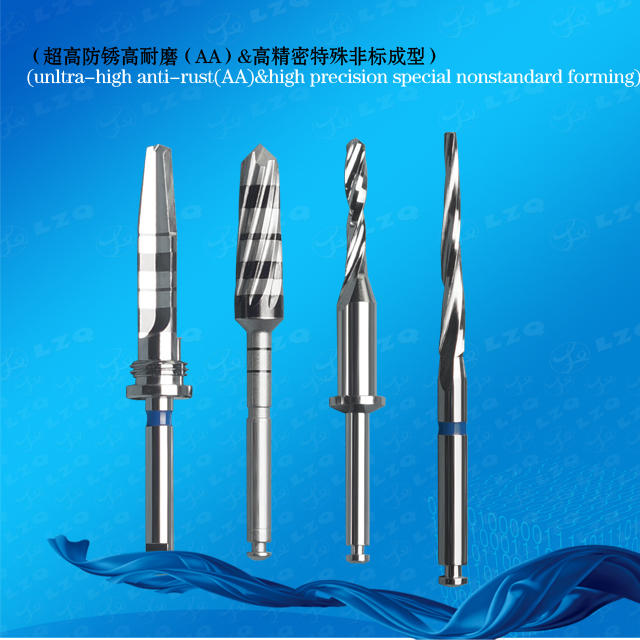

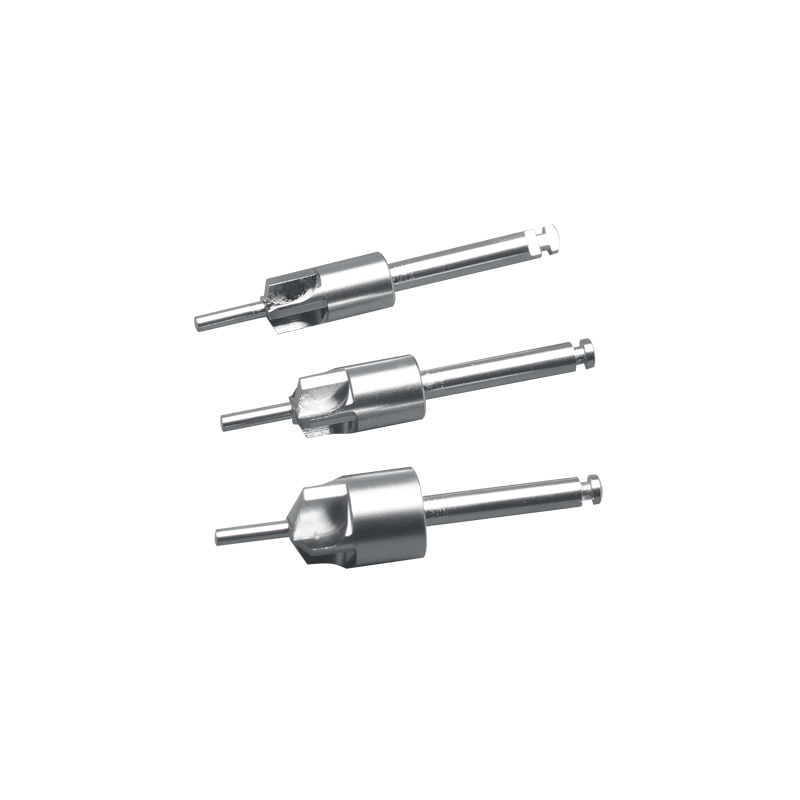

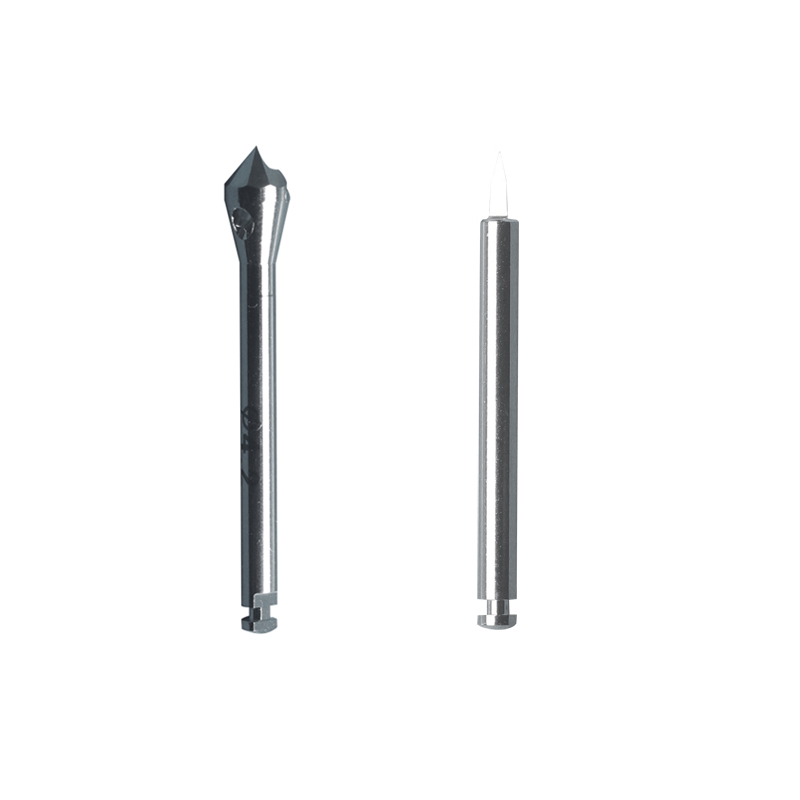

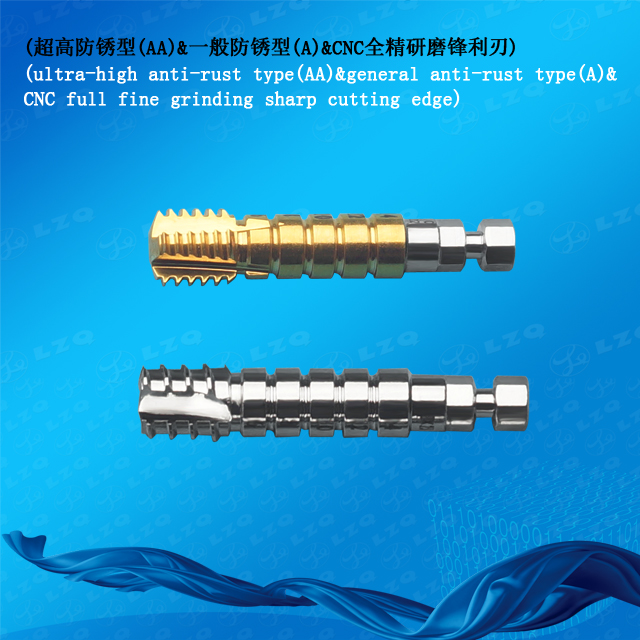

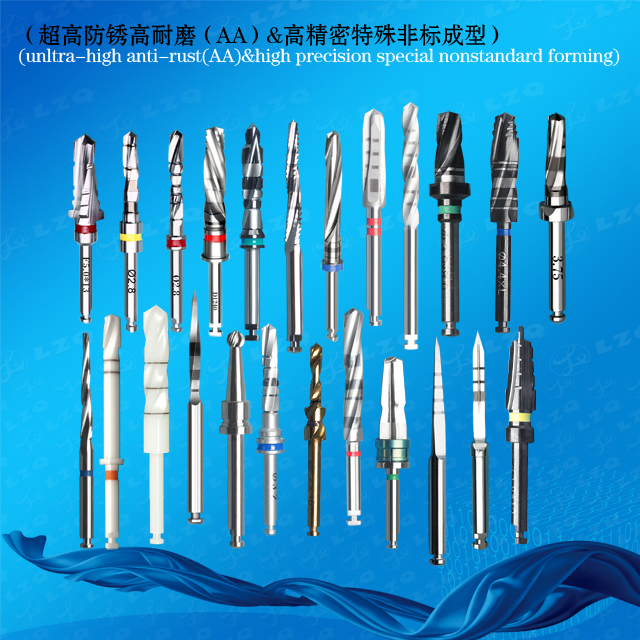

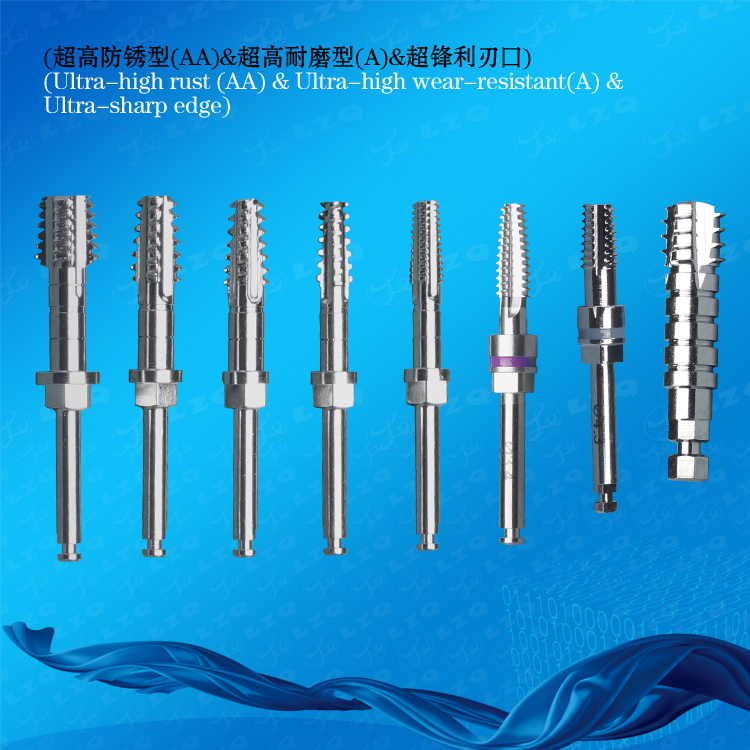

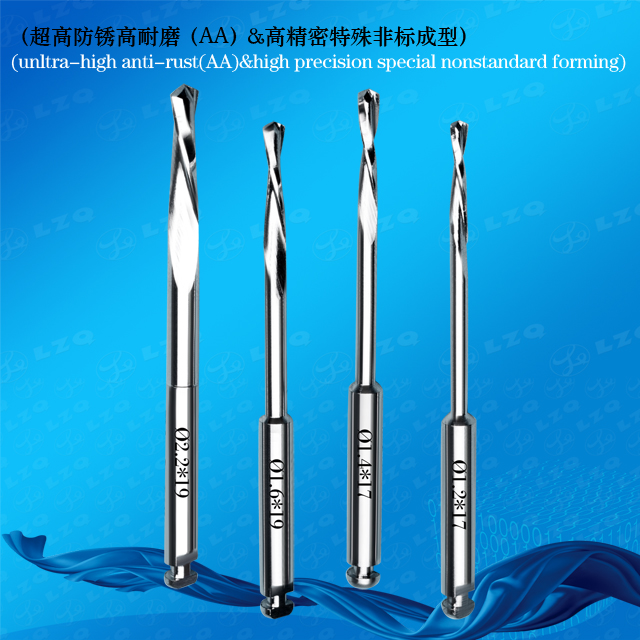

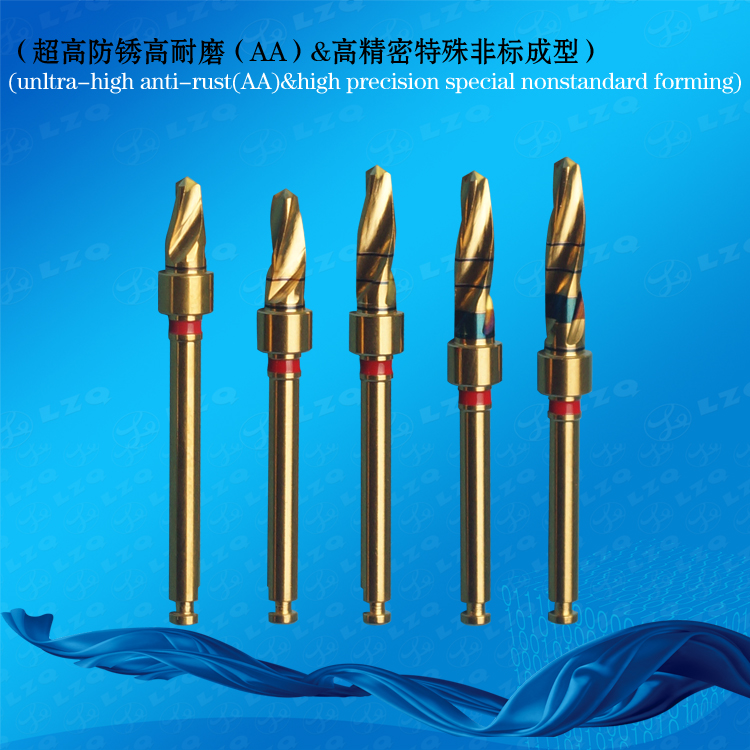

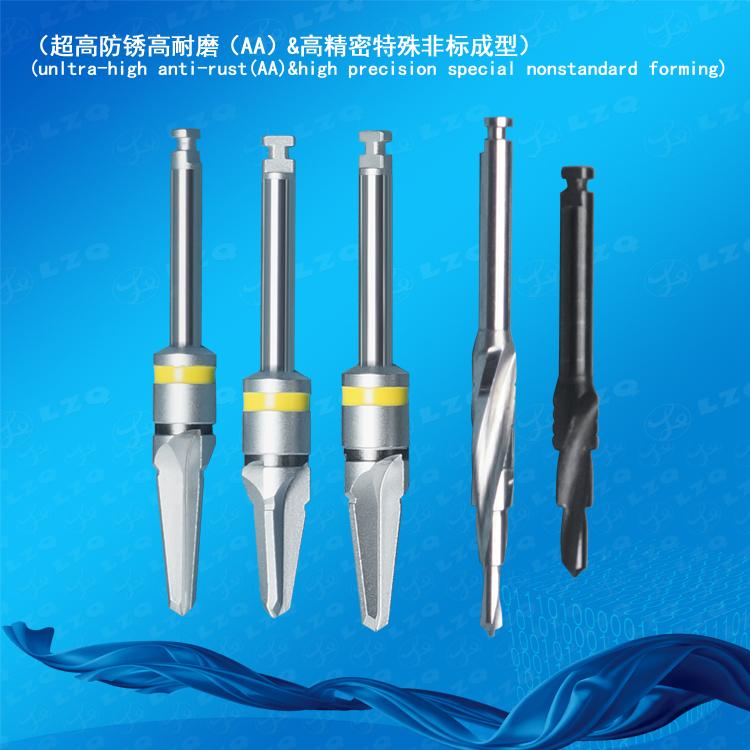

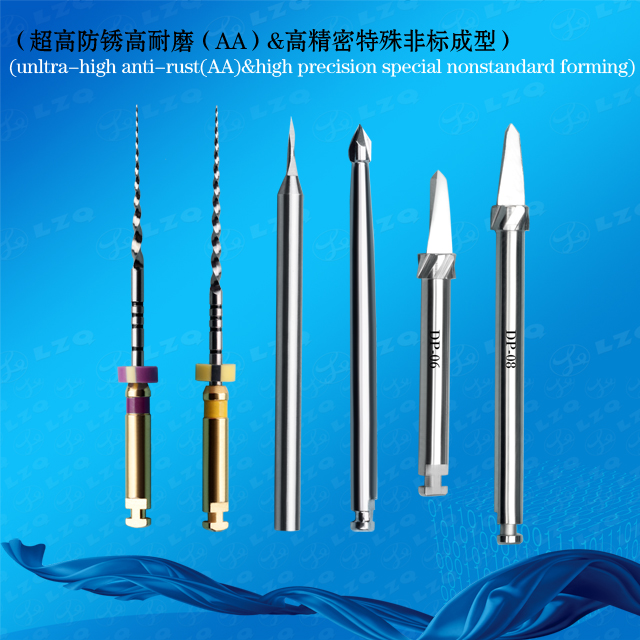

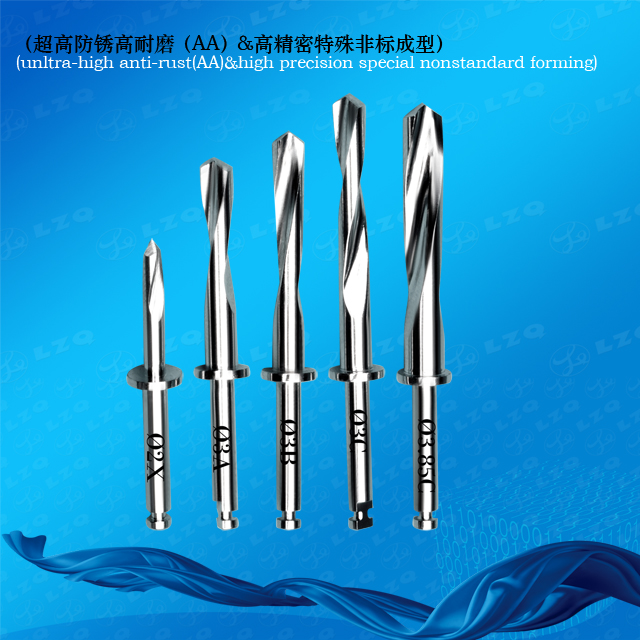

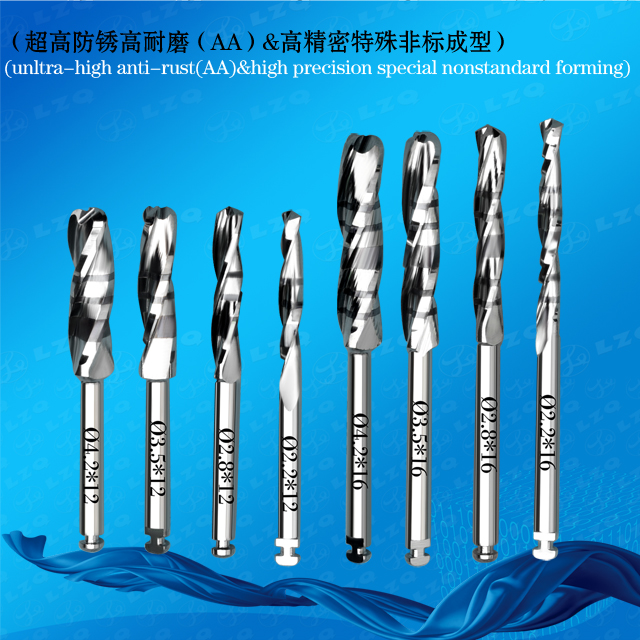

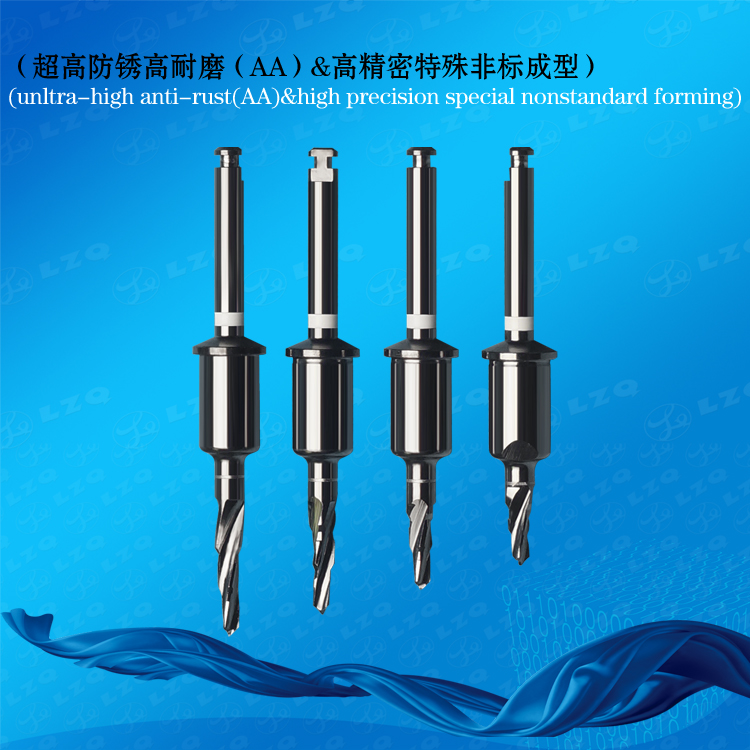

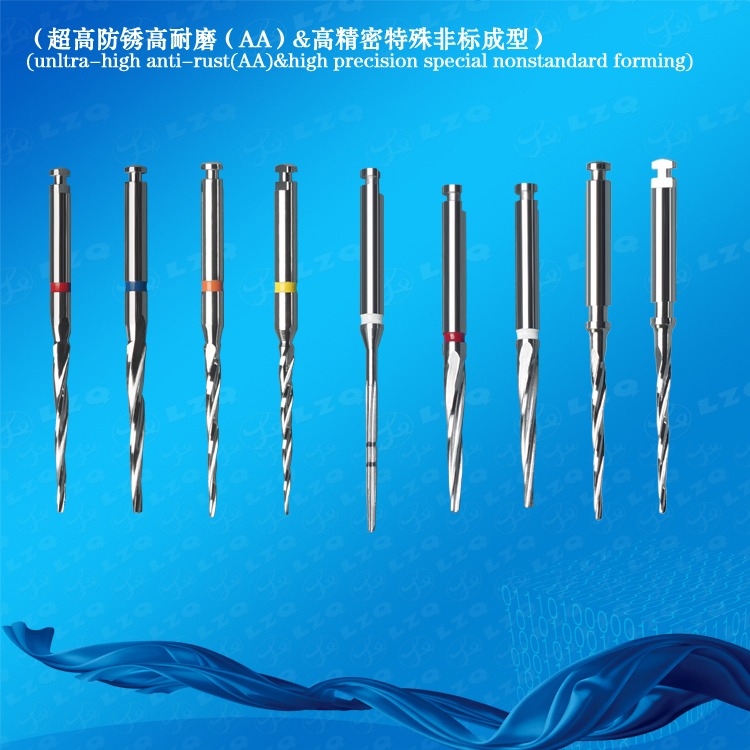

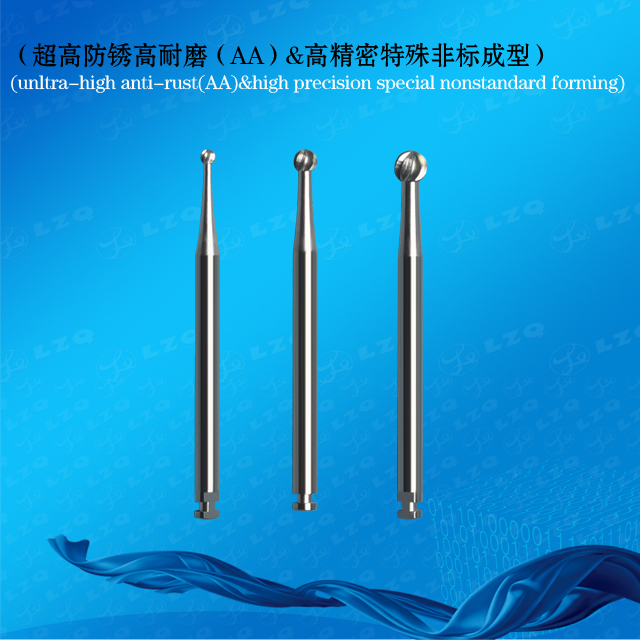

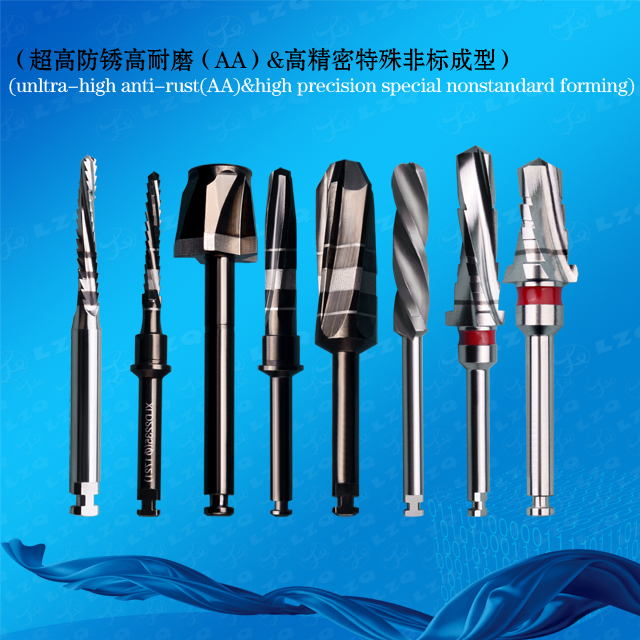

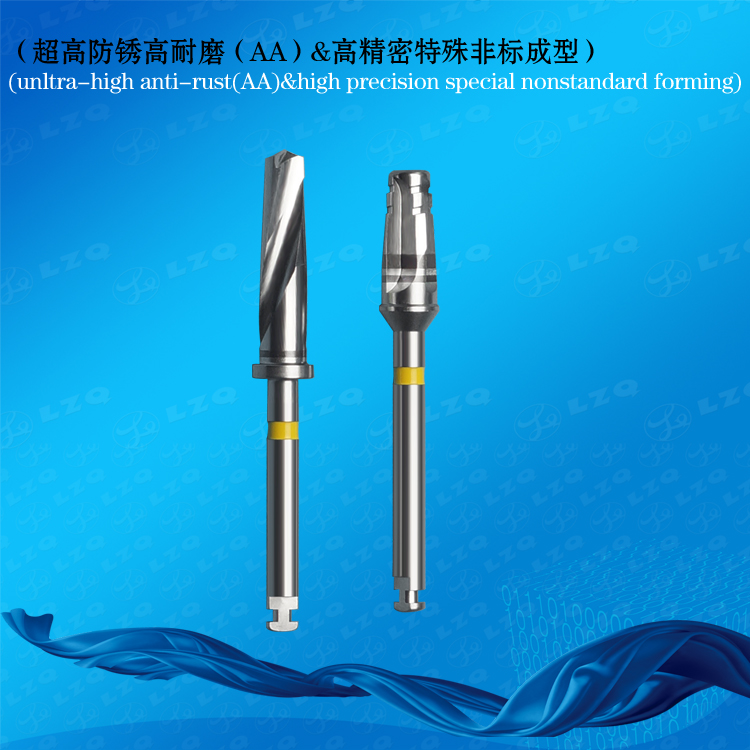

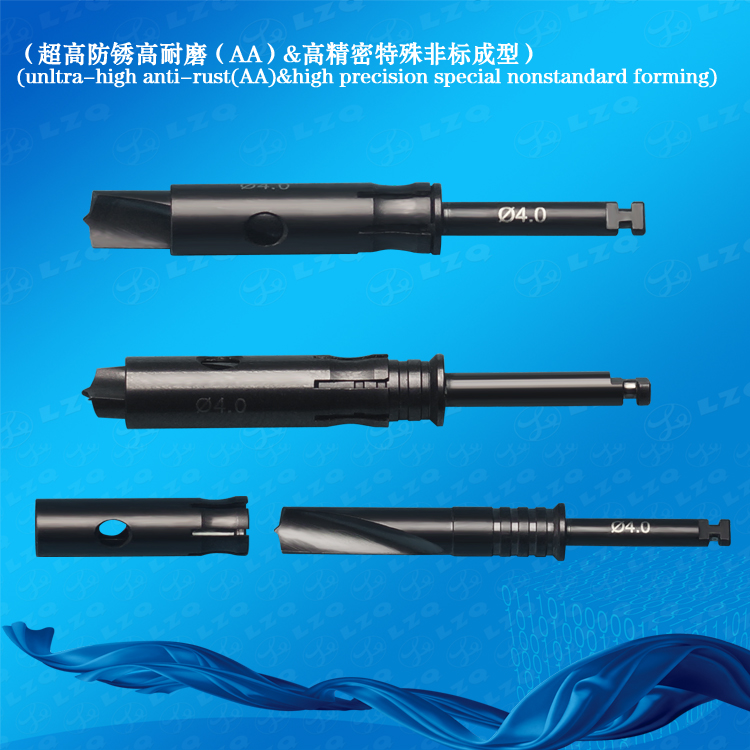

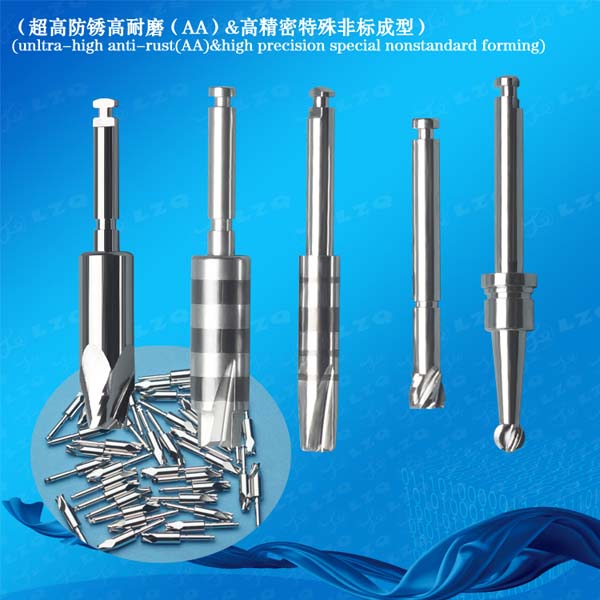

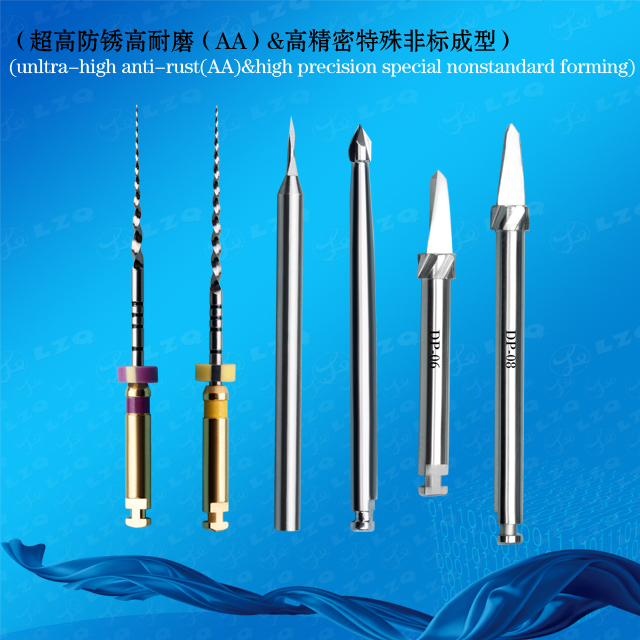

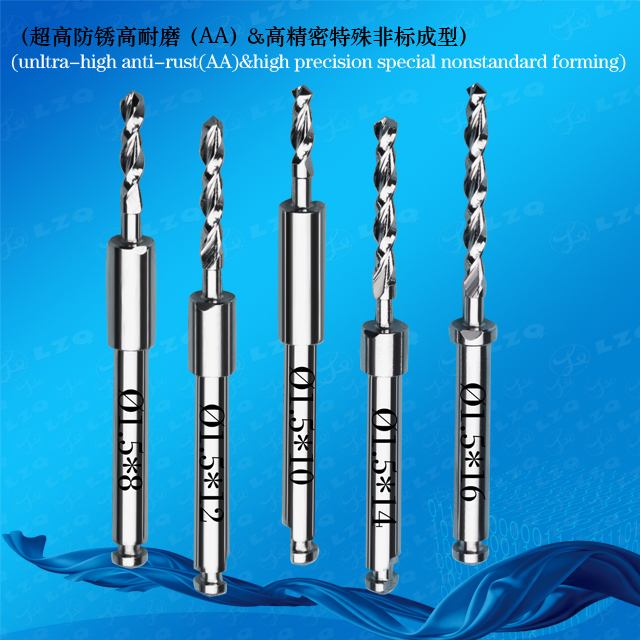

Drill Bit

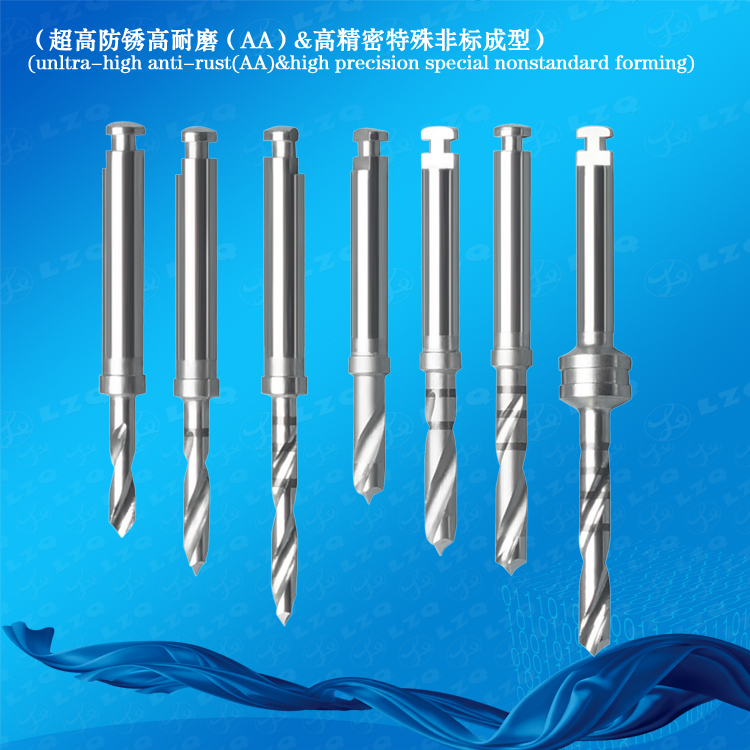

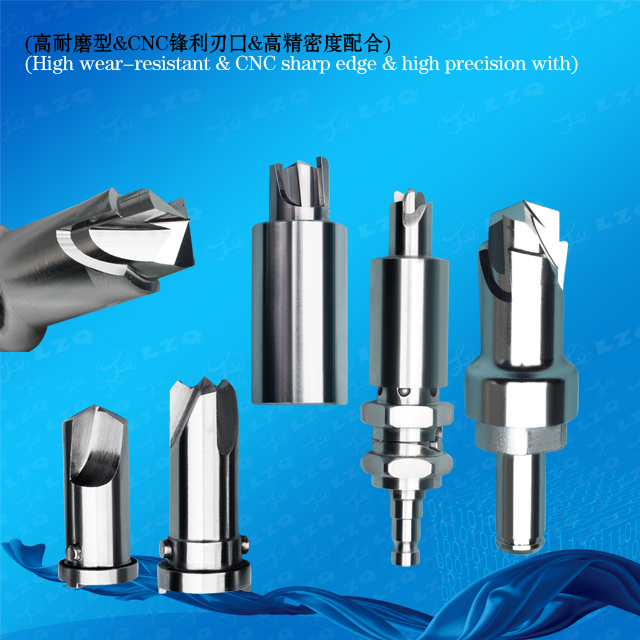

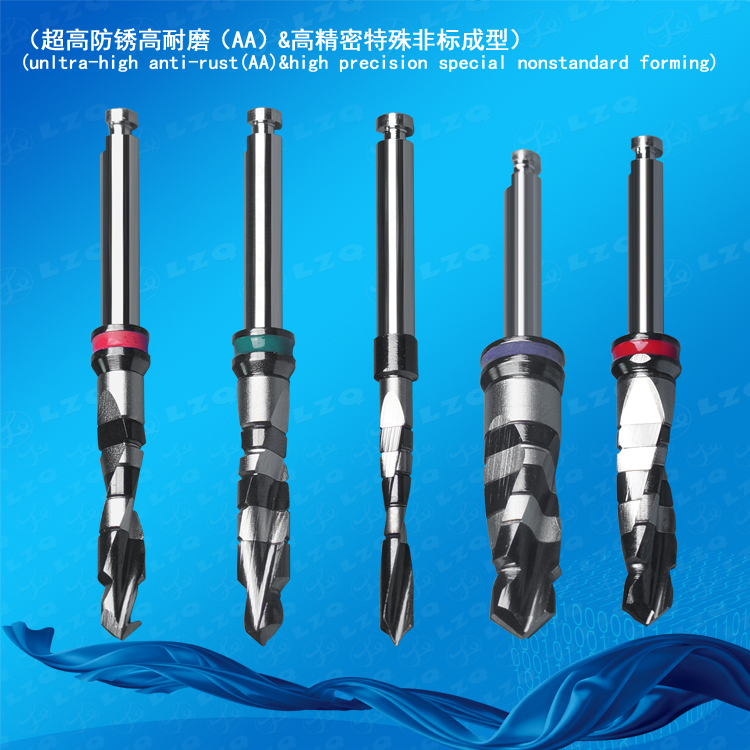

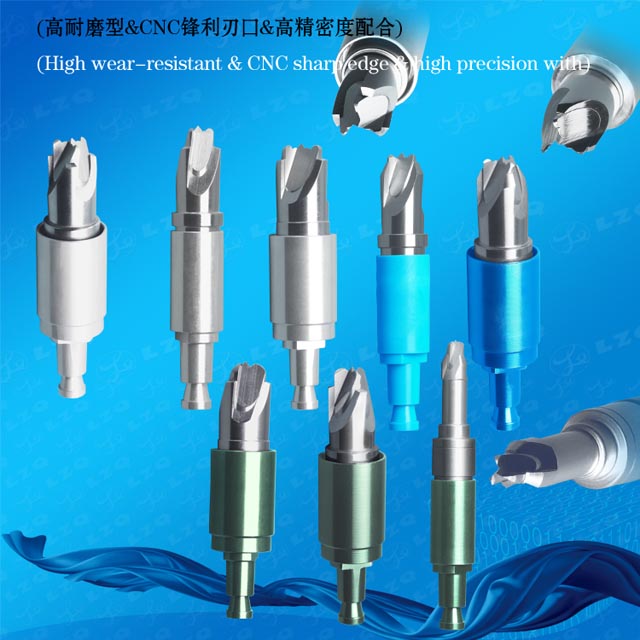

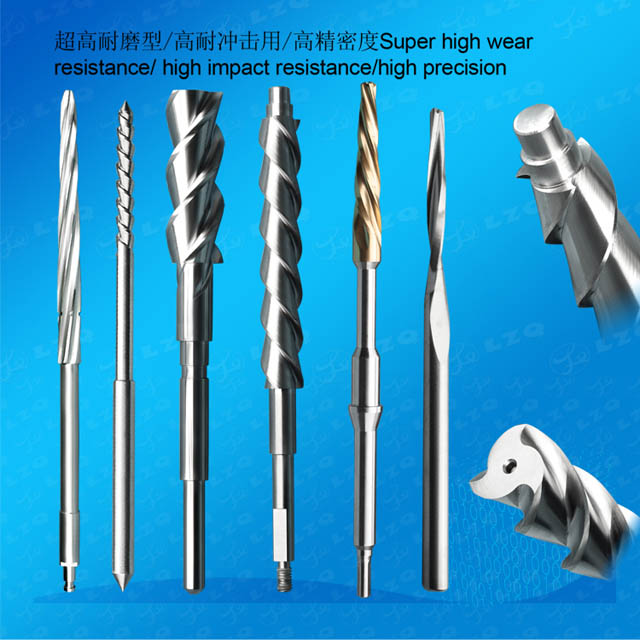

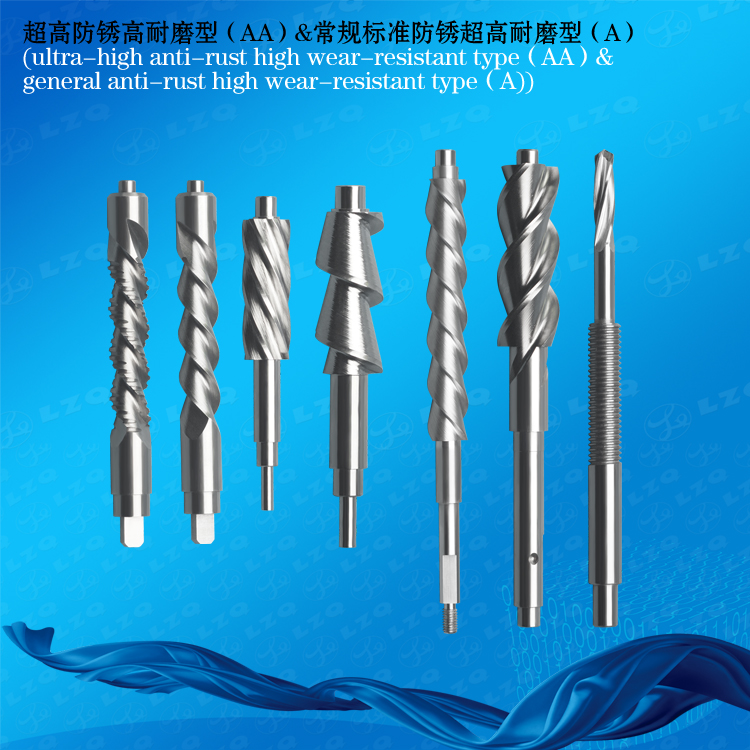

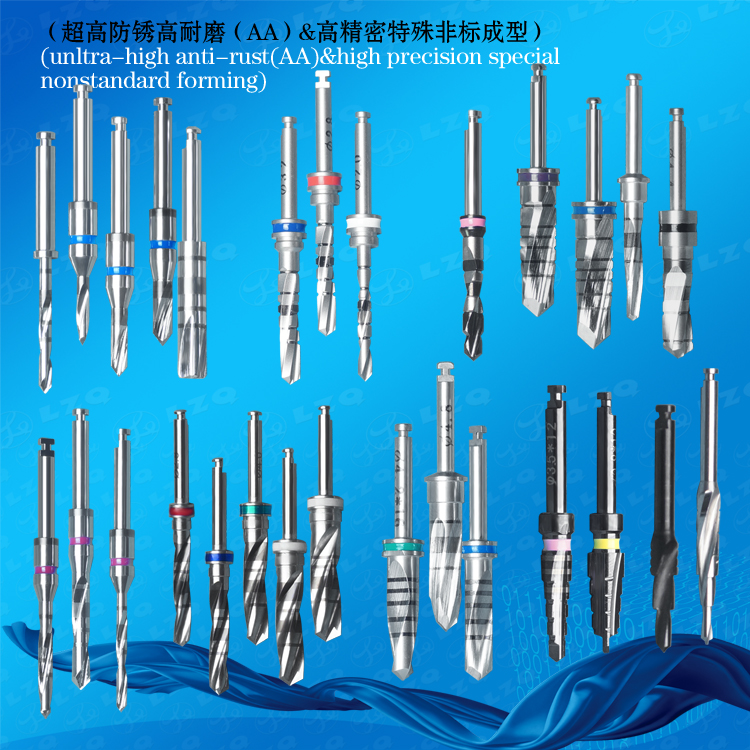

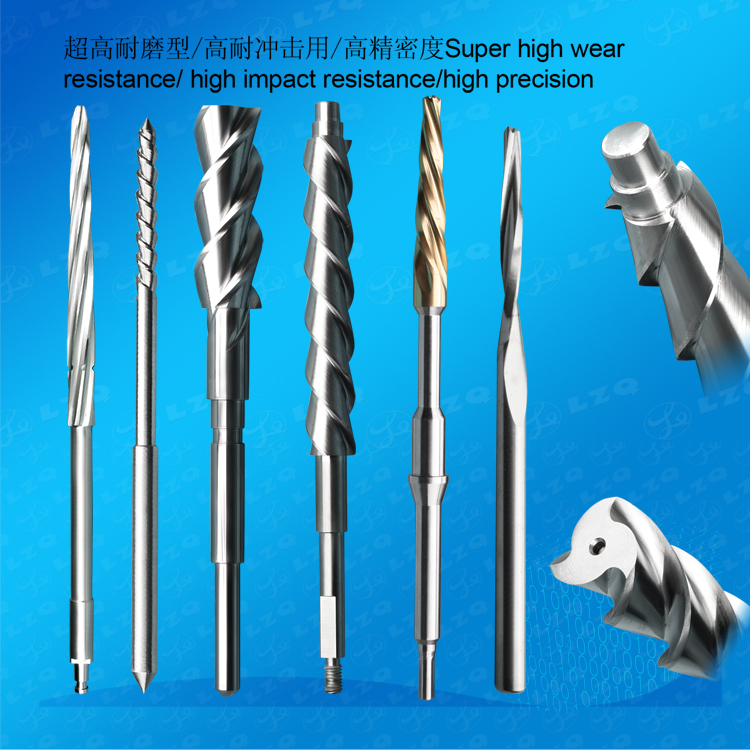

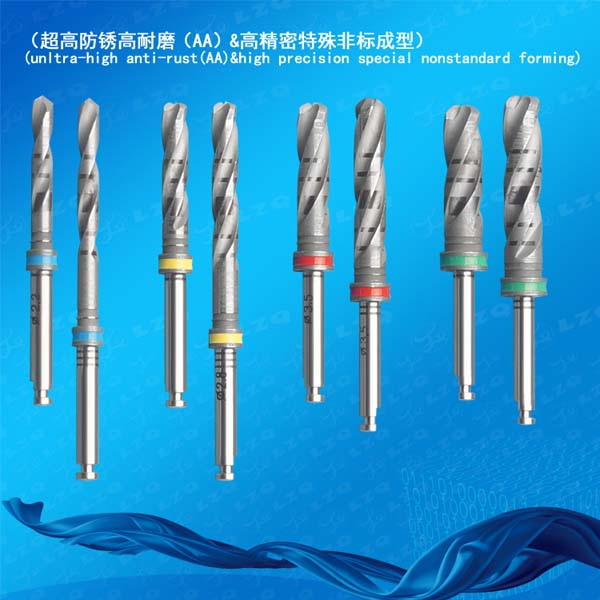

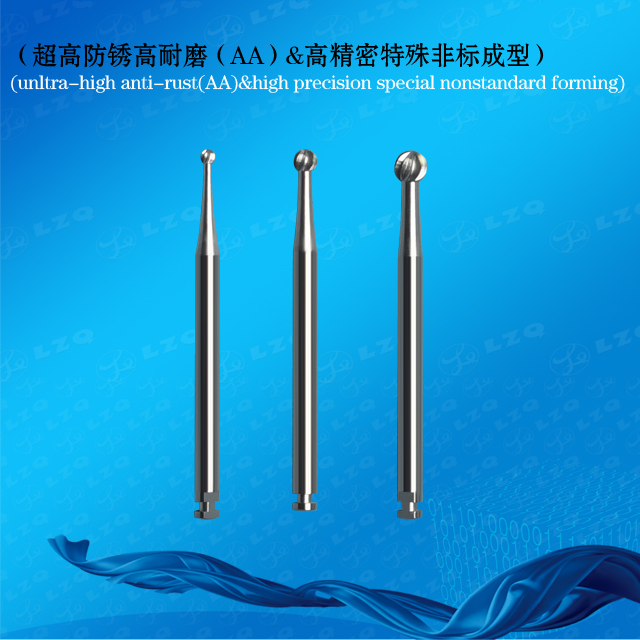

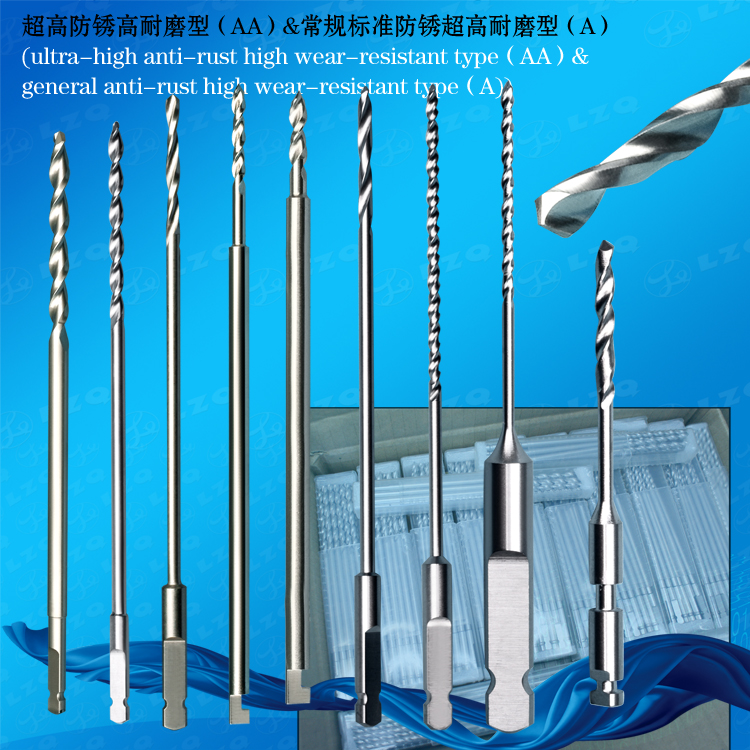

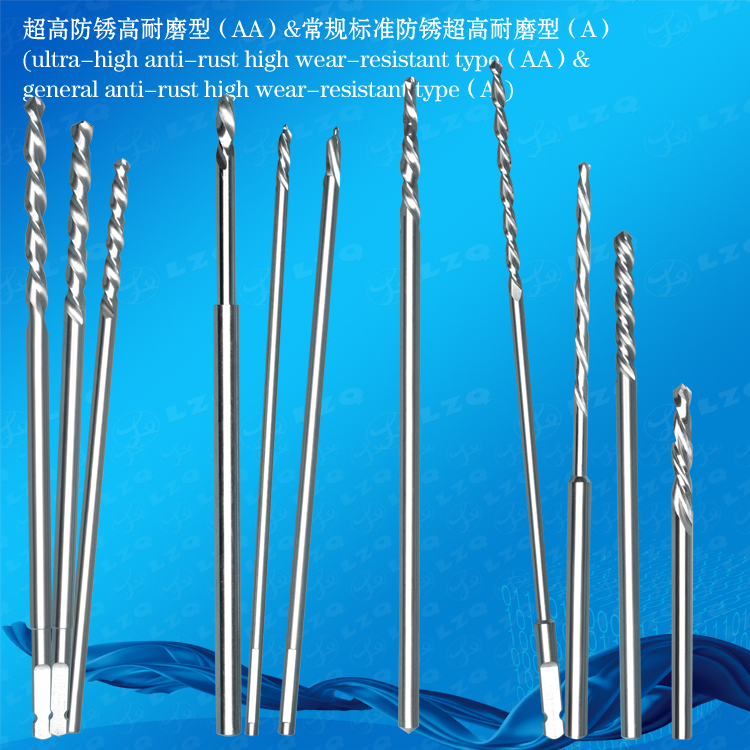

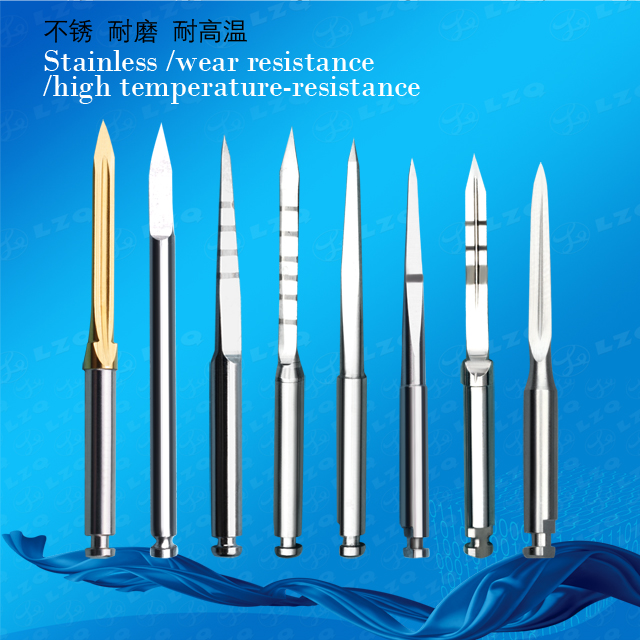

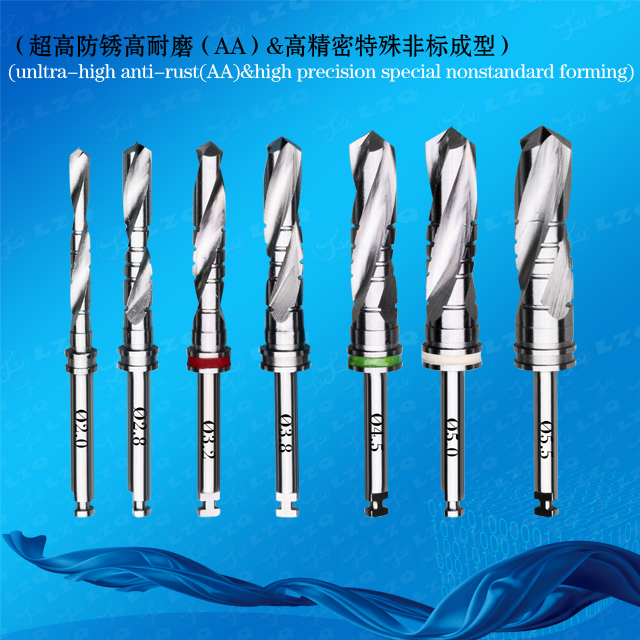

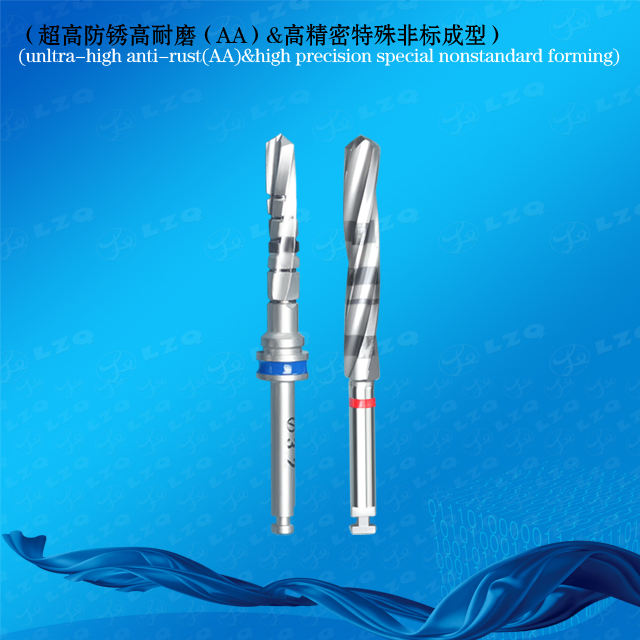

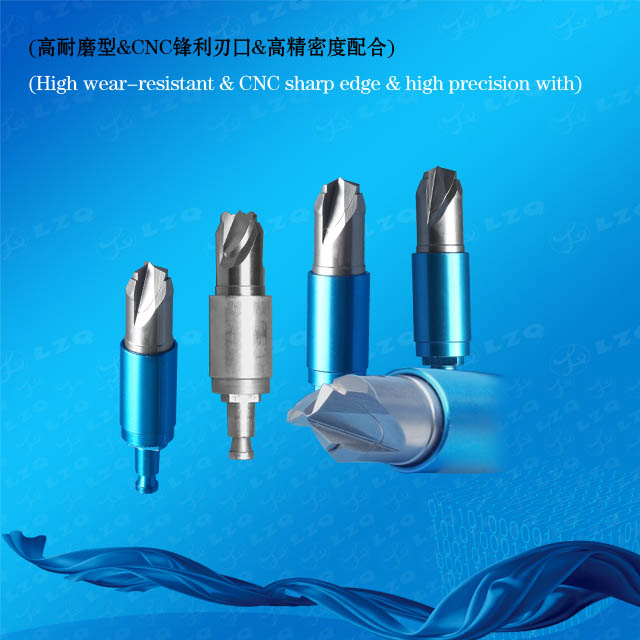

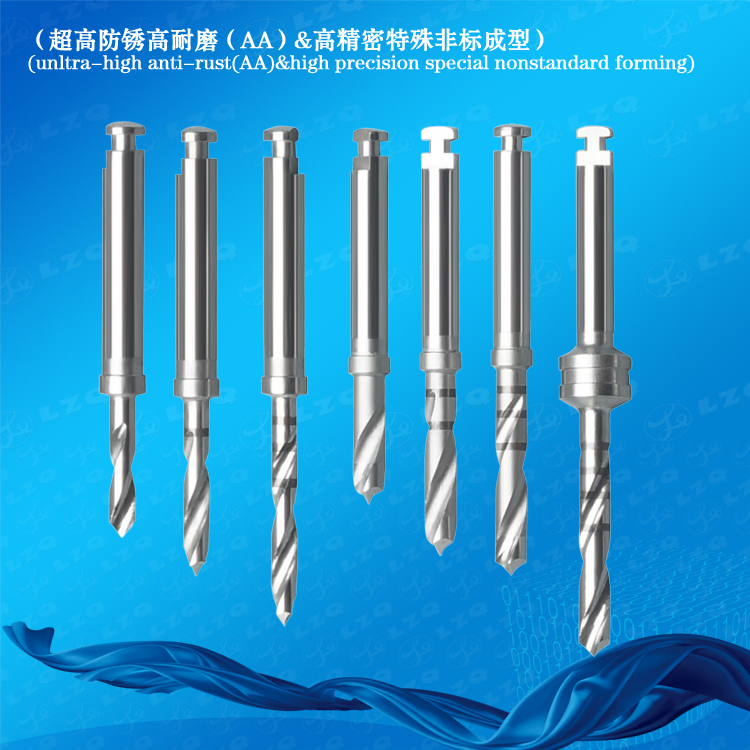

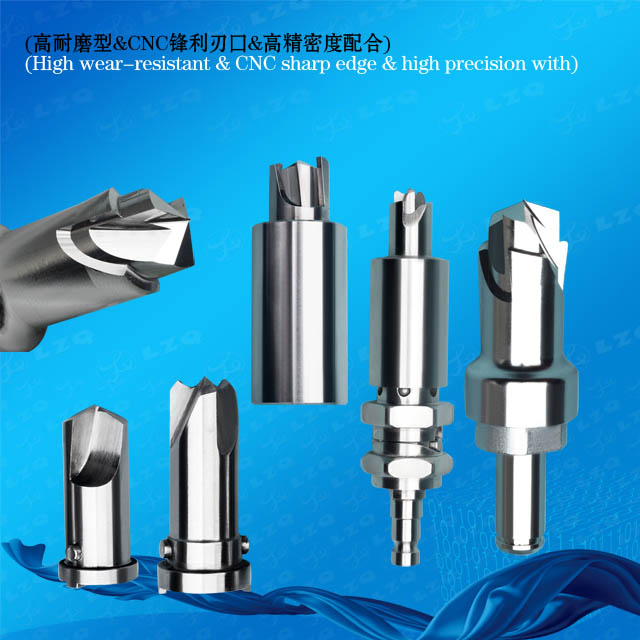

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined profile products, and realize high-efficiency and low-cost applications.

