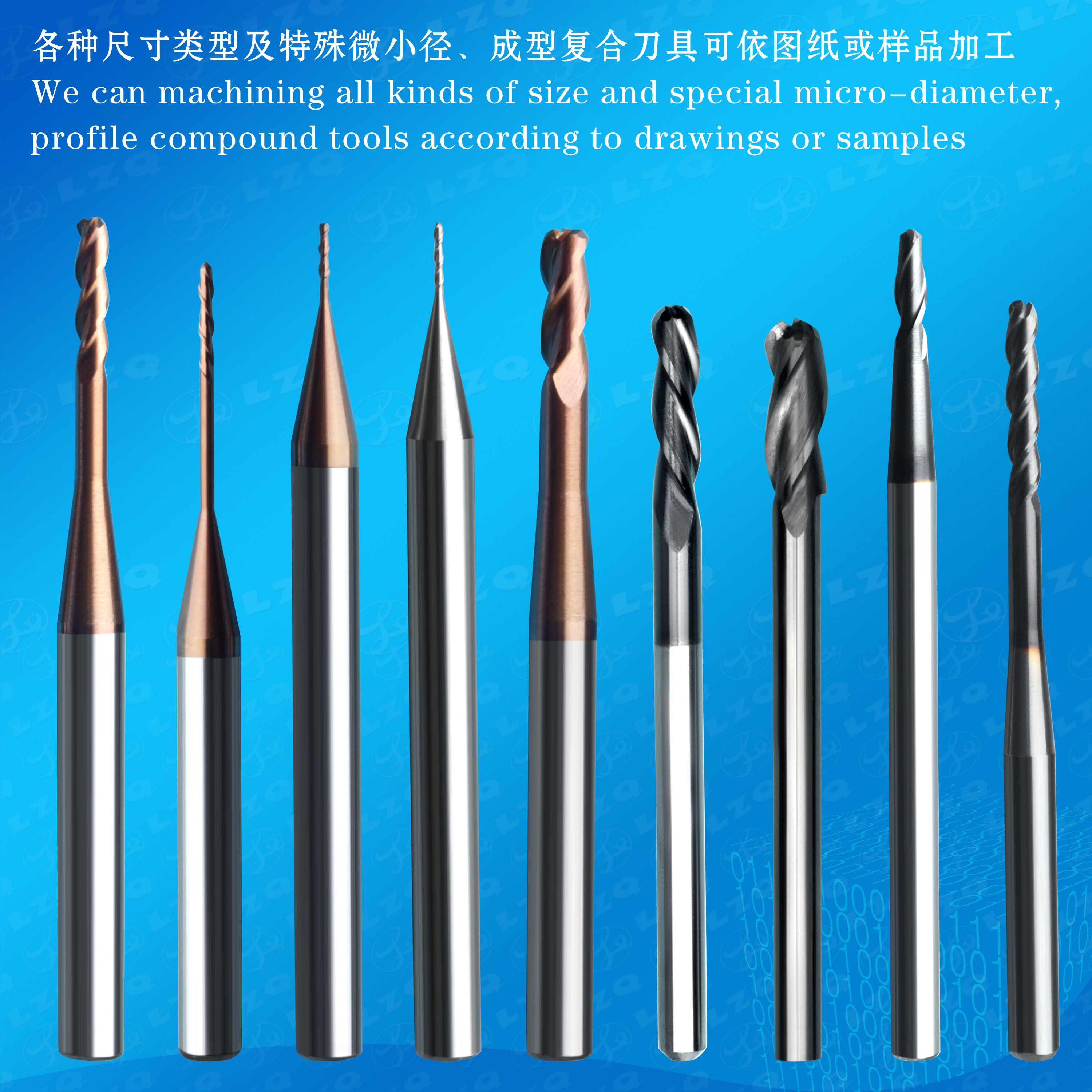

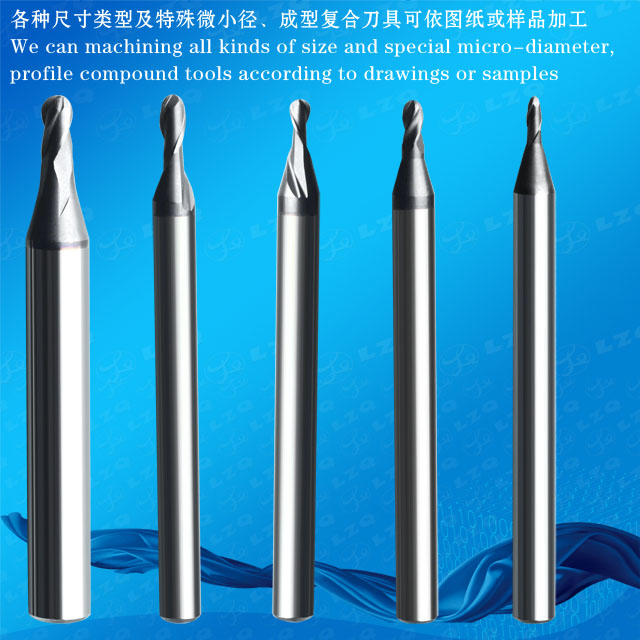

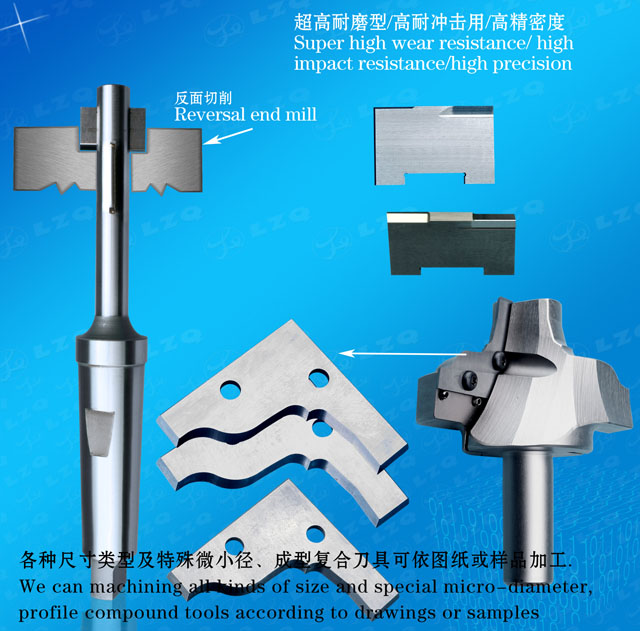

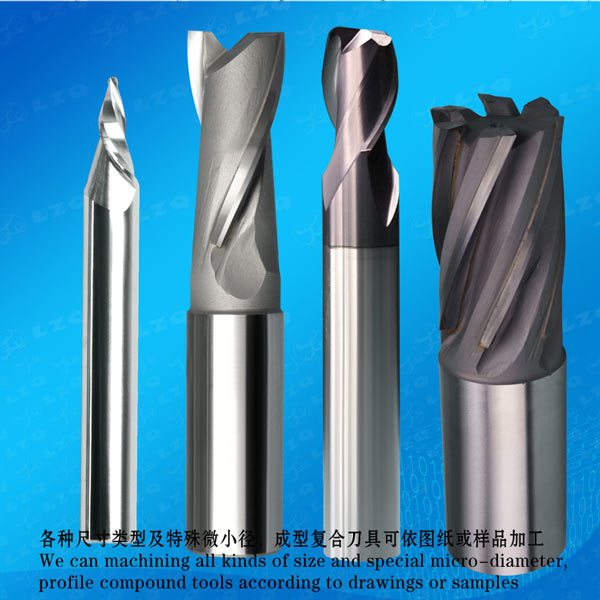

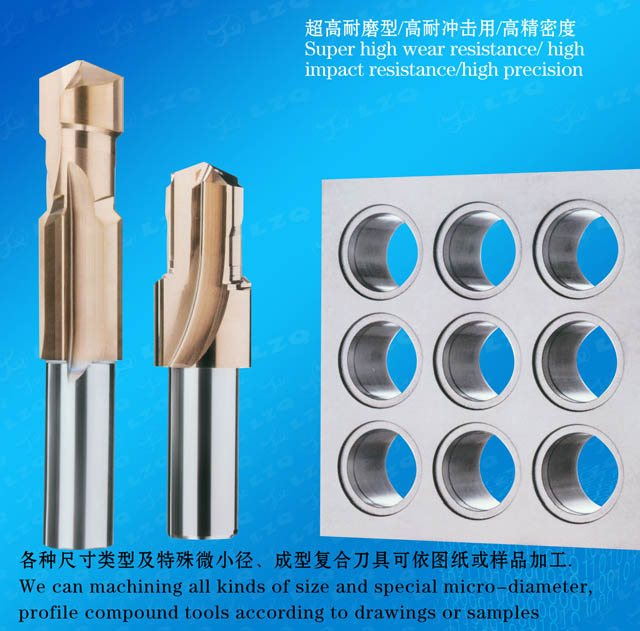

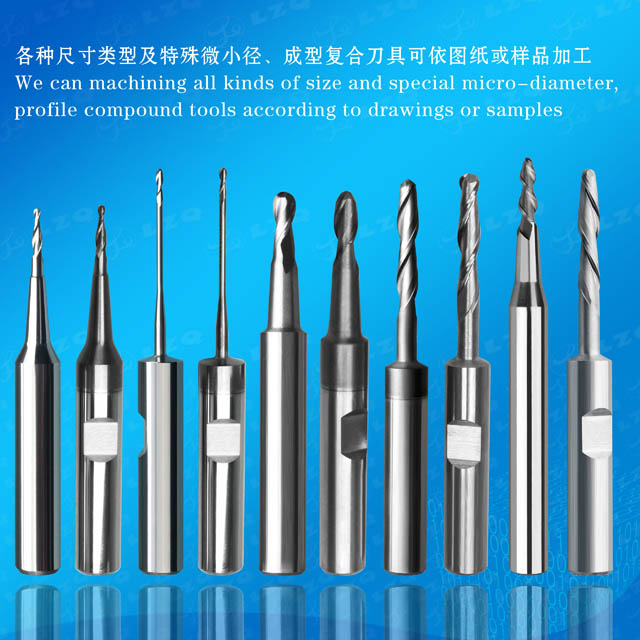

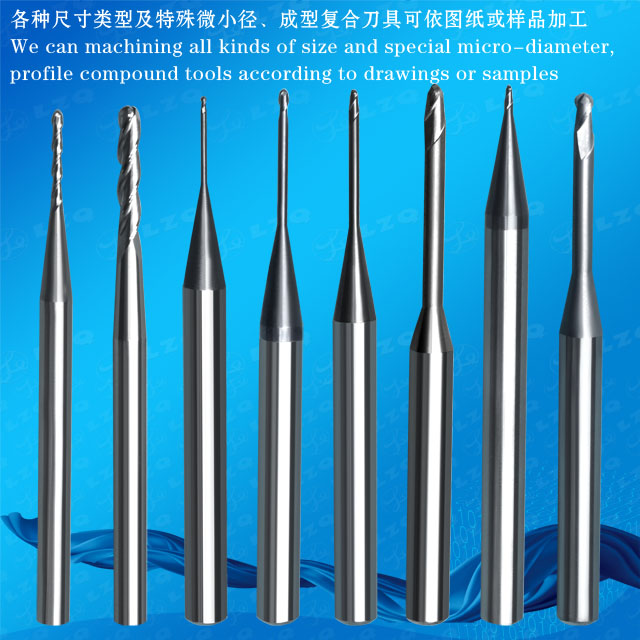

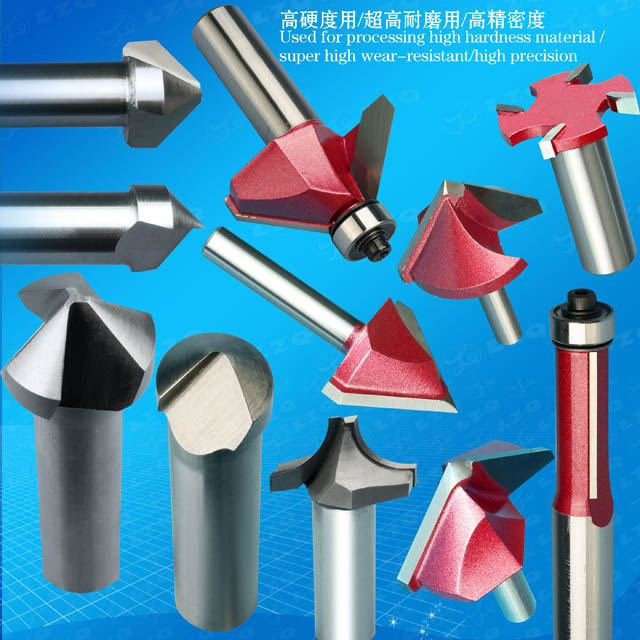

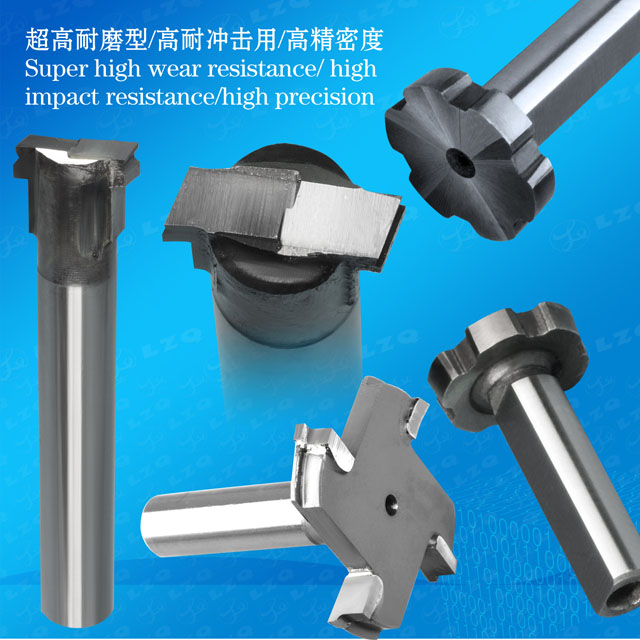

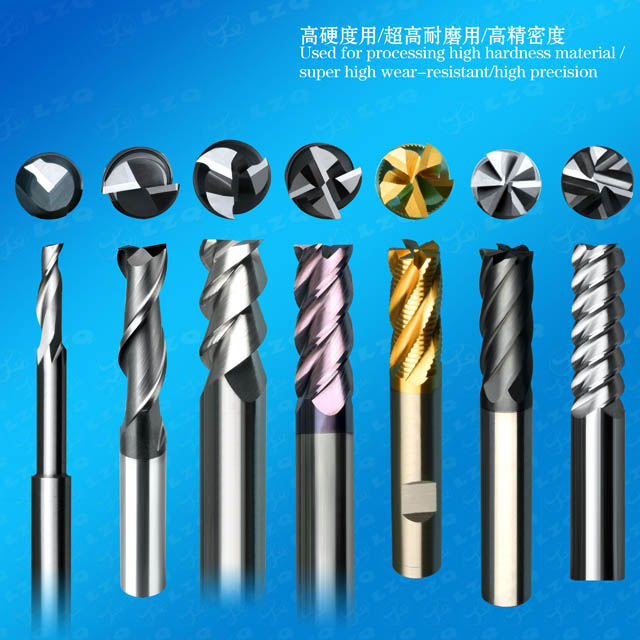

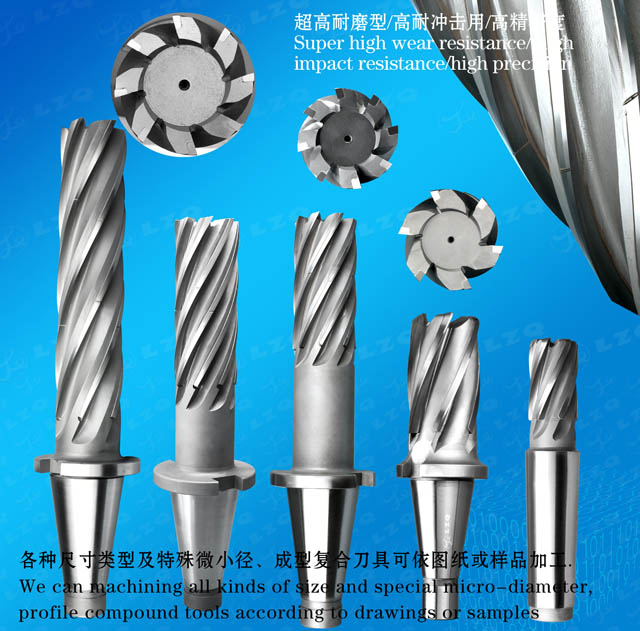

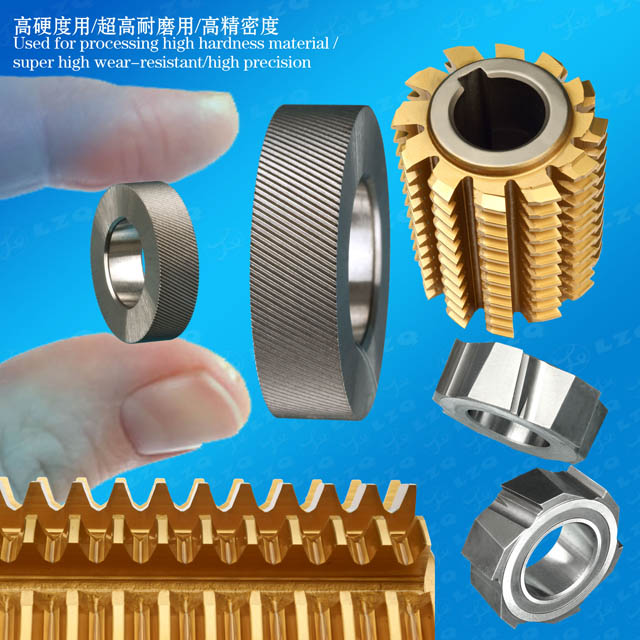

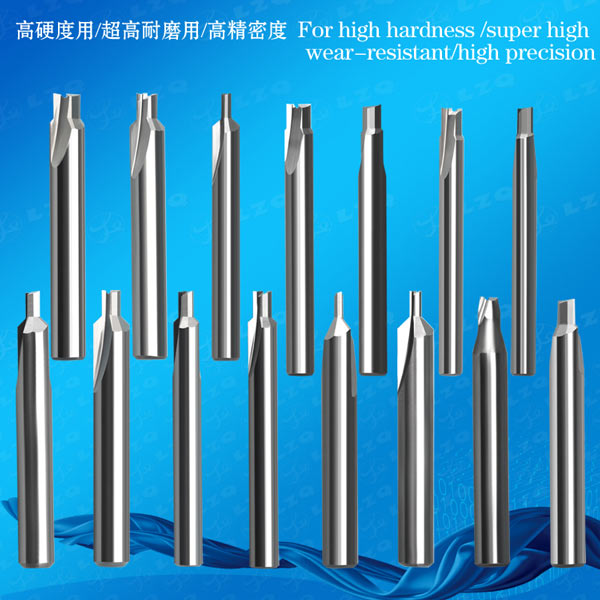

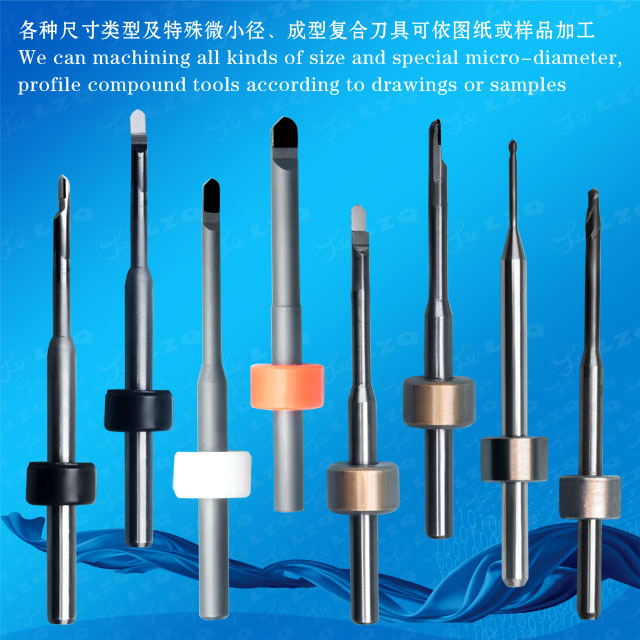

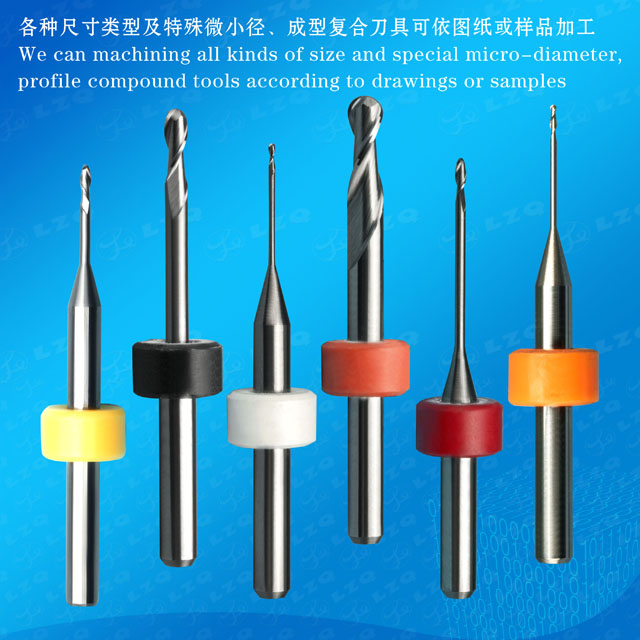

