Description

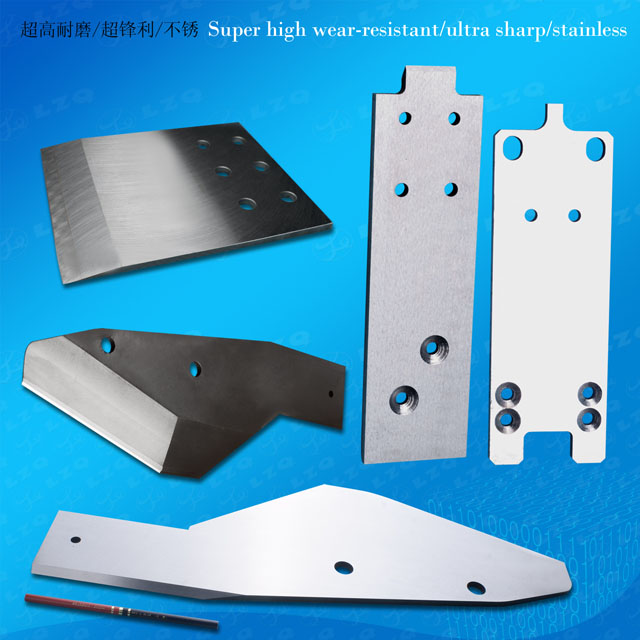

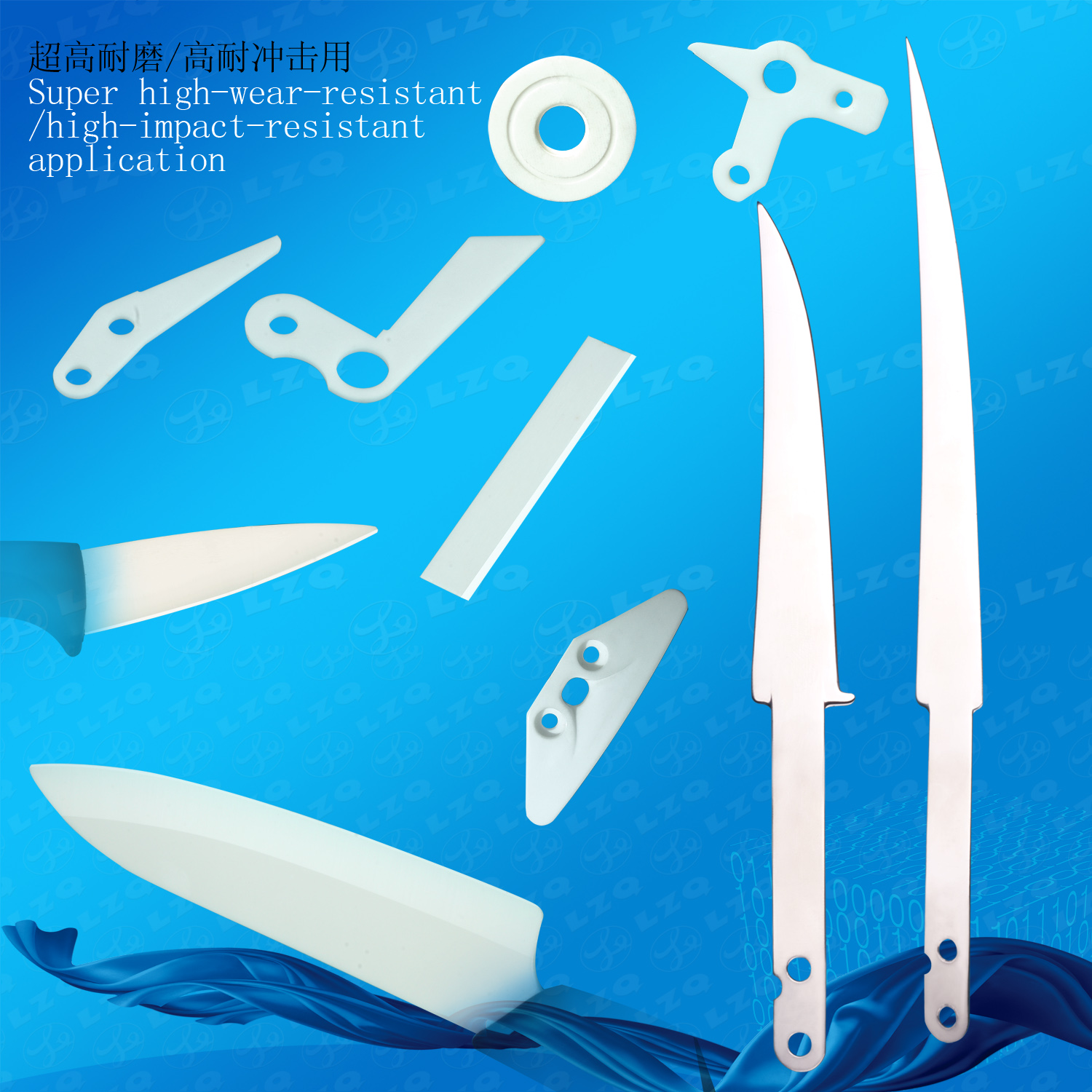

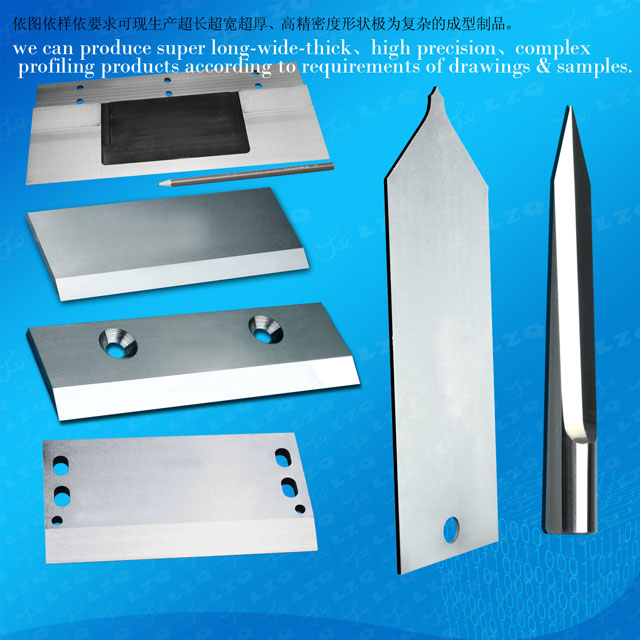

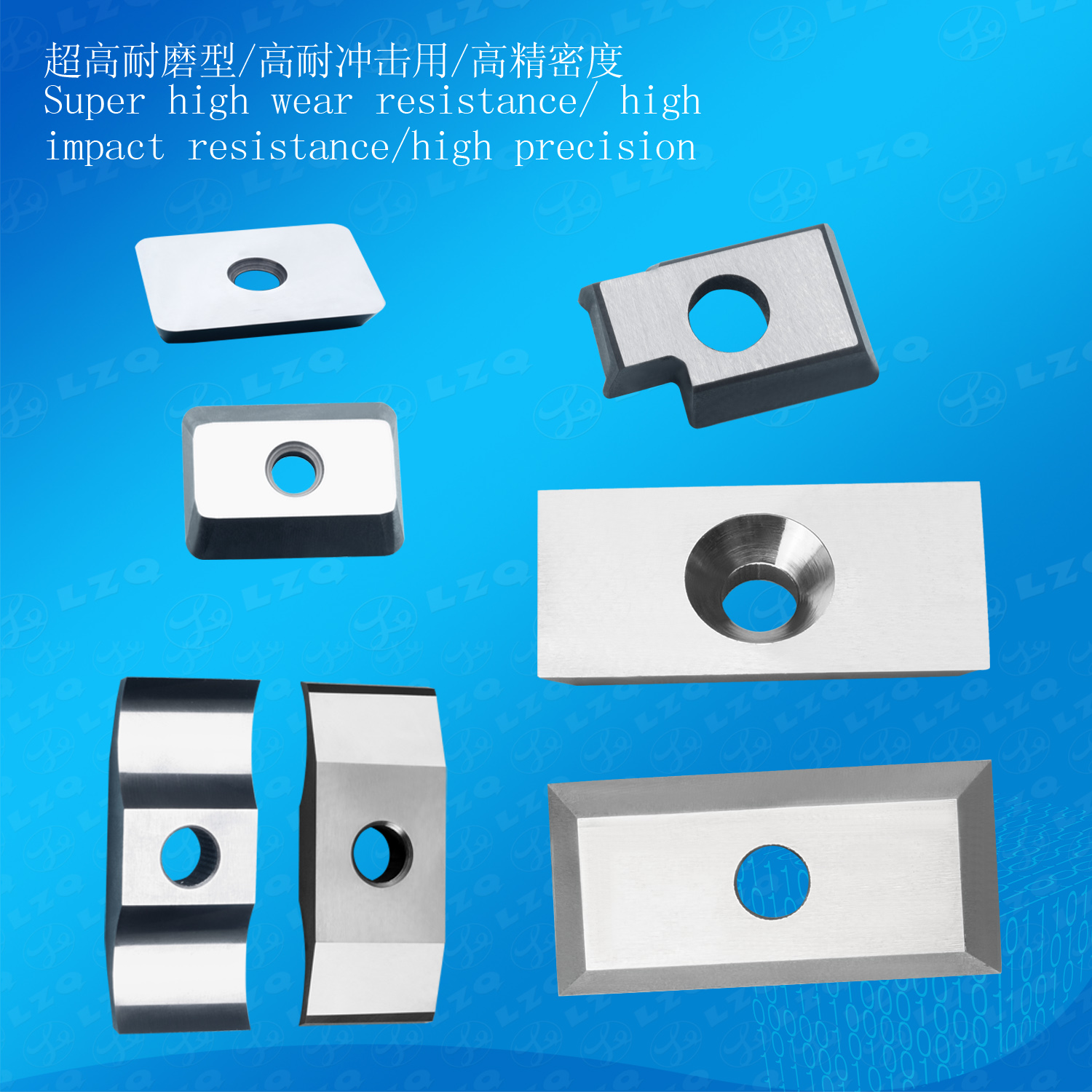

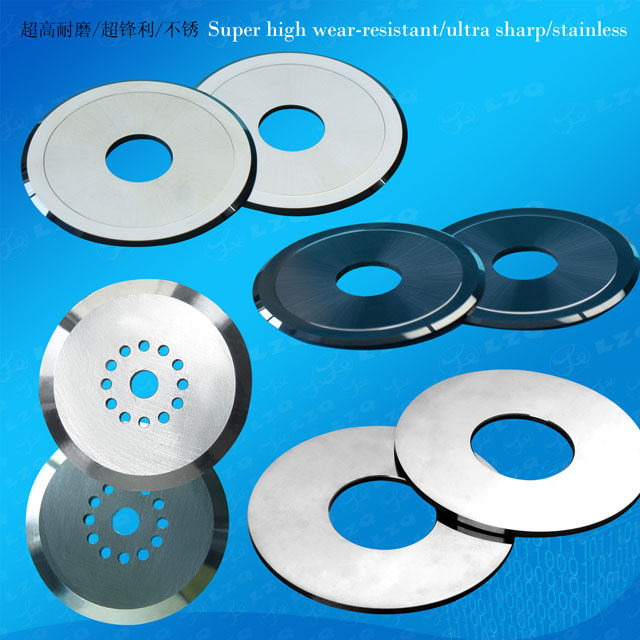

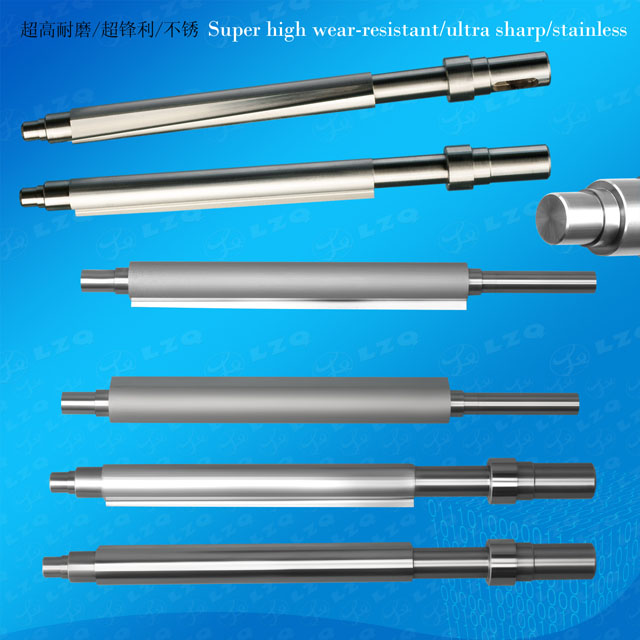

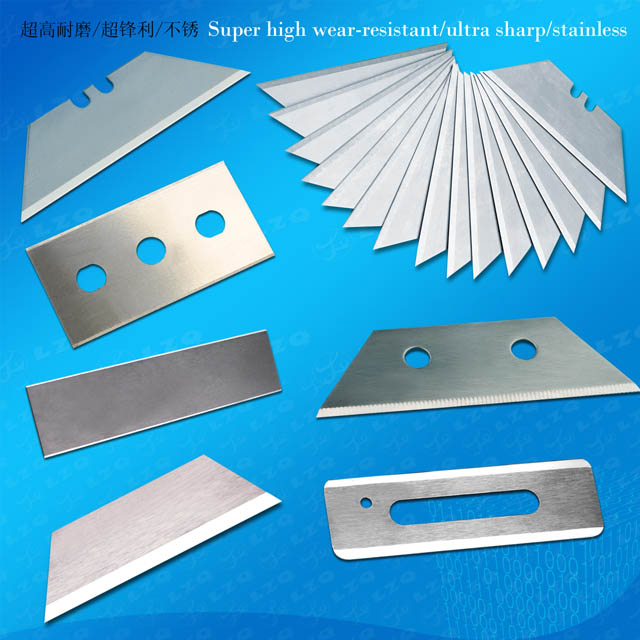

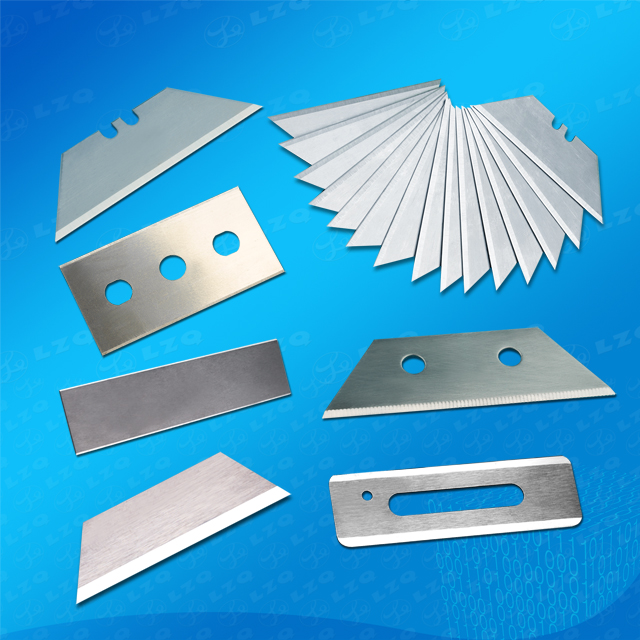

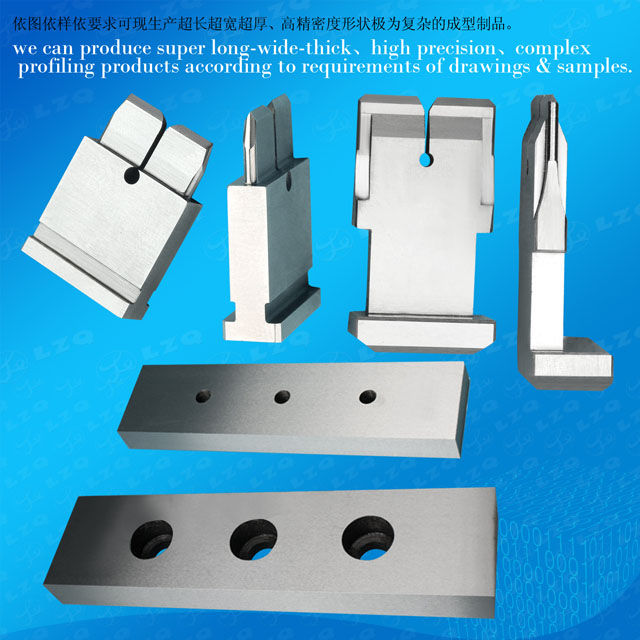

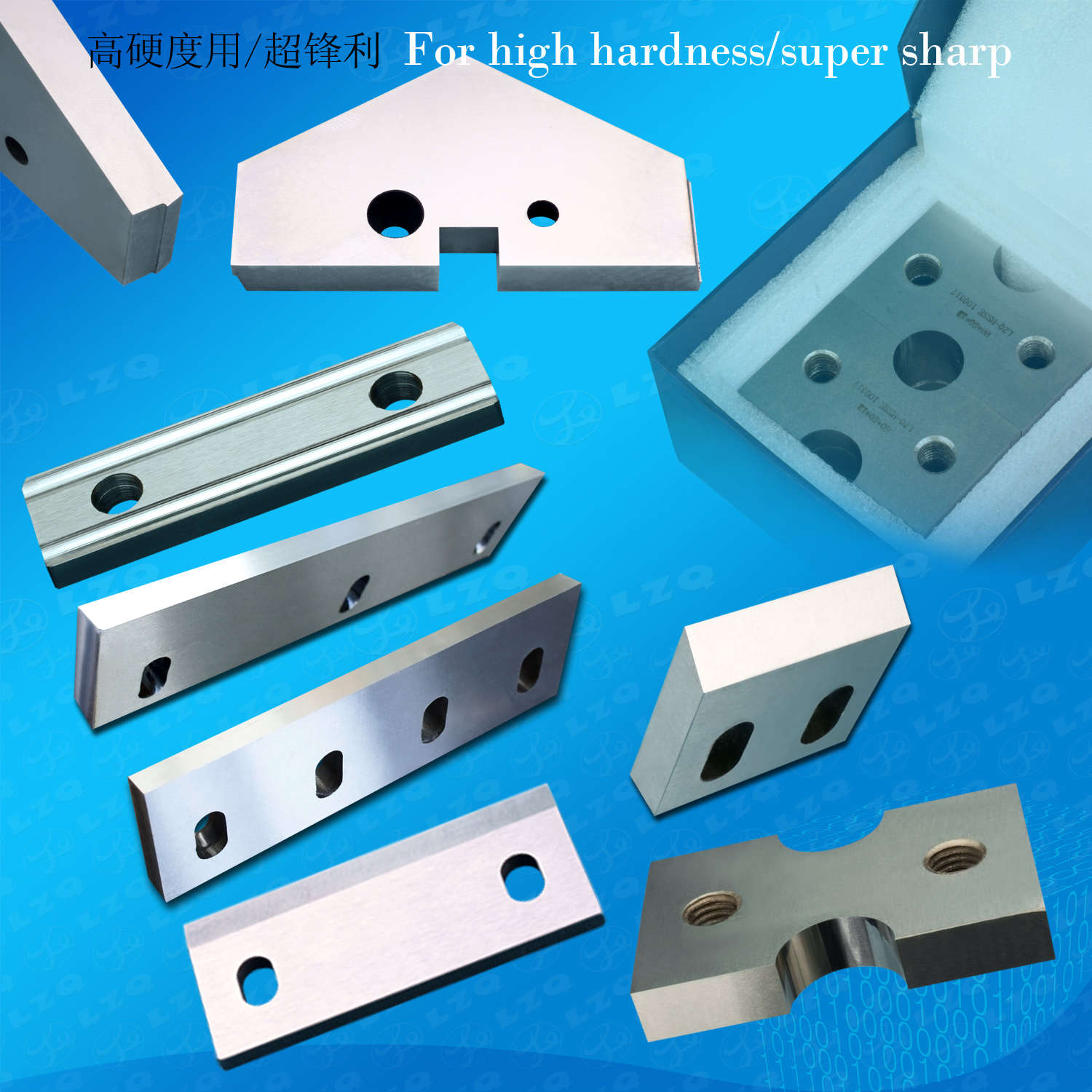