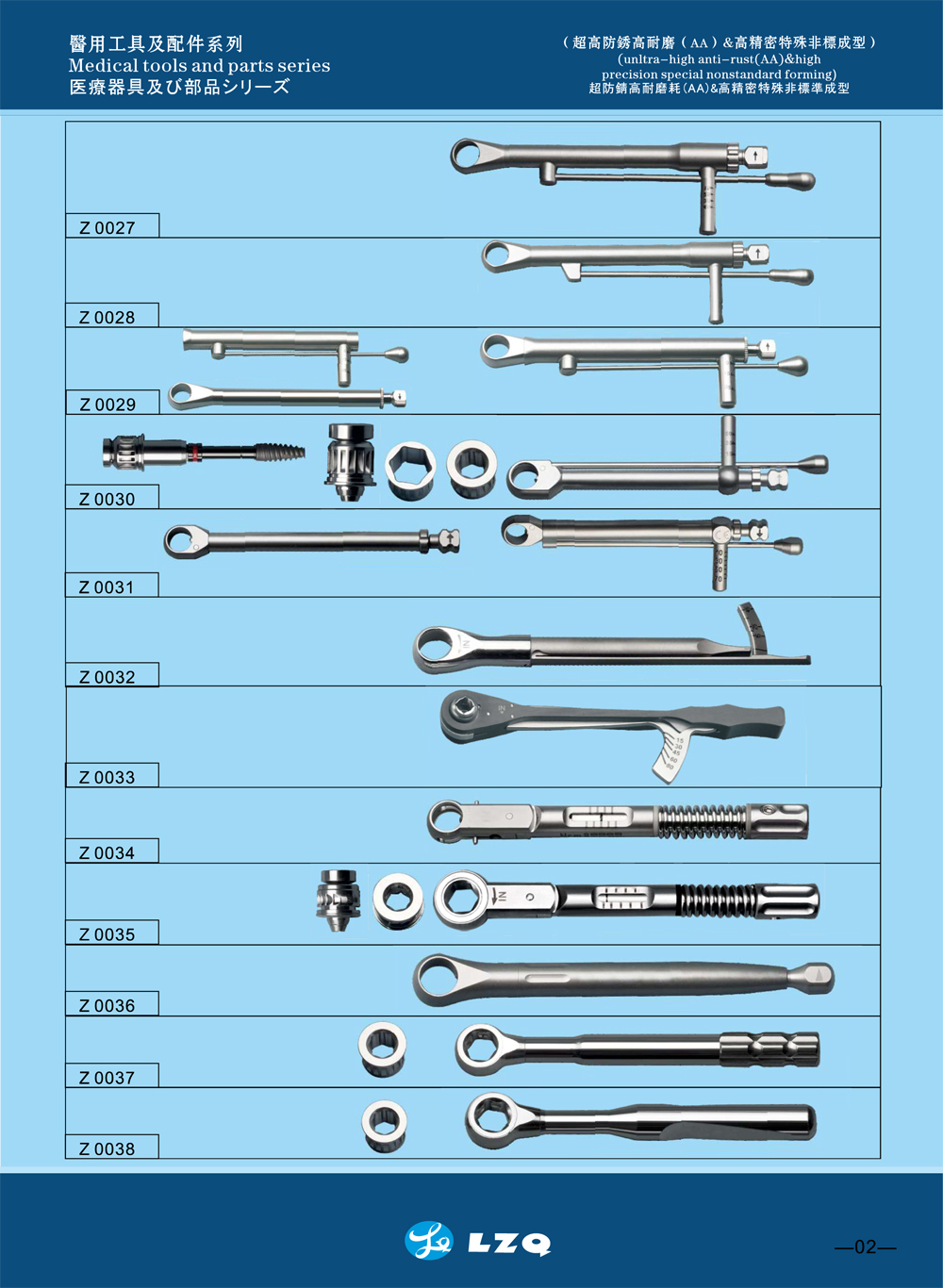

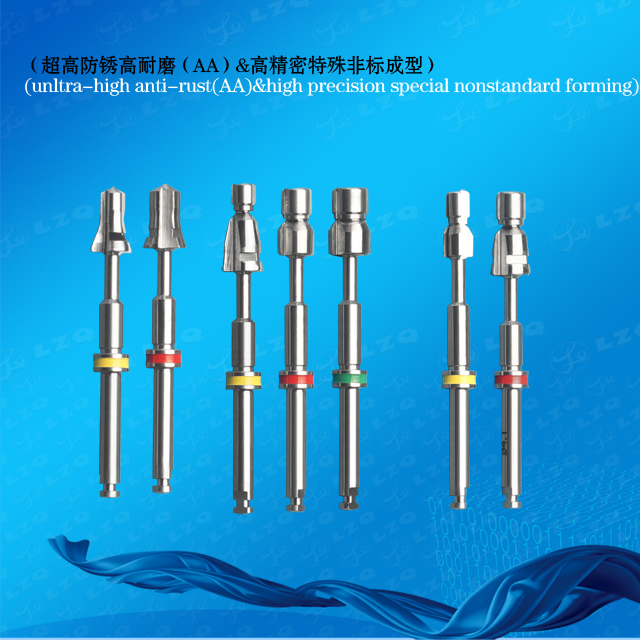

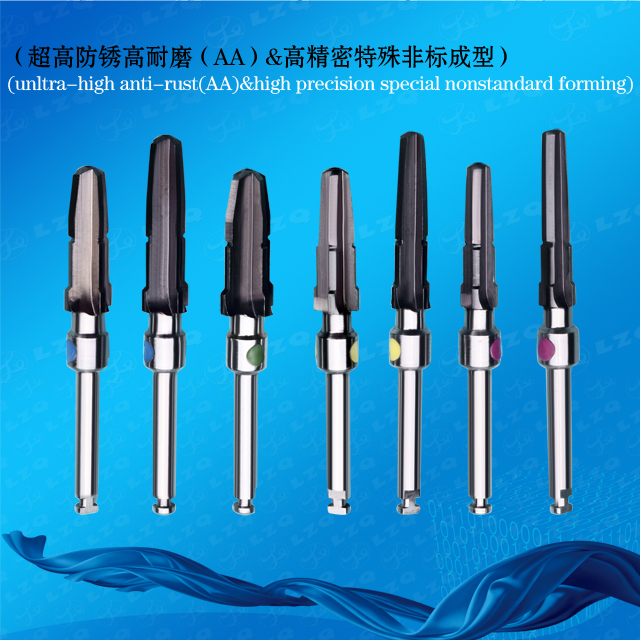

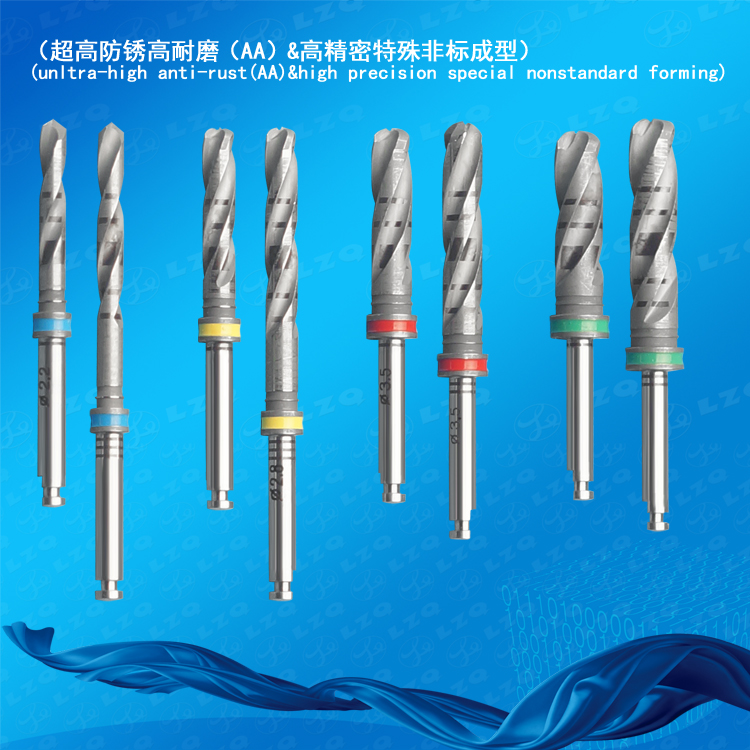

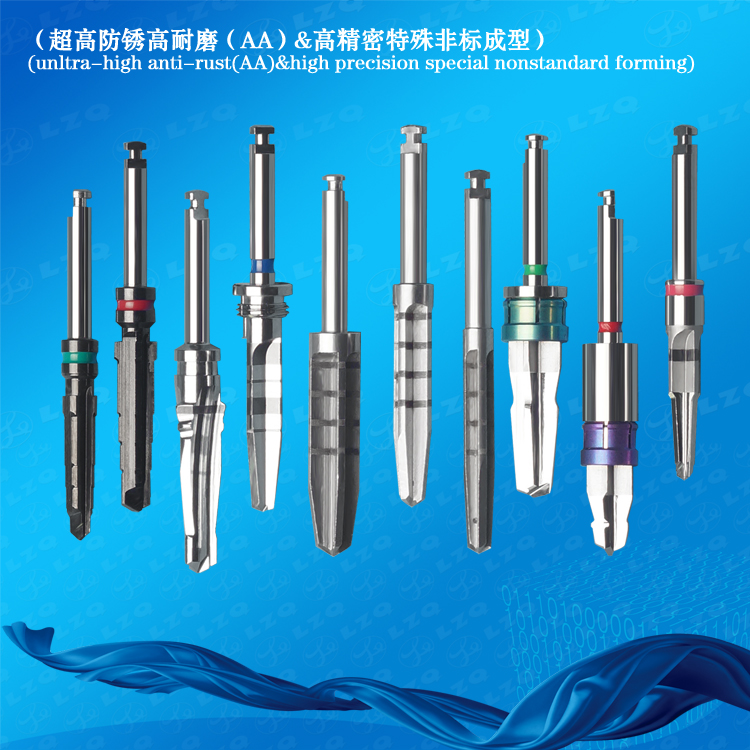

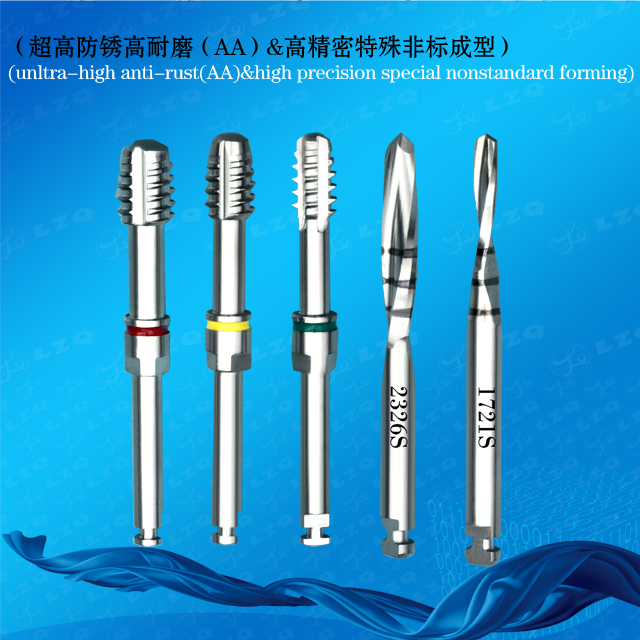

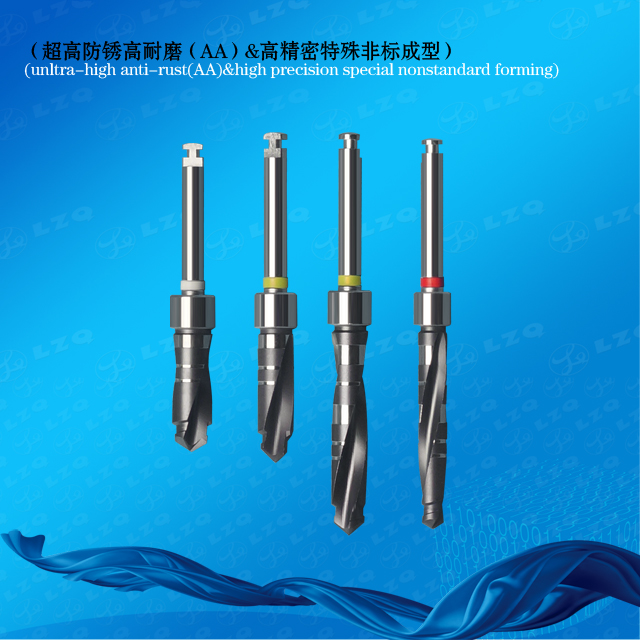

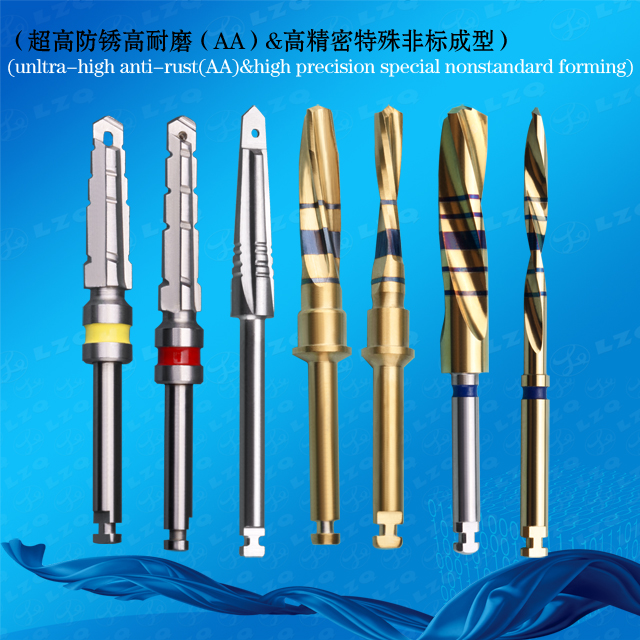

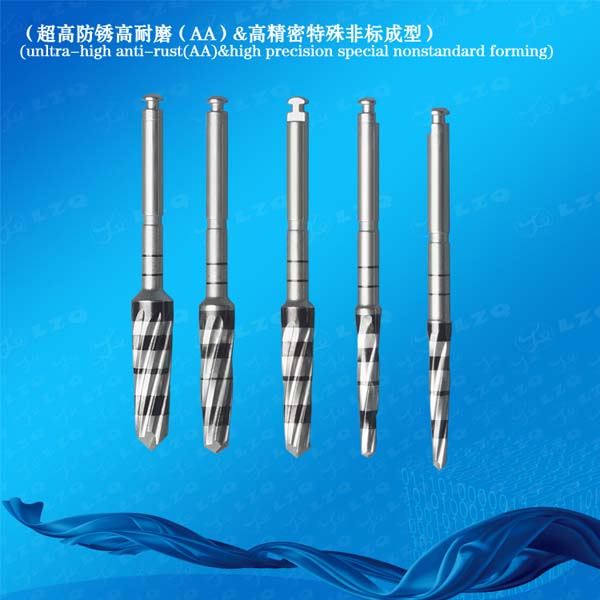

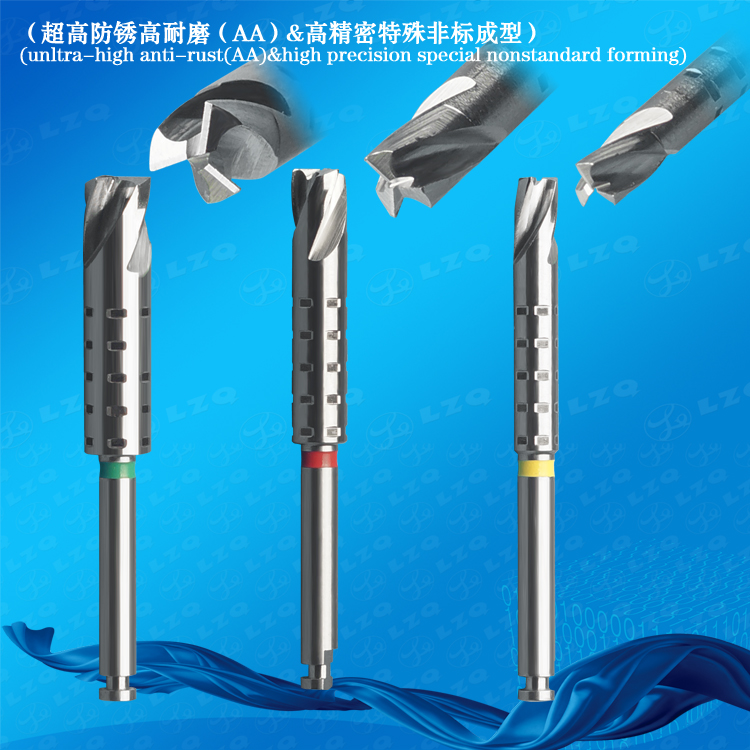

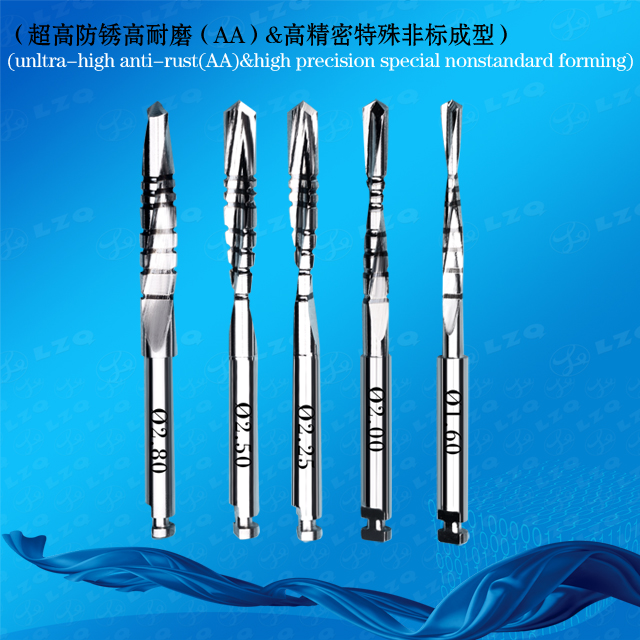

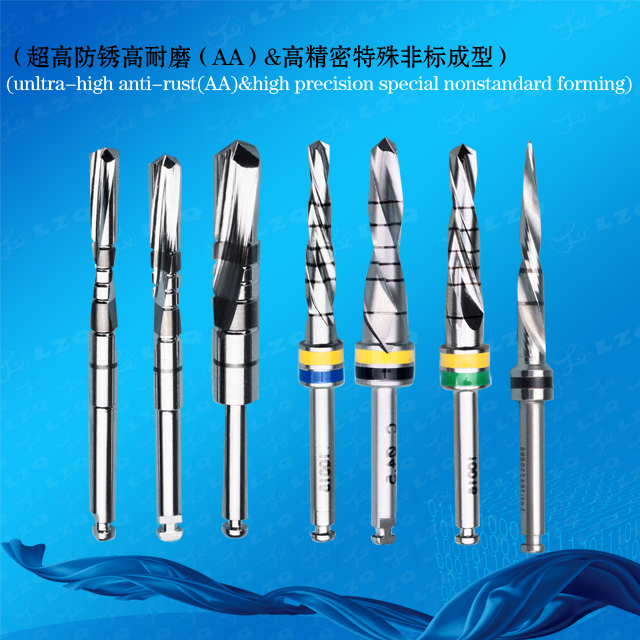

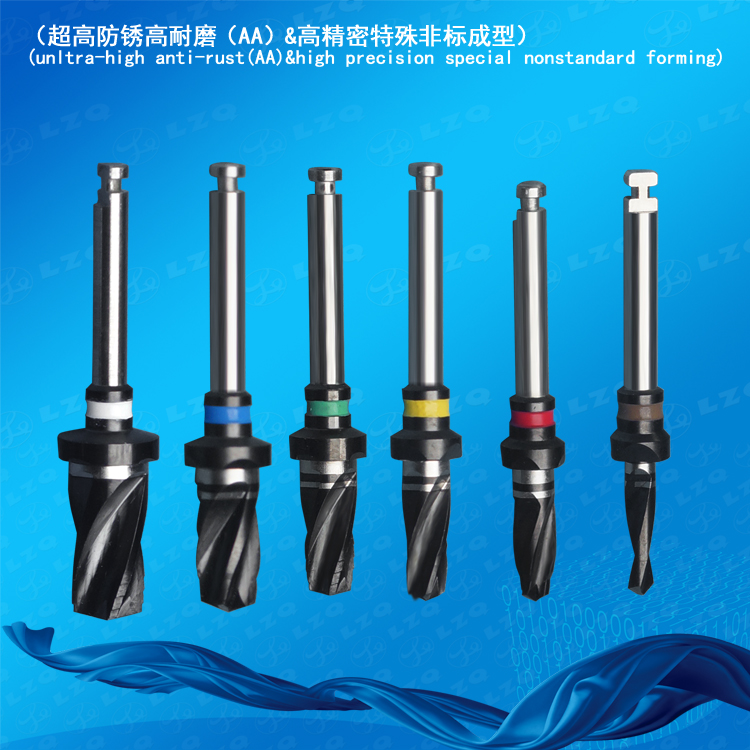

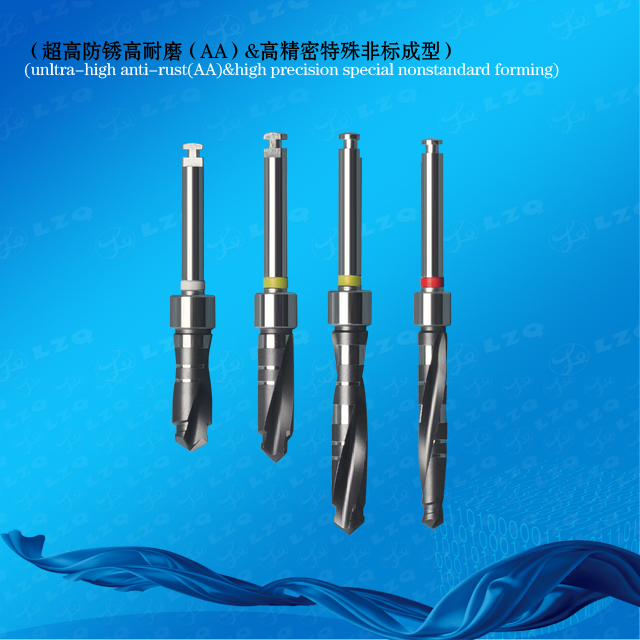

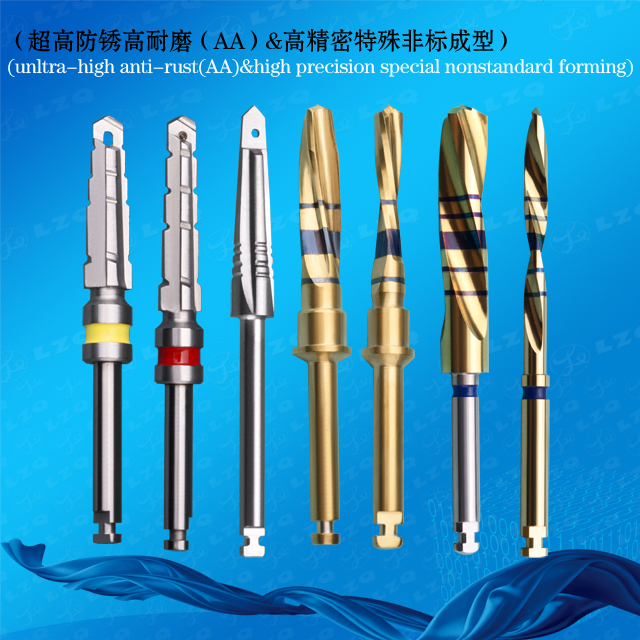

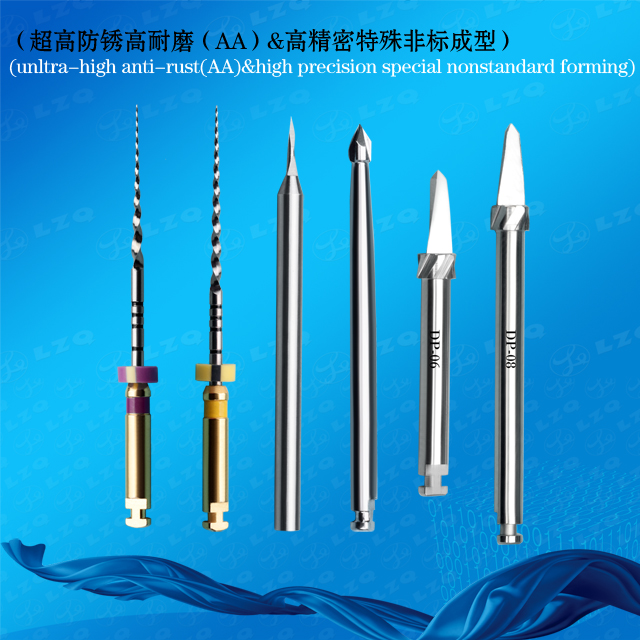

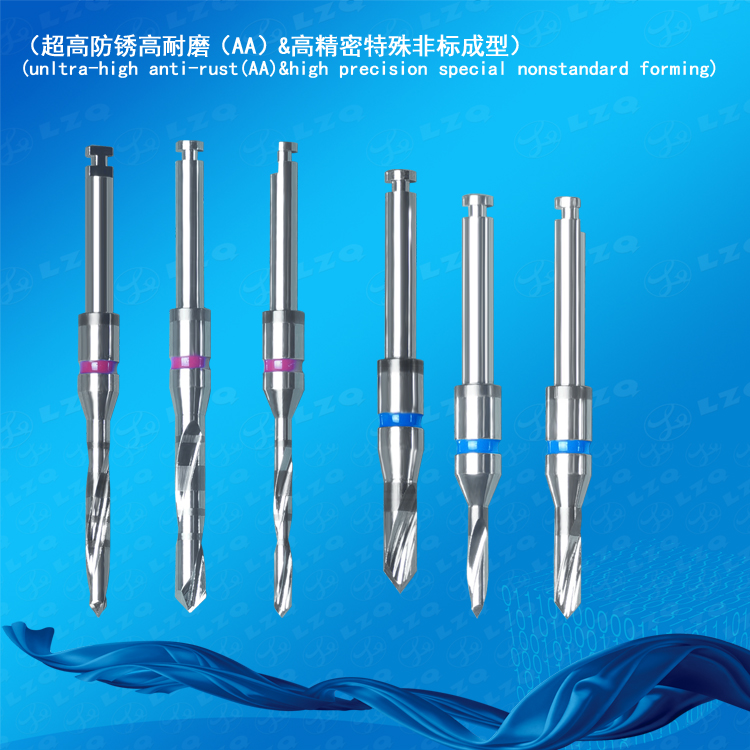

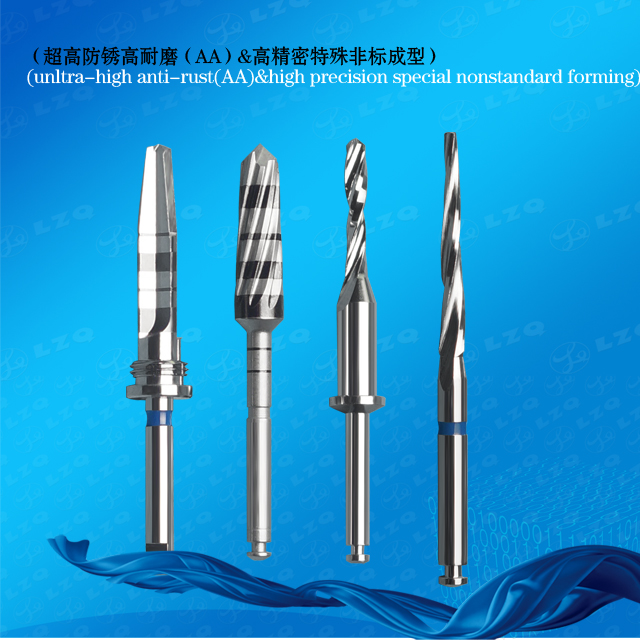

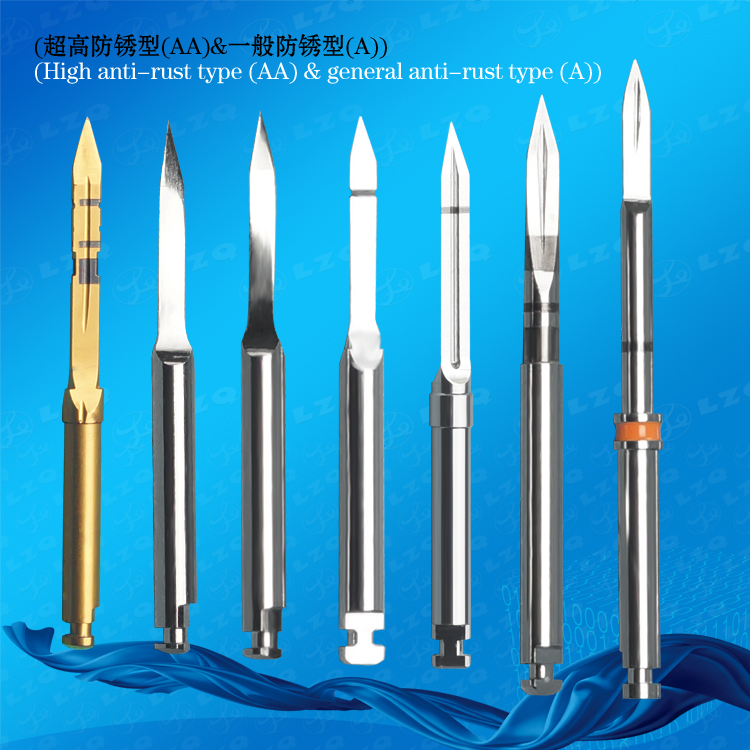

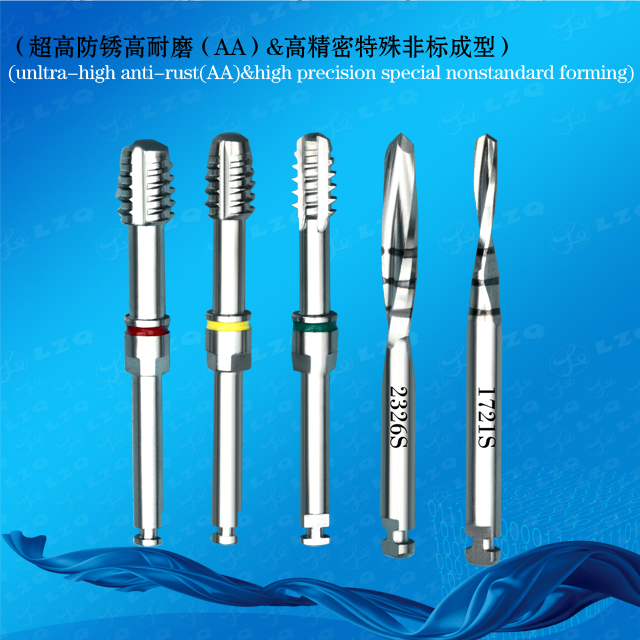

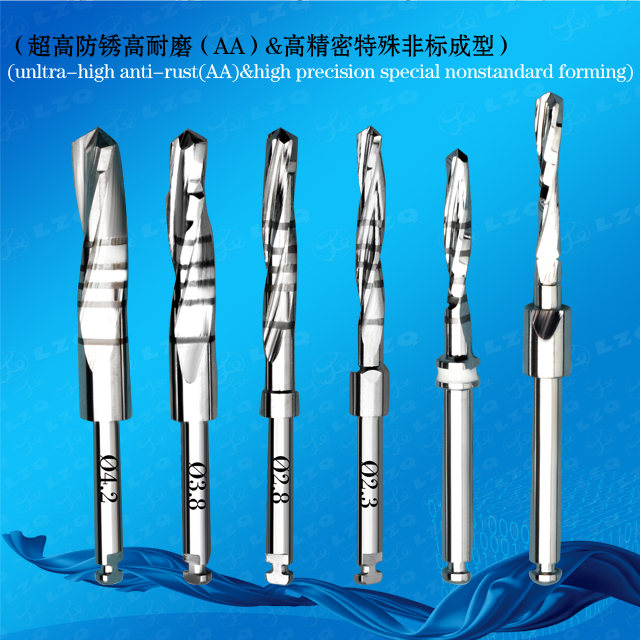

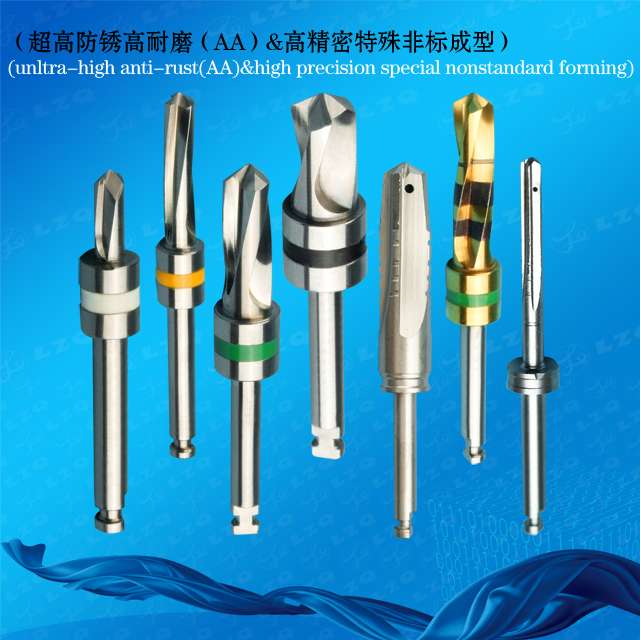

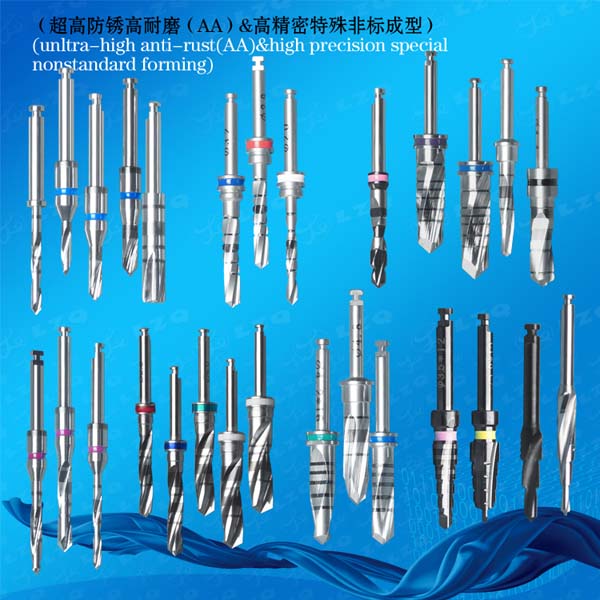