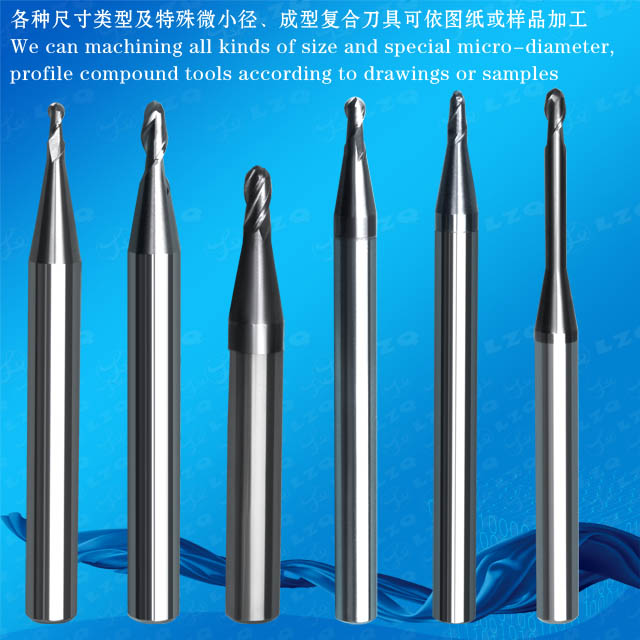

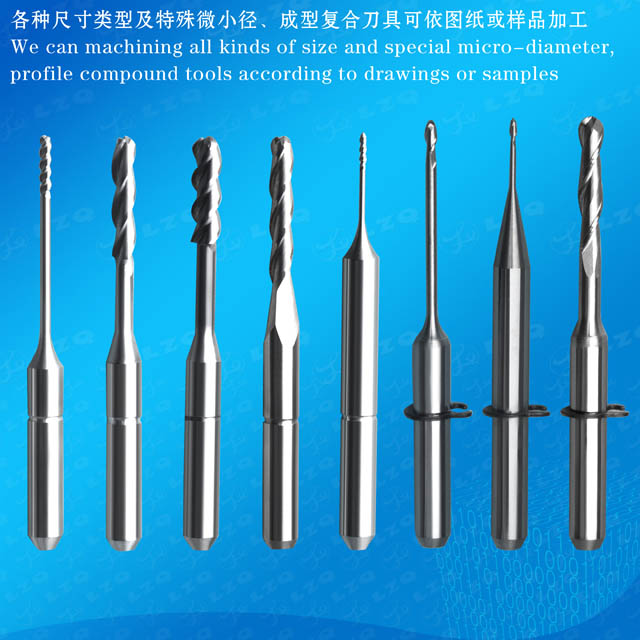

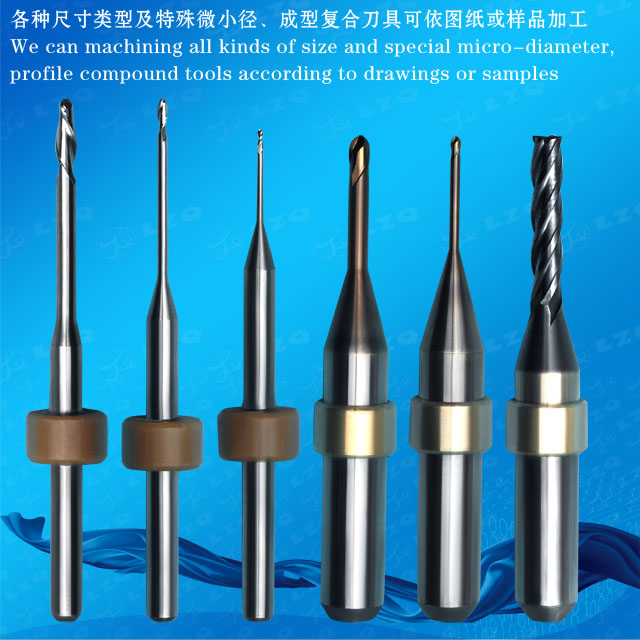

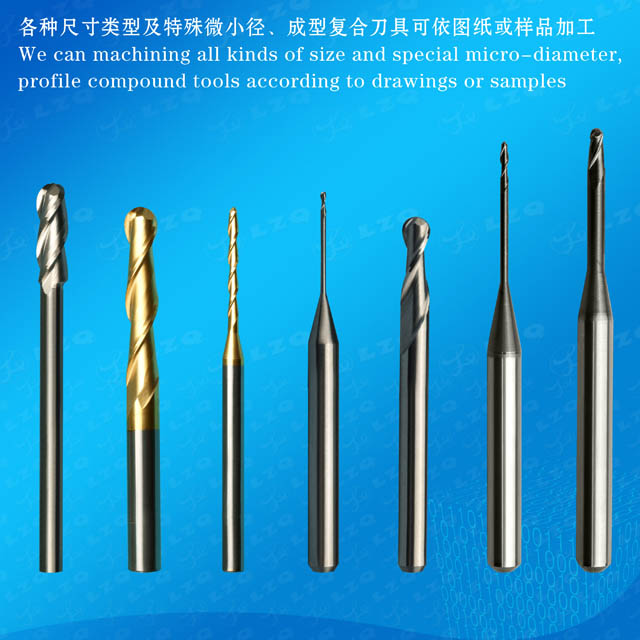

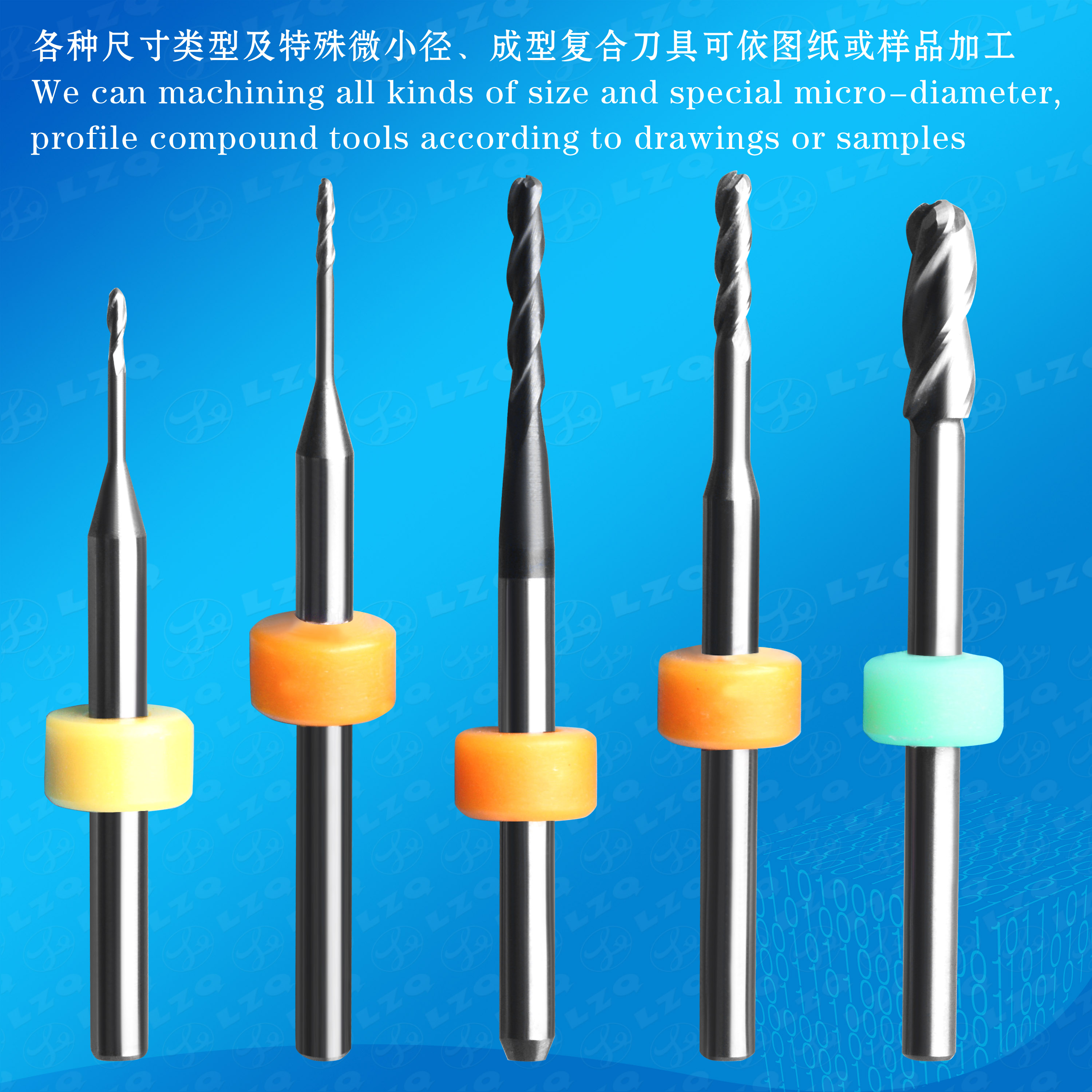

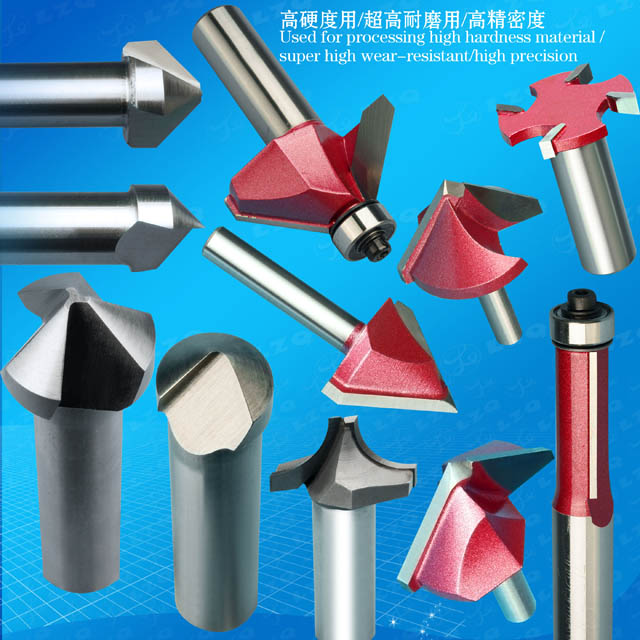

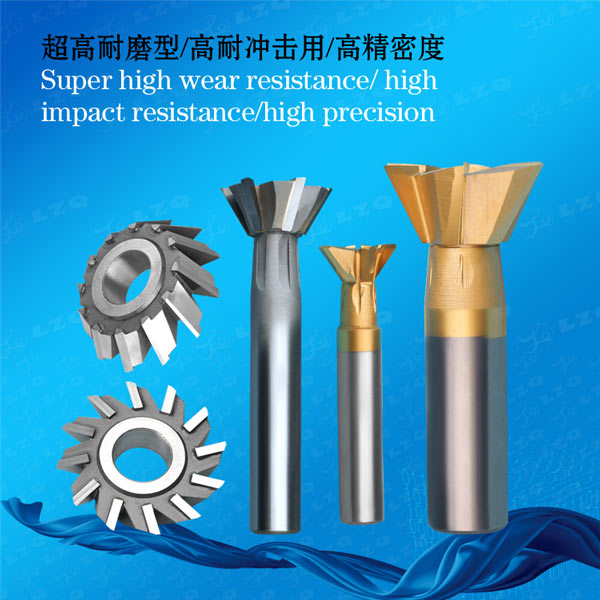

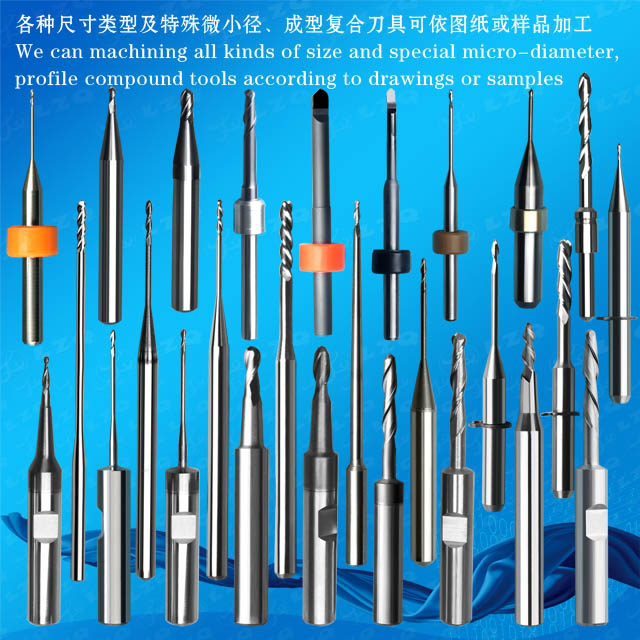

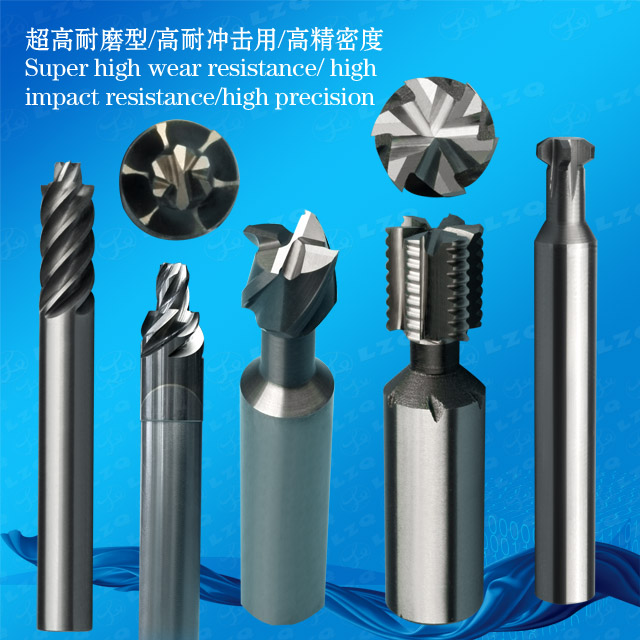

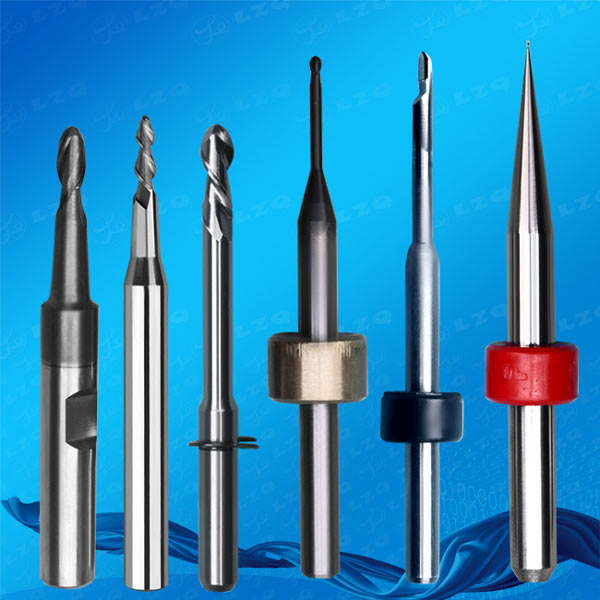

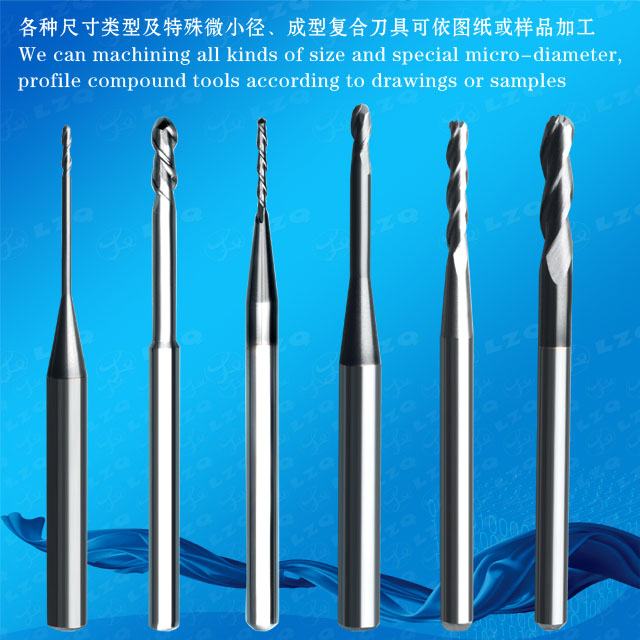

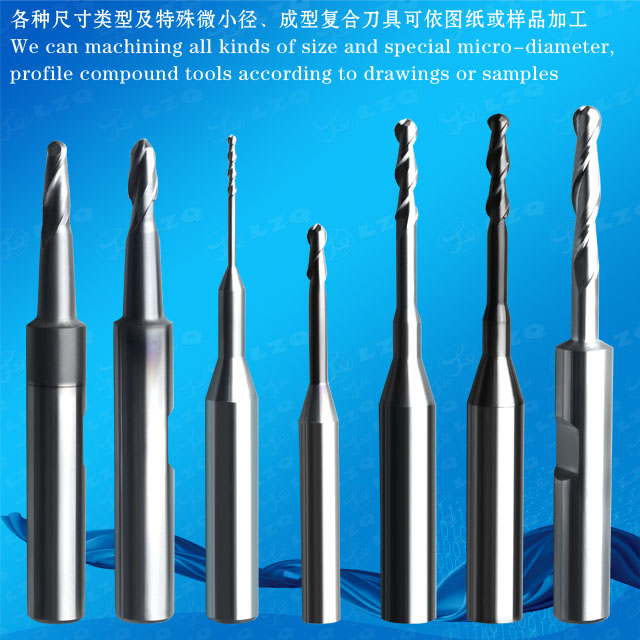

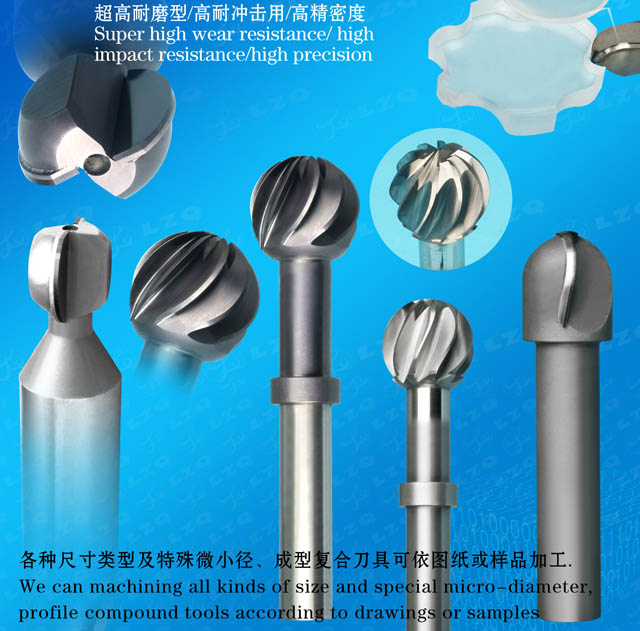

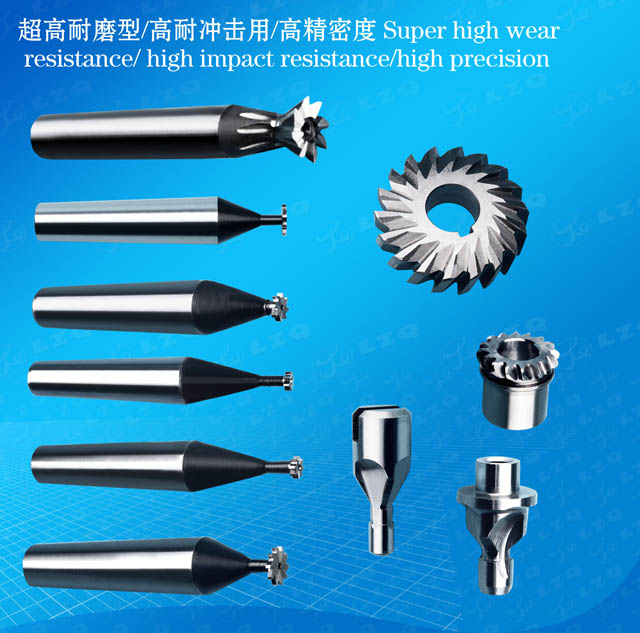

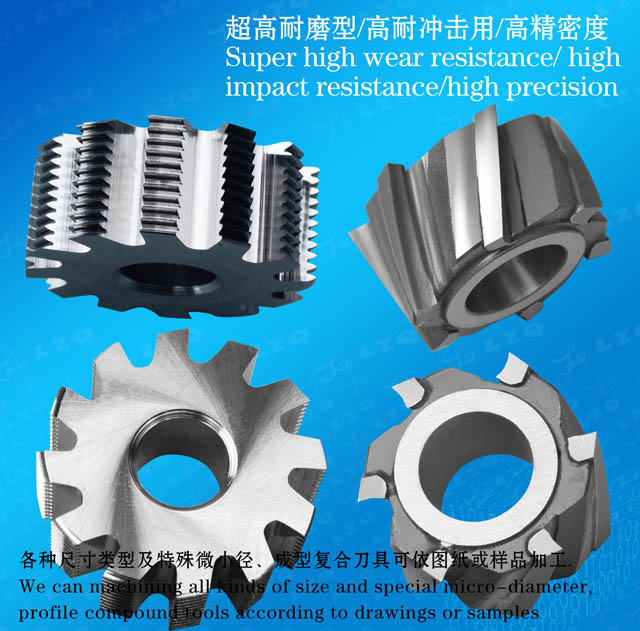