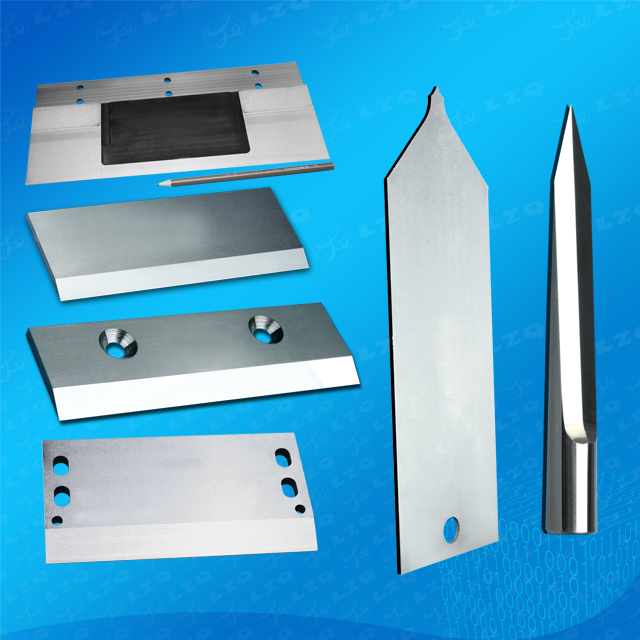

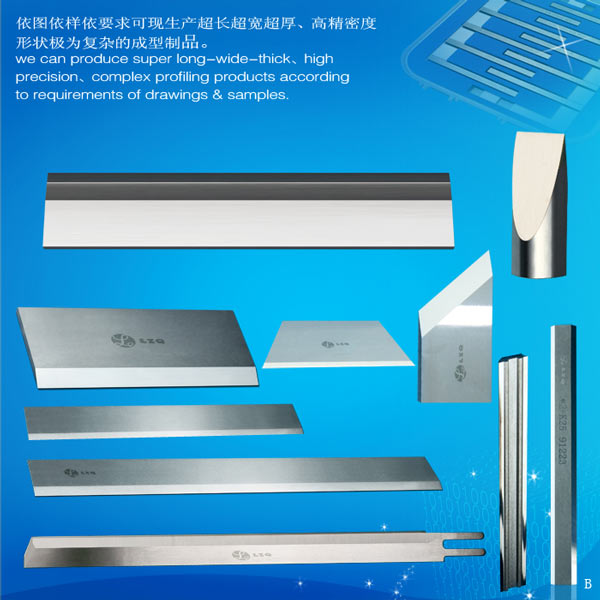

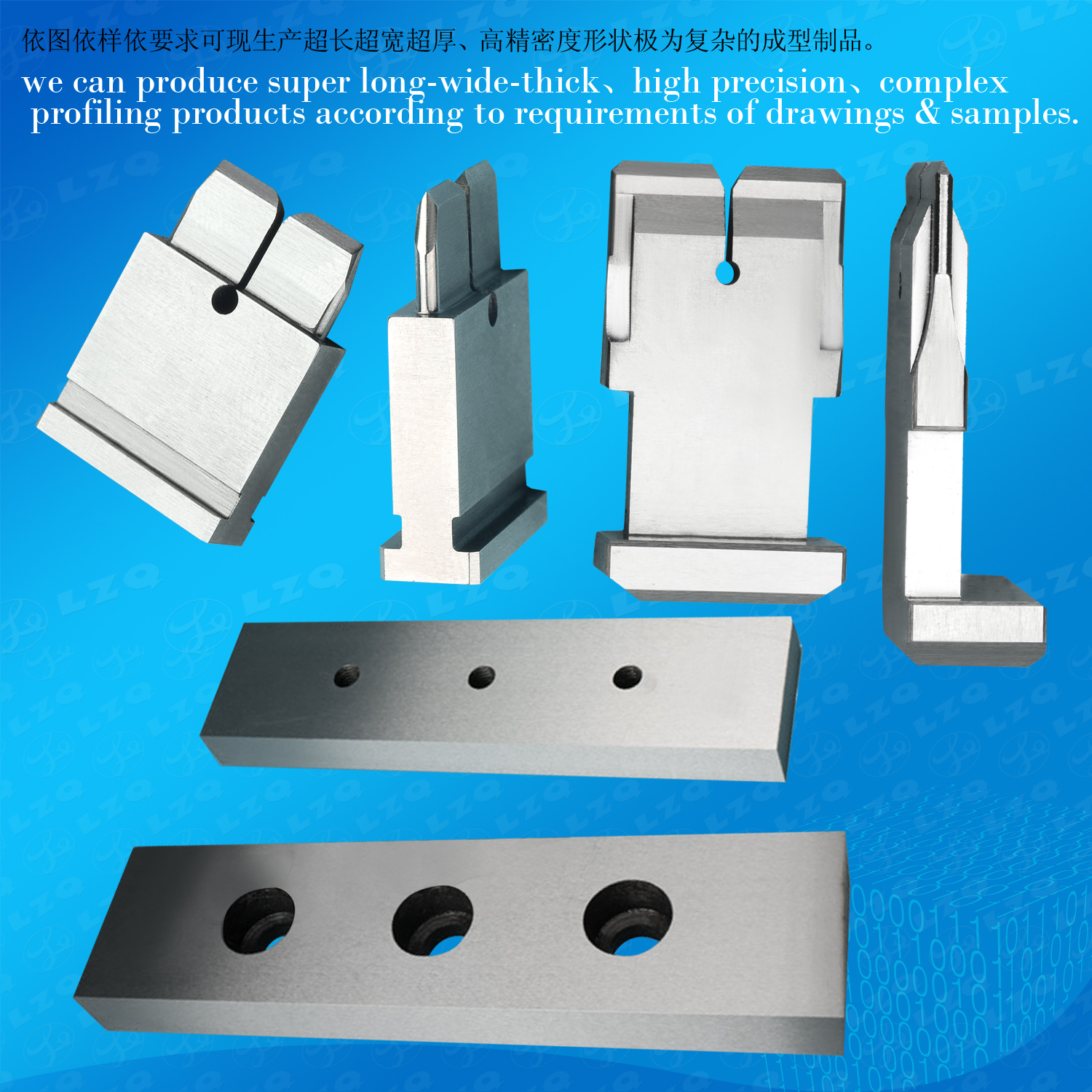

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material, semi-products, finished products in an ordinary year, we are capable to produce according to drawing or sample provided by the customer, so as to present you a favourable cost-performance ratio…Welcome to visit our factory.