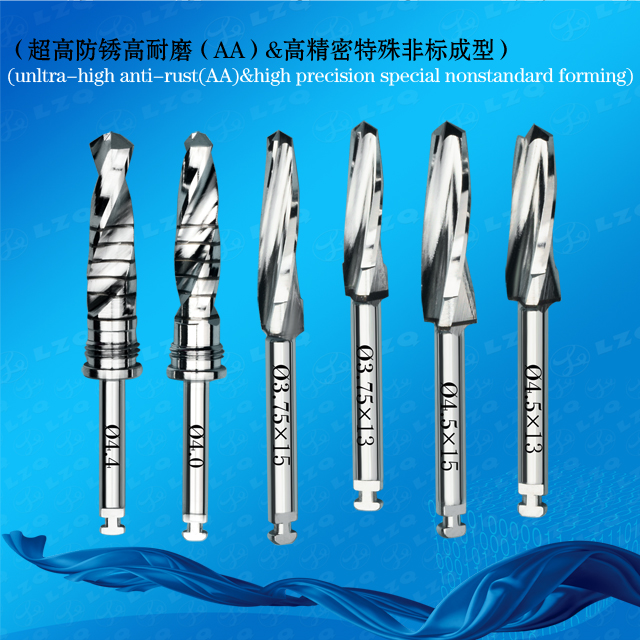

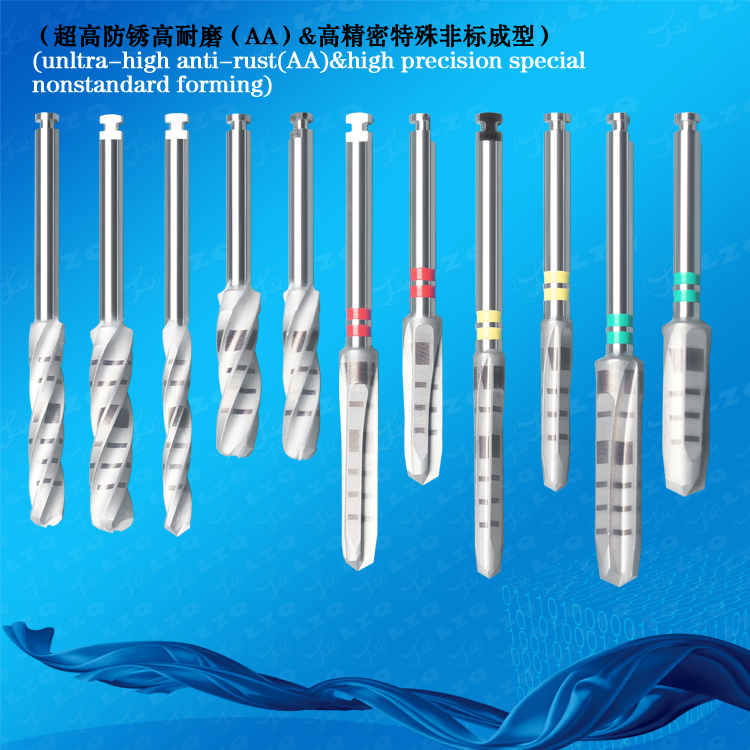

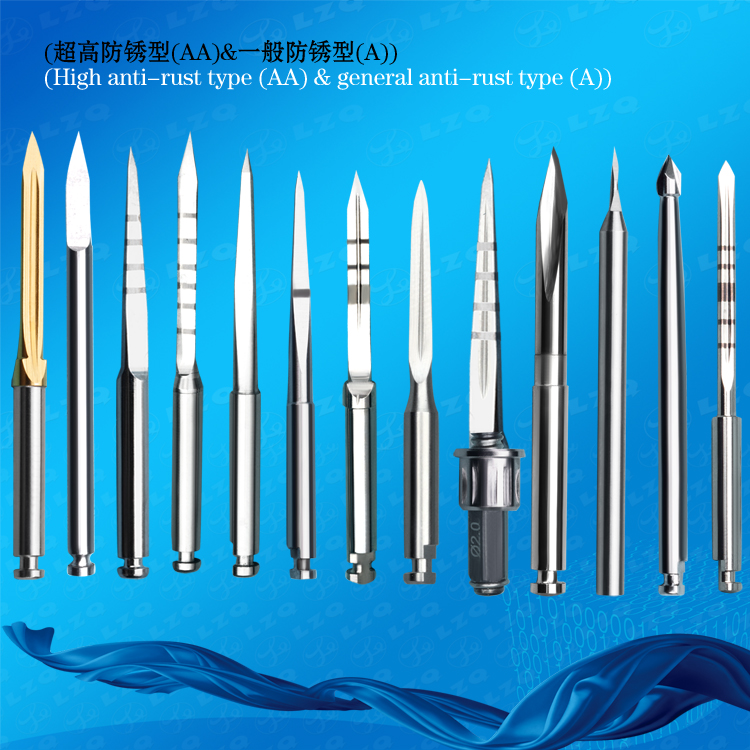

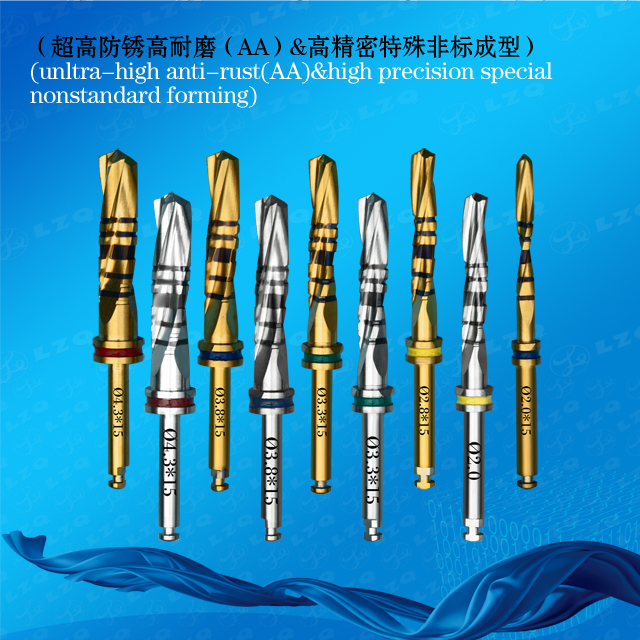

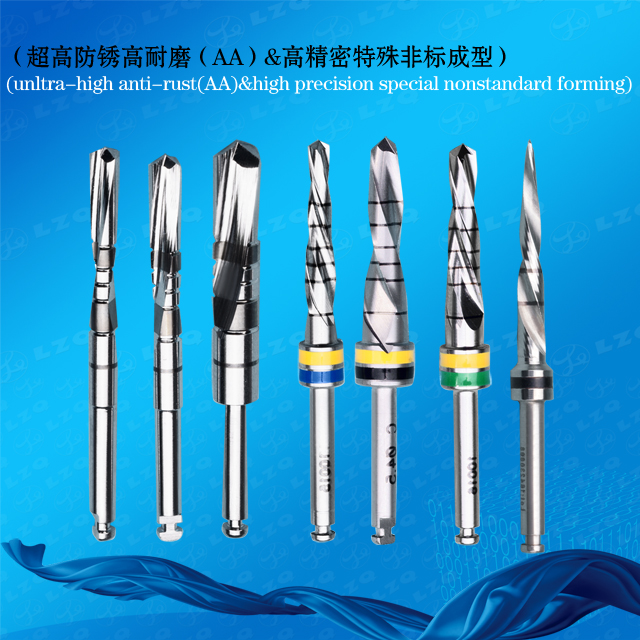

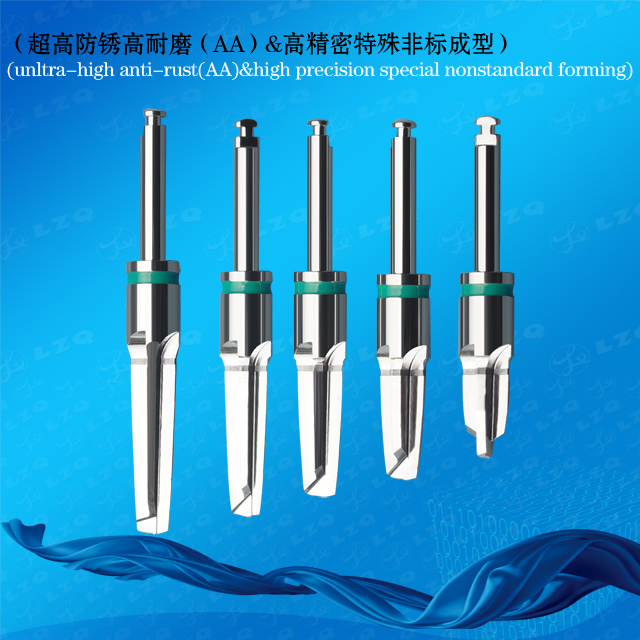

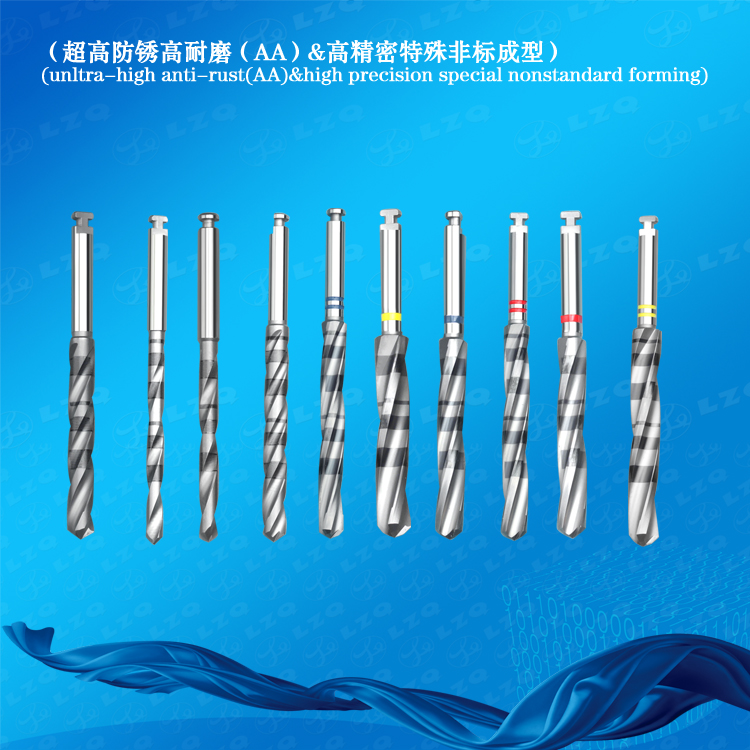

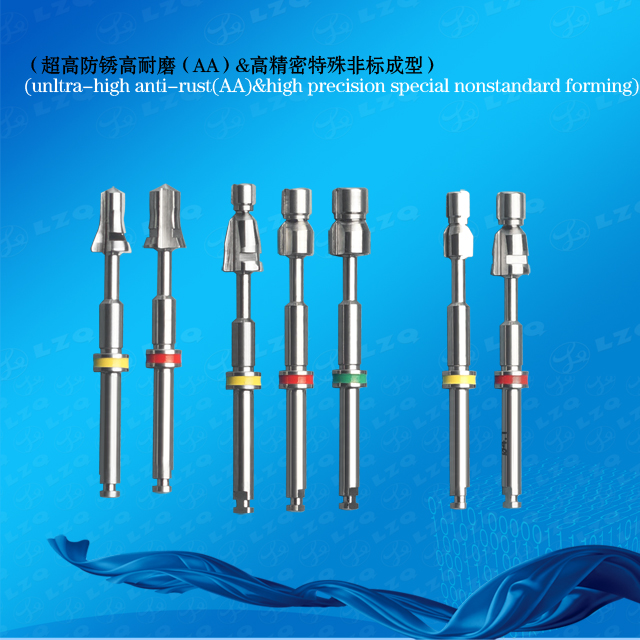

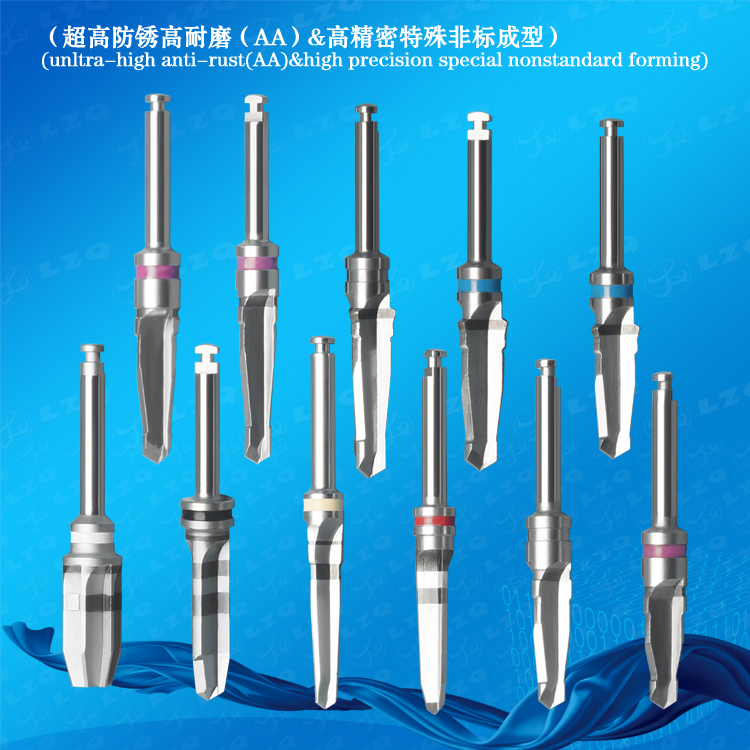

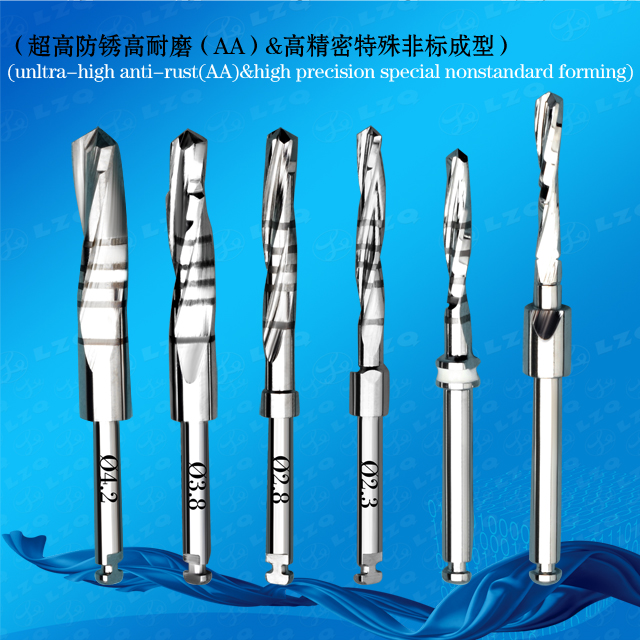

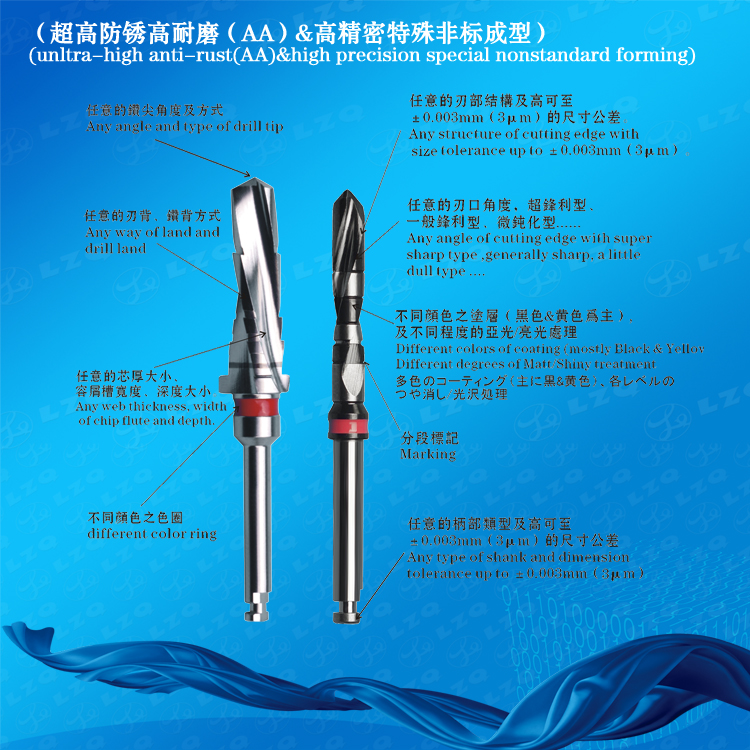

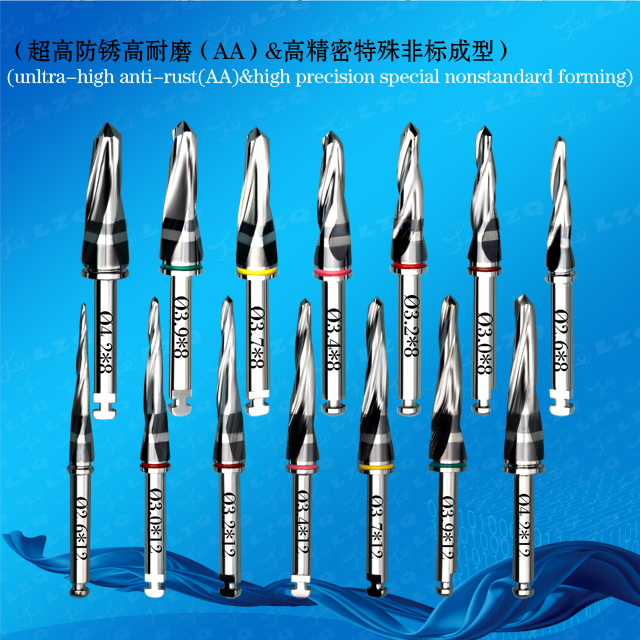

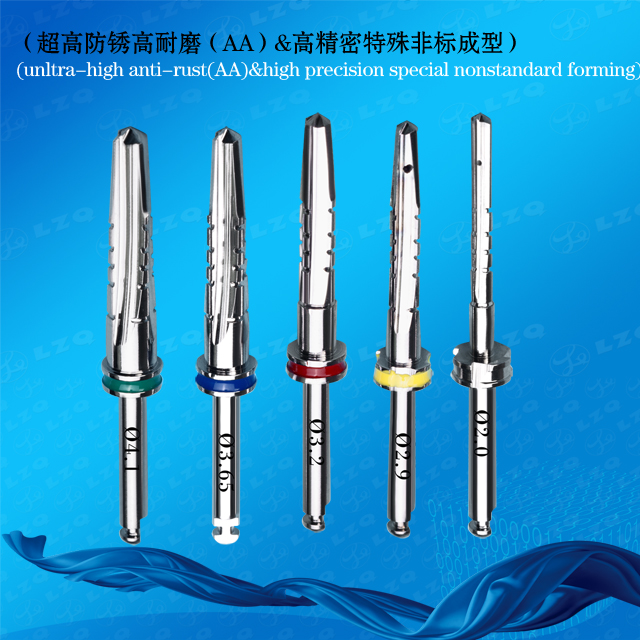

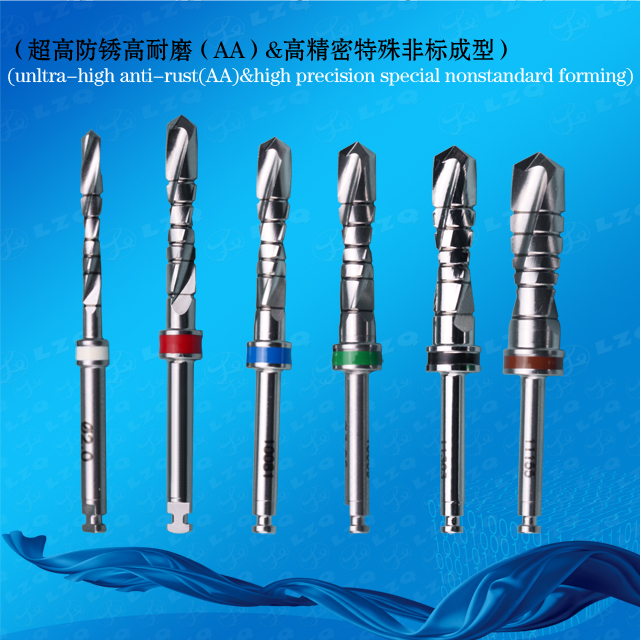

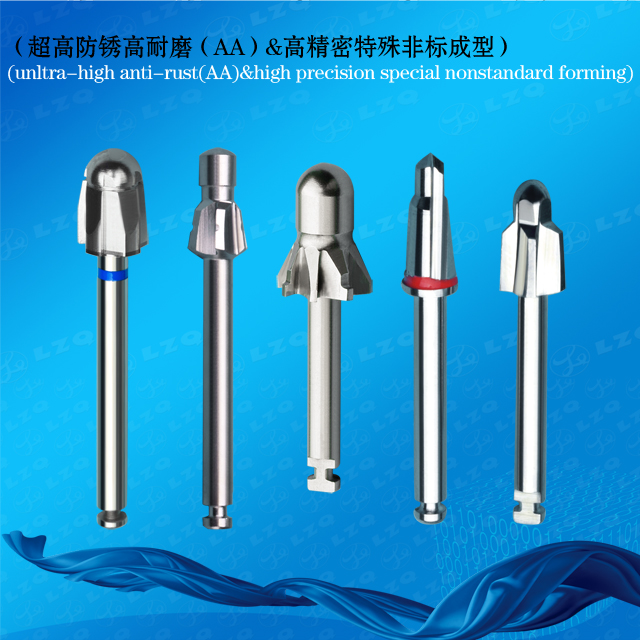

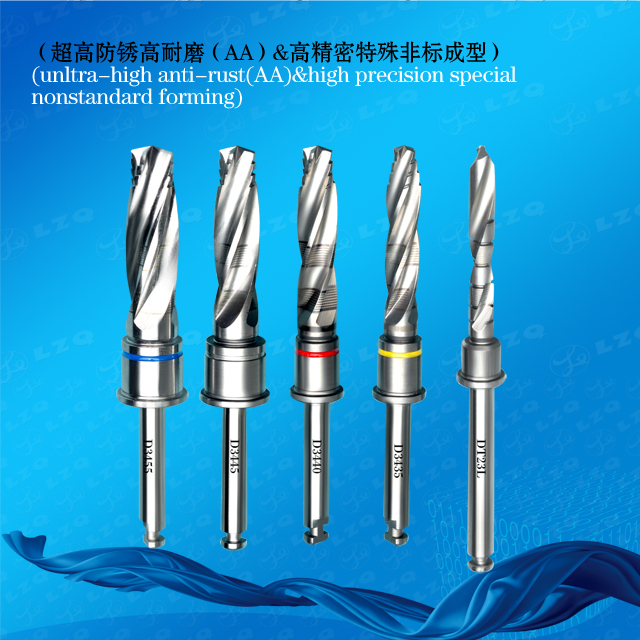

1、Any angle and type of drill tip

2、Any way of land and drill land

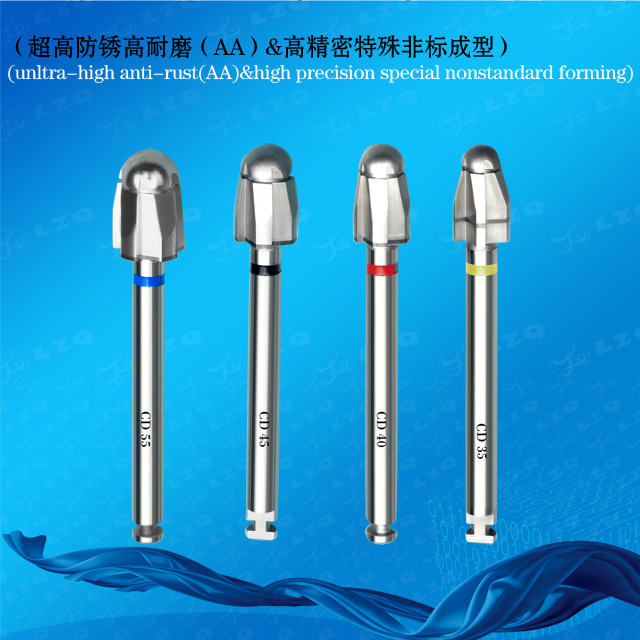

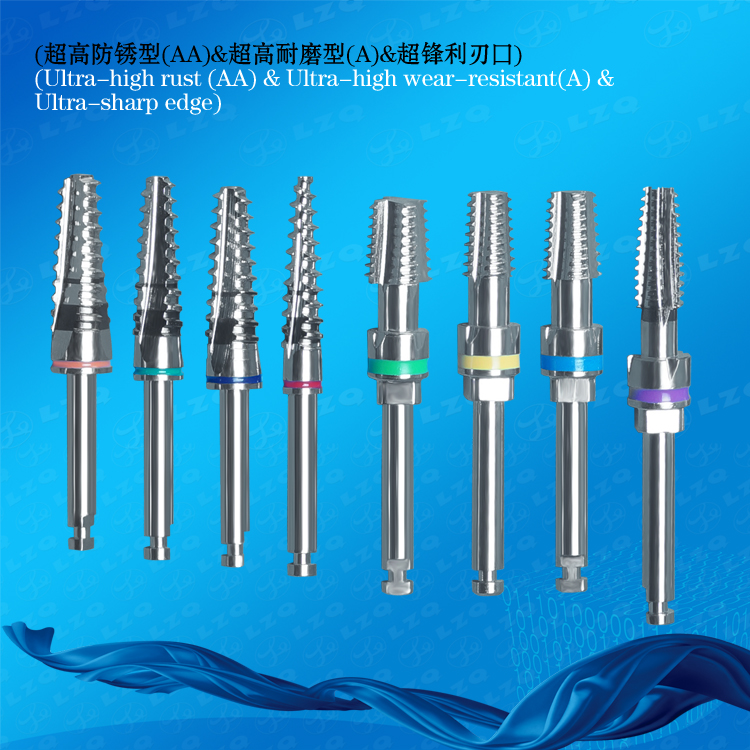

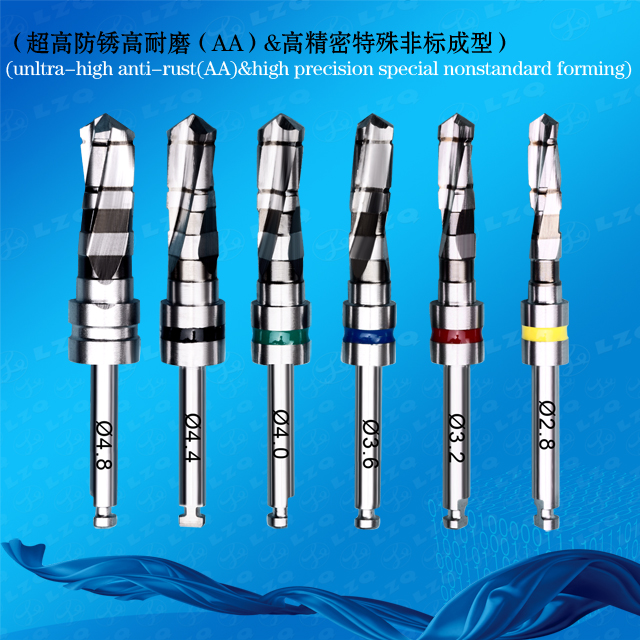

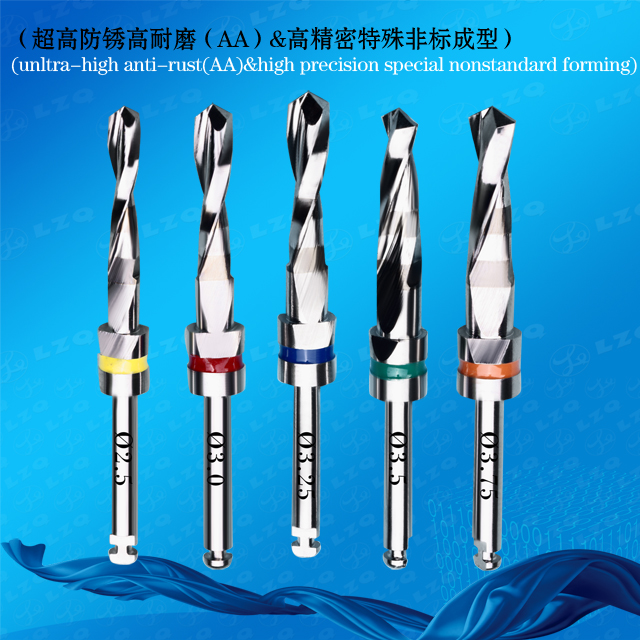

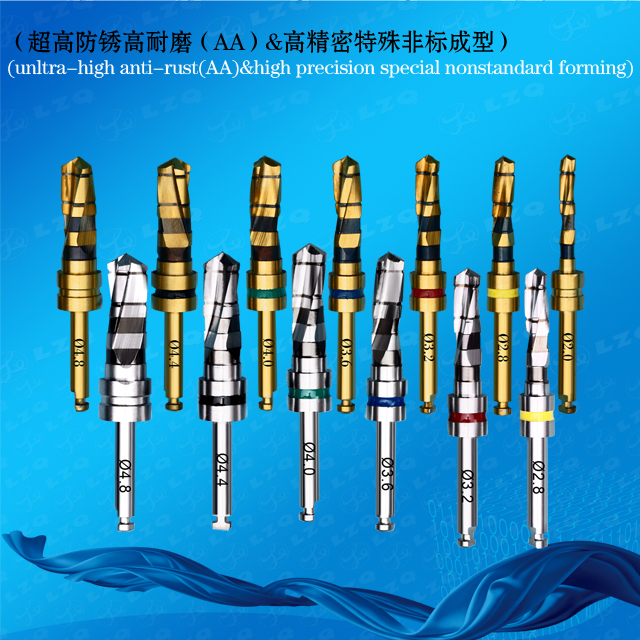

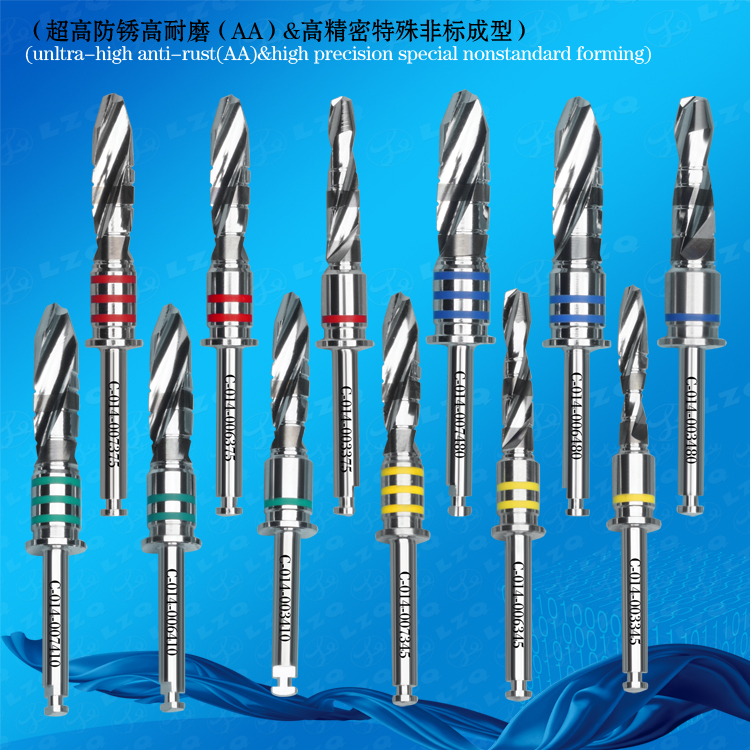