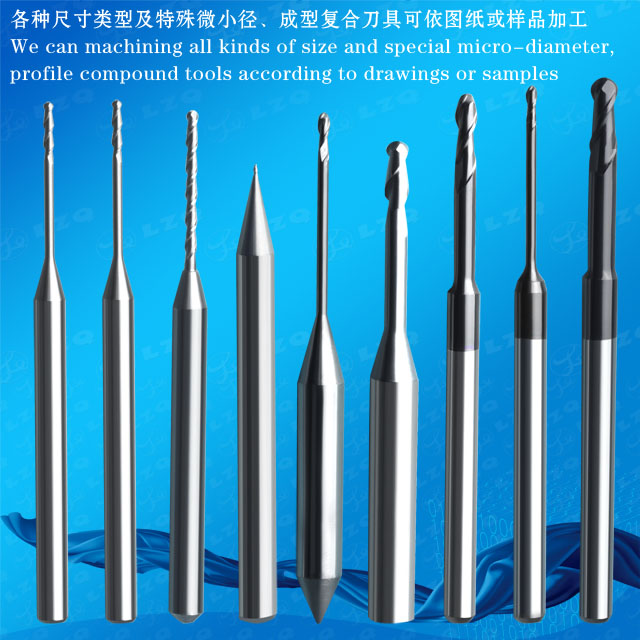

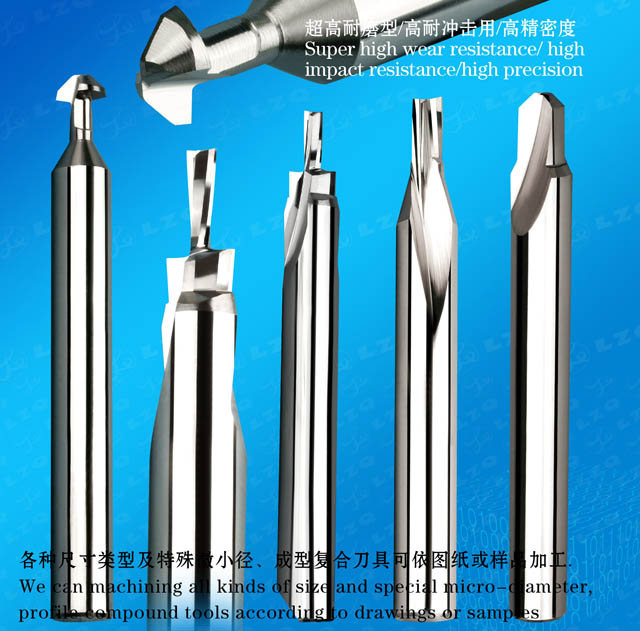

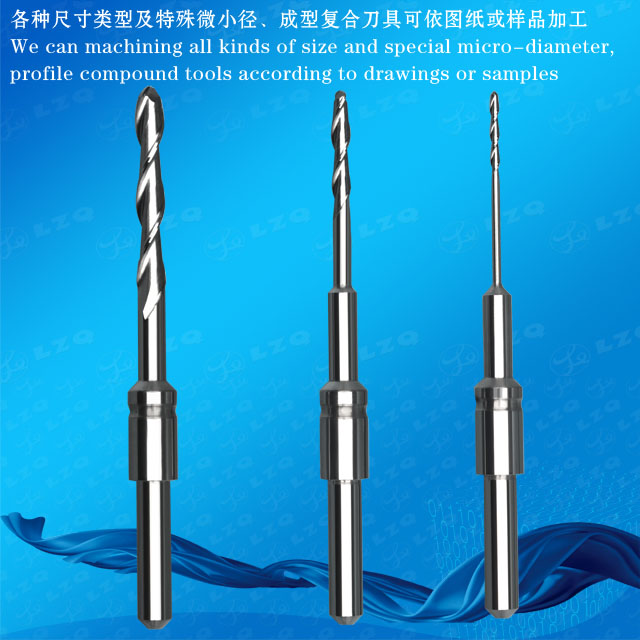

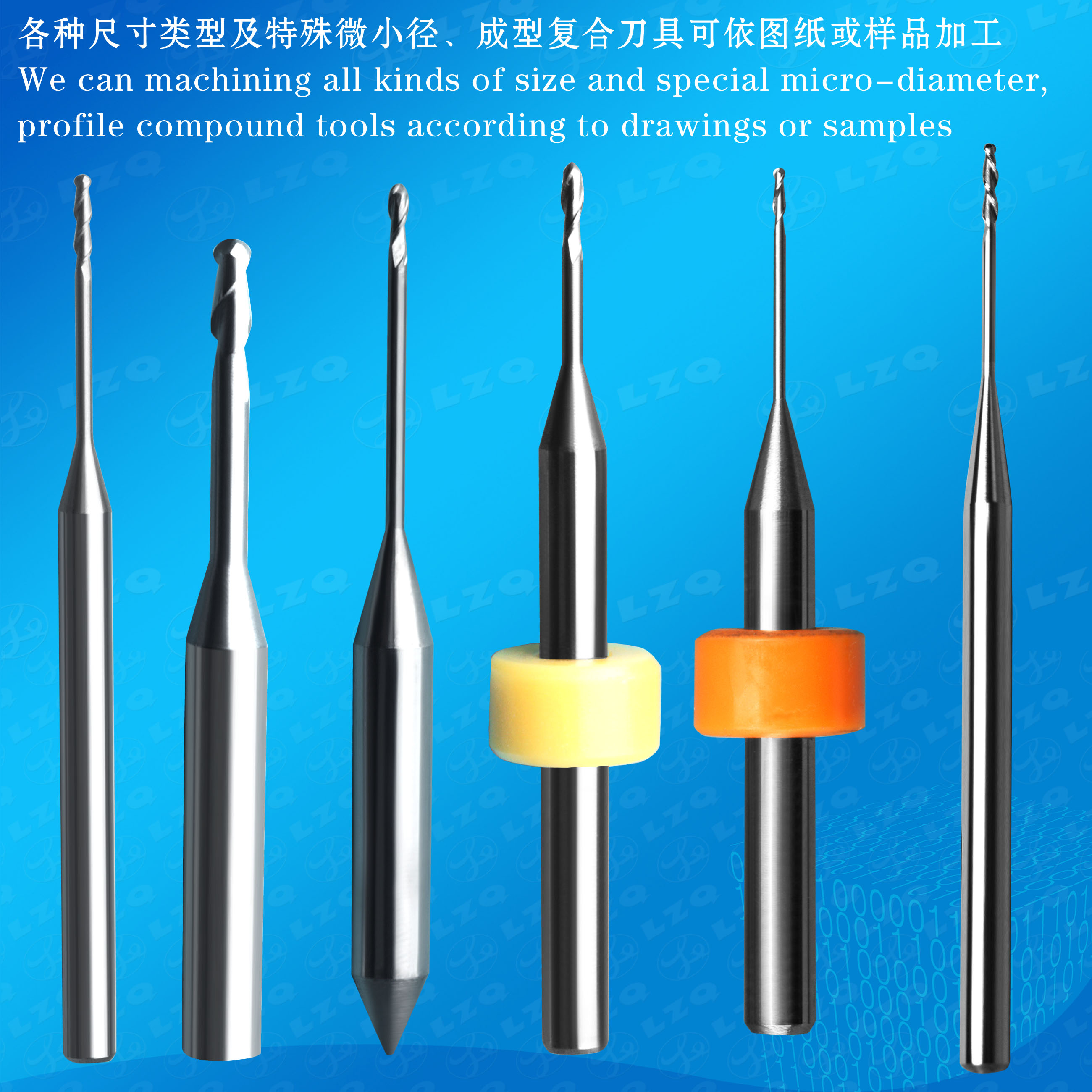

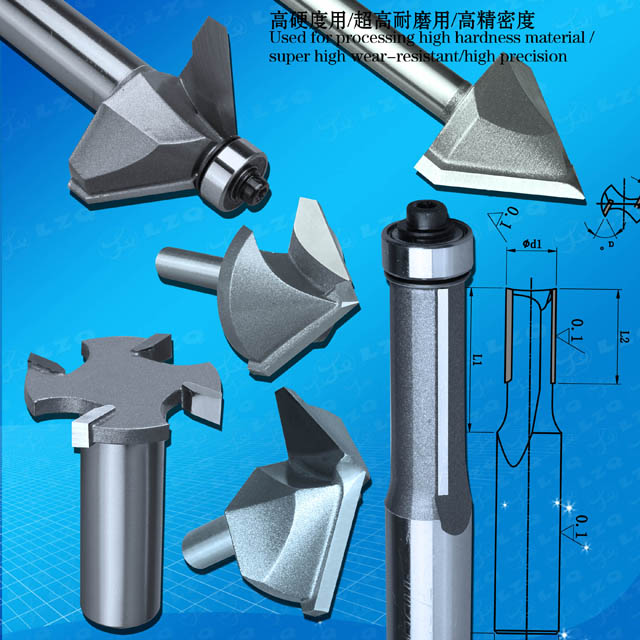

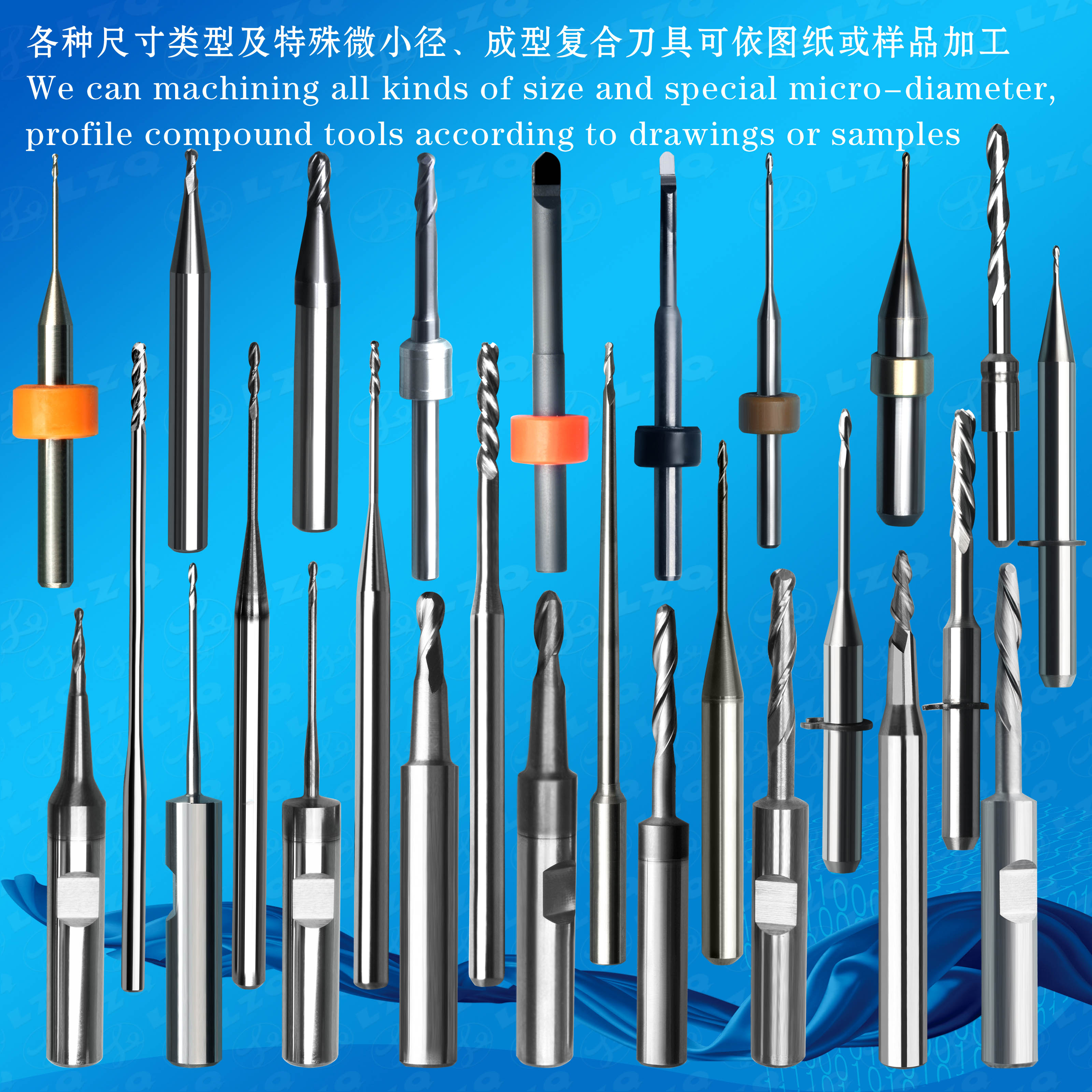

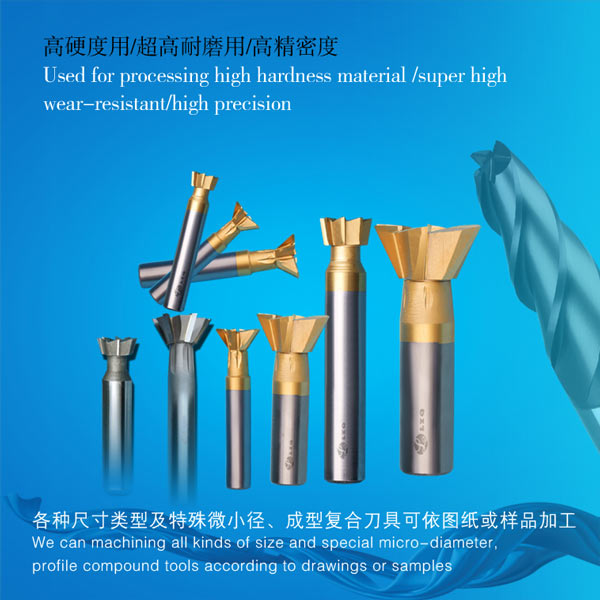

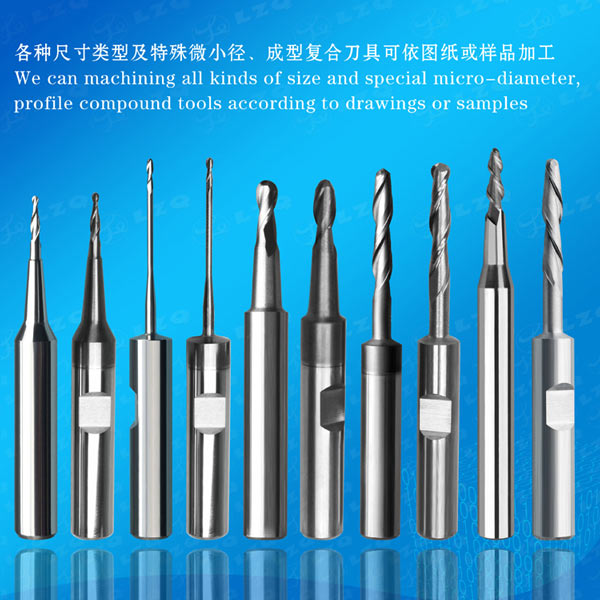

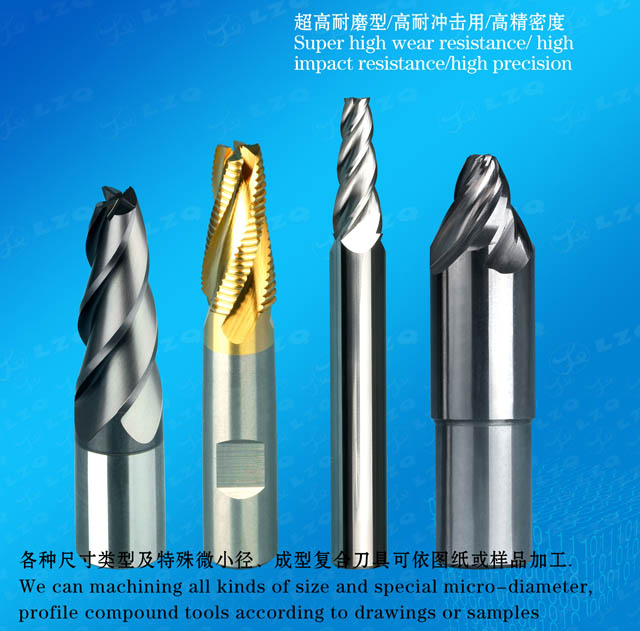

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material, semi-products, finished products in an ordinary year, we are capable to produce according to drawing or sample provided by the customer, so as to present you a favourable cost-performance ratio…Welcome to visit our factory.