Product Details

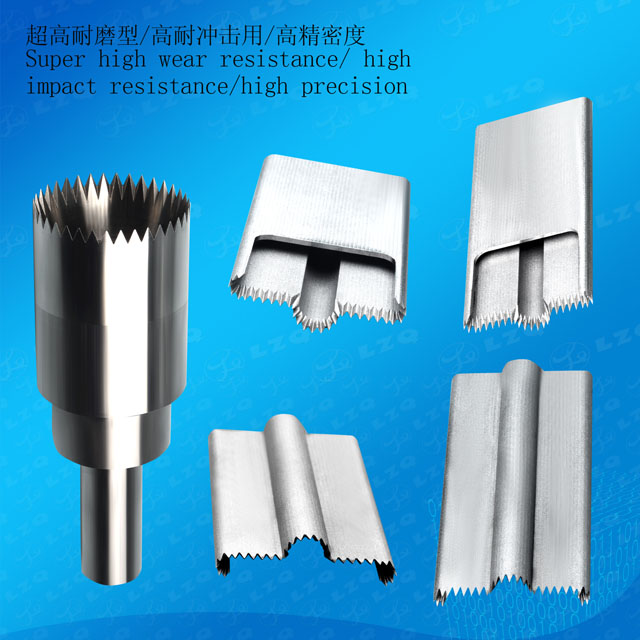

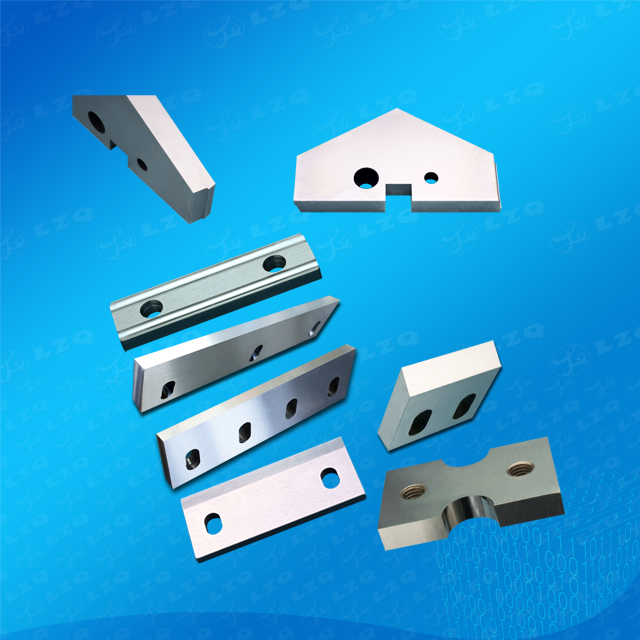

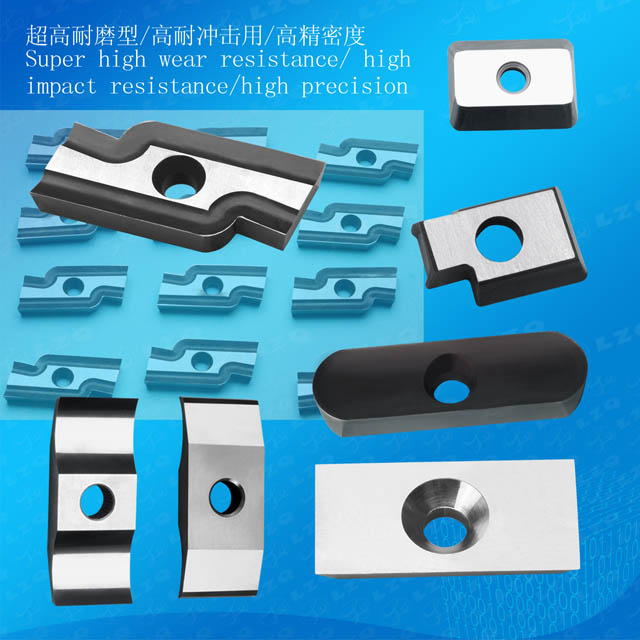

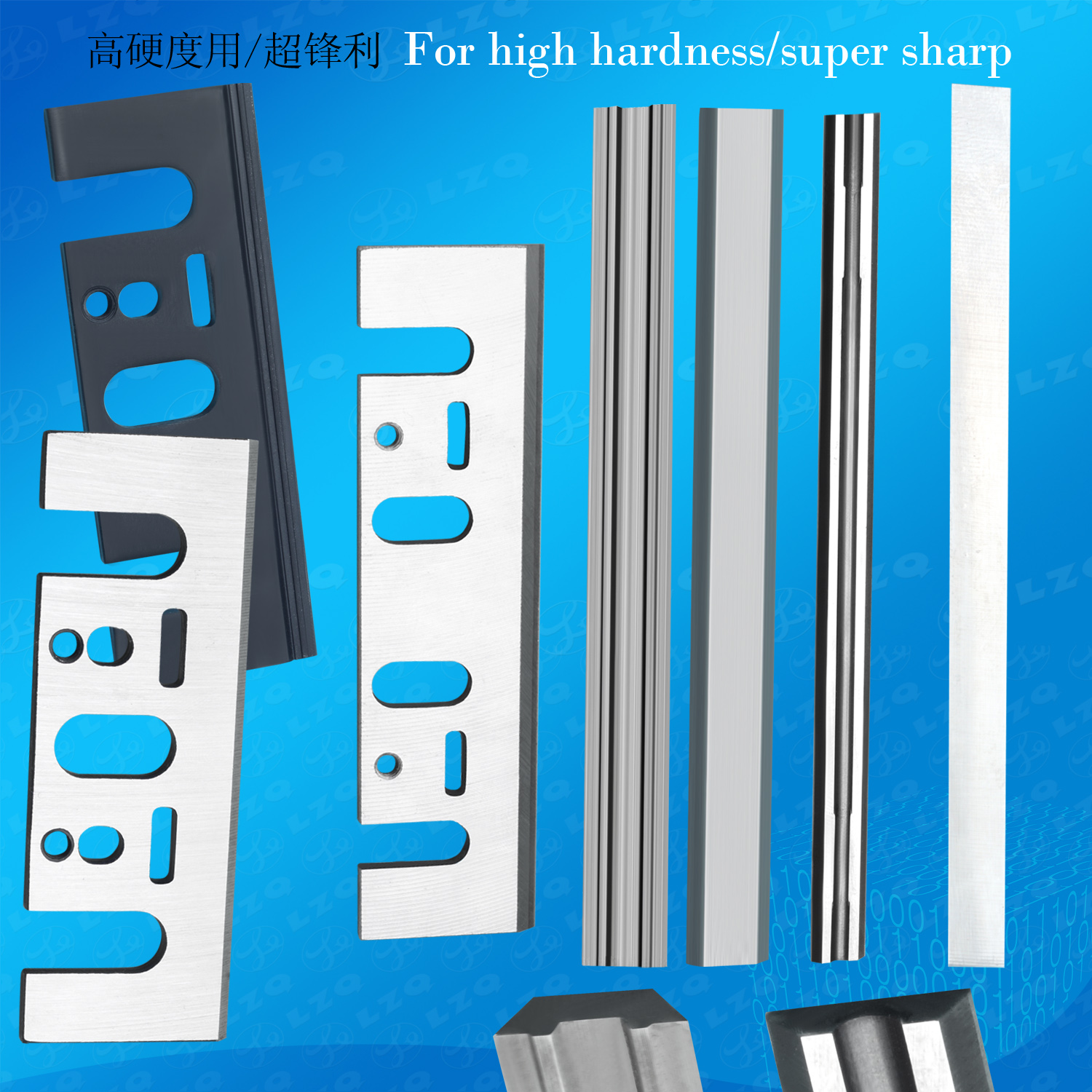

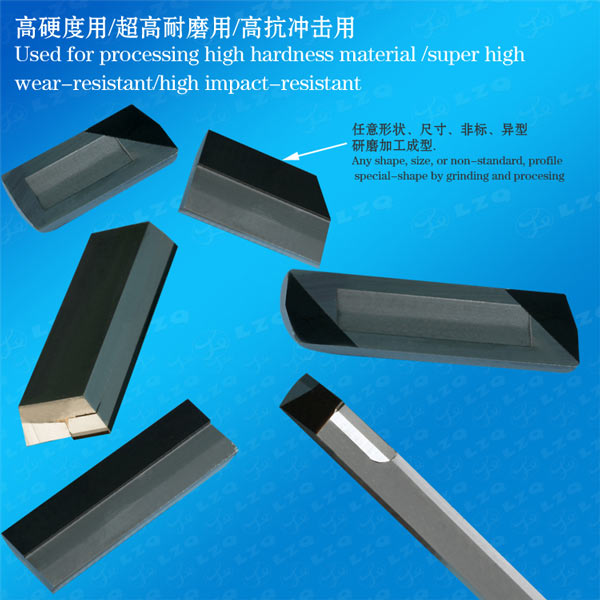

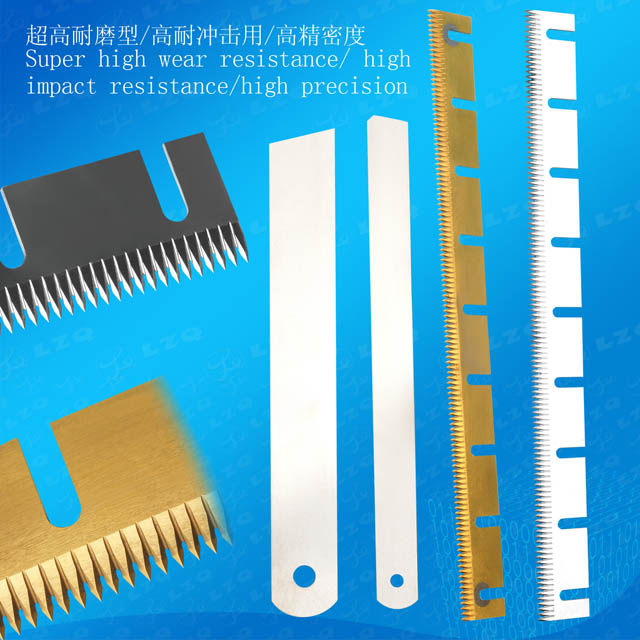

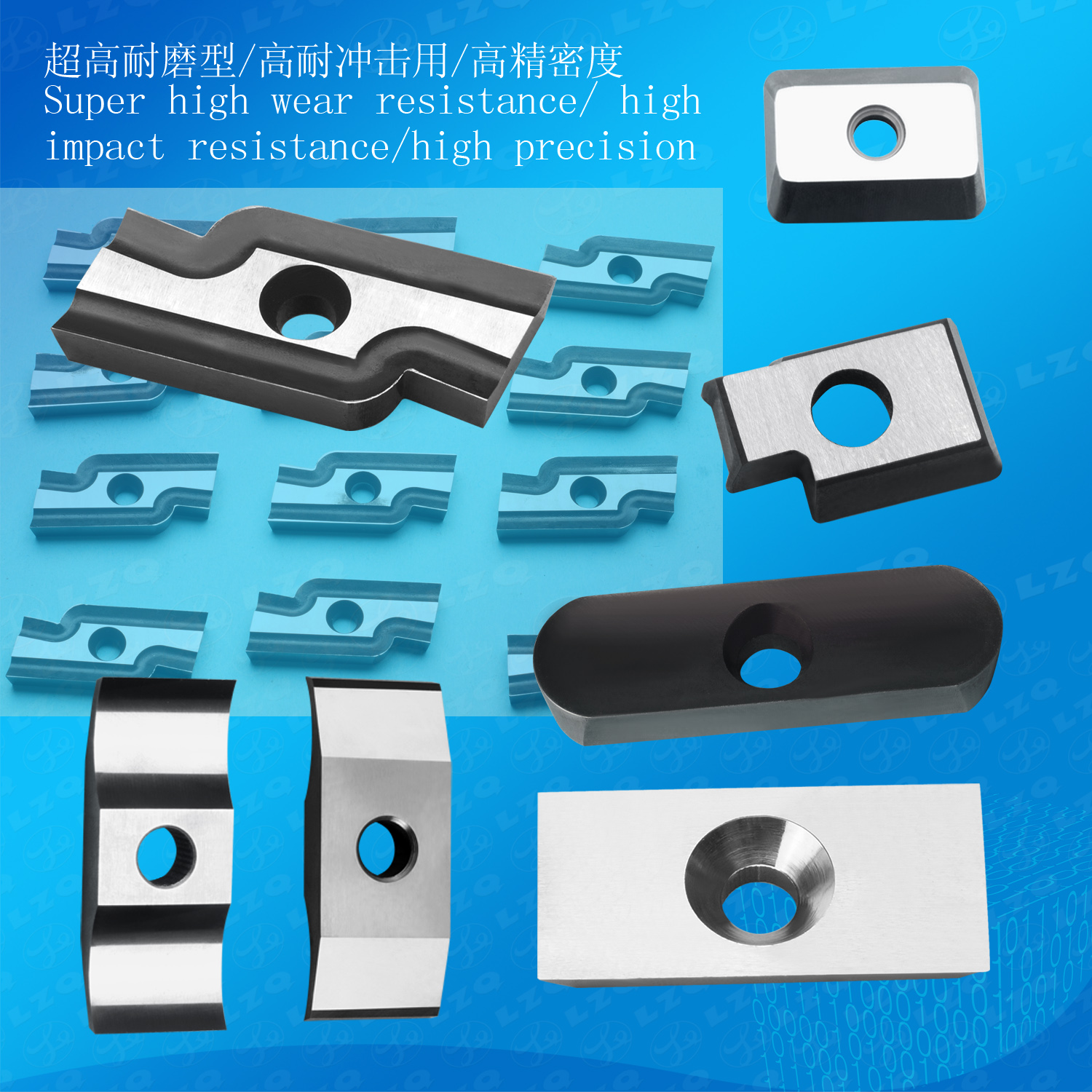

We adopt various business cooperation mode either royalty or part-time, and media promotion at the different time period, as well as technical support and wholesale to middle-scale or large-scale enterprises or agency, even OEM processing as per customers' requirements. From high-class products (via 6-axis/ 7-axis Blocking CNC-machine Tool (Class-AAA))to medium-class products (via 3-axis/ 4-axis Blocking CNC-machine Tool (Class-D)), different quality and price, our reliable products can replace to first-class products, and we are professional in wholesale, R&D, producing & processing, as well as design revision according to client's designs and samples of special, non-standard, abnormal shape and new products with high cost-performance ratio, also our on-demand service will decrease your comprehensive cost greatly!