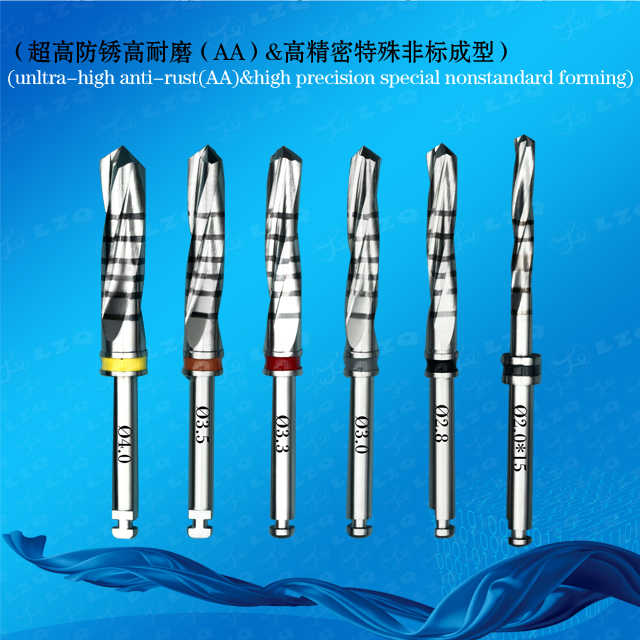

3、Any web thickness,width of chip flute and depth

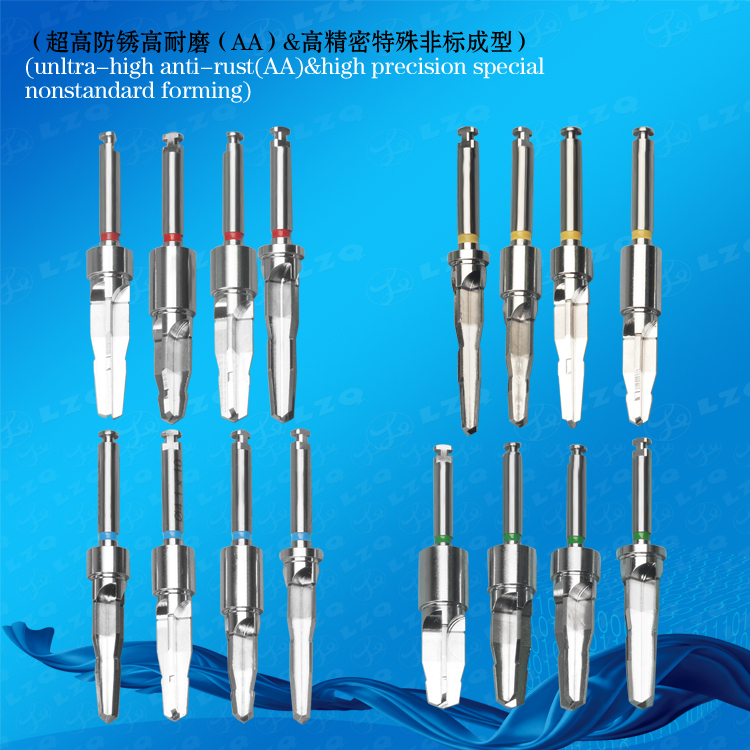

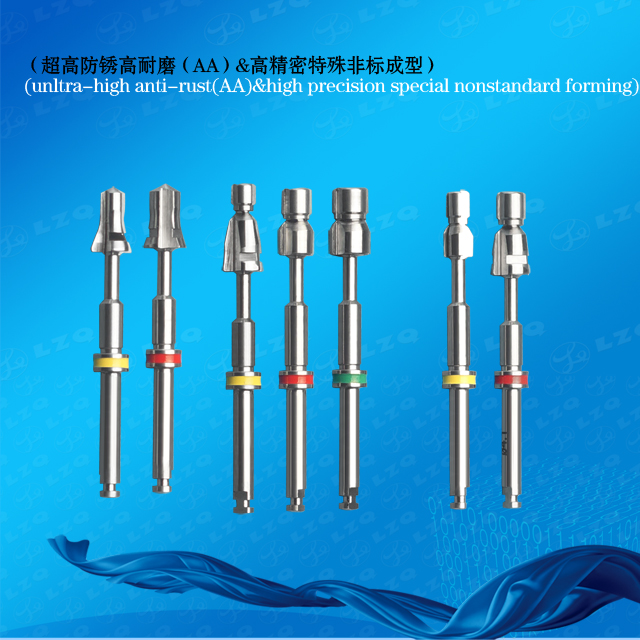

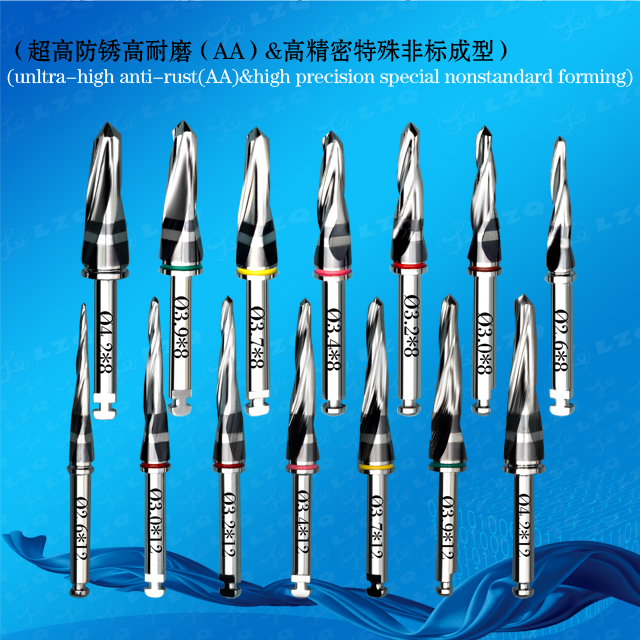

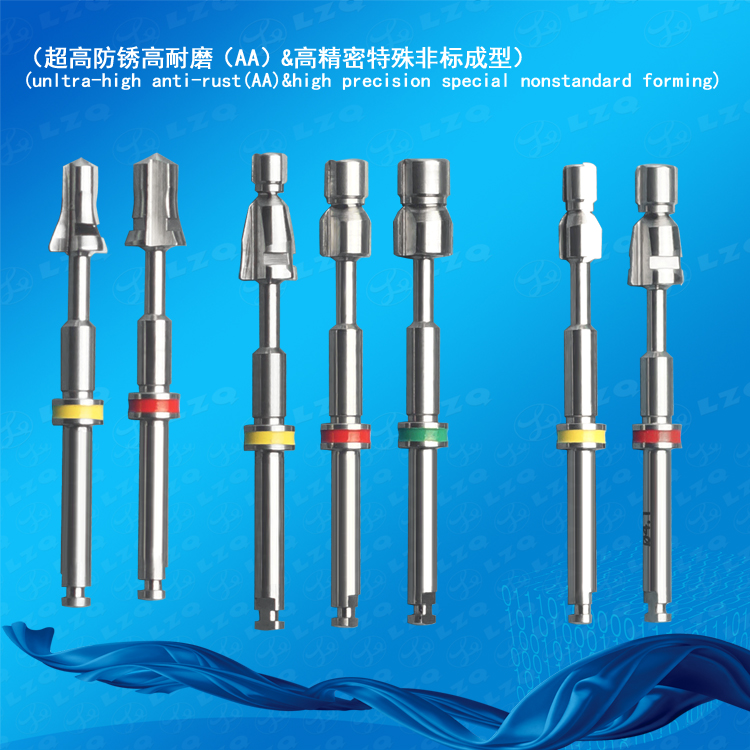

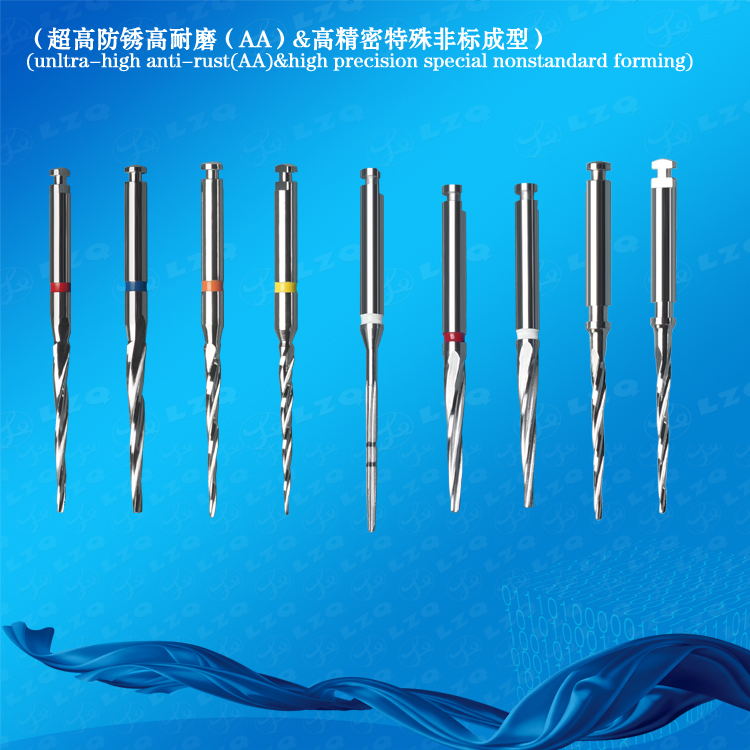

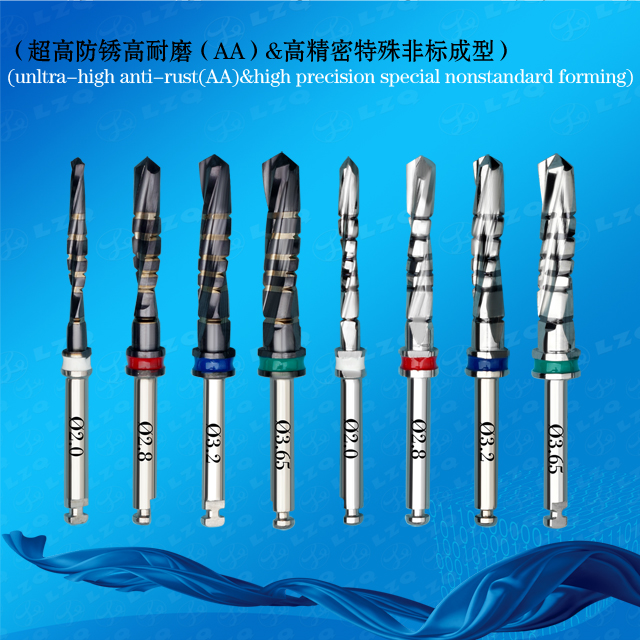

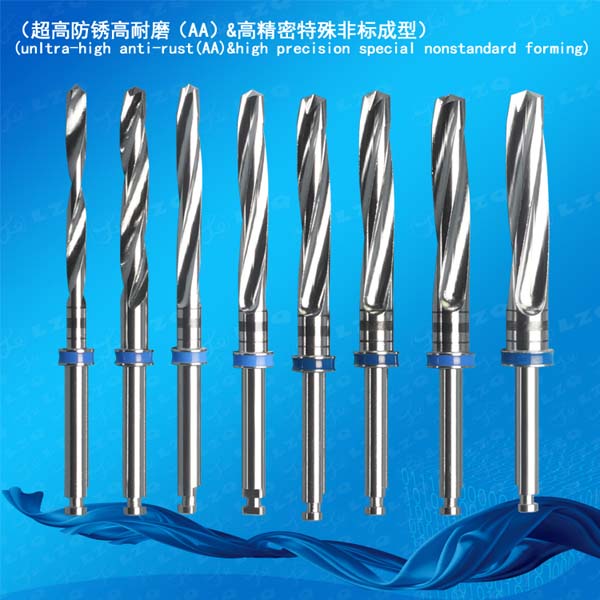

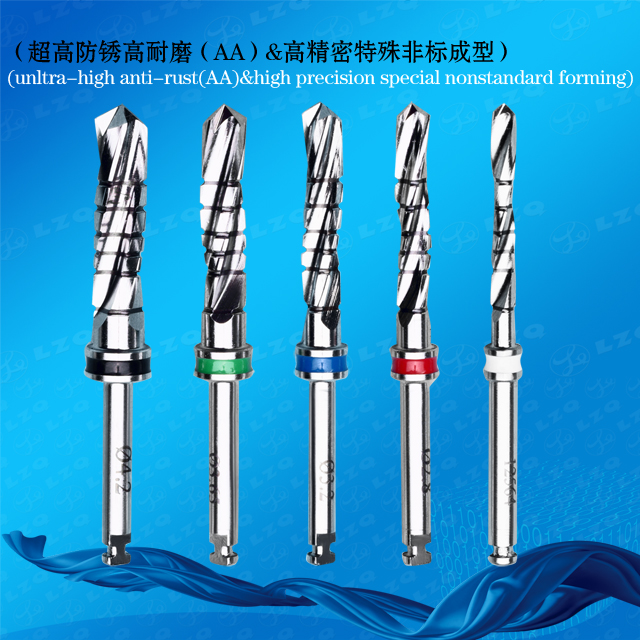

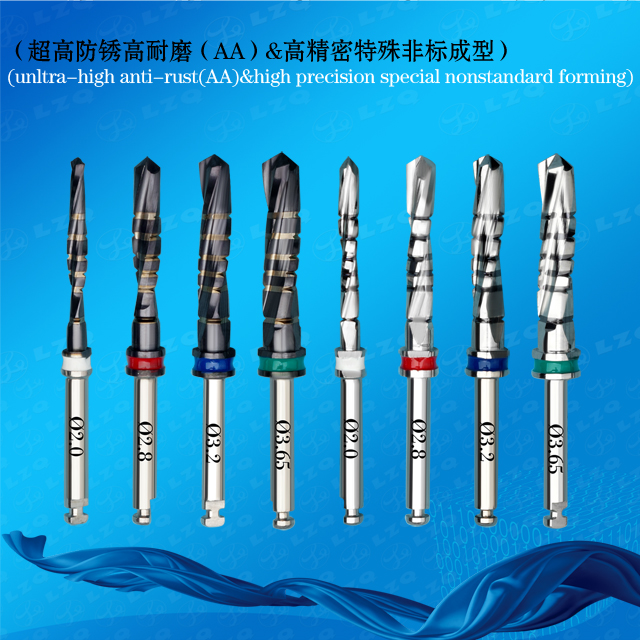

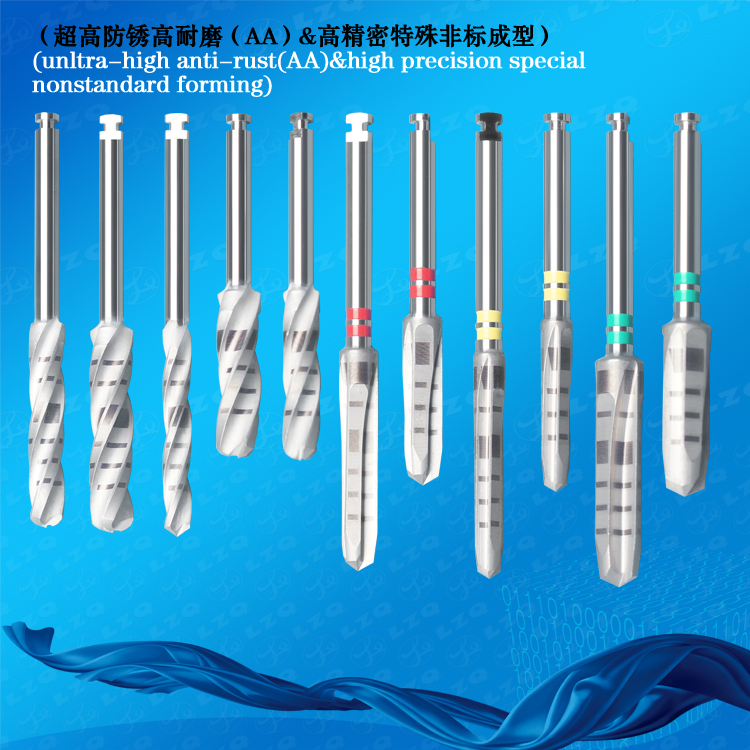

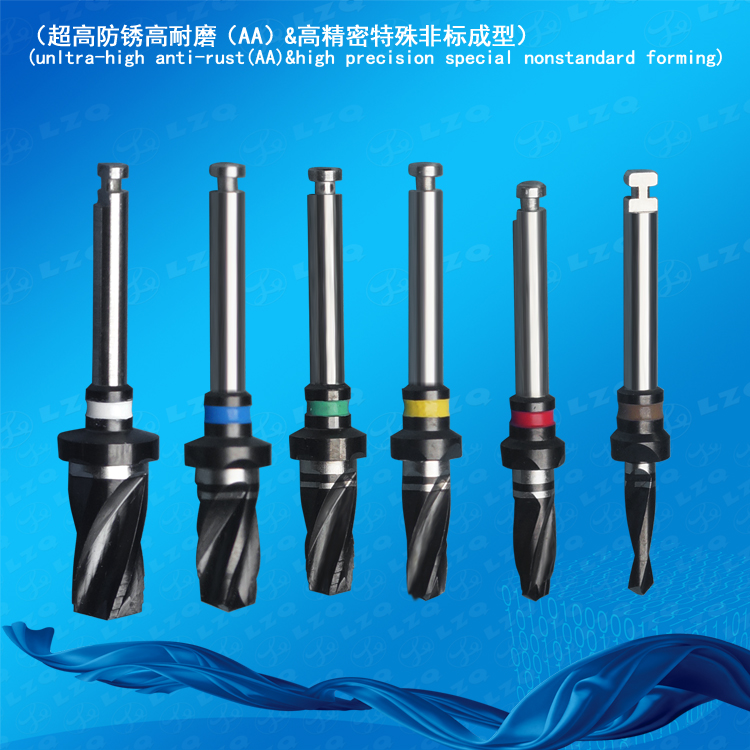

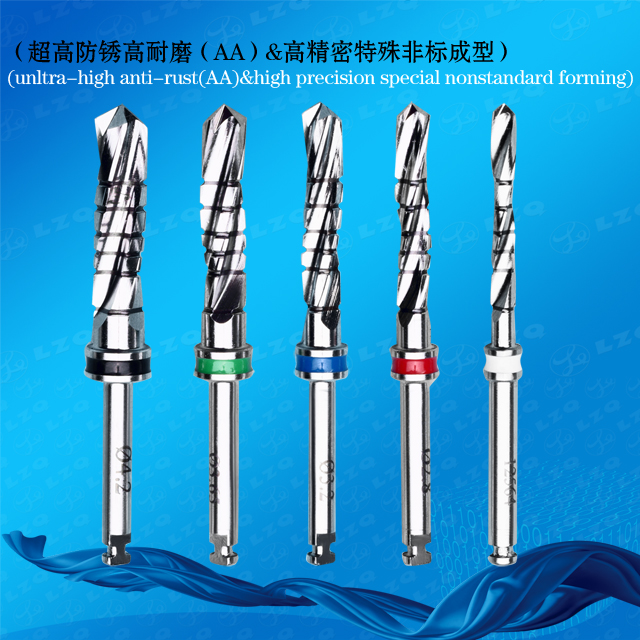

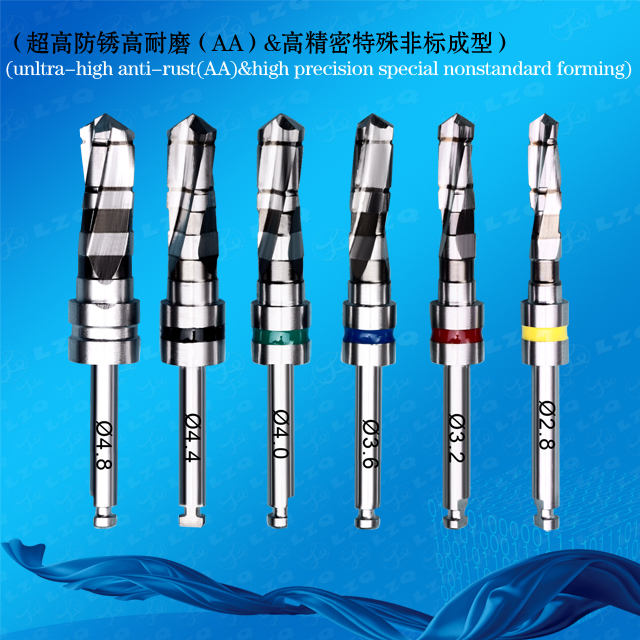

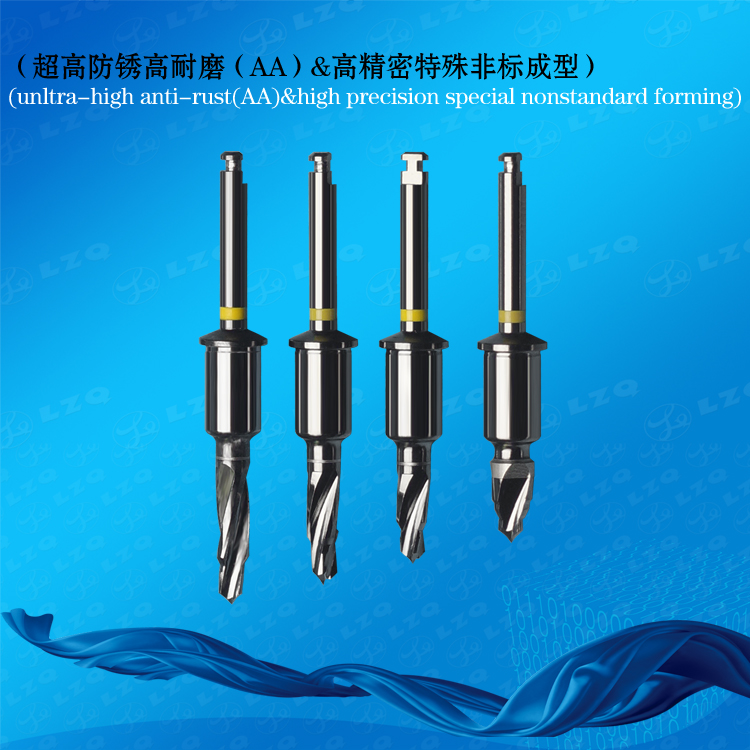

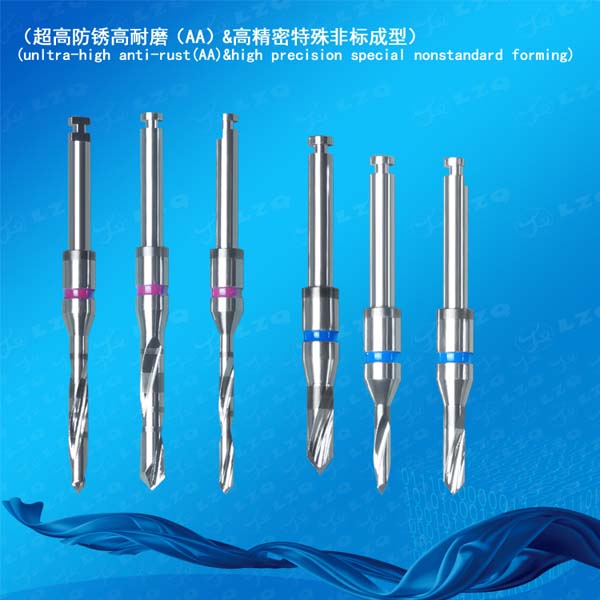

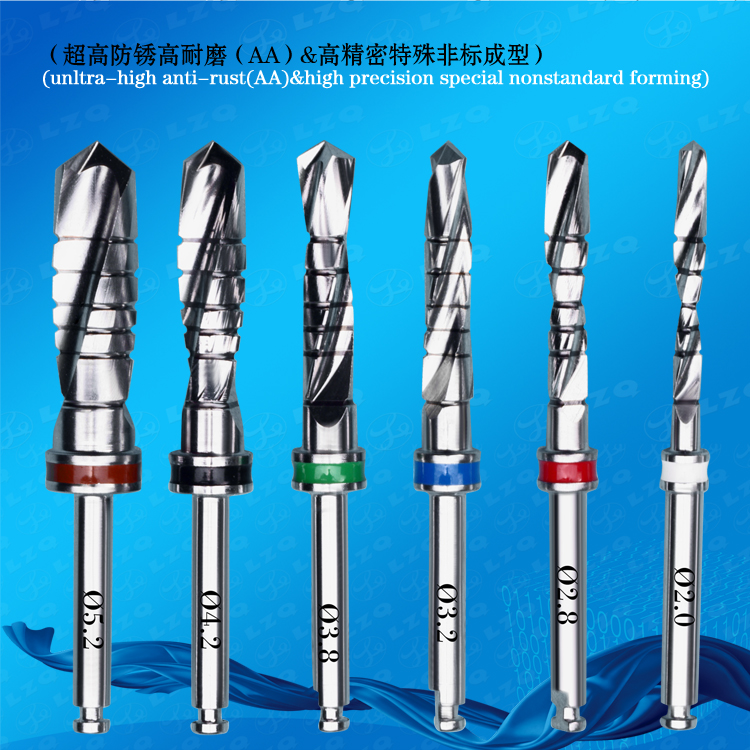

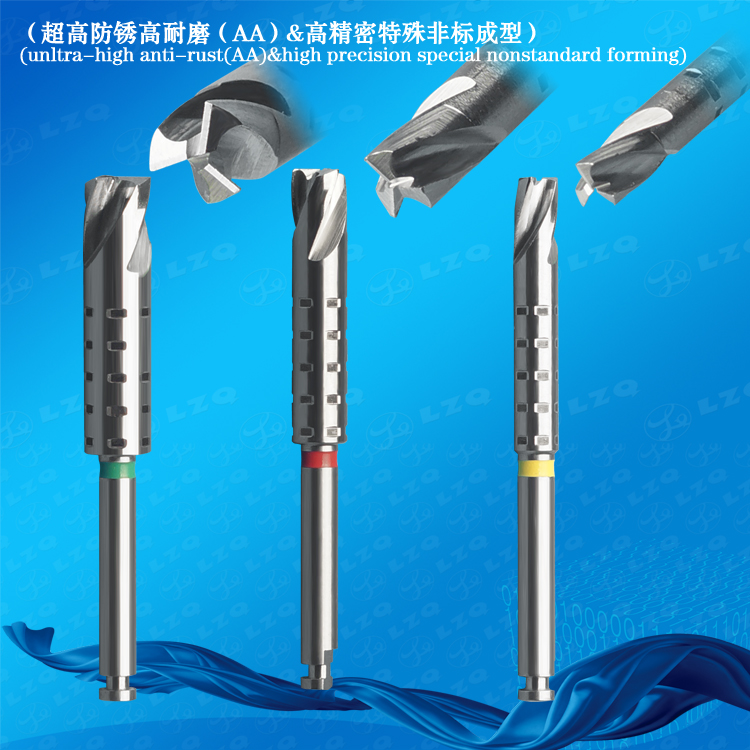

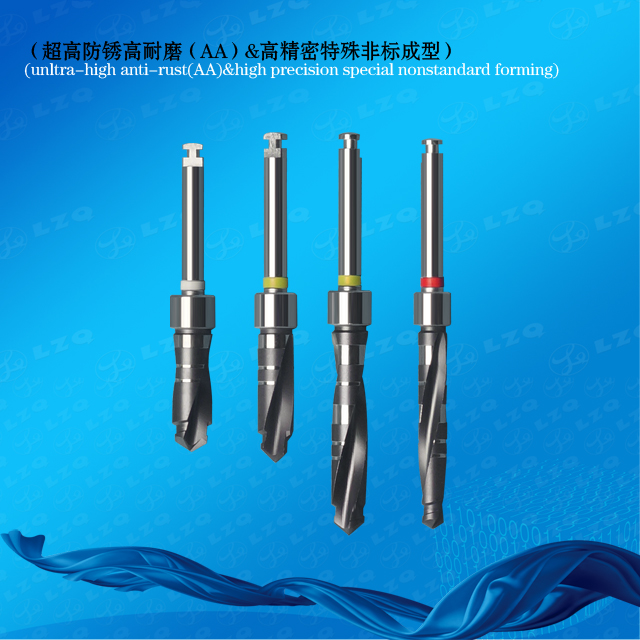

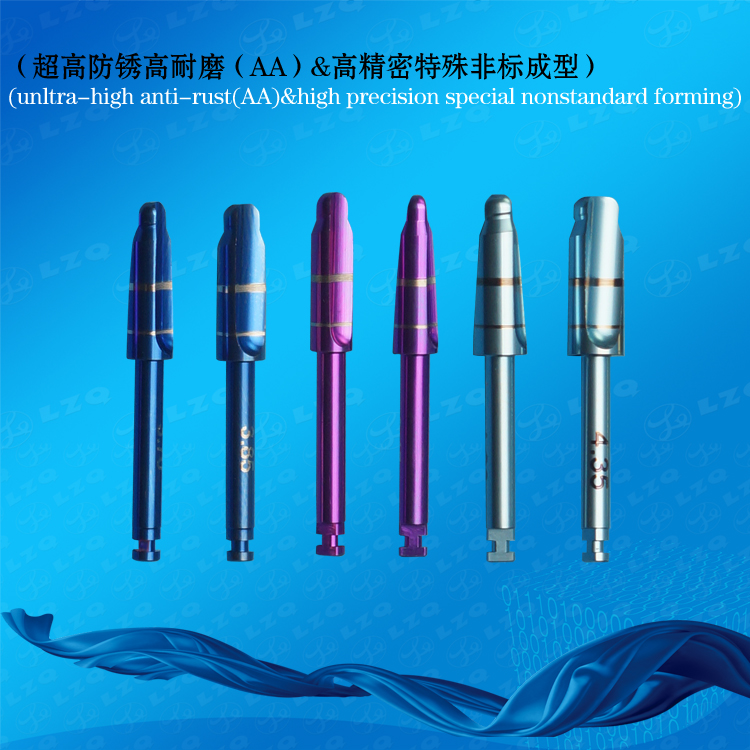

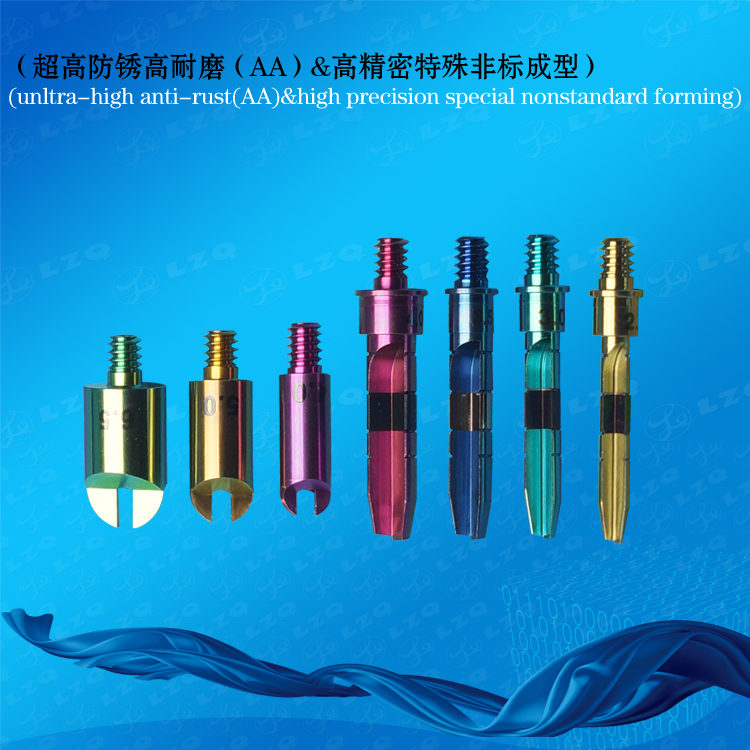

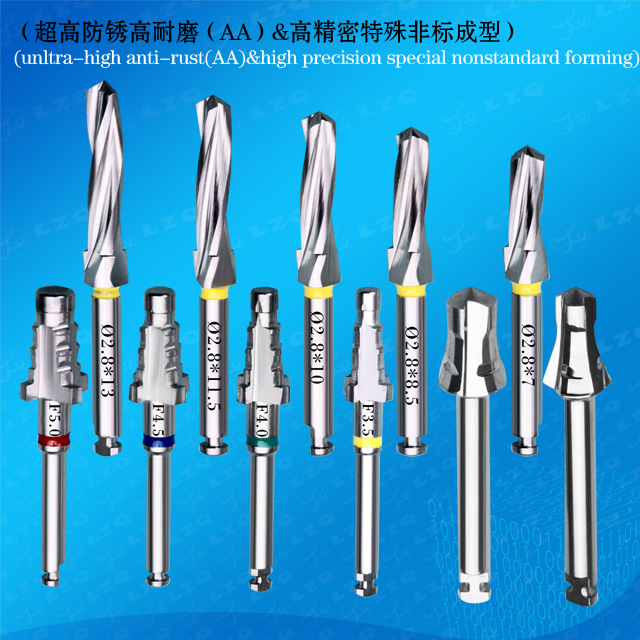