Product Details

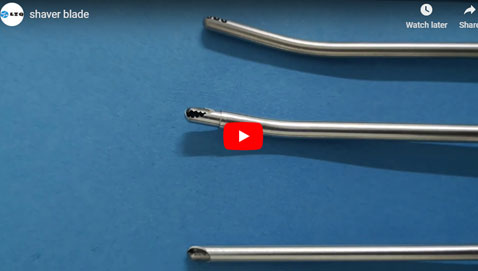

Equipment

Milling is carried out with a milling cutter in a number of forms, held in a collet or similar which, in turn, is held in the spindle of a milling machine.

Types and nomenclature

Mill orientation is the primary classification for milling machines. The two basic configurations are vertical and horizontal. However, there are alternative classifications in accordance to the technique of control, size, purpose and electricity source.

Mill orientation Vertical mill

milling machine. 1: milling cutter 2: spindle 3: top slide or over arm 4: column 5: desk 6: Y-axis slide 7: knee 8: base

In the vertical mill, the spindle axis is vertically oriented. Milling cutters are held in the spindle and rotate on its axis. The spindle can generally be prolonged (or the table can be raised/lowered, giving the identical effect), allowing plunge cuts and drilling. There are two subcategories of vertical mills: the mattress mill and the turret mill.

Voronoi design approach: In the Voronoi format approach, the pocket boundary is segmented and Voronoi diagram is constructed for the complete pocket boundary. These Voronoi diagrams are used for generating the tool course for machining. This technique is considered to be greater environment-friendly and robust. Moreover, it avoids topological issues associated with regular offsetting algorithms.

Curvilinear device path In this approach, the tool travels along a progressively evolving spiral path. The spiral starts off evolved at the core of the pocket to be machined and the device steadily strikes closer to the pocket boundary. The course of the device course modifications steadily and neighbourhood acceleration and deceleration of the tool are minimized. This reduces device wear.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