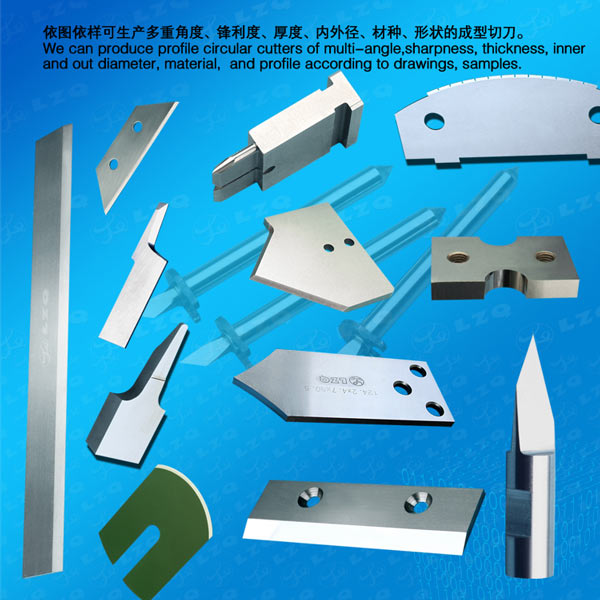

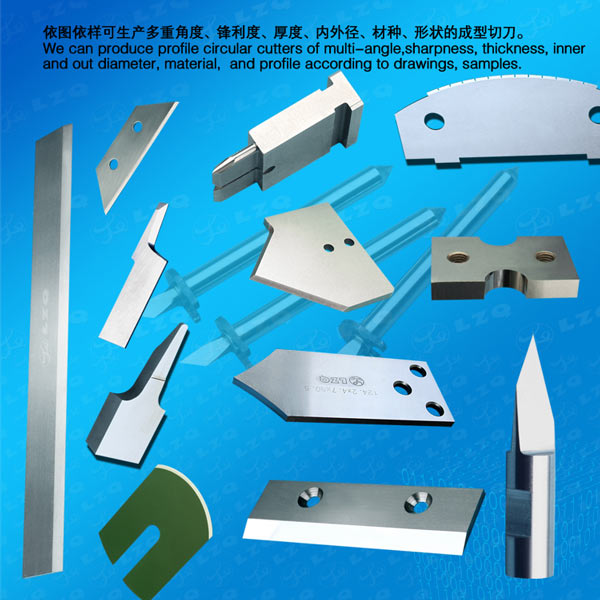

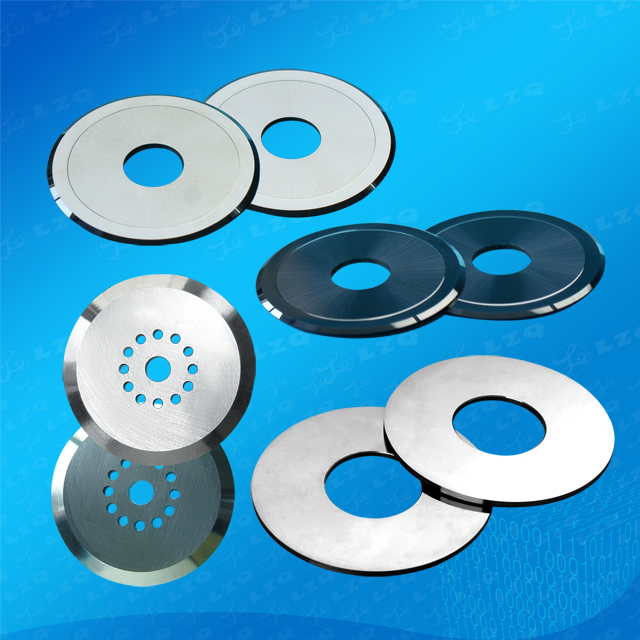

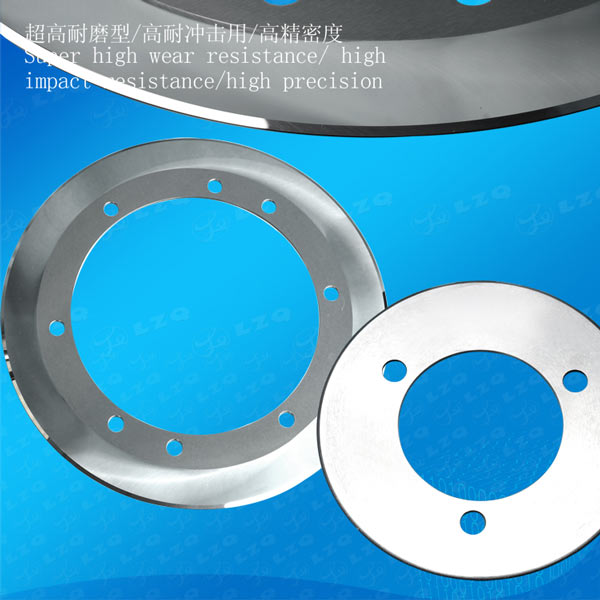

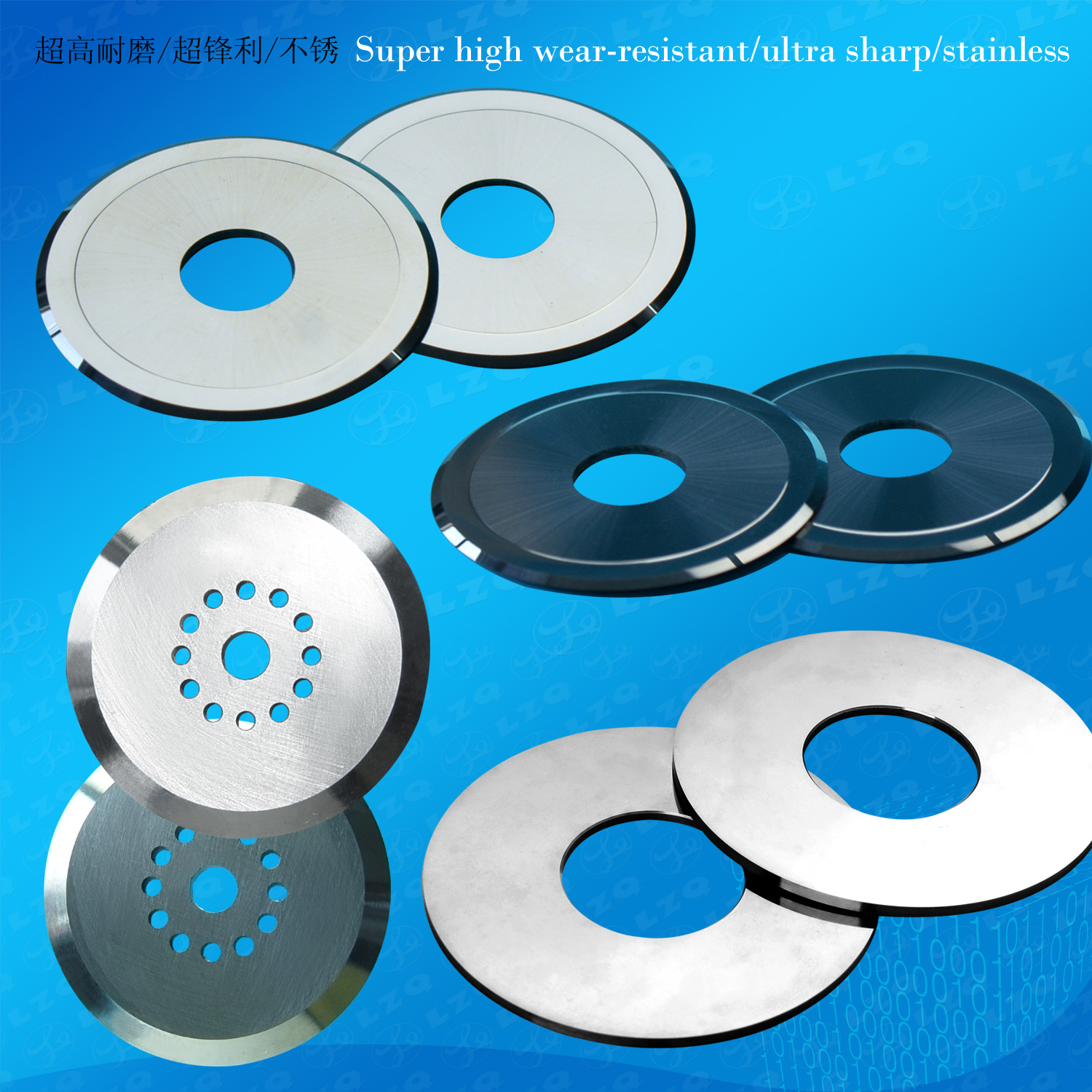

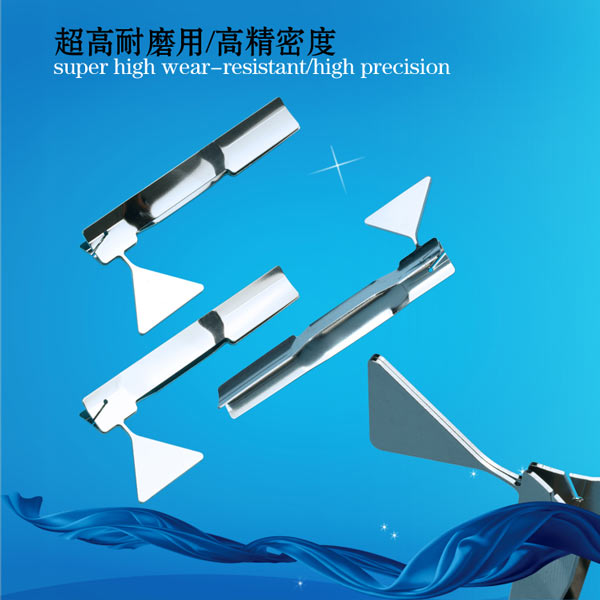

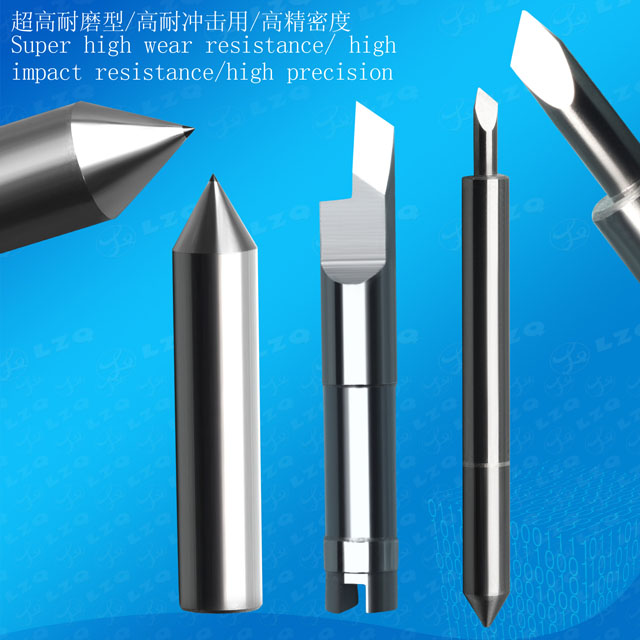

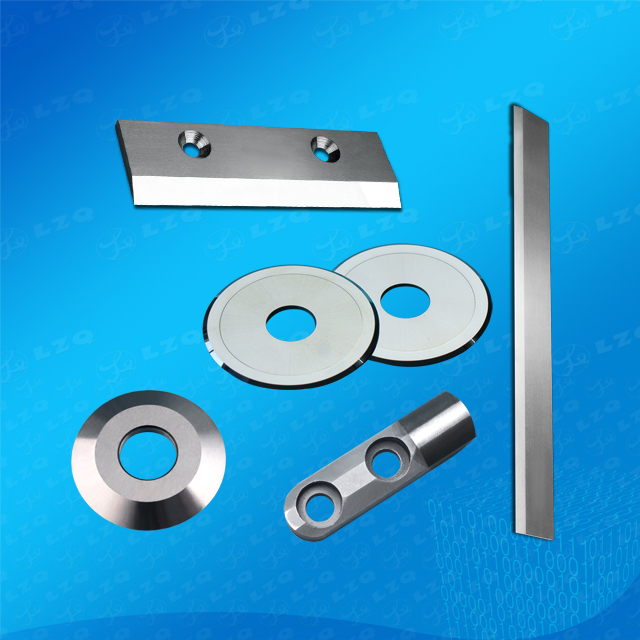

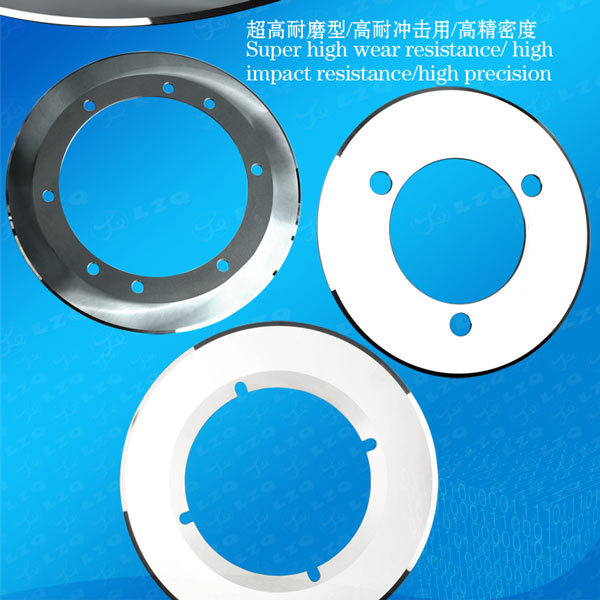