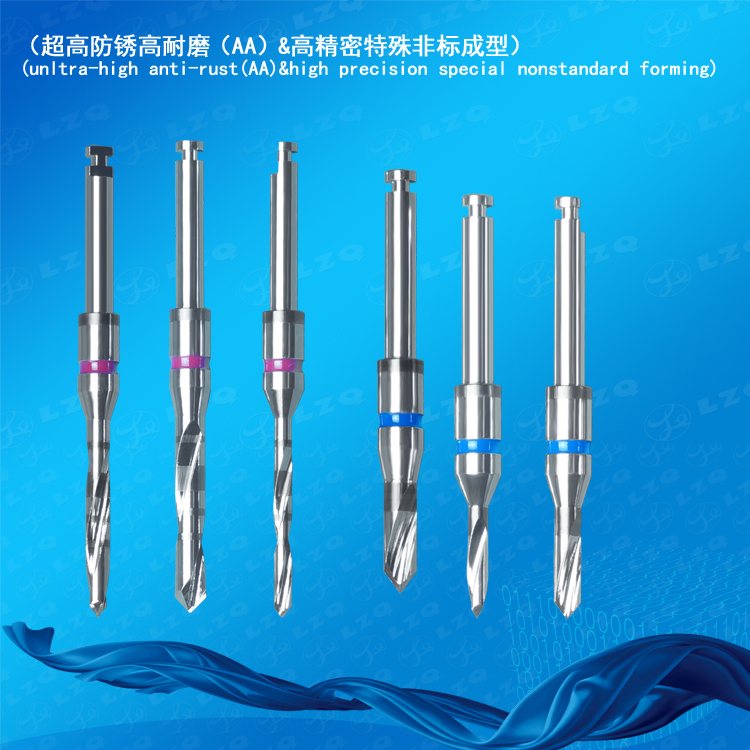

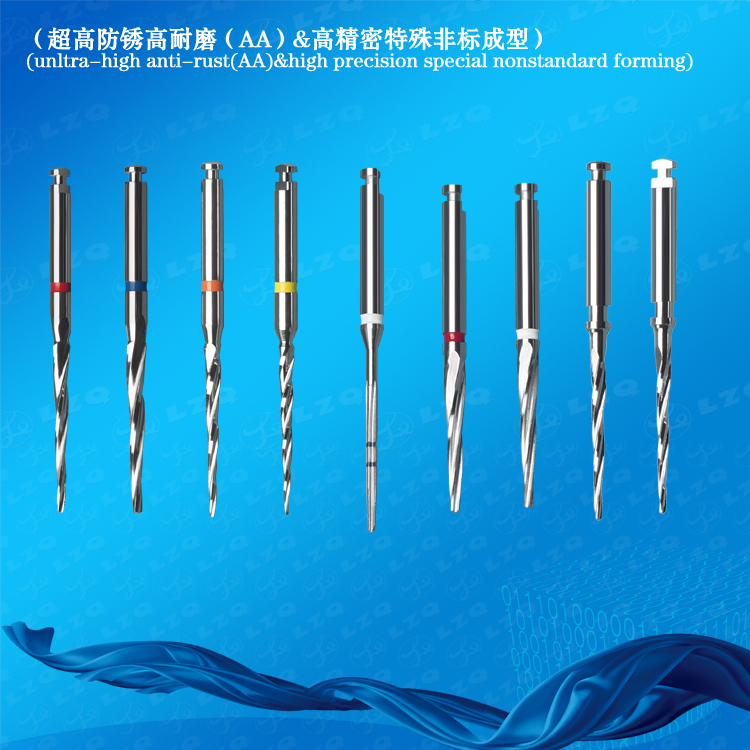

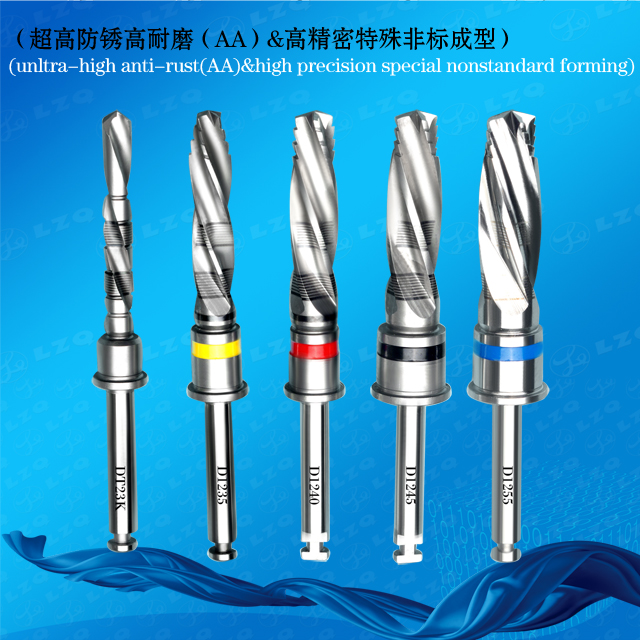

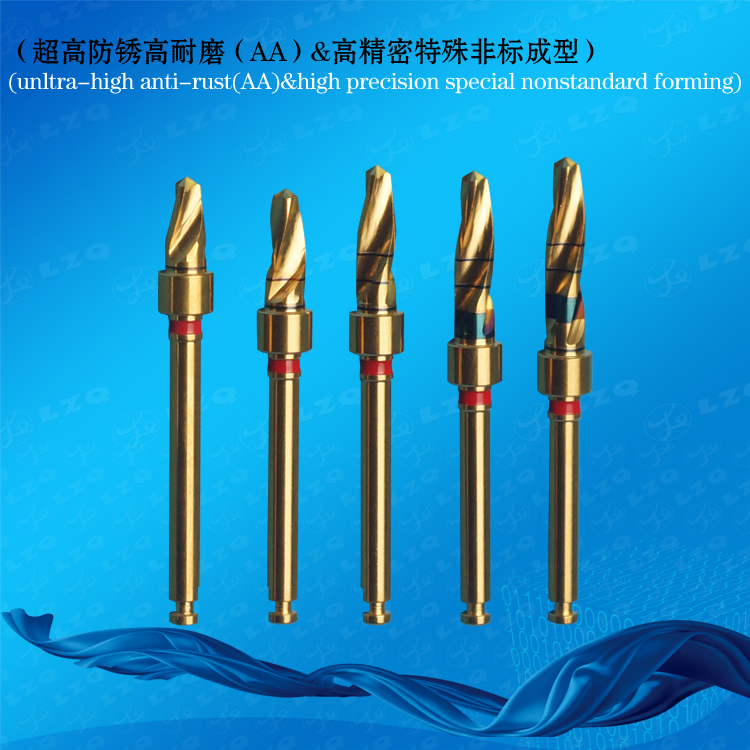

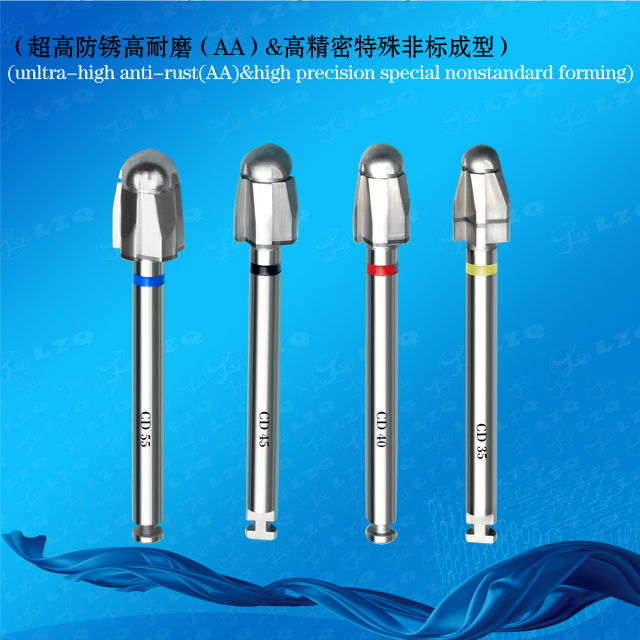

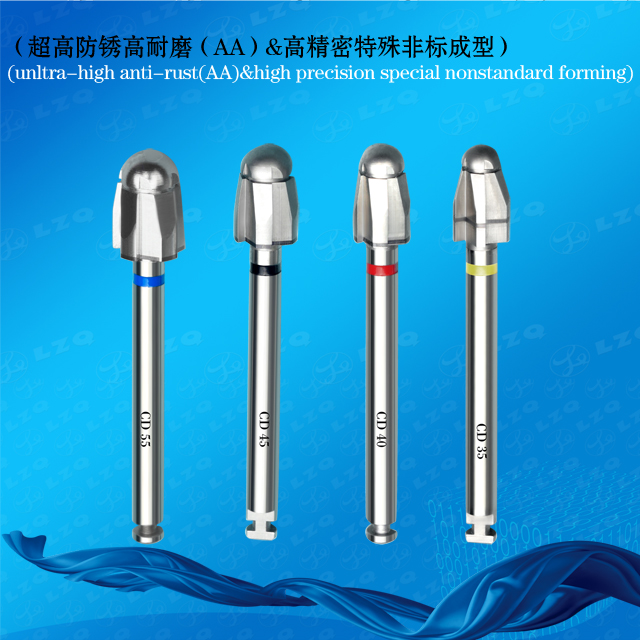

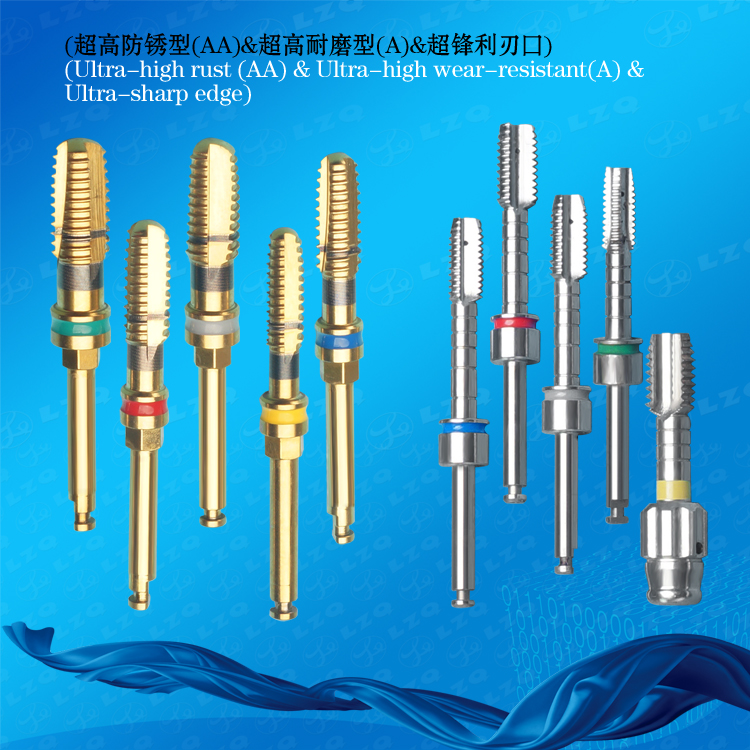

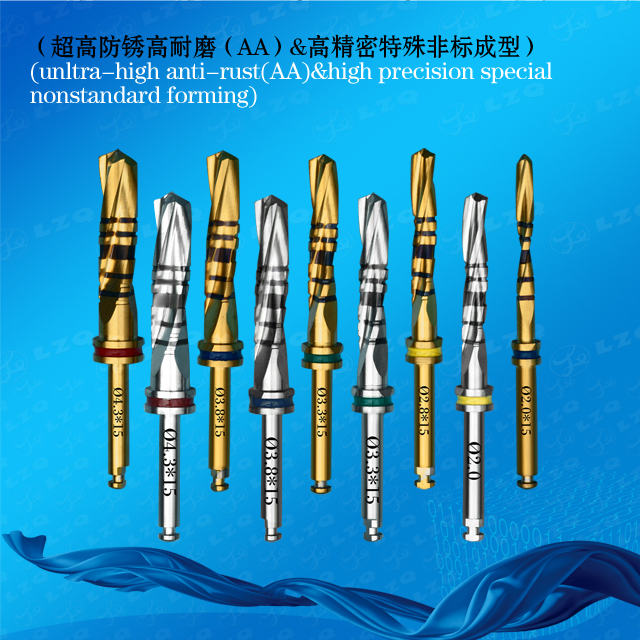

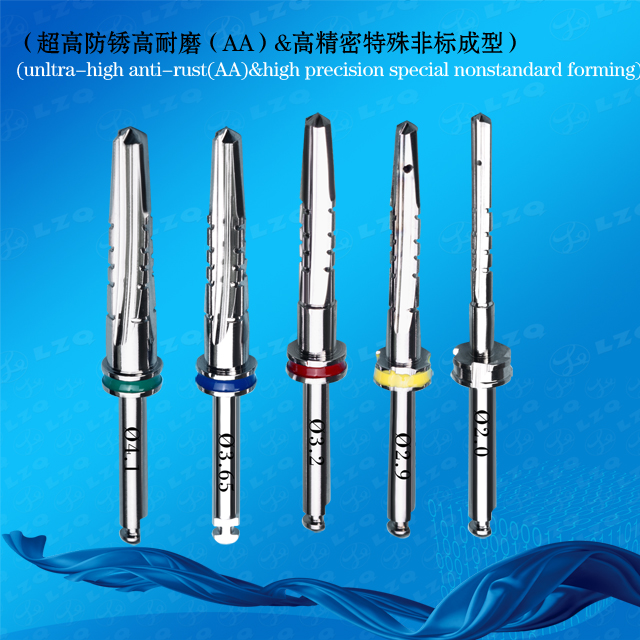

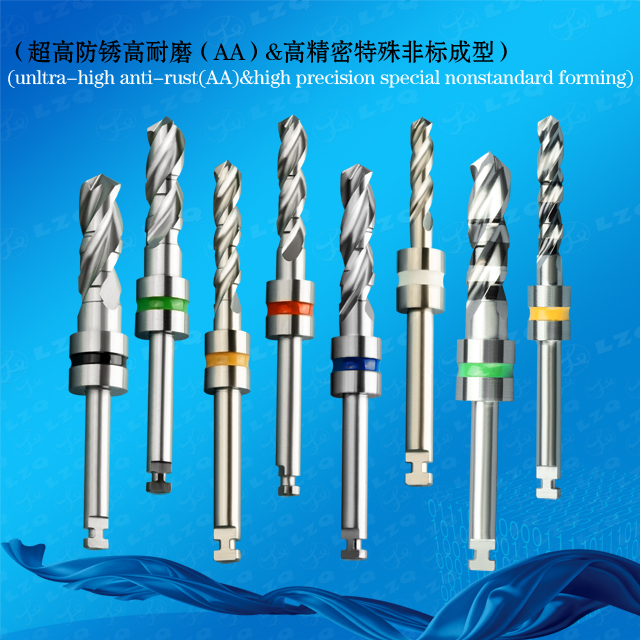

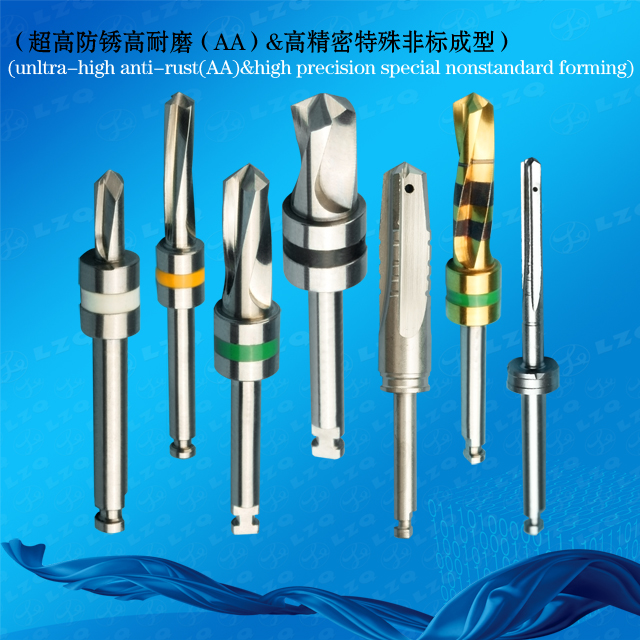

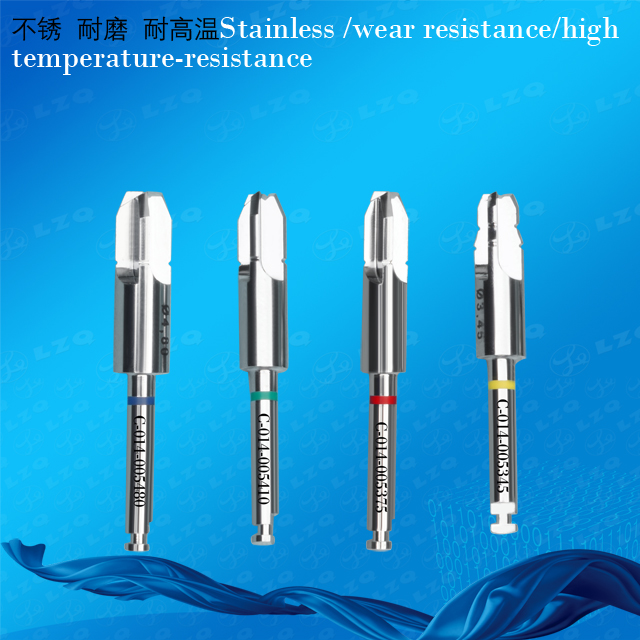

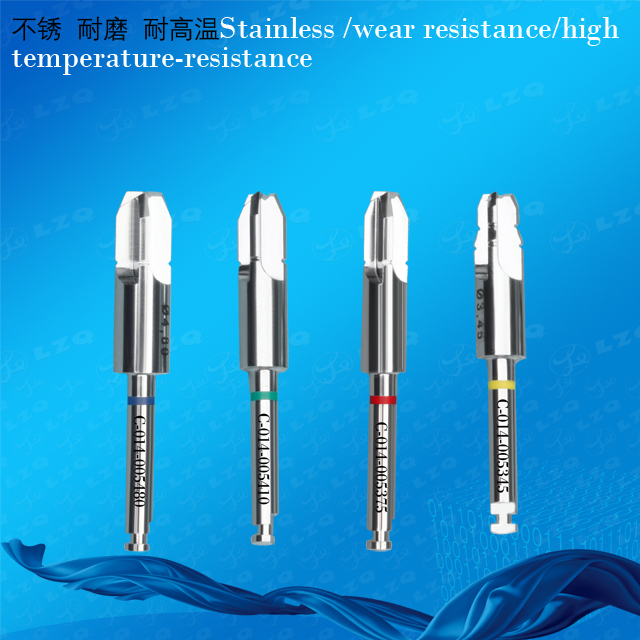

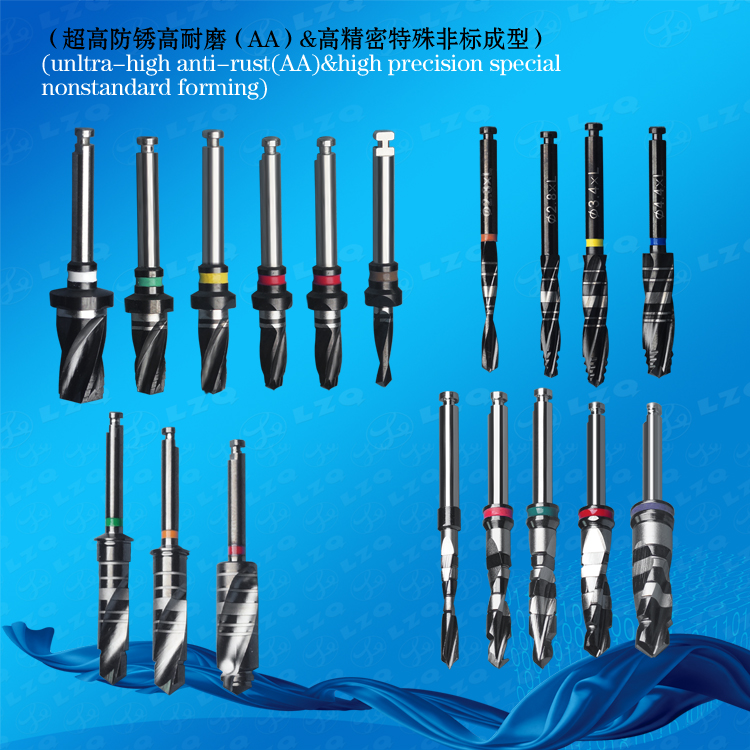

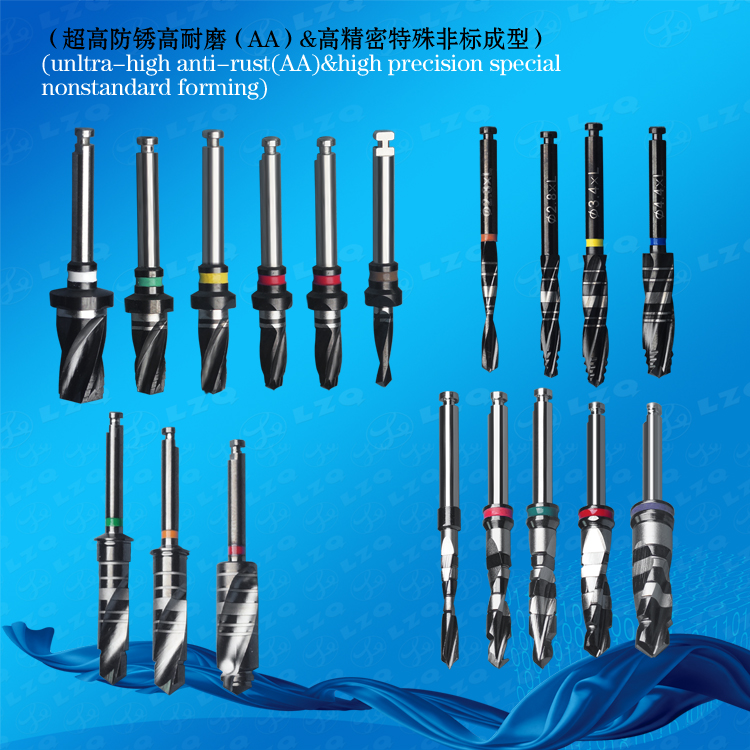

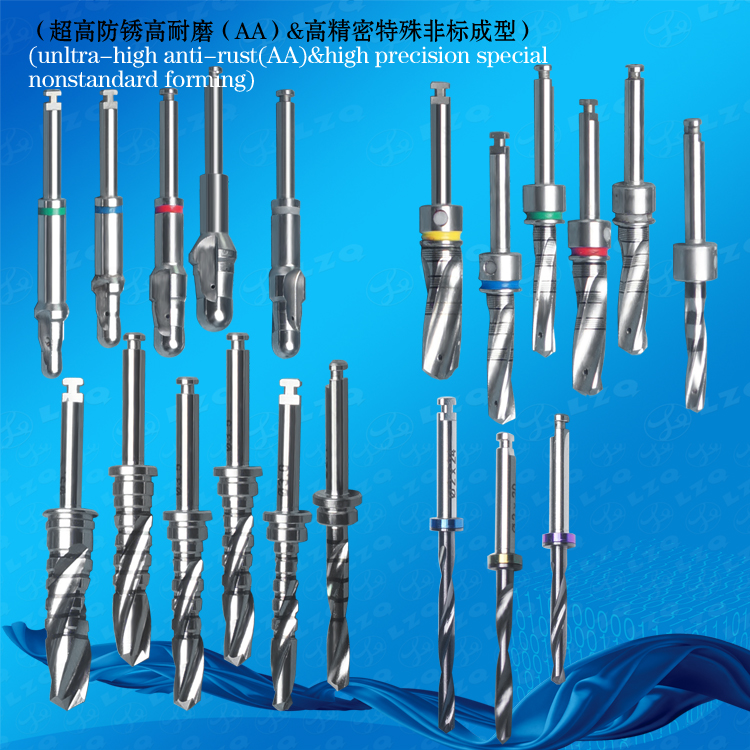

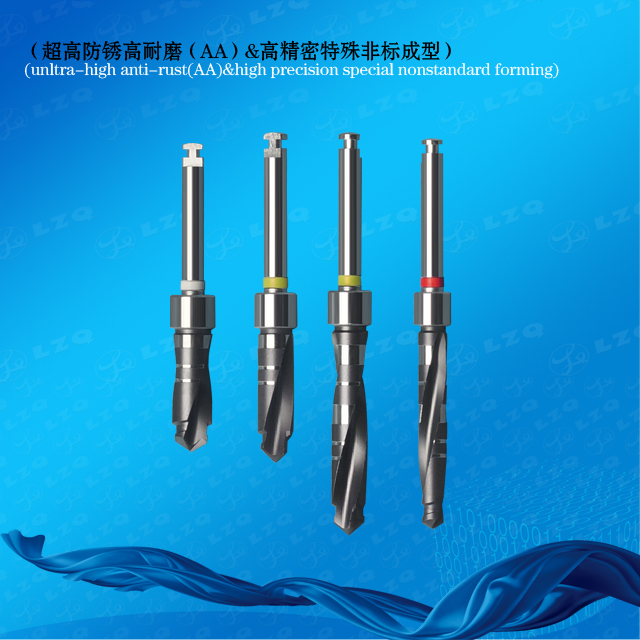

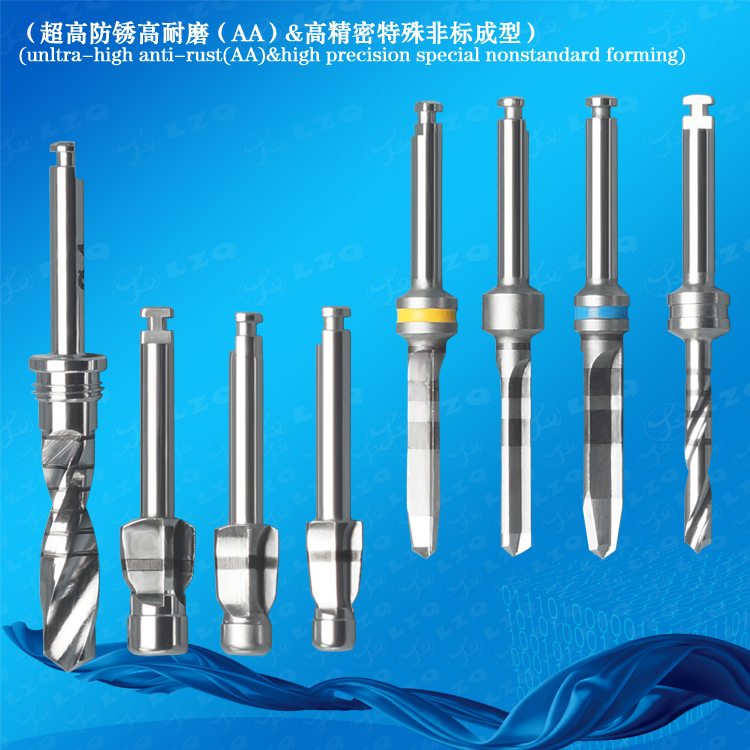

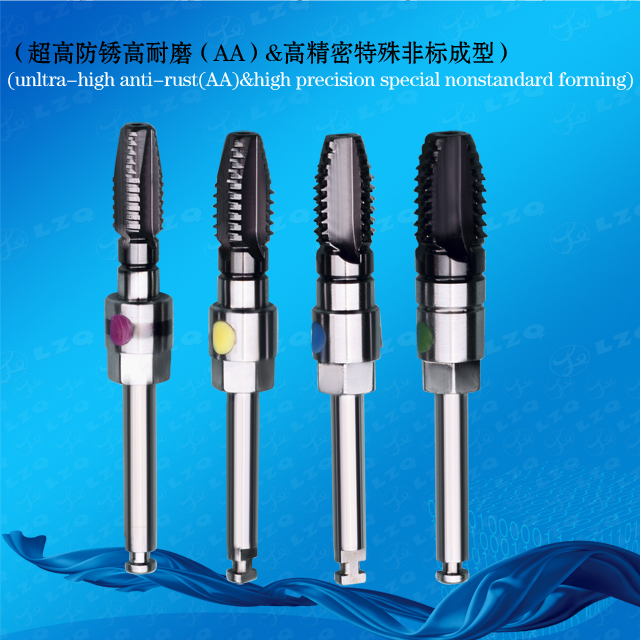

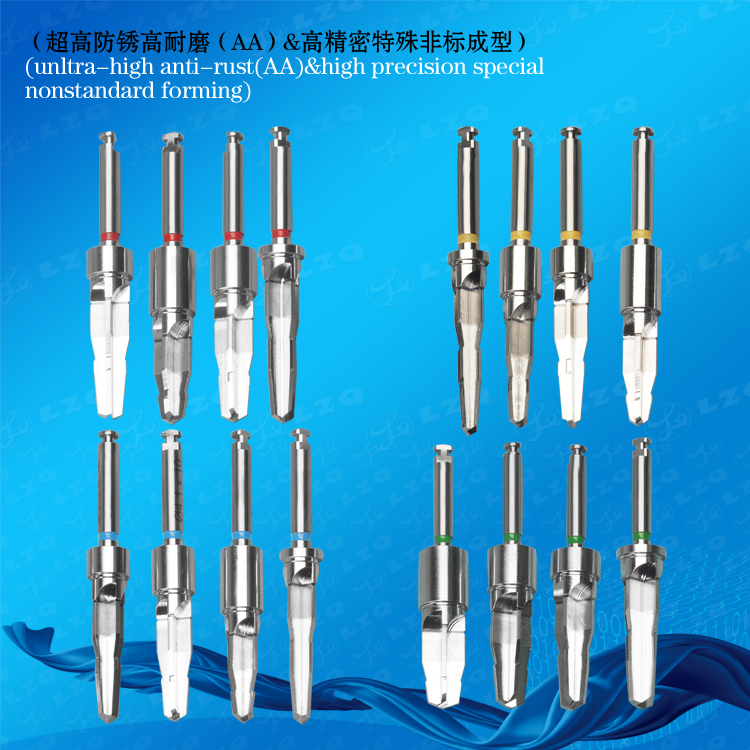

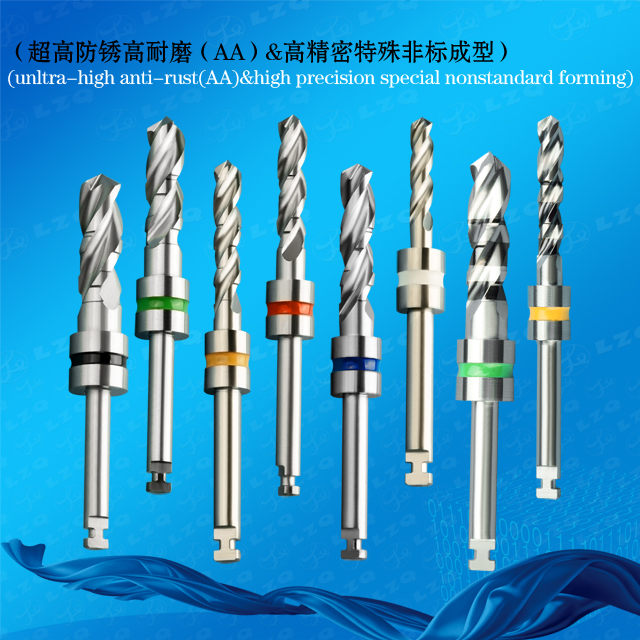

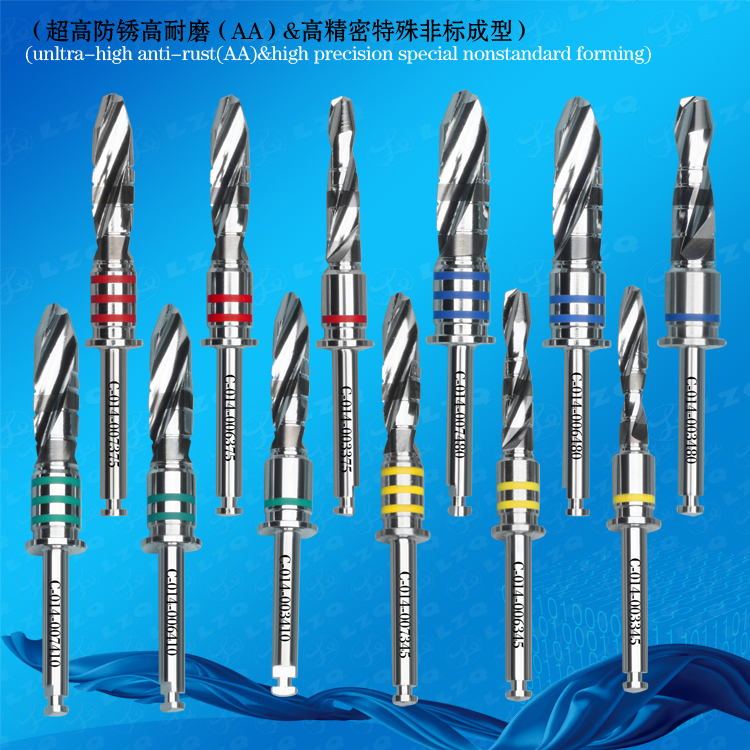

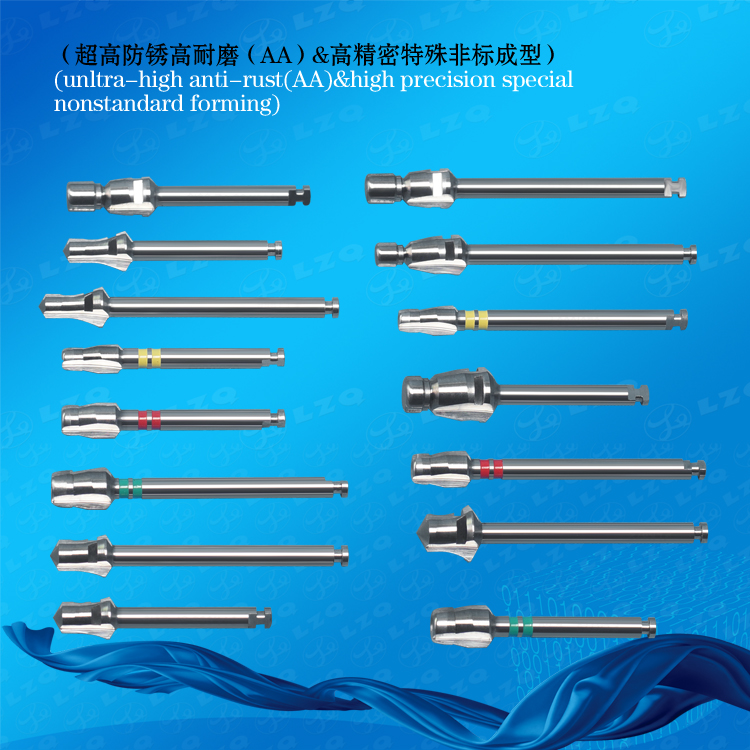

4、Different color ring