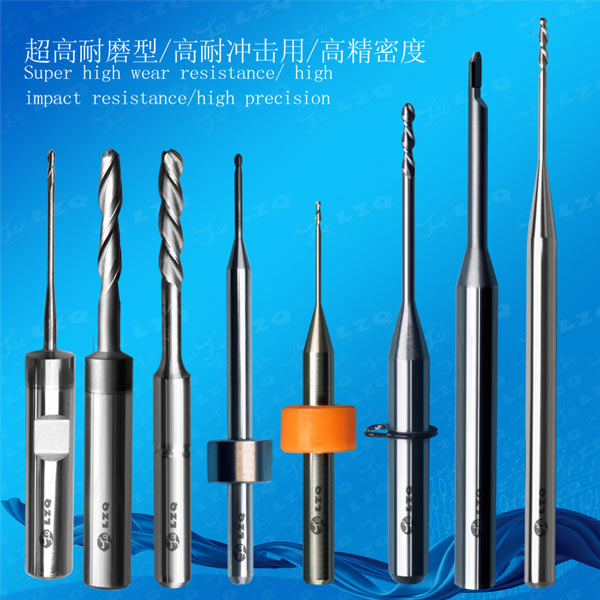

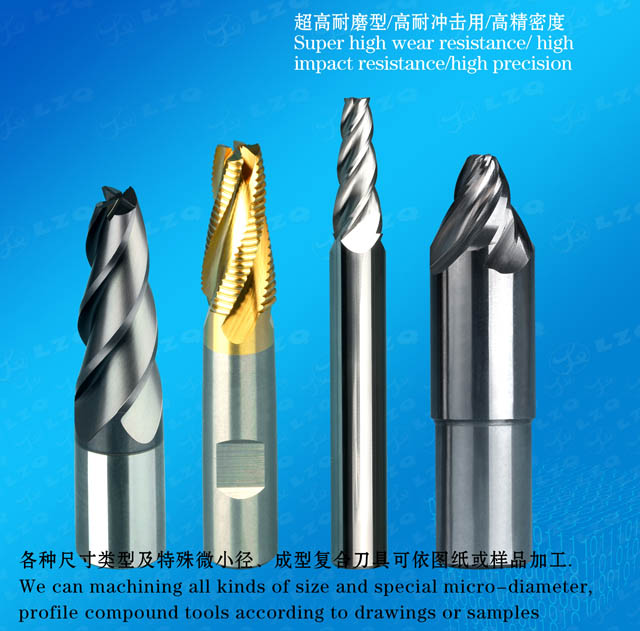

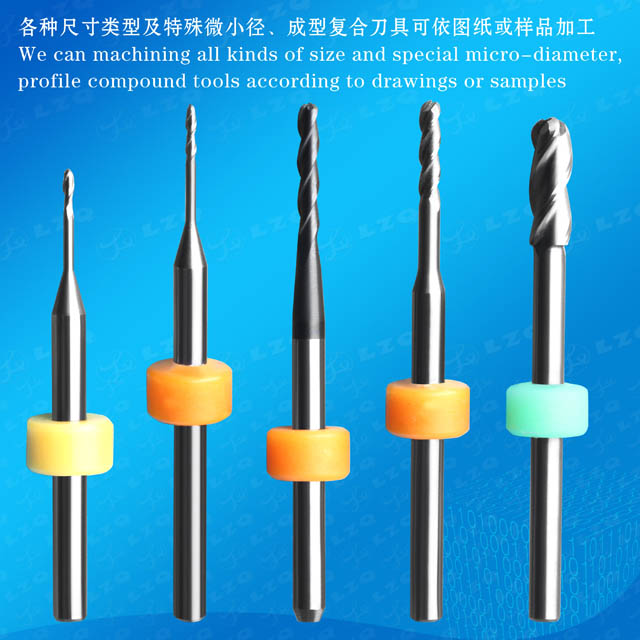

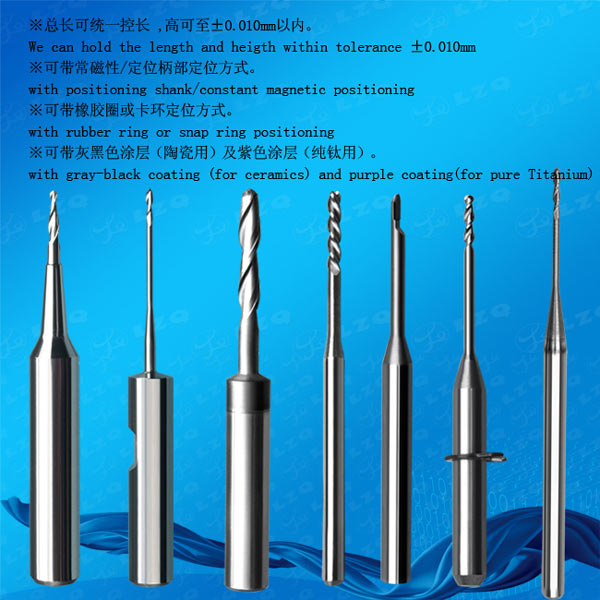

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

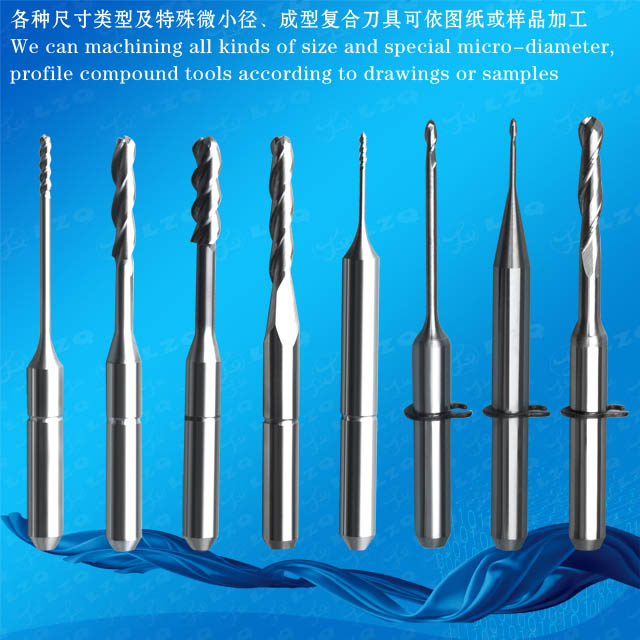

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

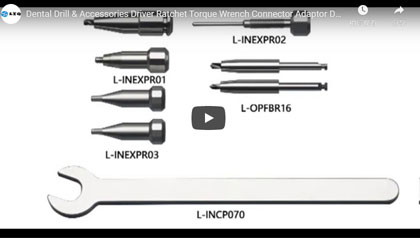

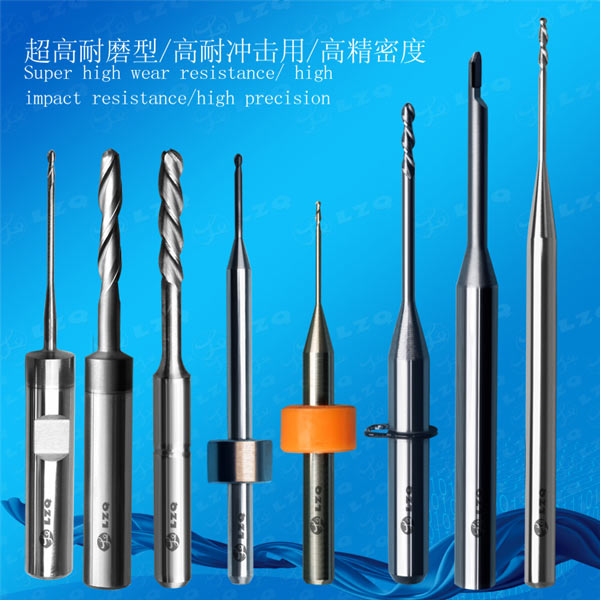