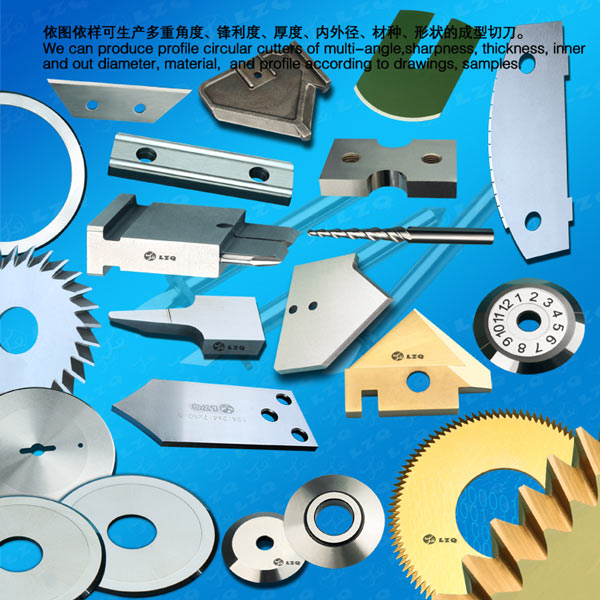

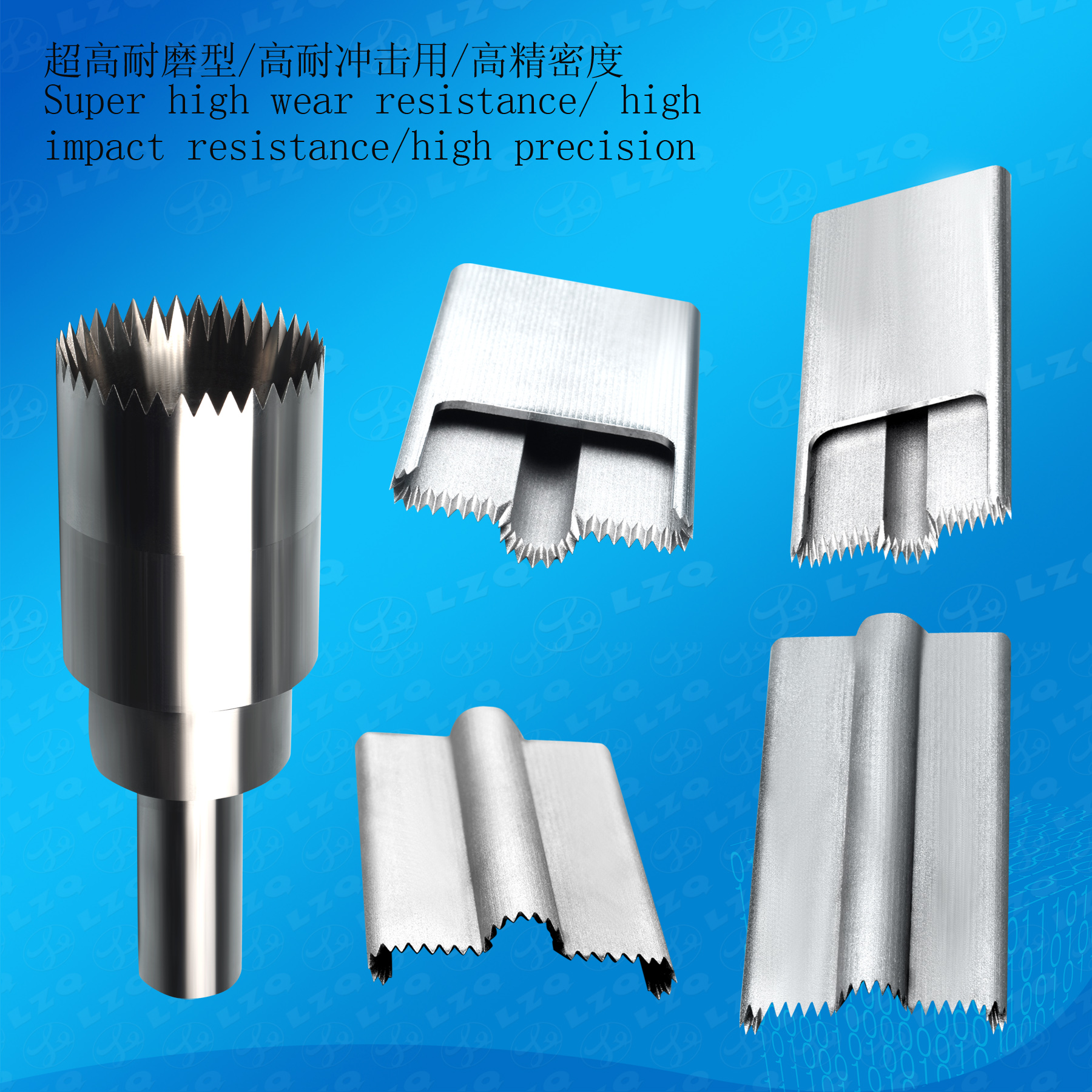

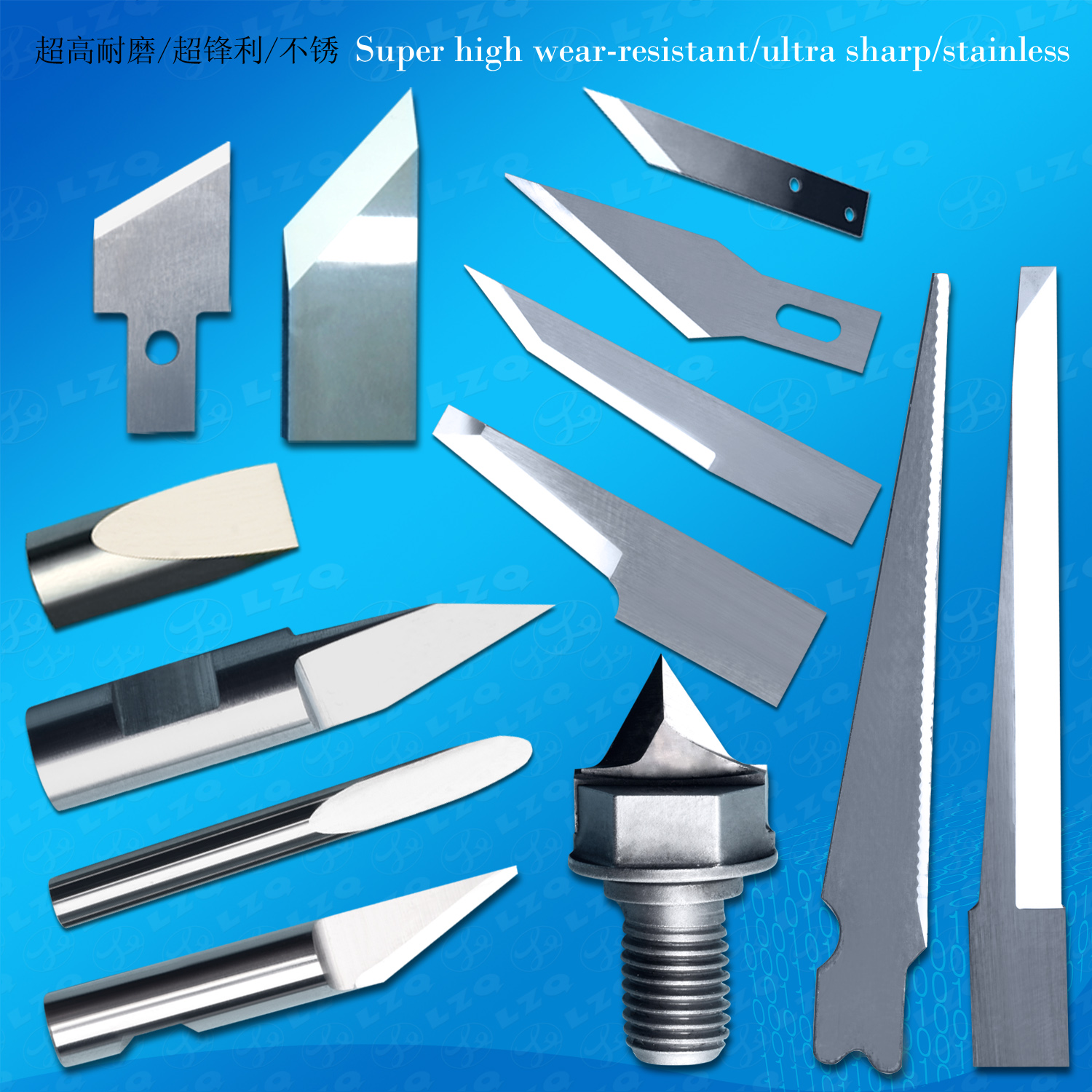

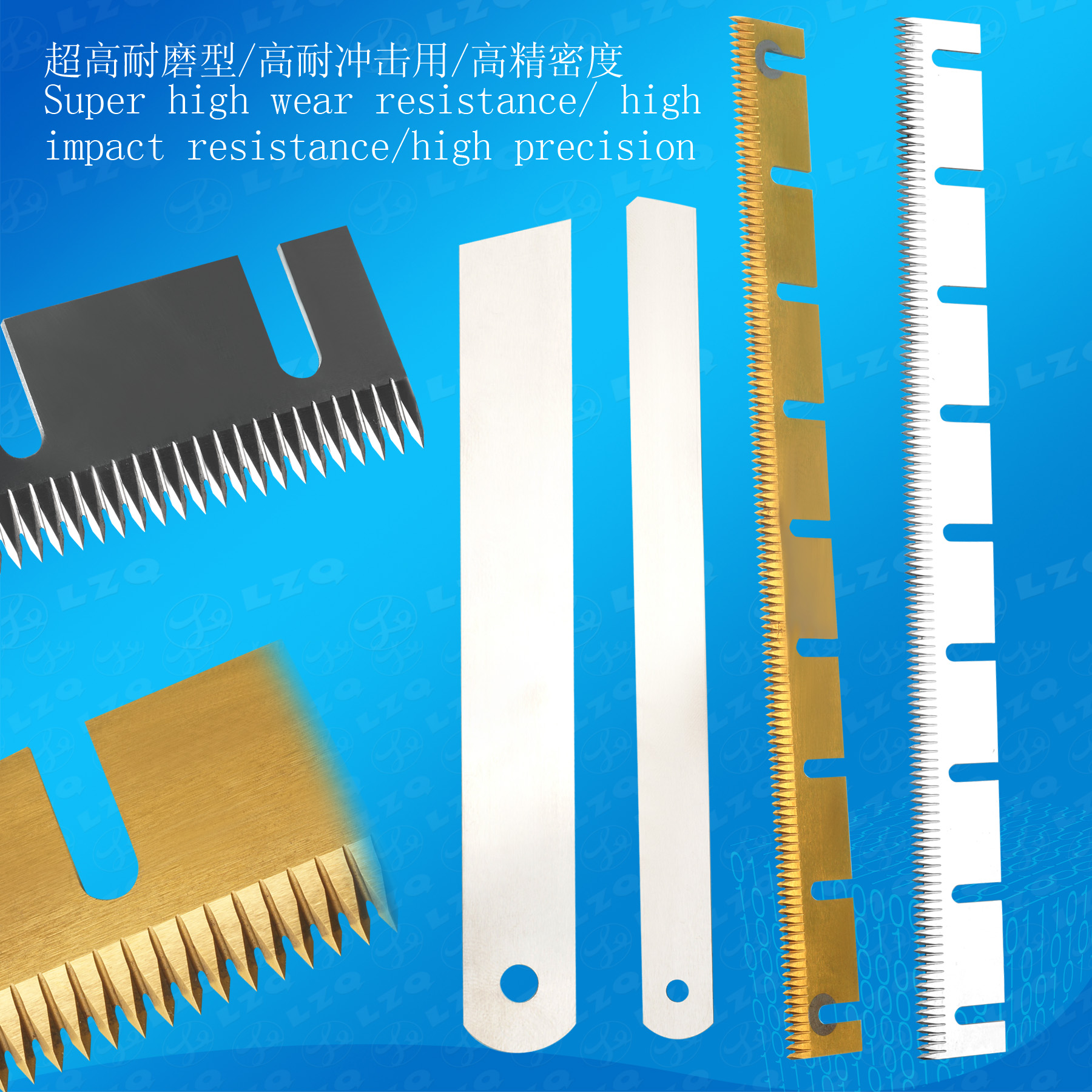

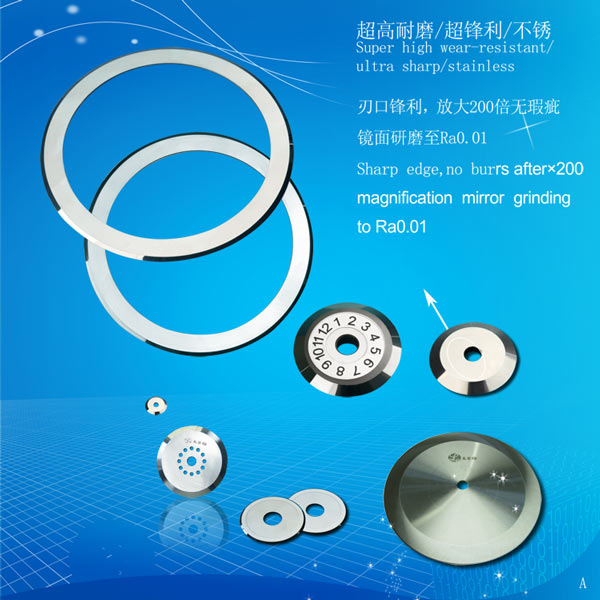

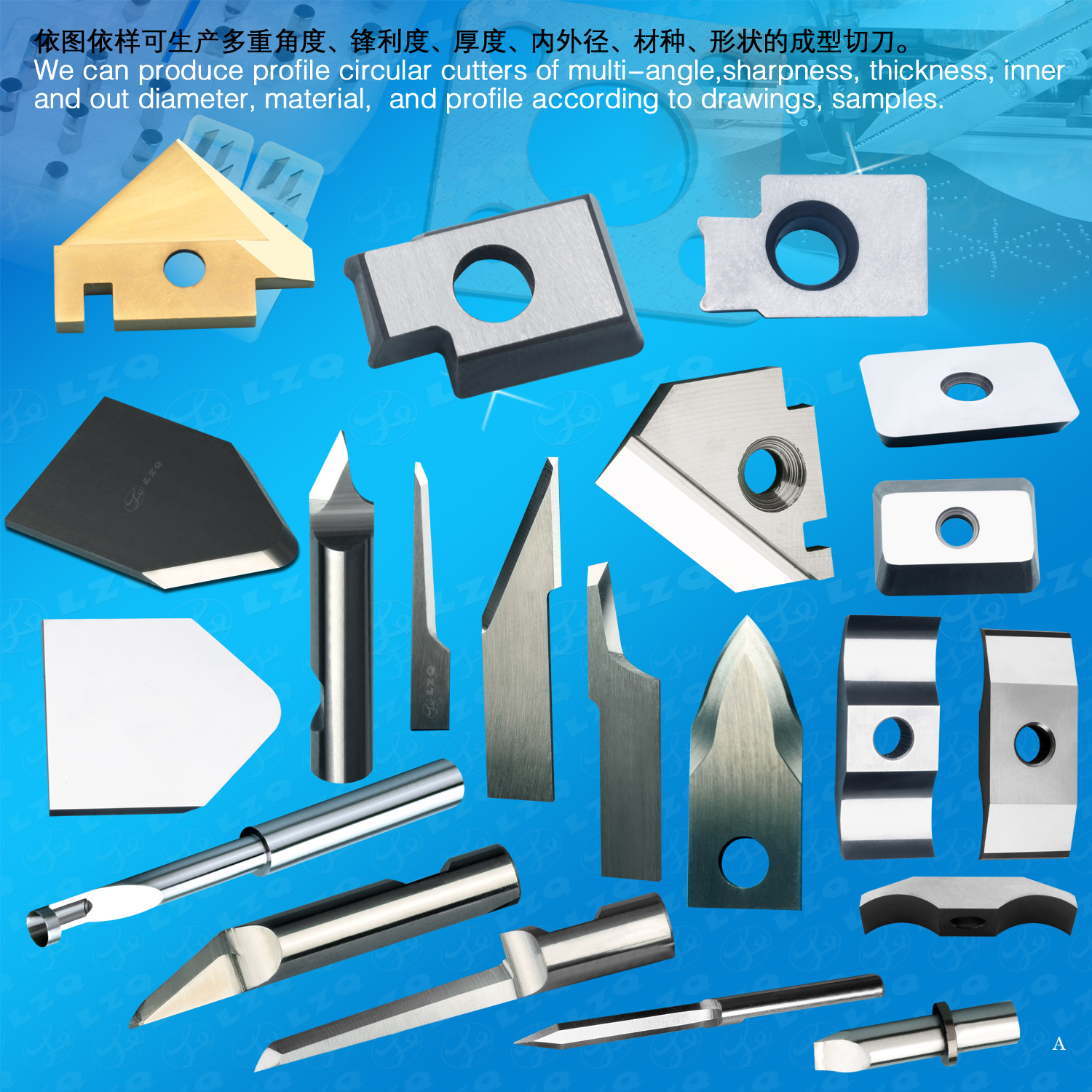

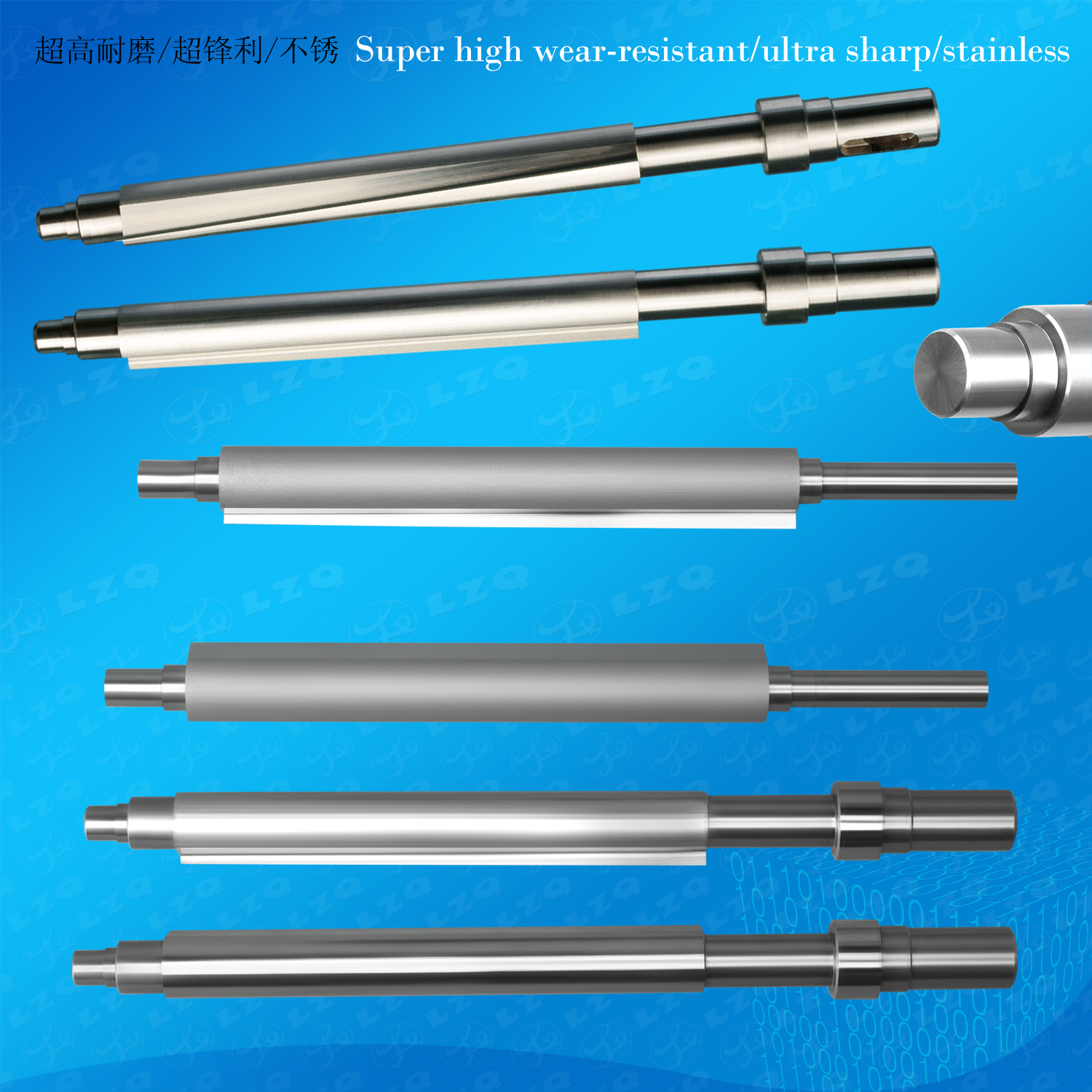

We can produce profile circular cutters of multi-angle, sharpness, thickness, inner and out diameter, material, and profile according to drawings, samples. We supply all kind of fibre cleaver blades. We are the manufacture of fibre cleaver blades, we can mass produce all sizes blade for you, only supply us your sample or detailed drawings. We adopt material import from Germany and 7-axis linkage CNC machine of Switzerland.