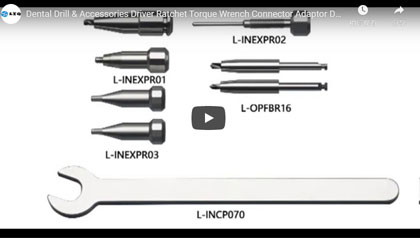

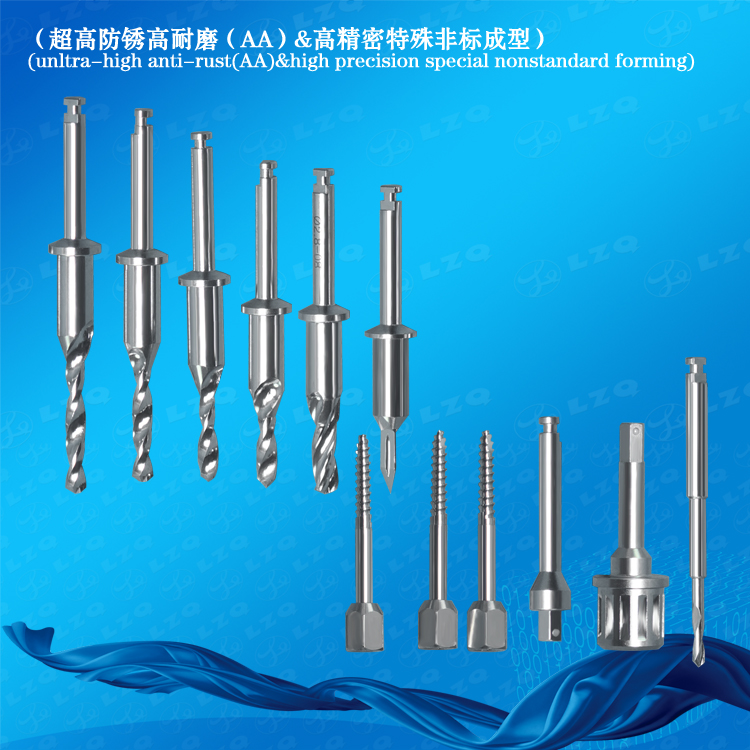

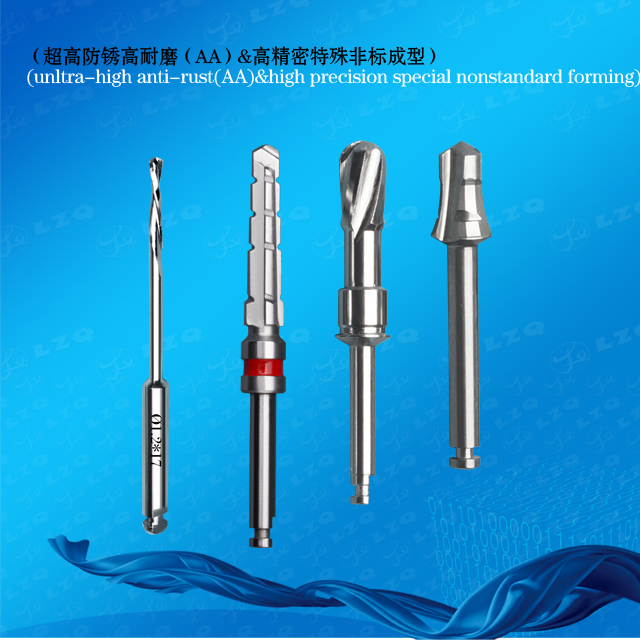

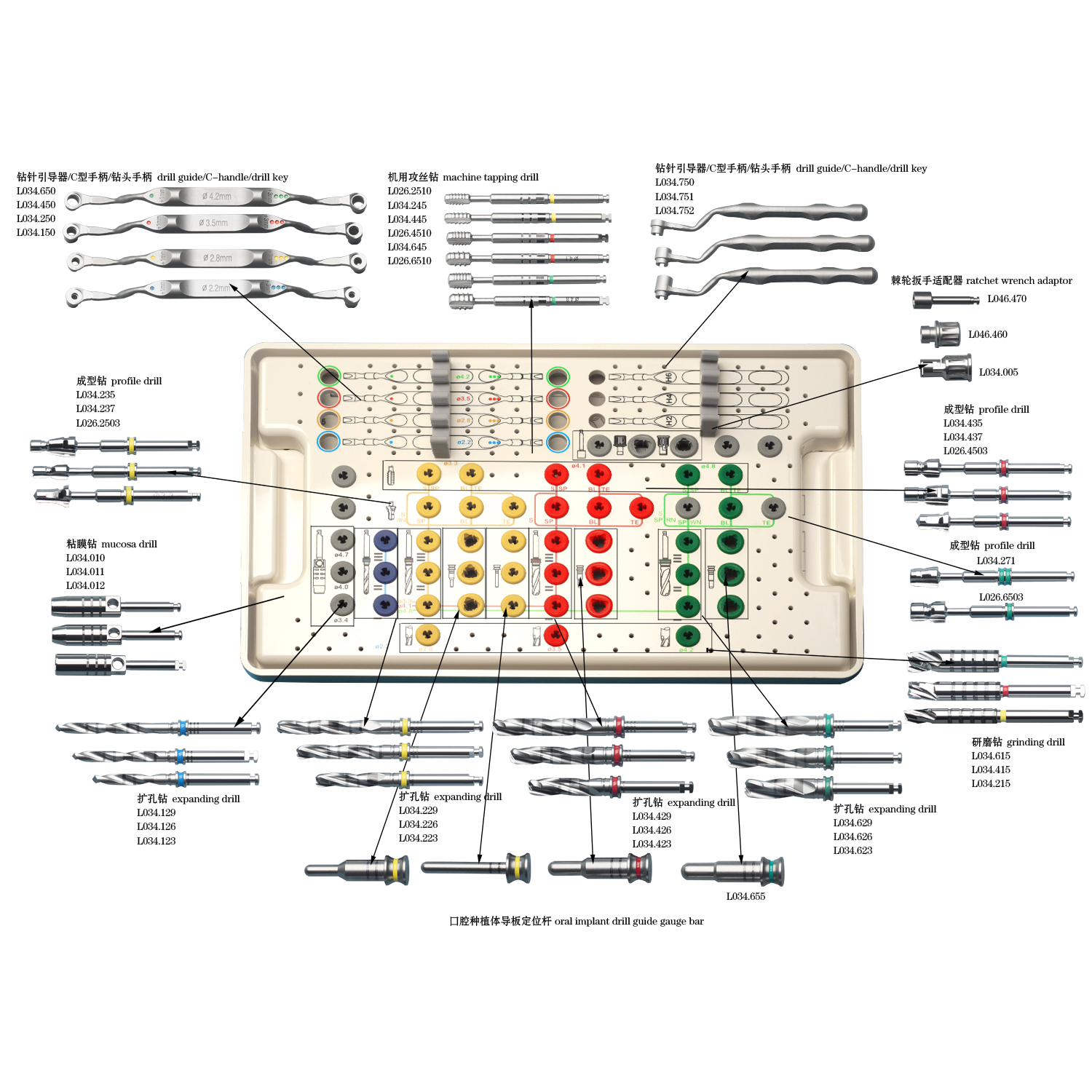

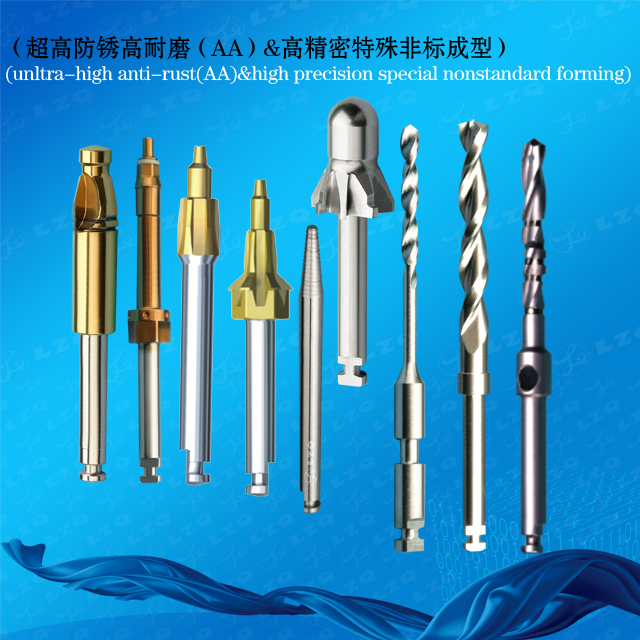

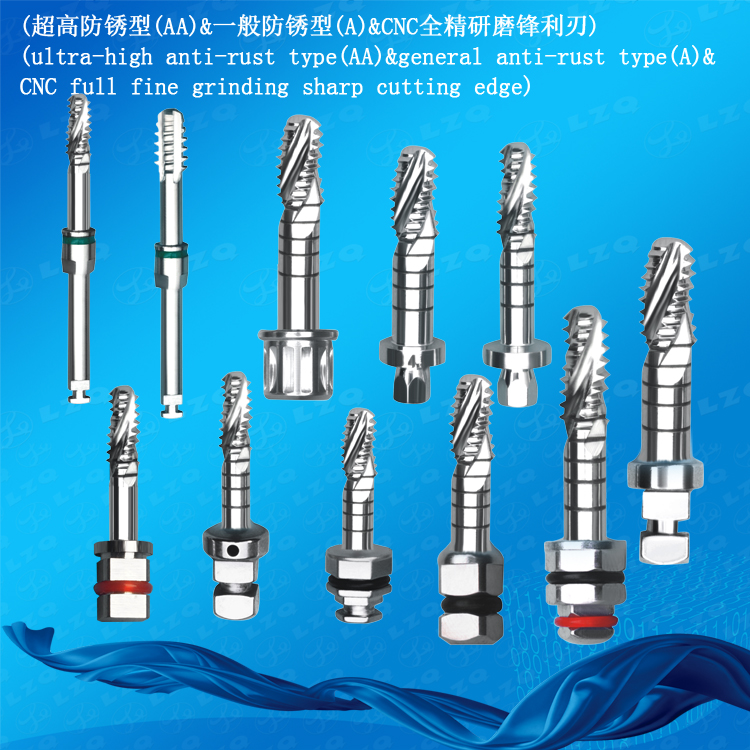

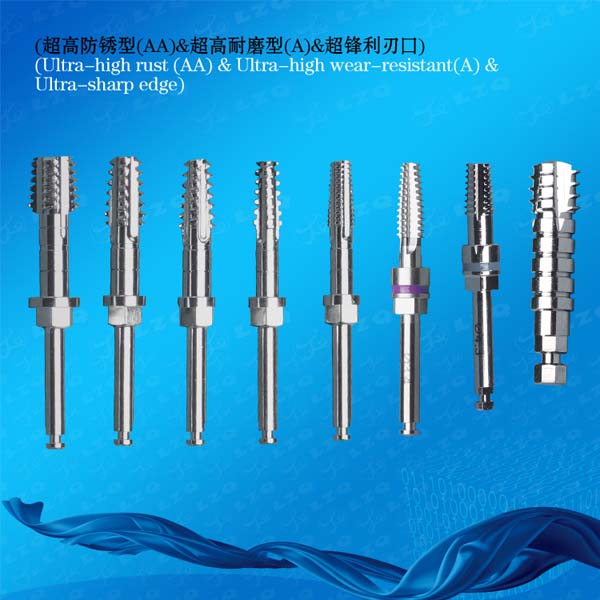

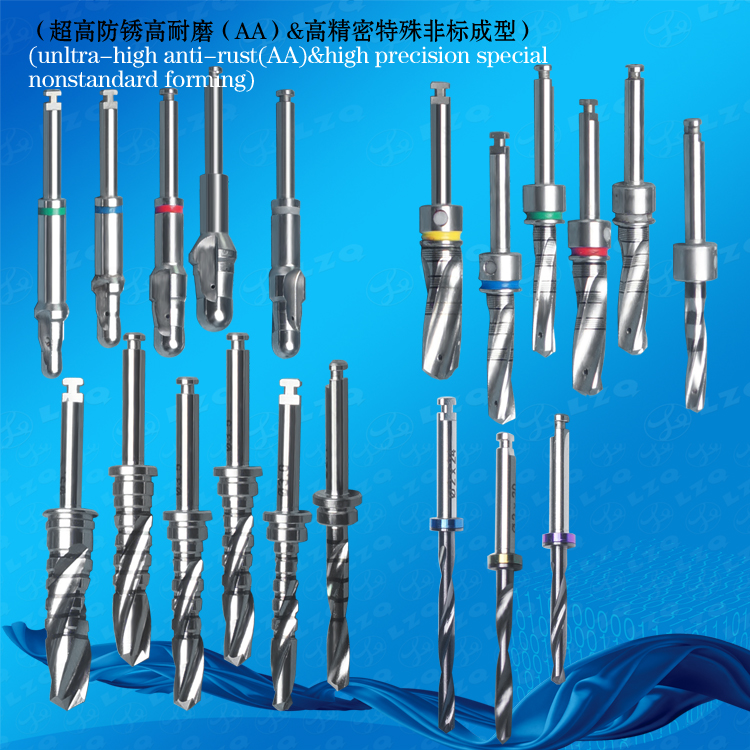

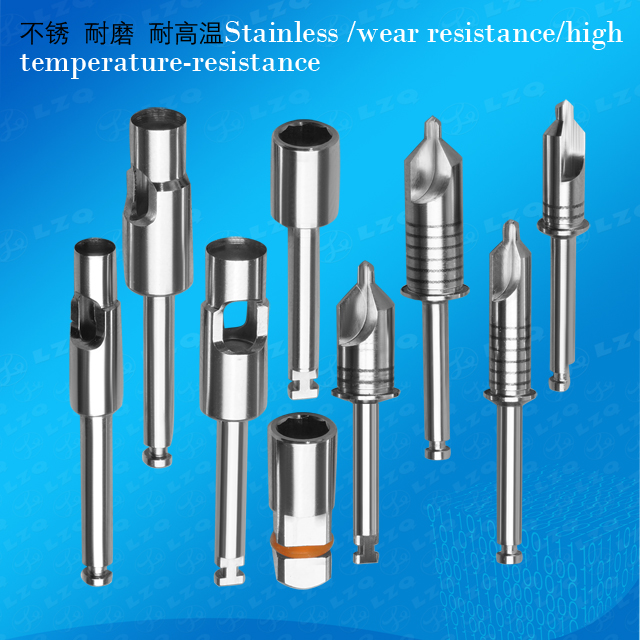

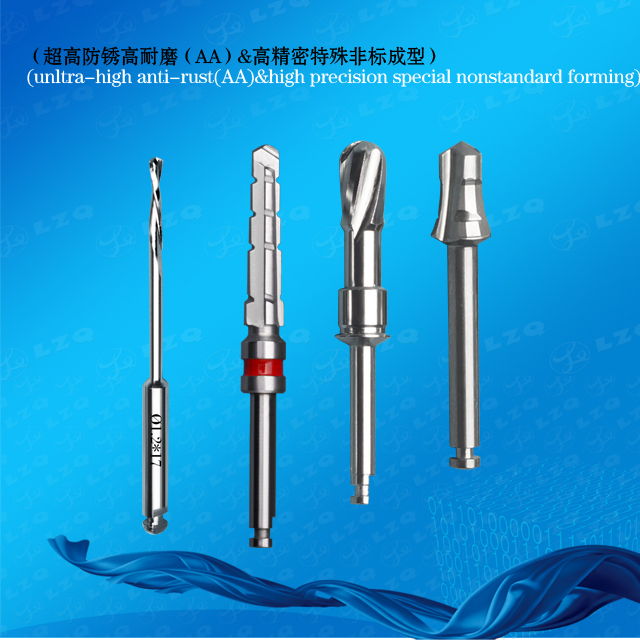

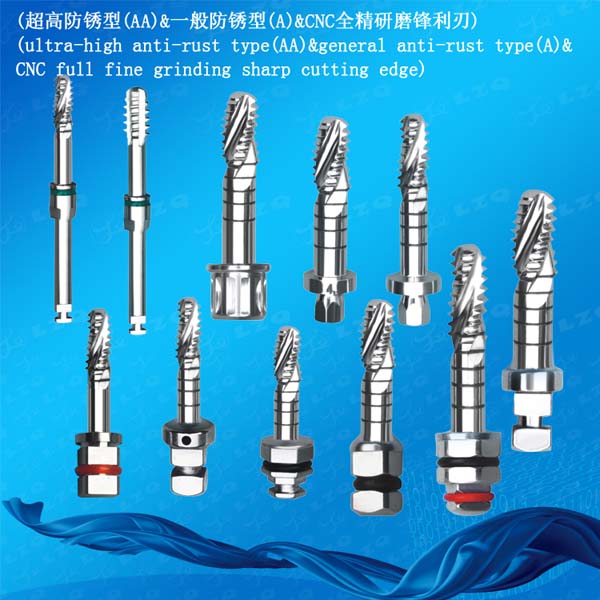

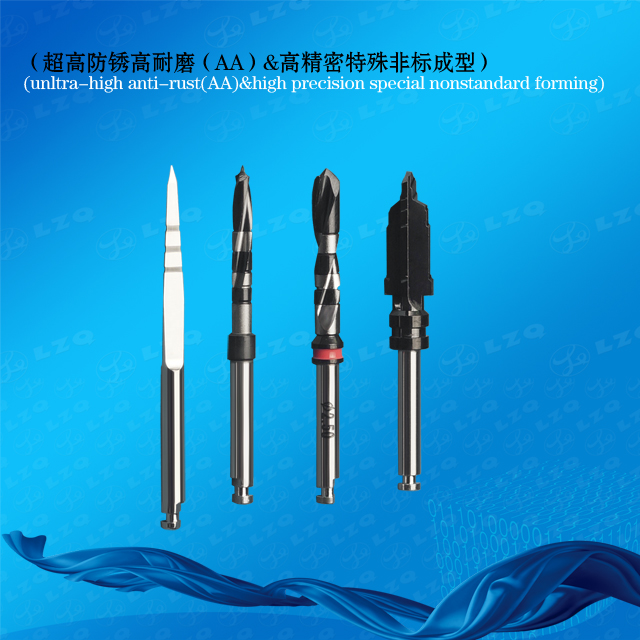

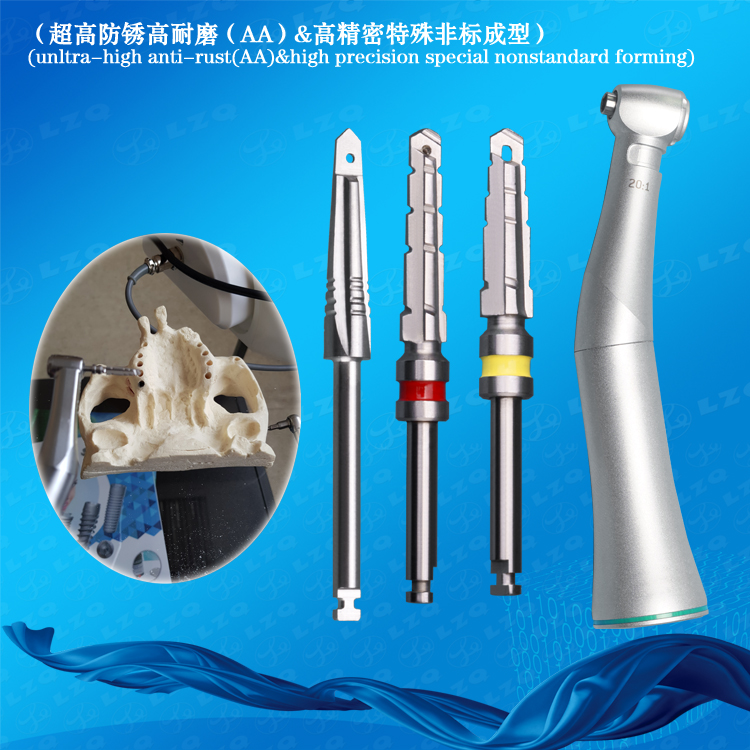

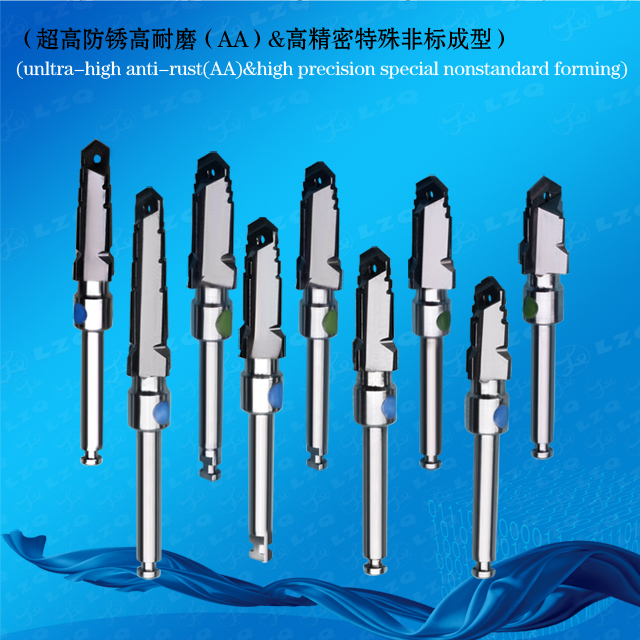

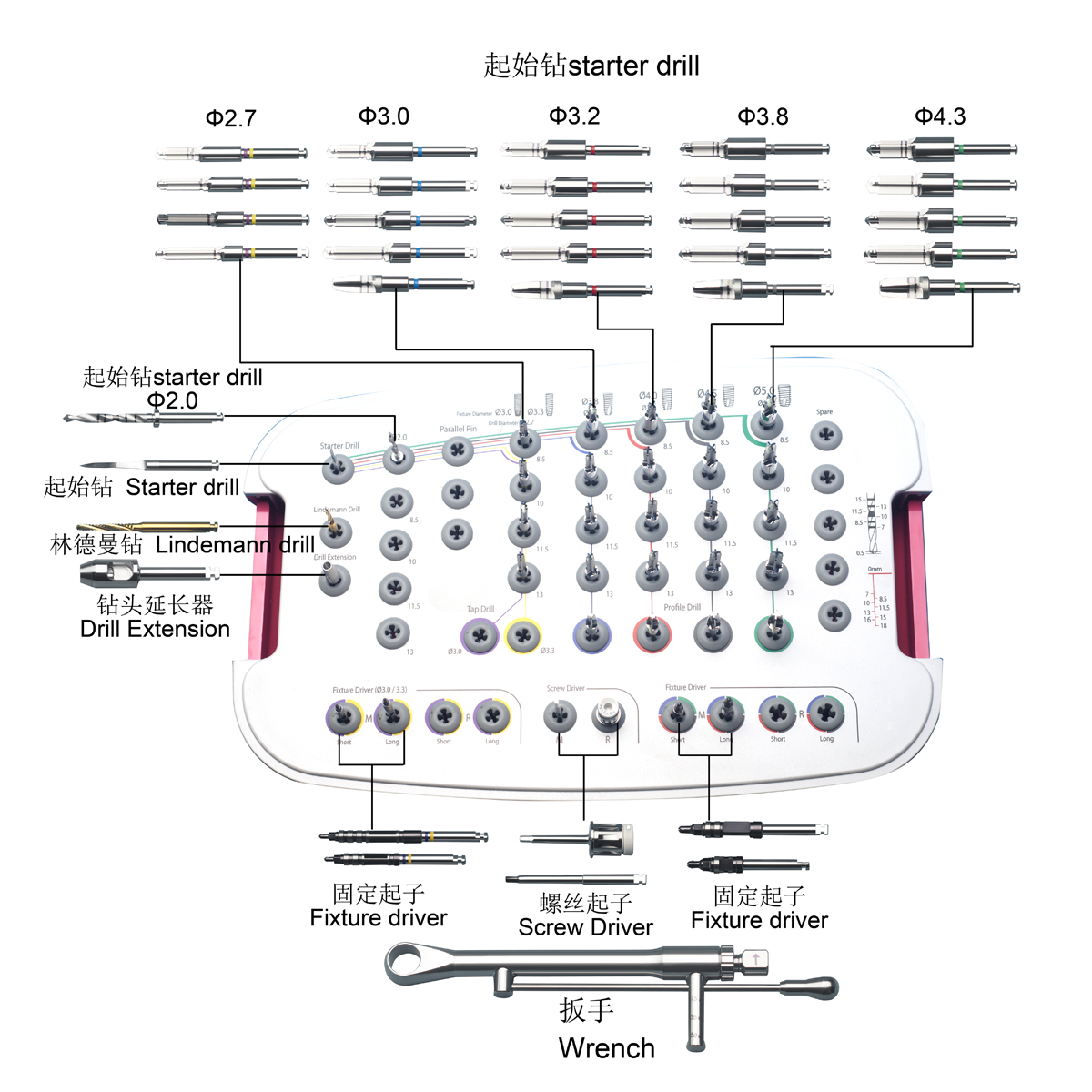

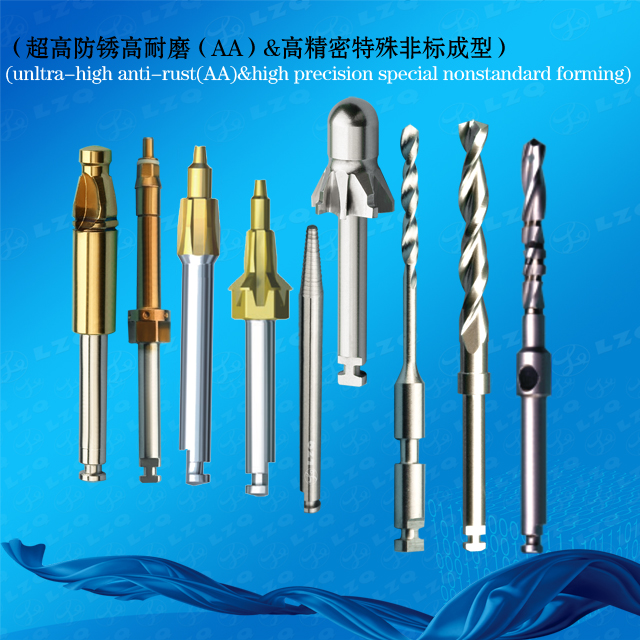

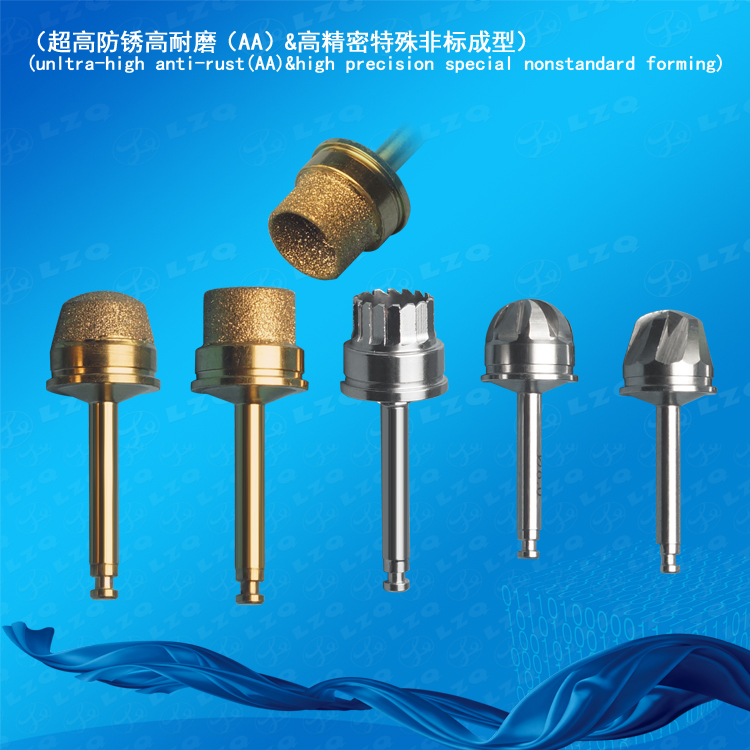

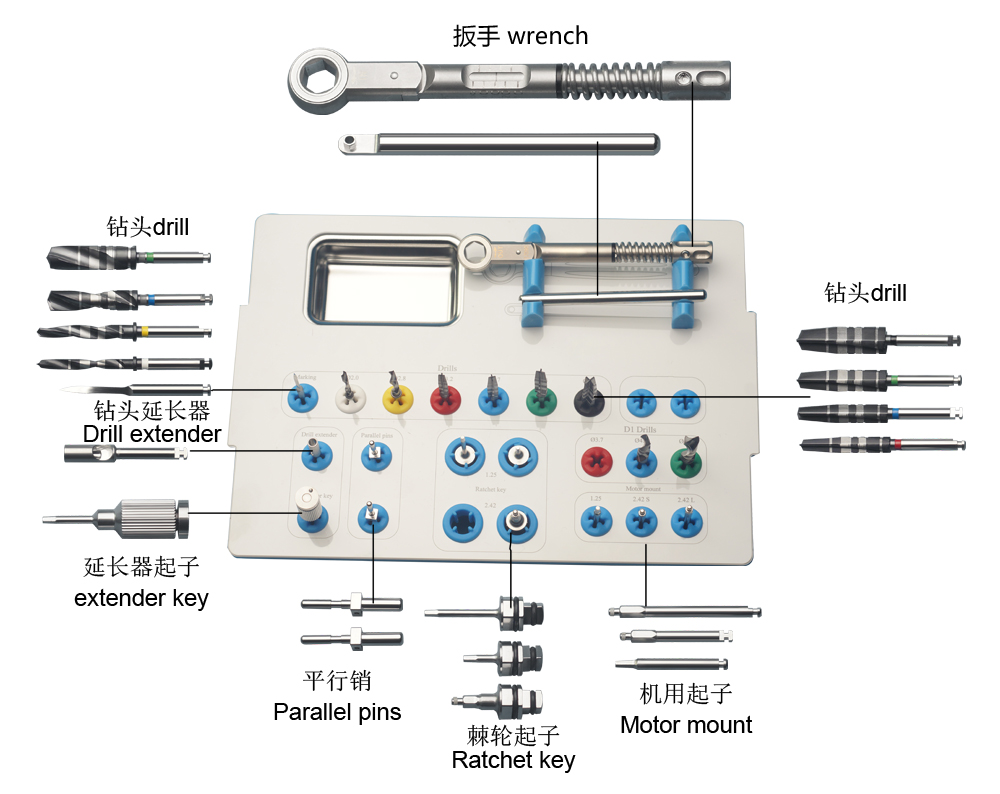

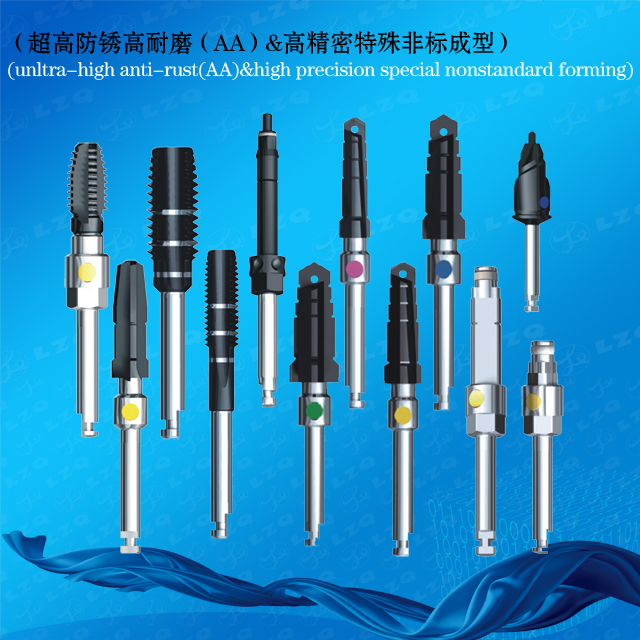

LZQ is an OEM factory for all kinds of dental implant drills, such as Ceramic Drill P100, Drill with Inner Irrigation P121, Wrench P53, Screwdriver P79, Bone Fetcher P165, etc.