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

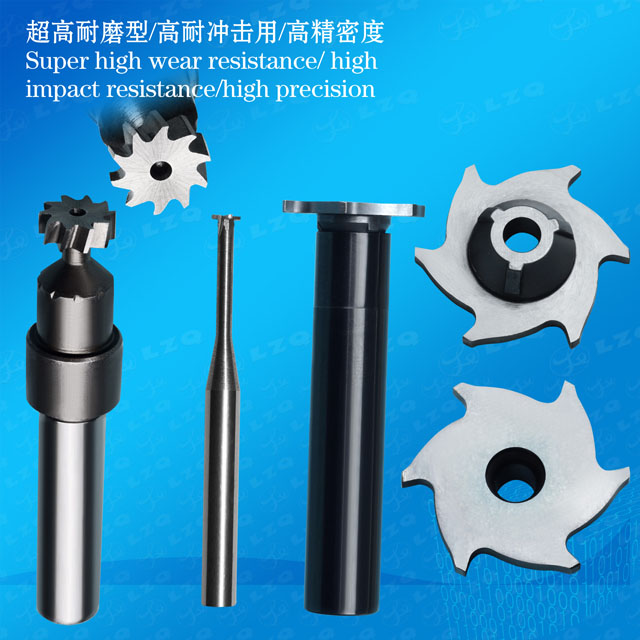

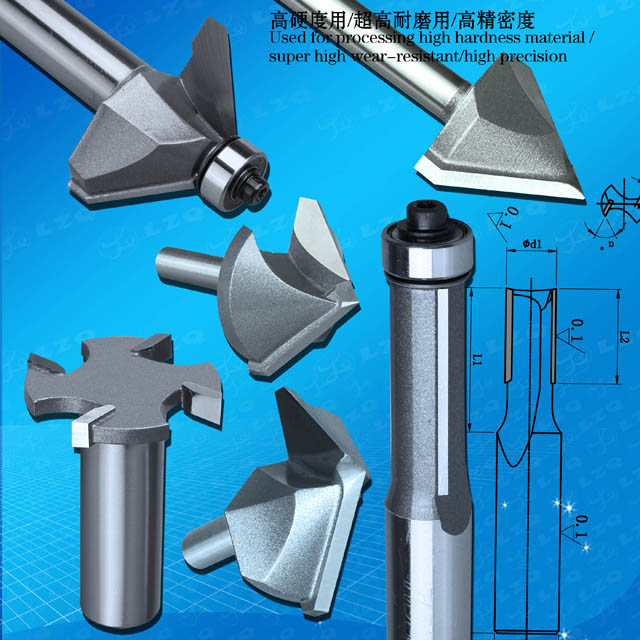

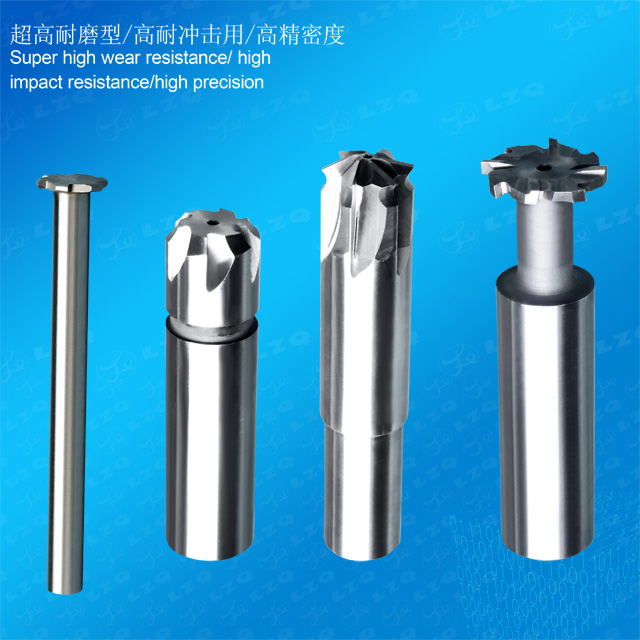

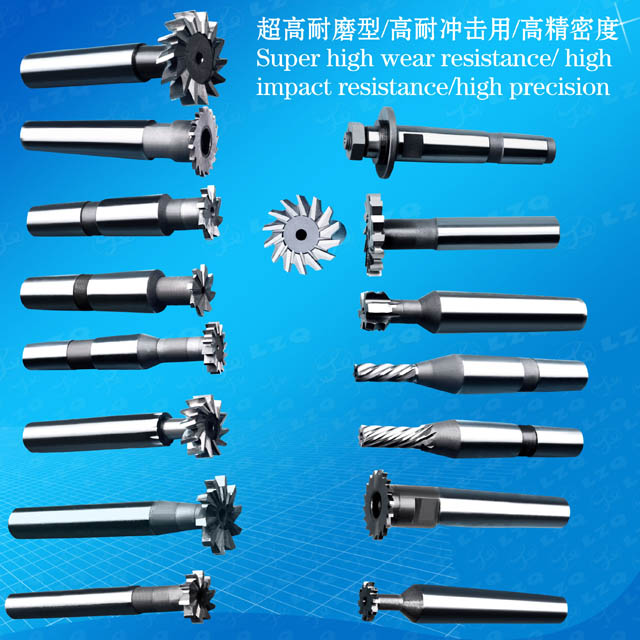

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

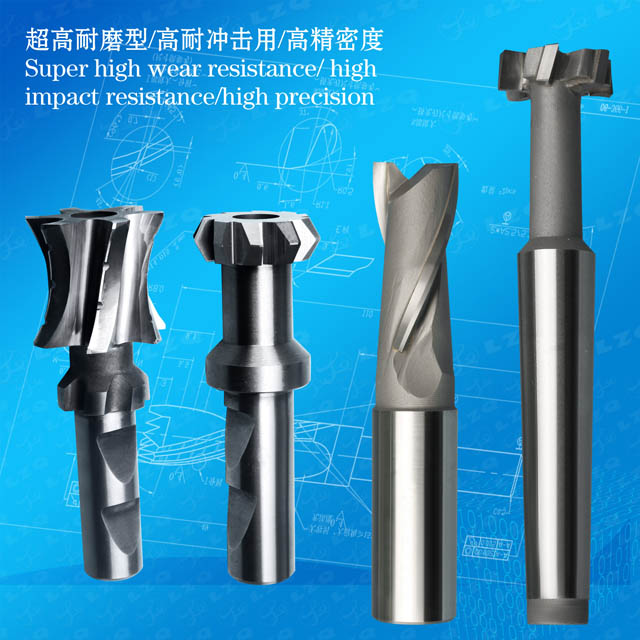

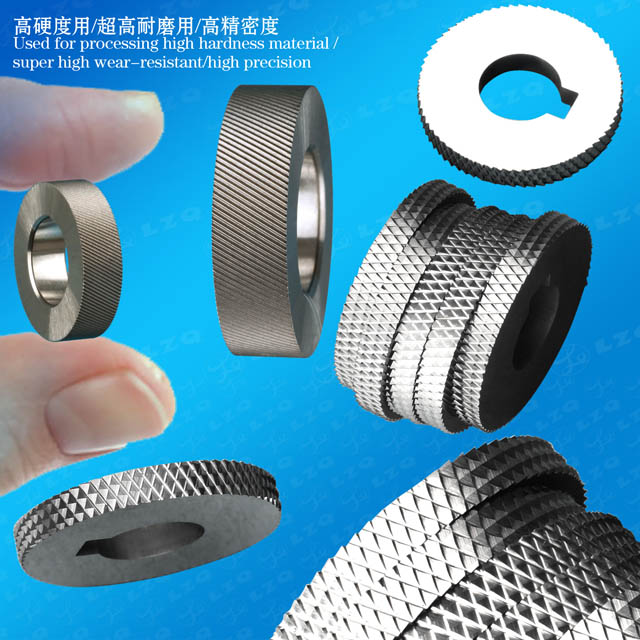

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.