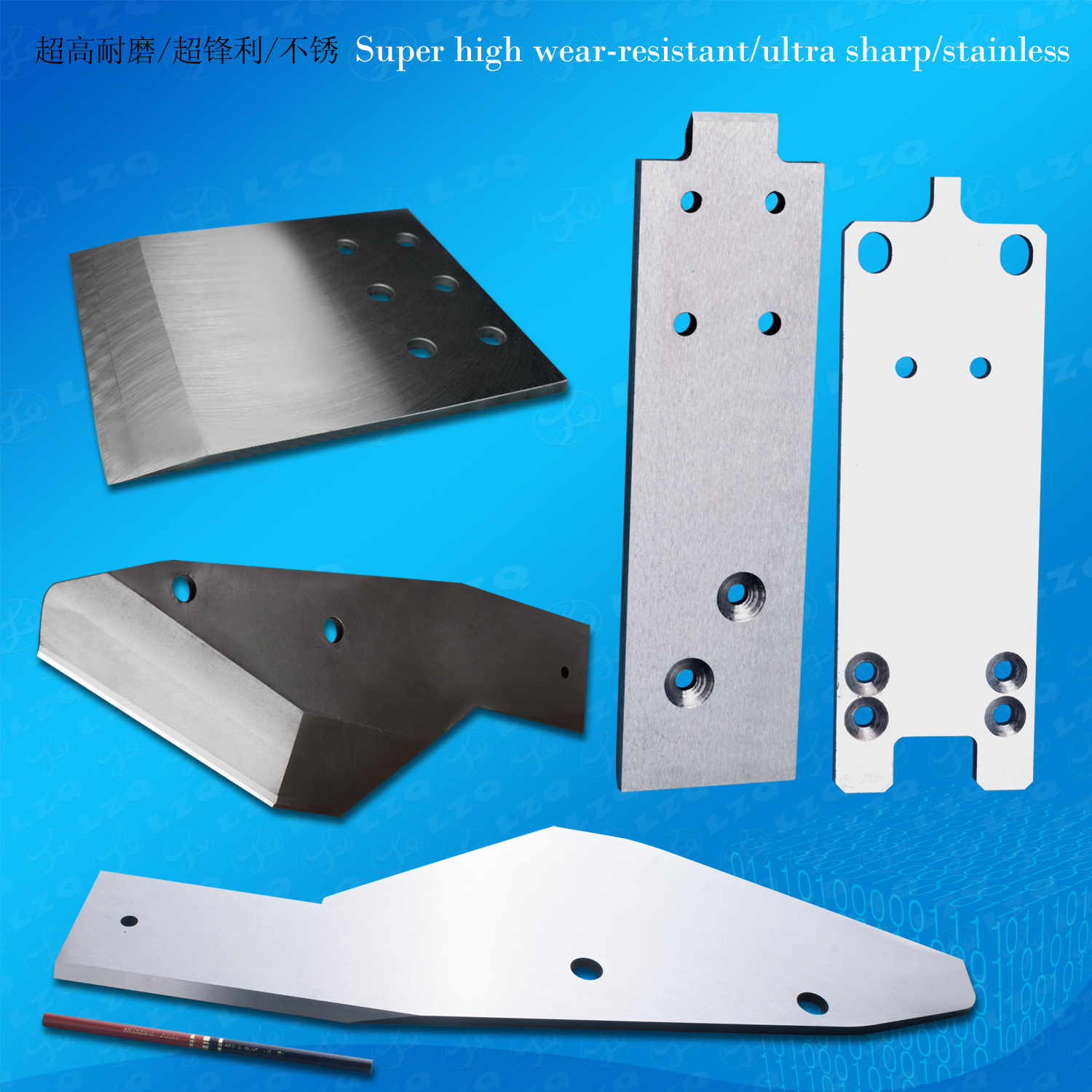

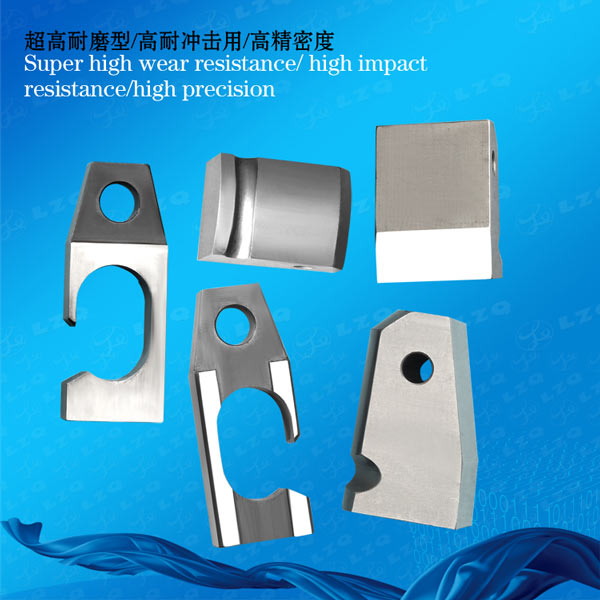

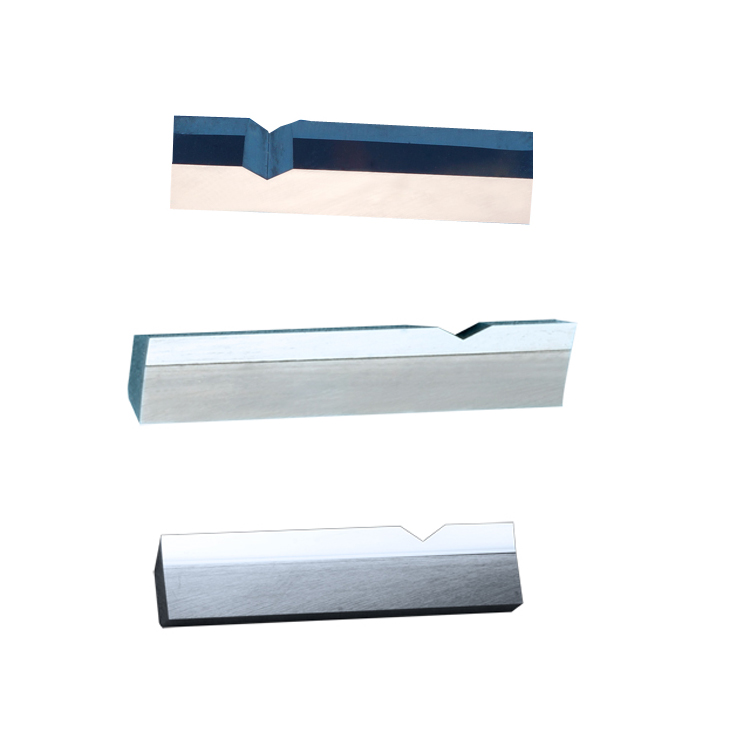

Cutting tool materials must be harder than the material which is to be cut, and the tool must be able to withstand the heat generated in the metal-cutting process. Also, the tool must have a specific geometry, with clearance angles designed so that the cutting edge can contact the workpiece without the rest of the tool dragging on the workpiece surface. The angle of the cutting face is also important, as is the flute width, number of flutes or teeth, and margin size. In order to have a long working life, all of the above must be optimized, plus the speeds and feeds at which the tool is run.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