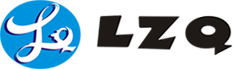

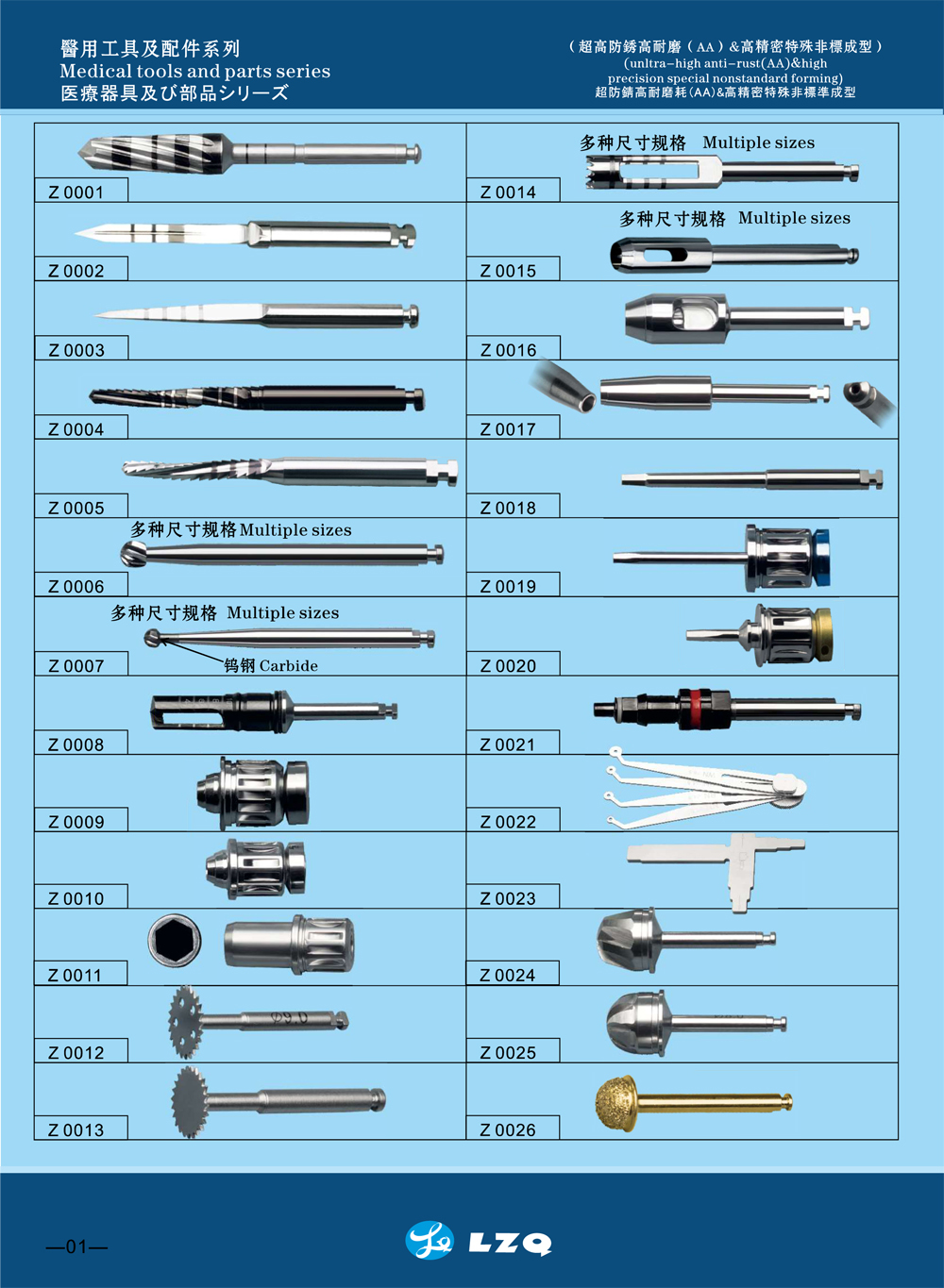

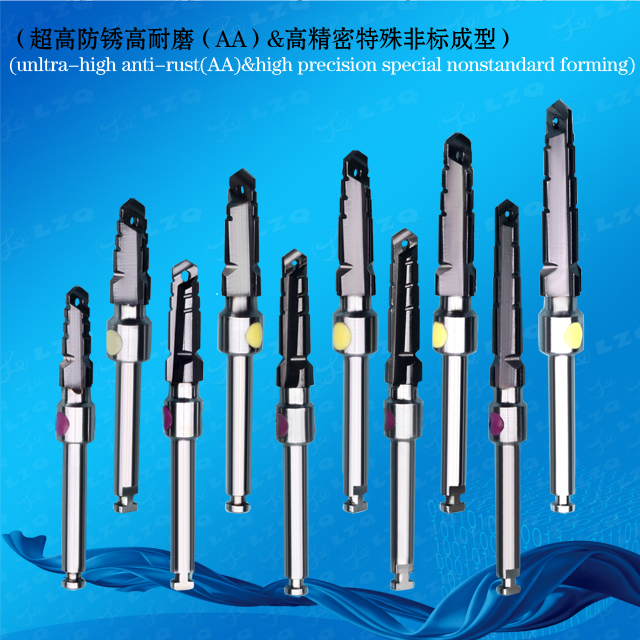

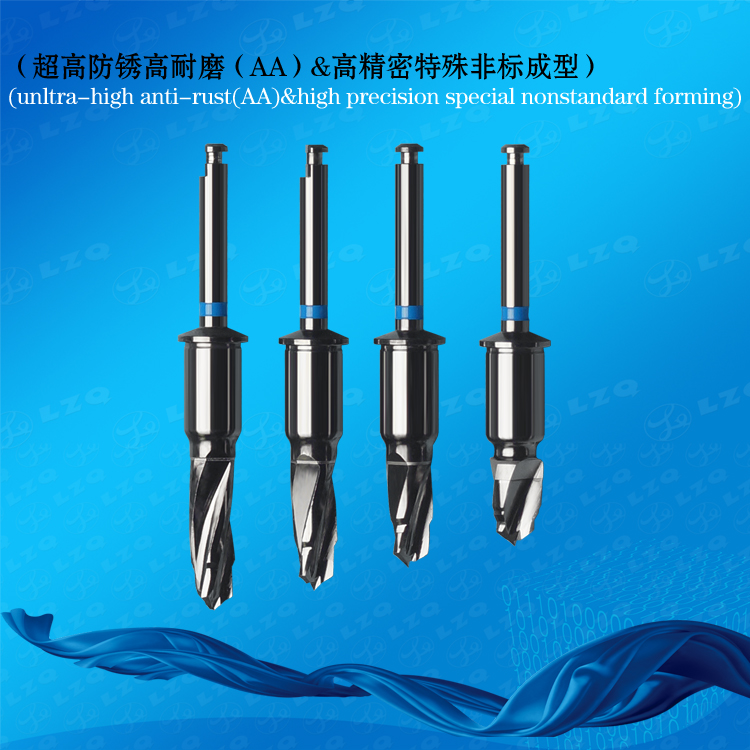

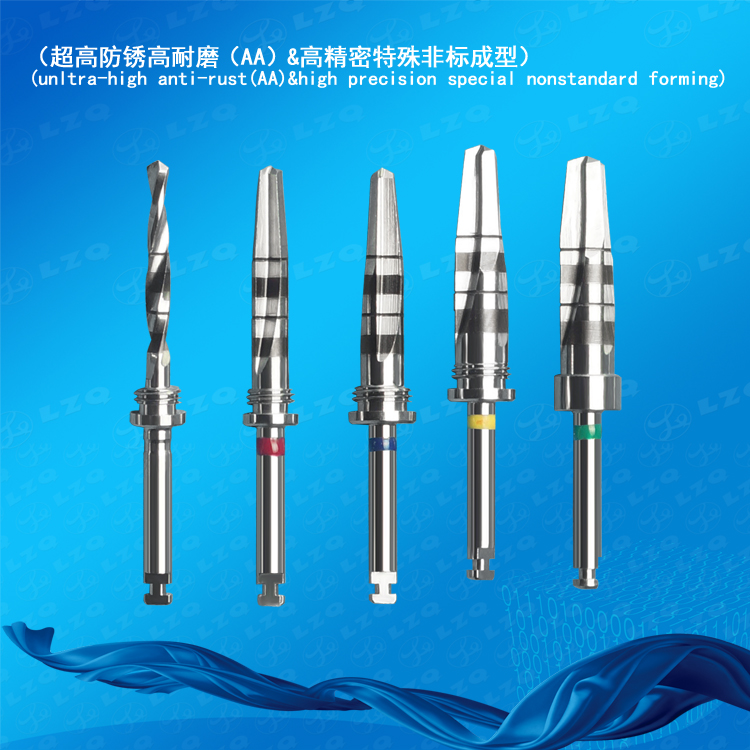

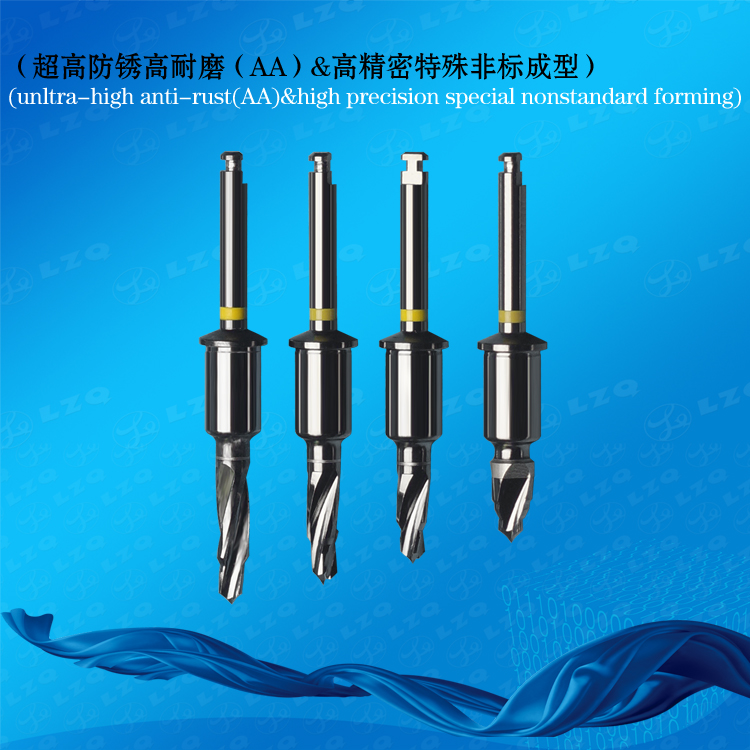

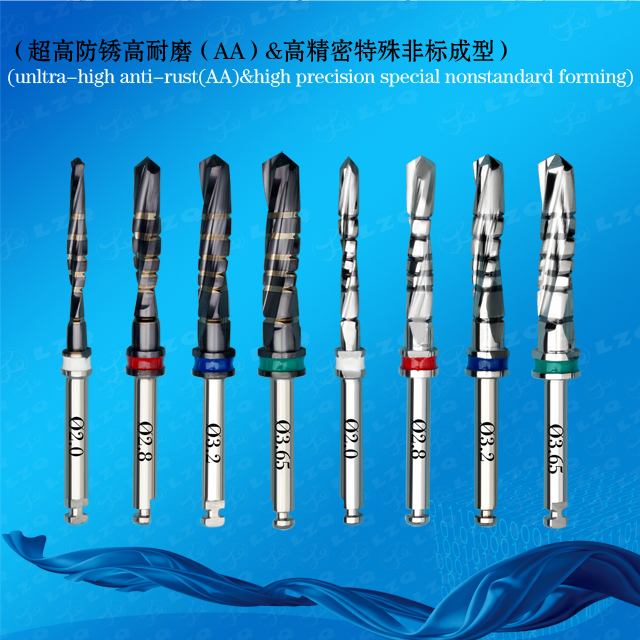

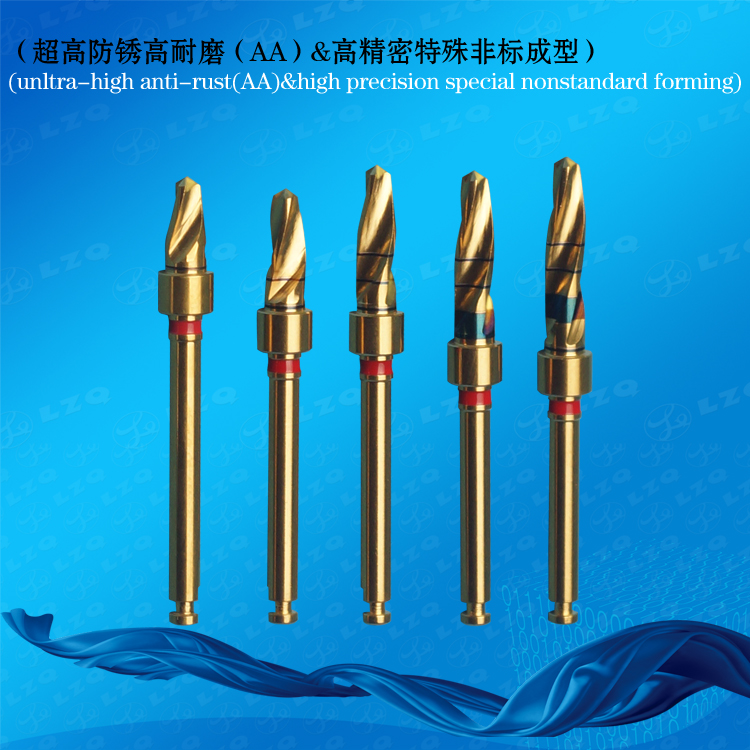

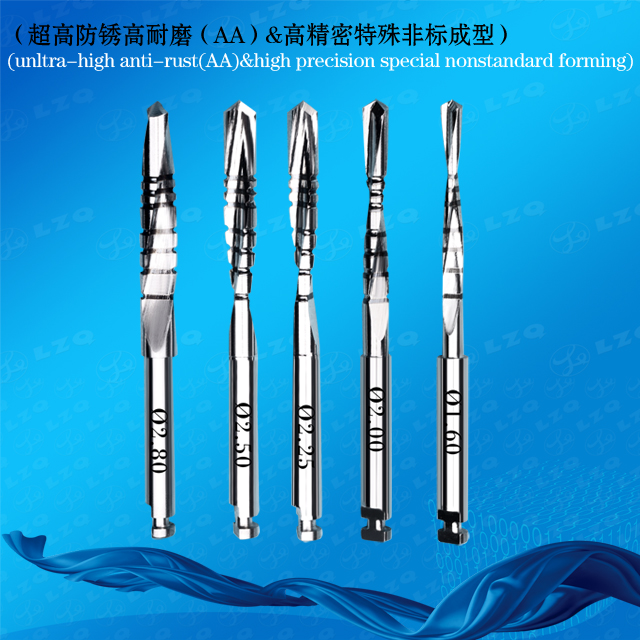

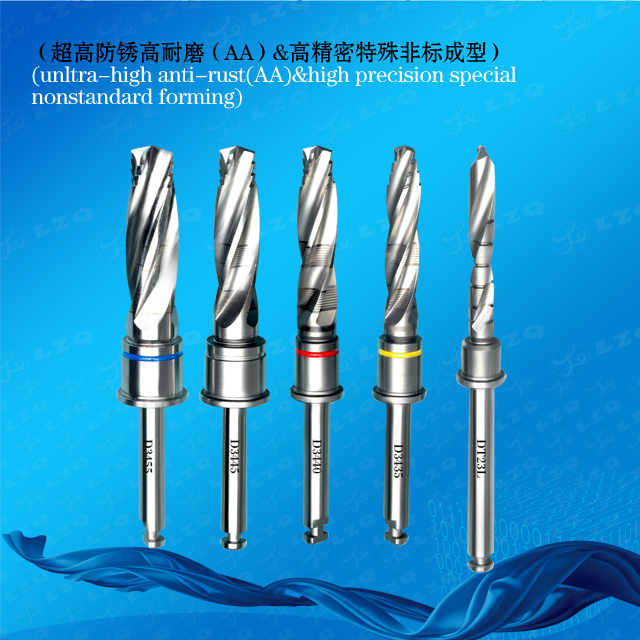

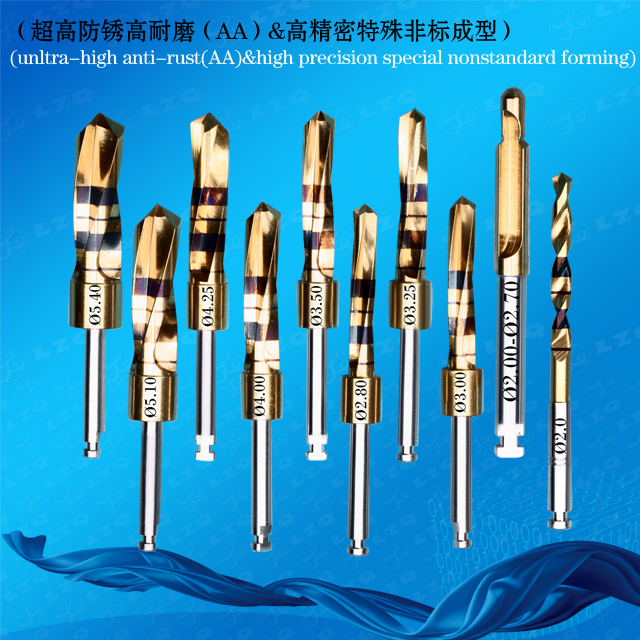

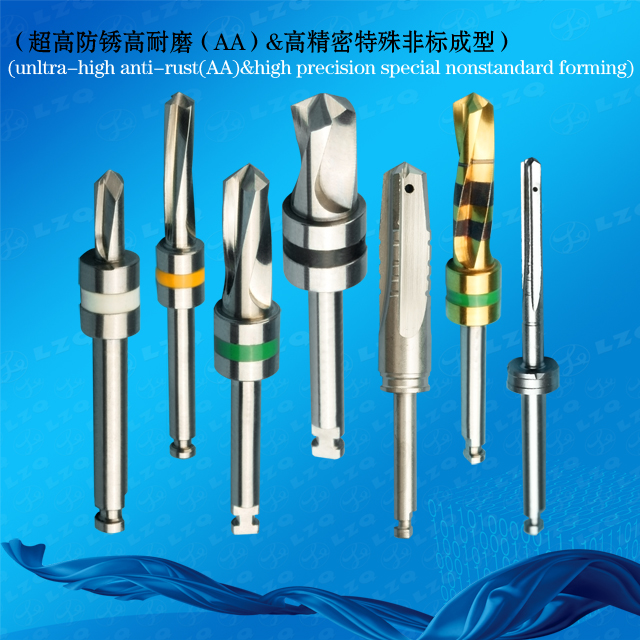

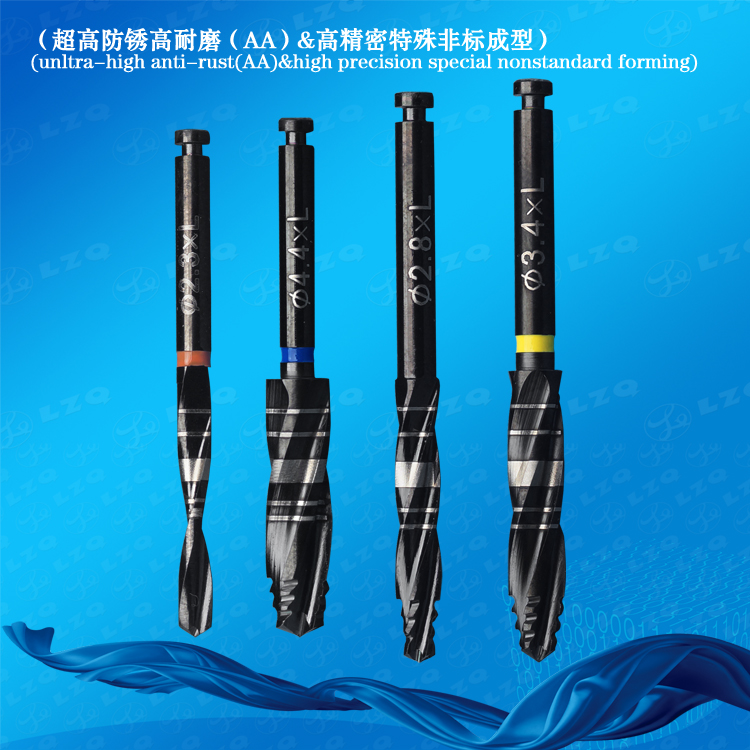

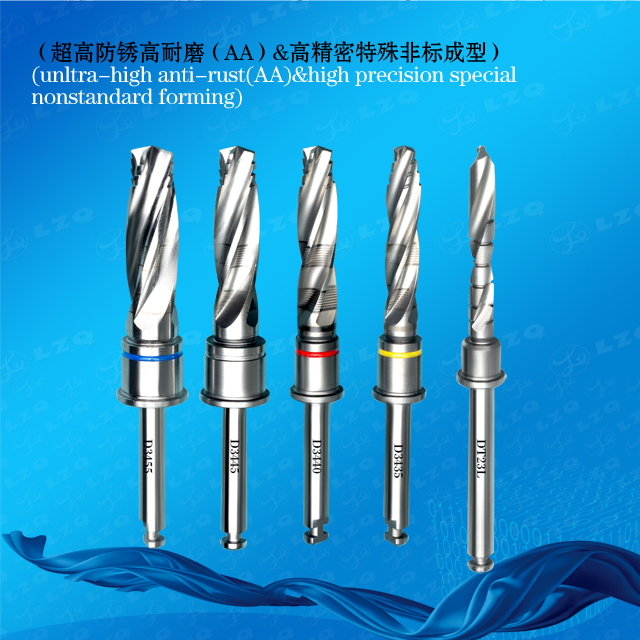

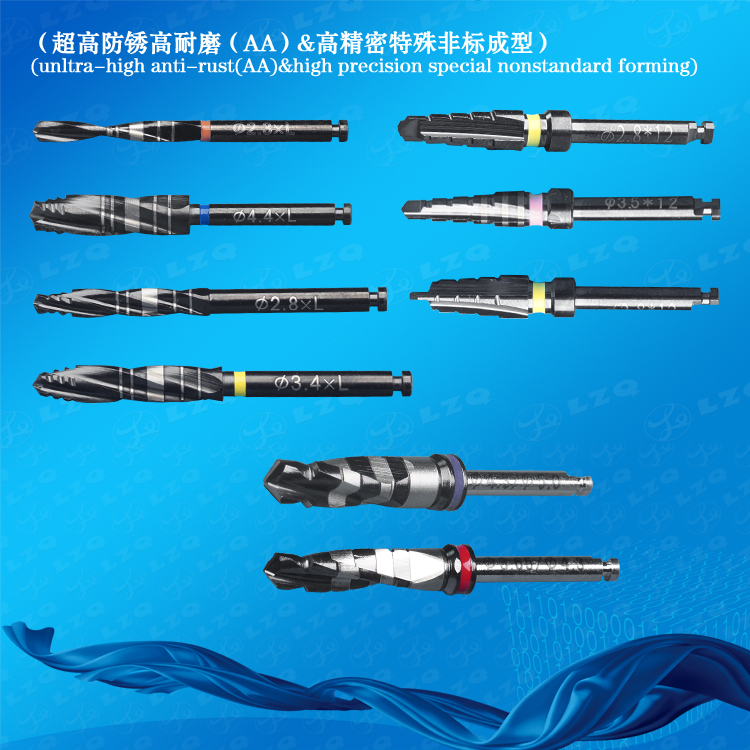

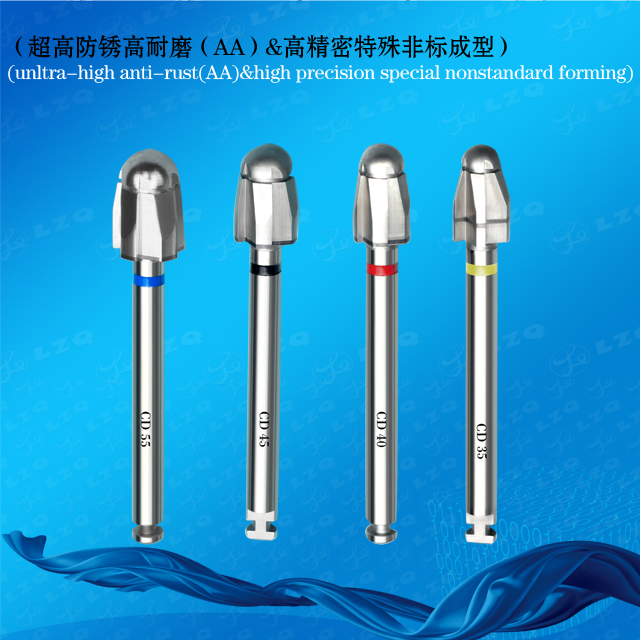

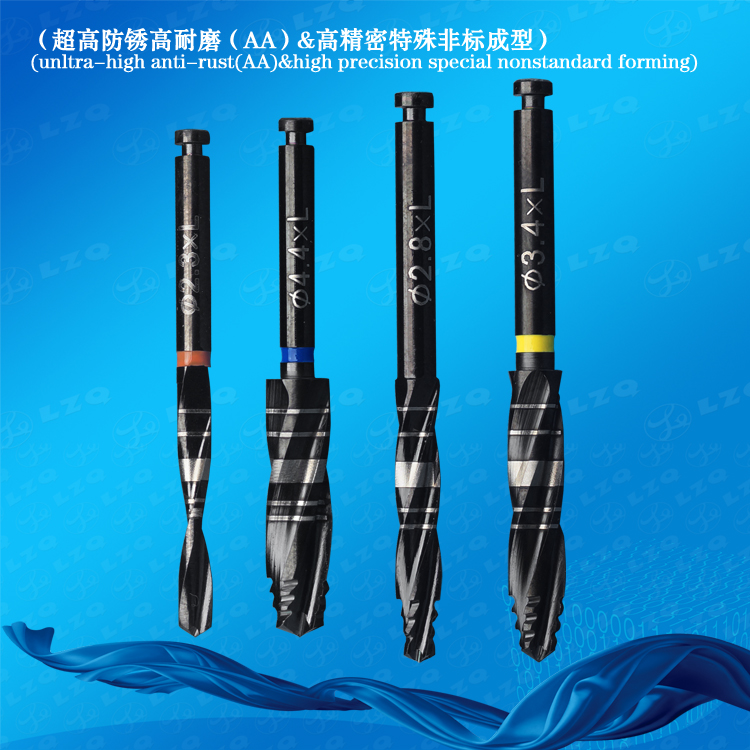

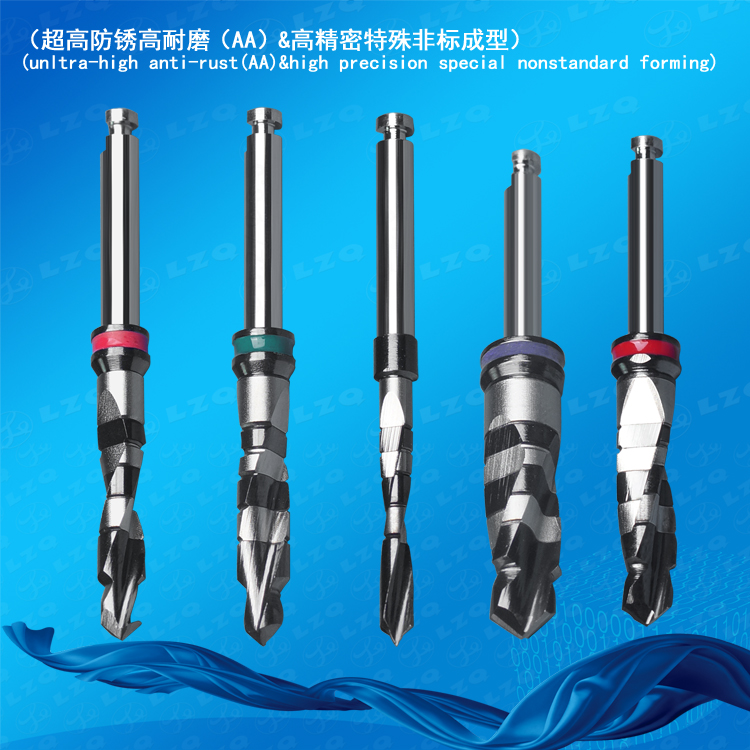

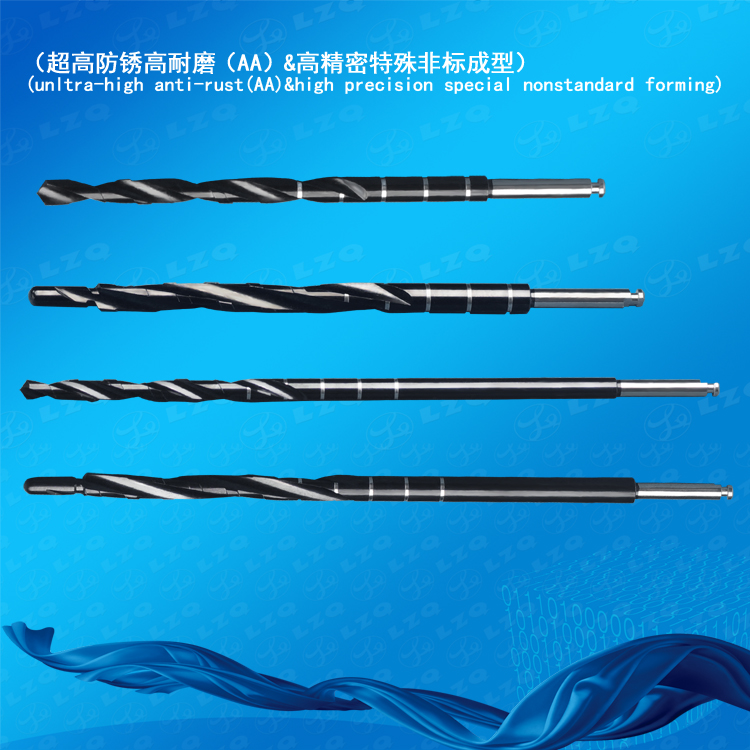