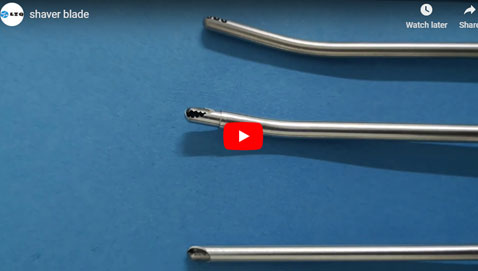

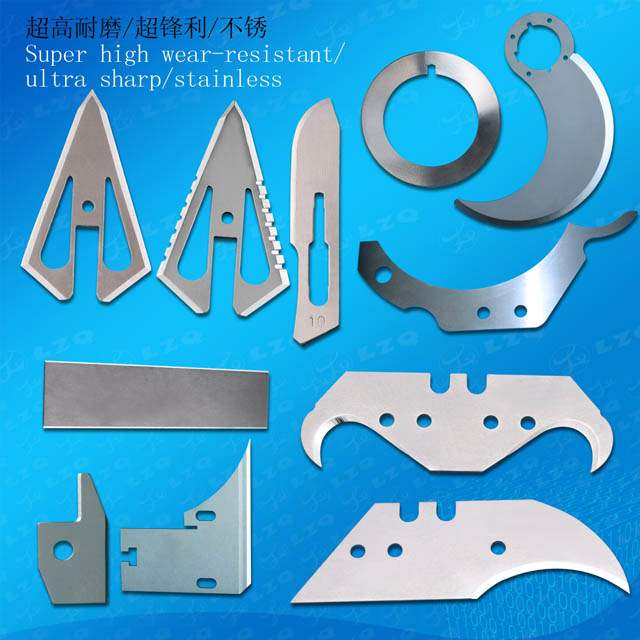

Medical Instrument

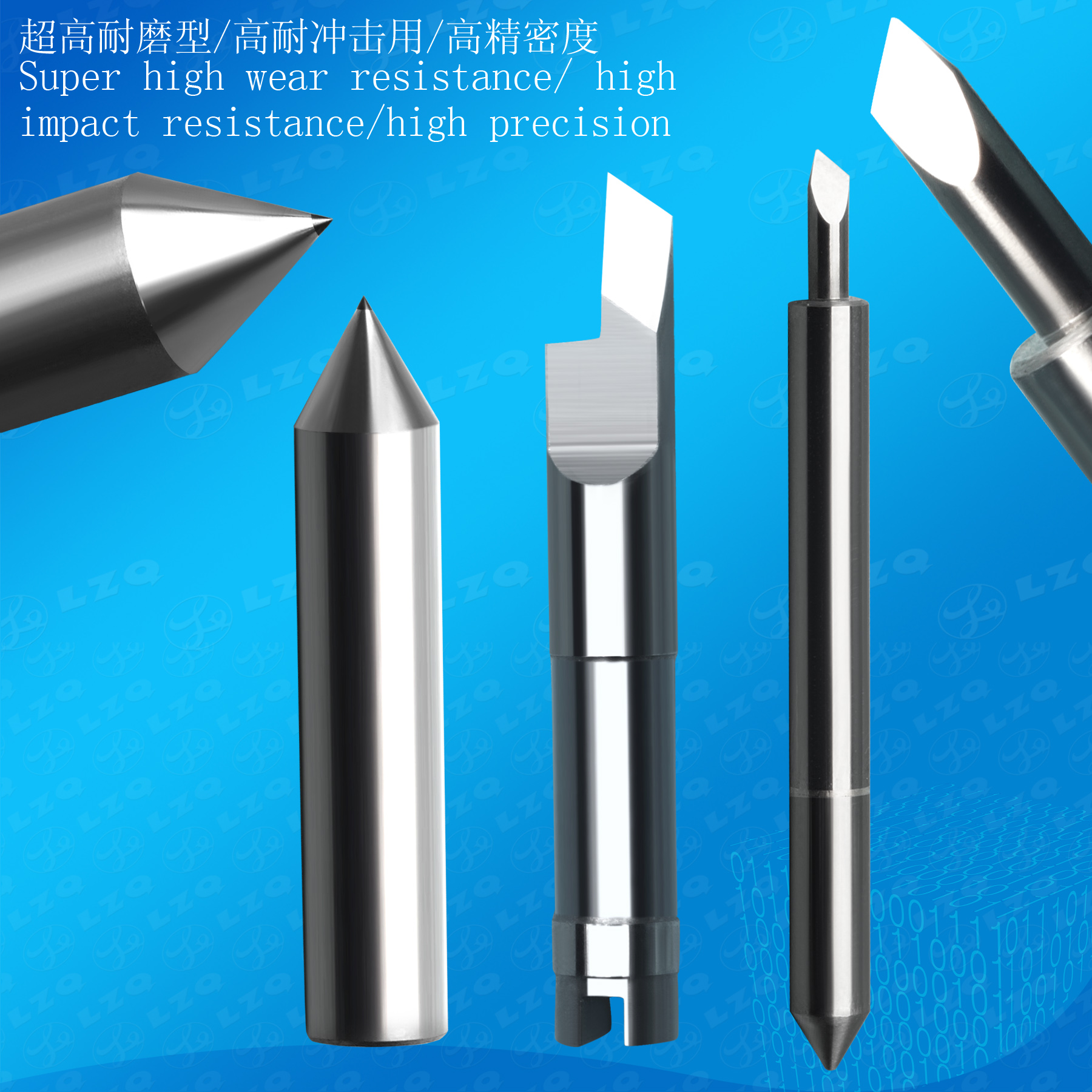

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

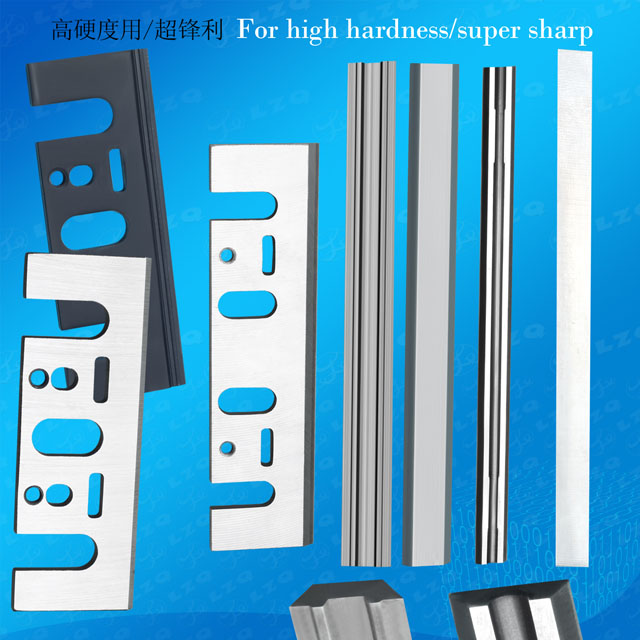

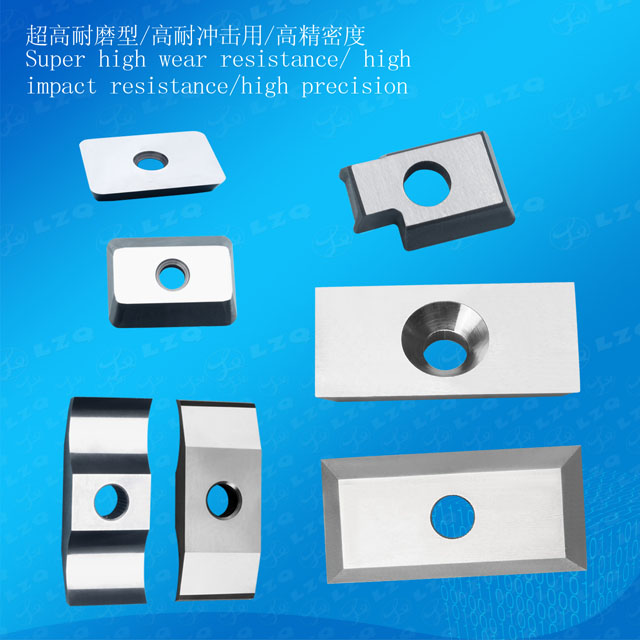

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

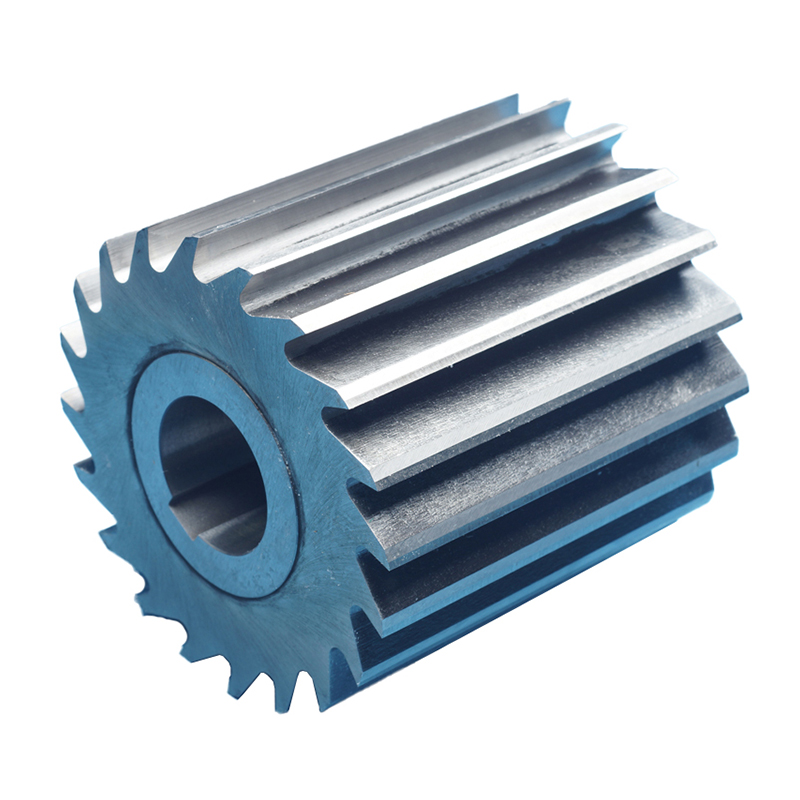

Cutting Tools

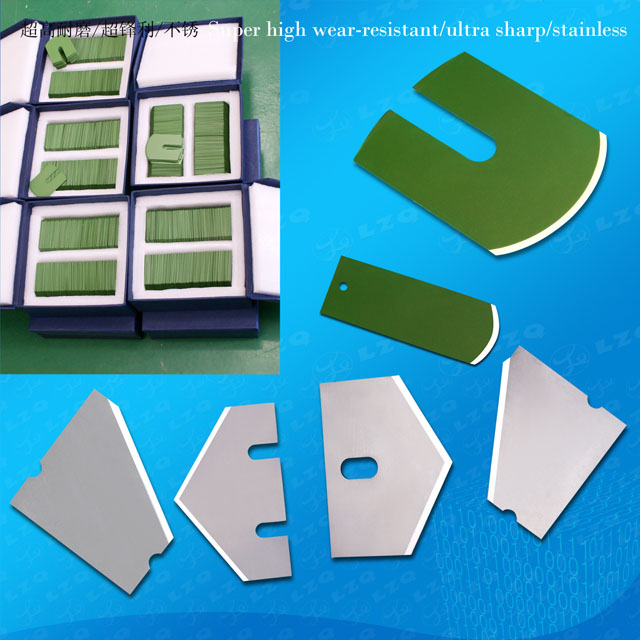

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

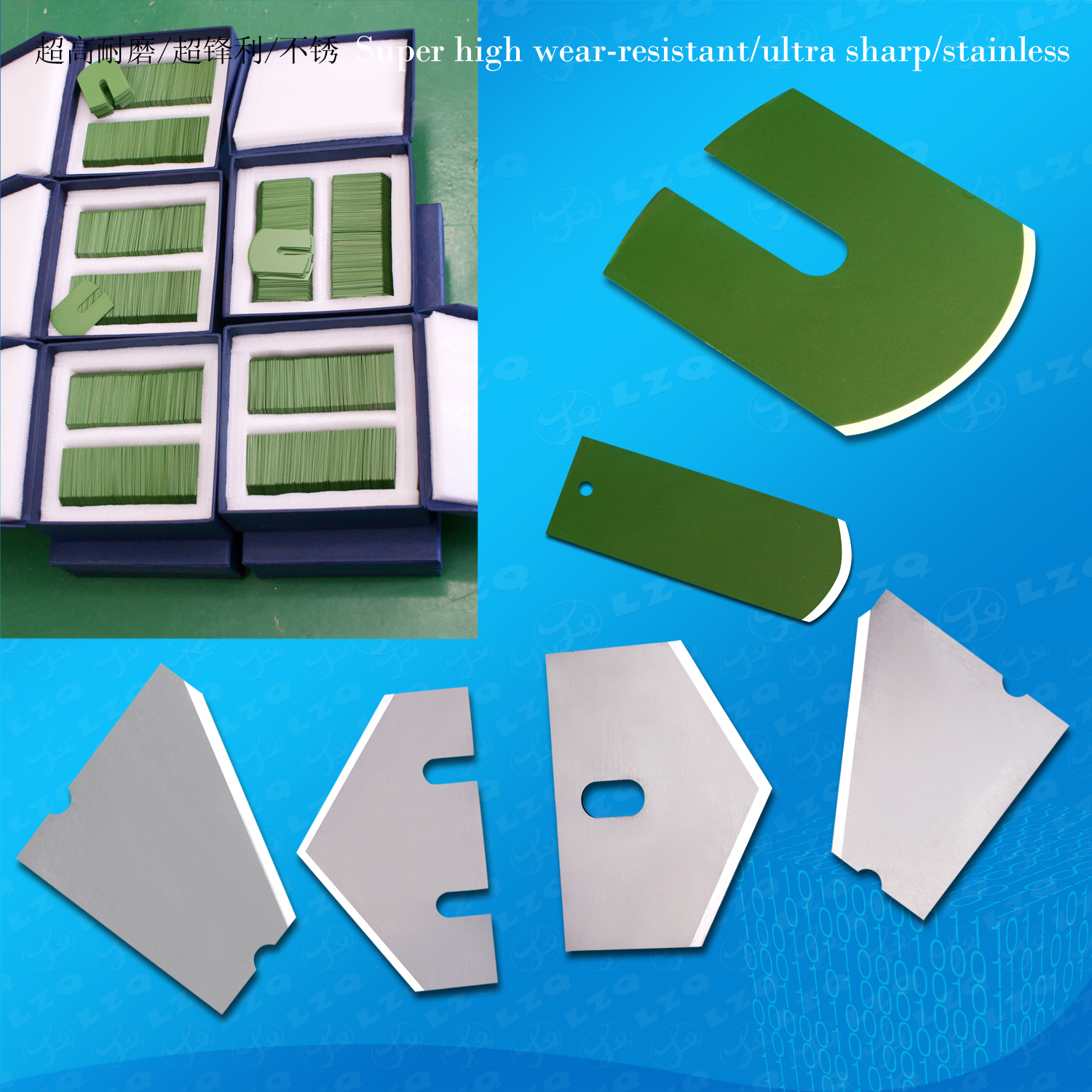

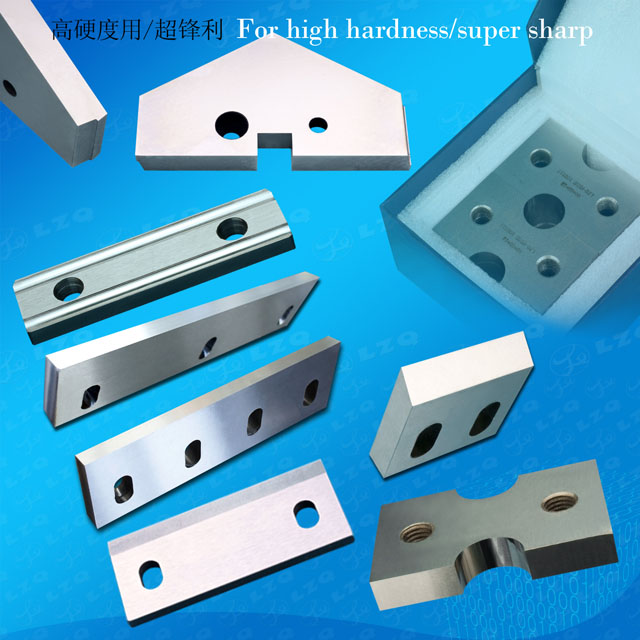

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.