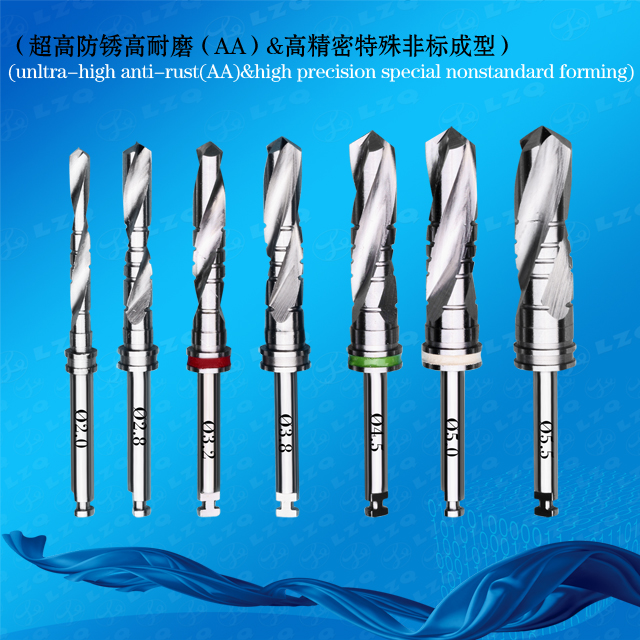

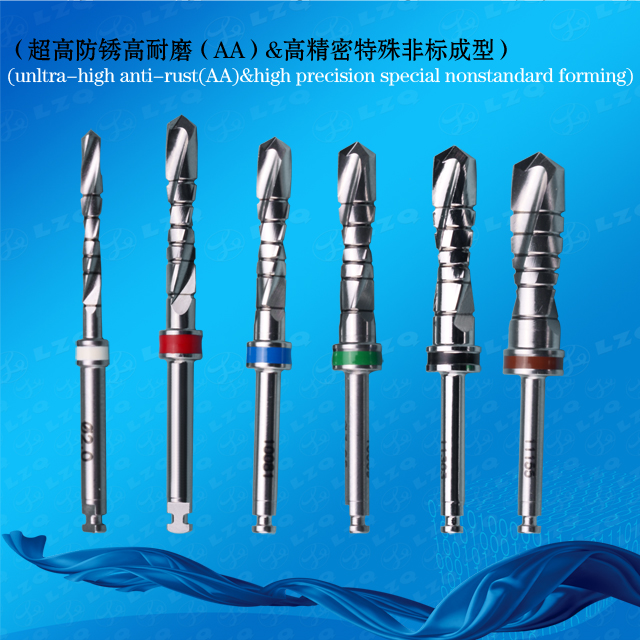

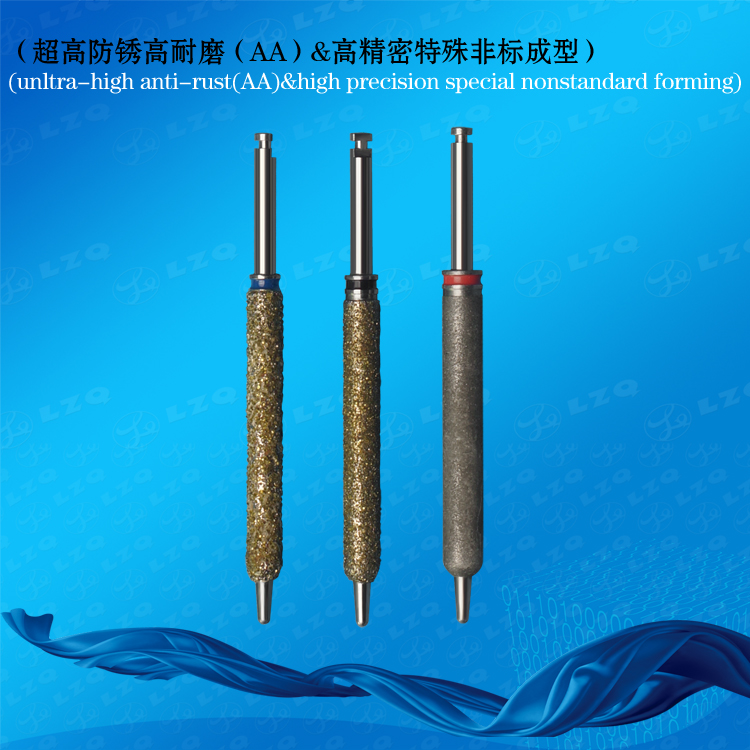

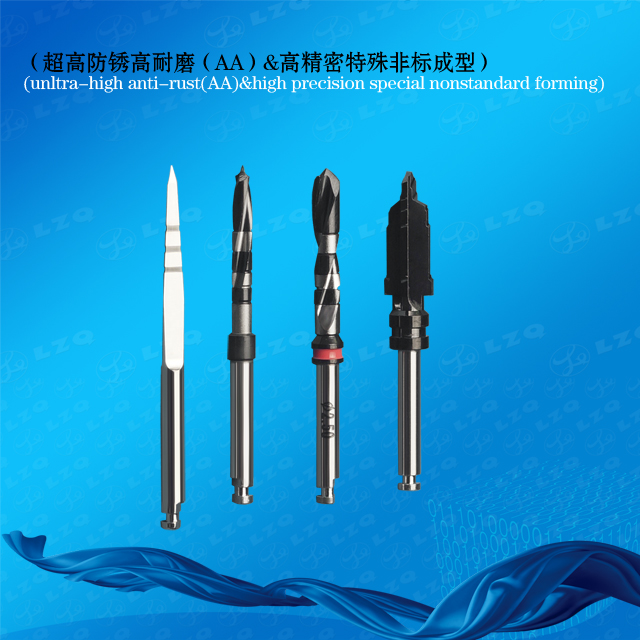

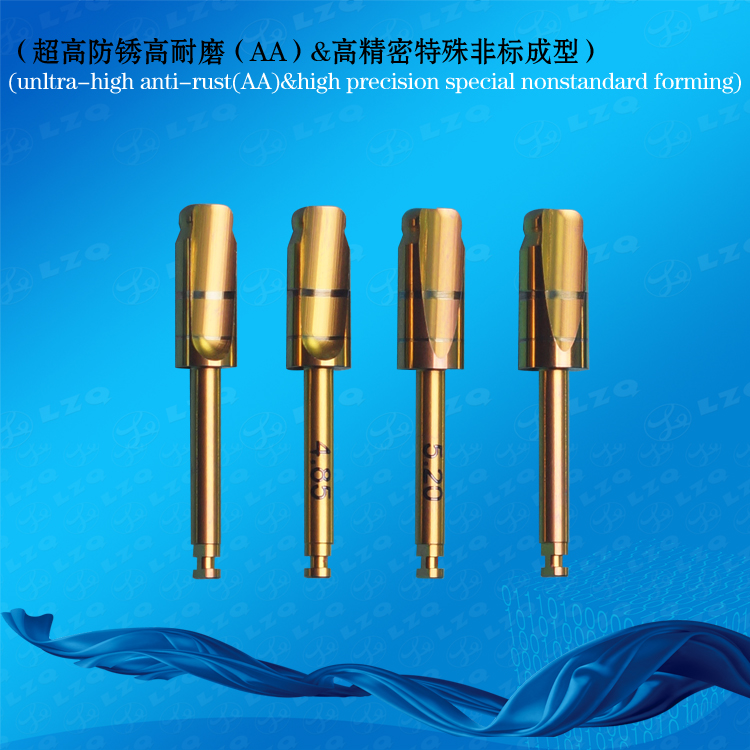

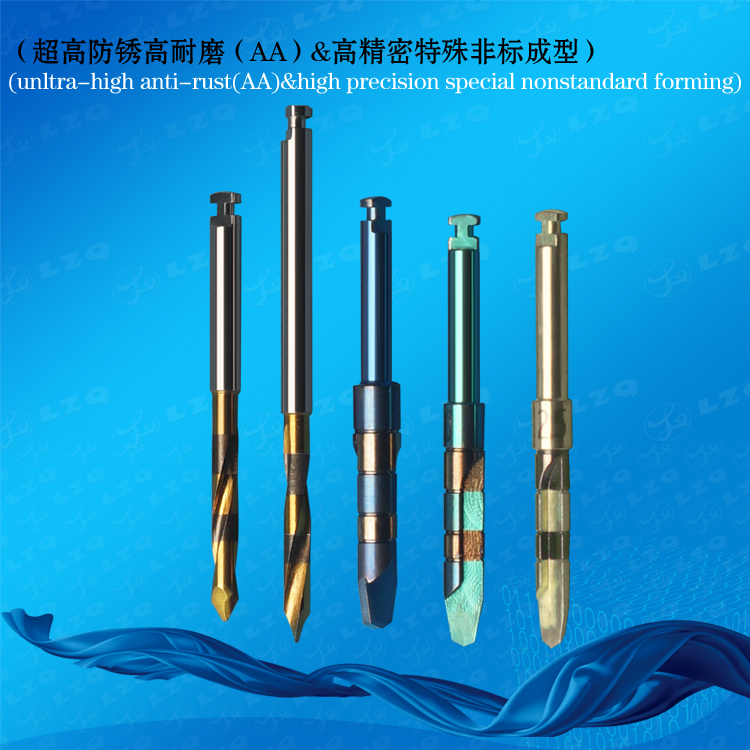

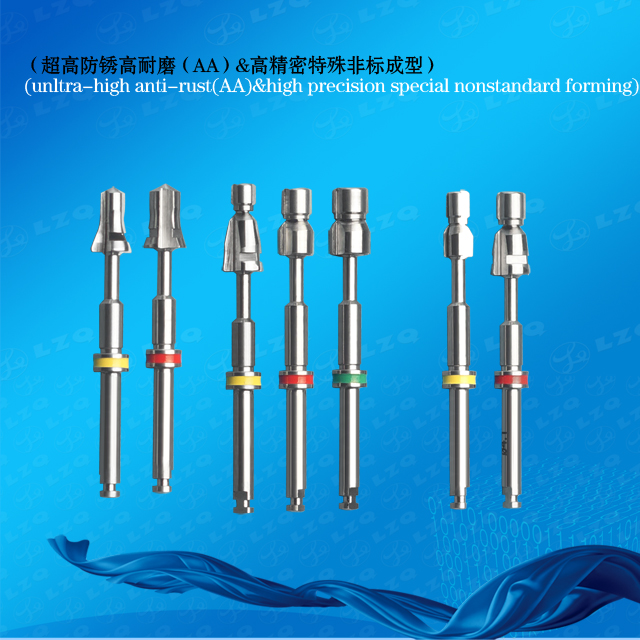

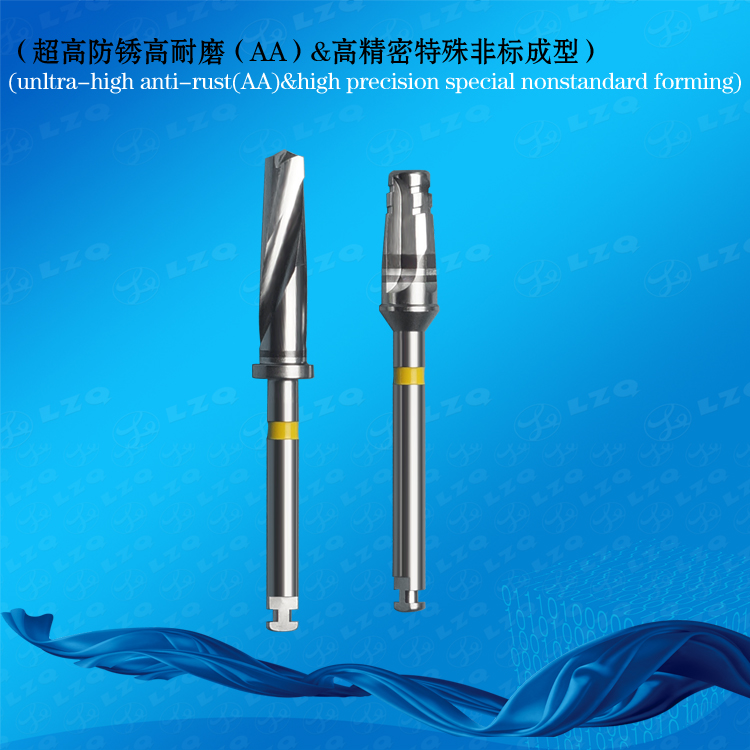

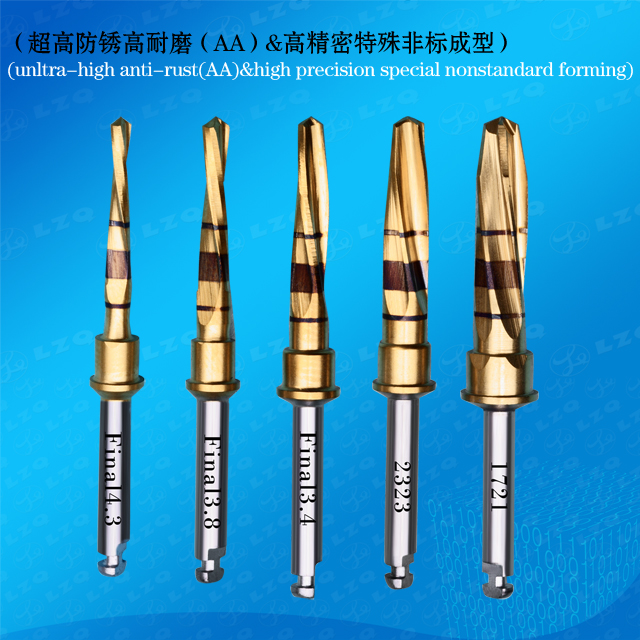

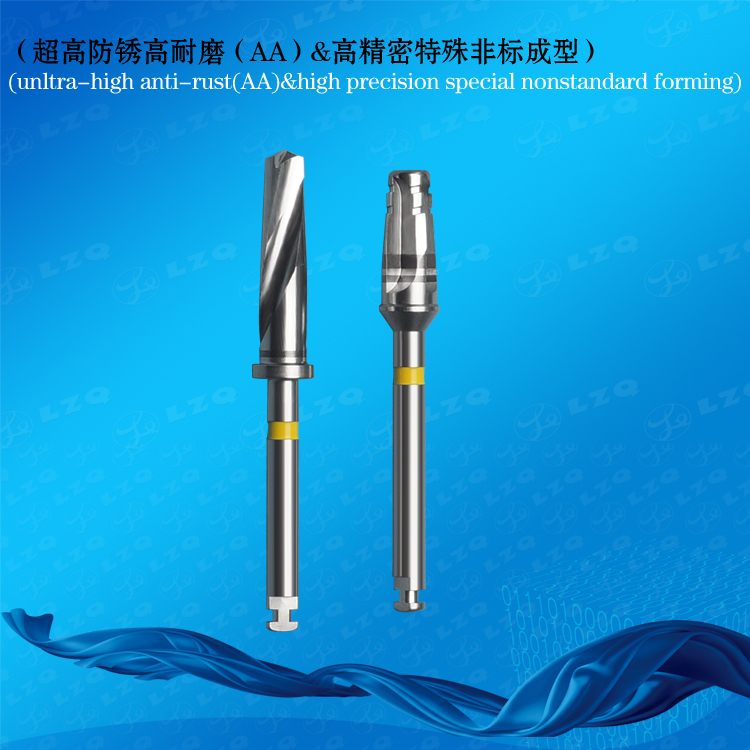

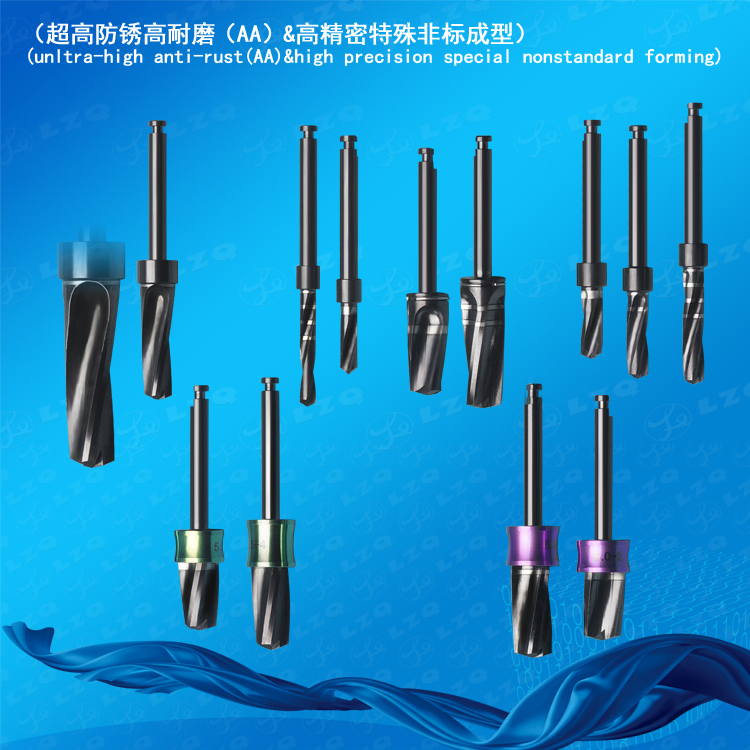

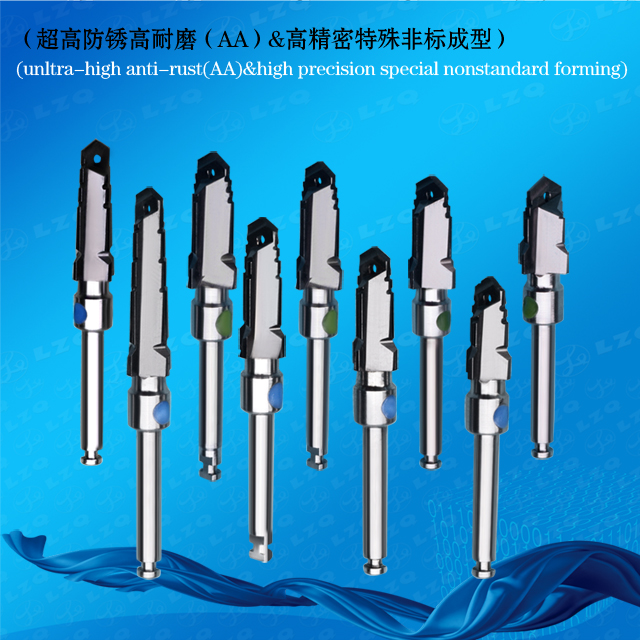

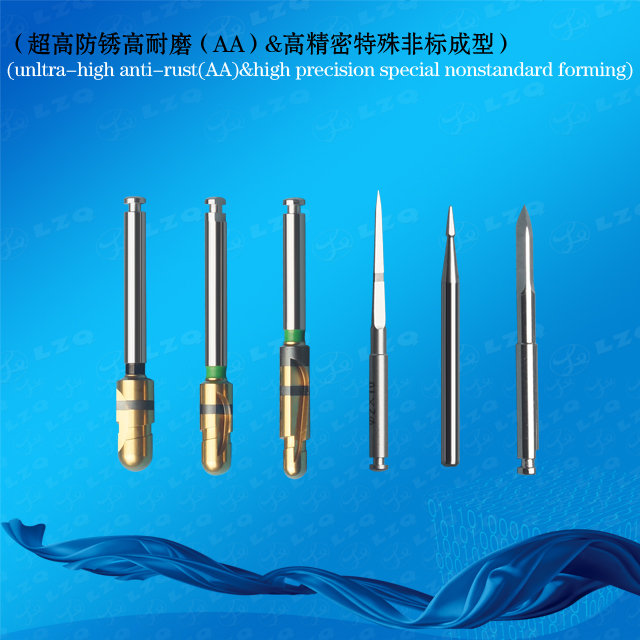

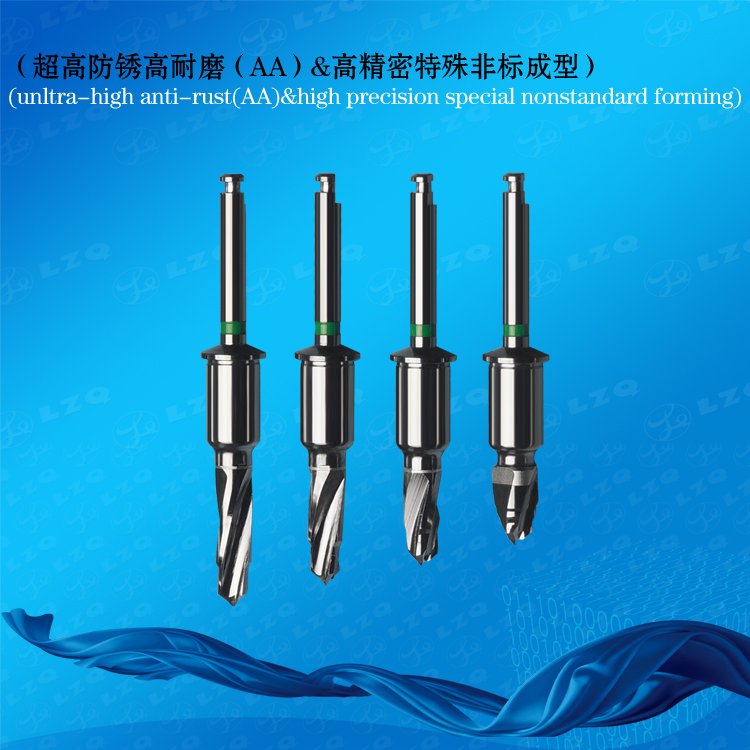

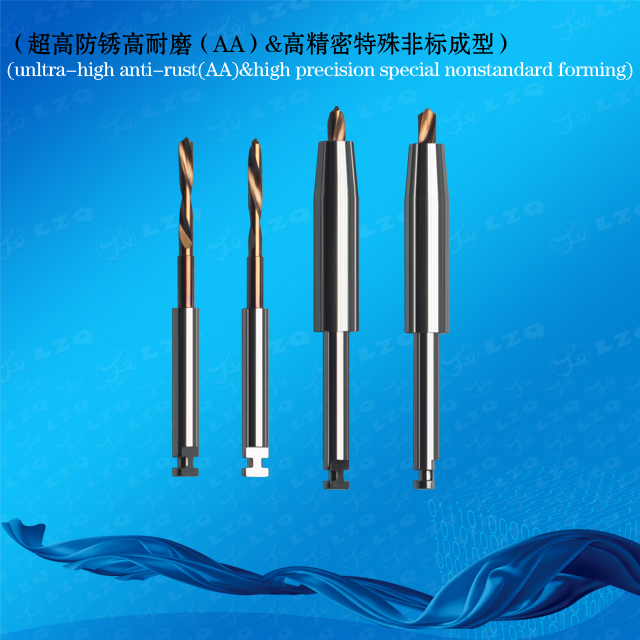

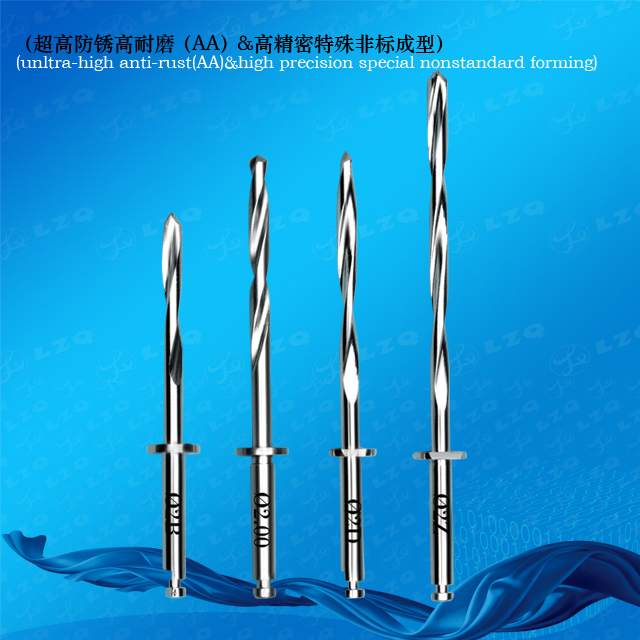

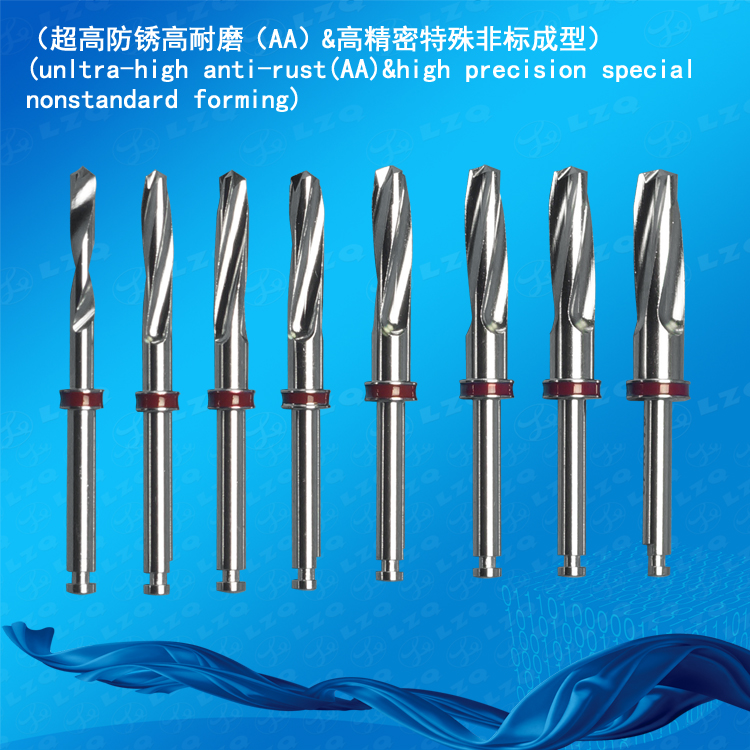

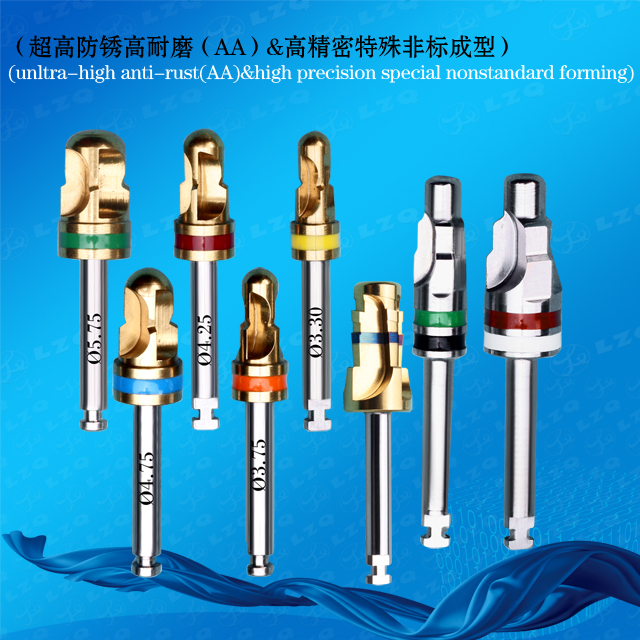

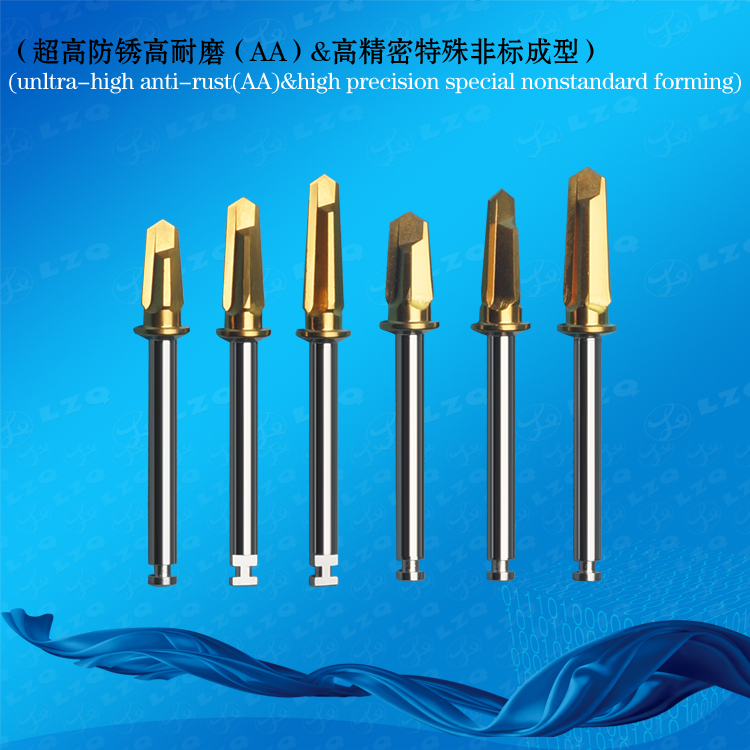

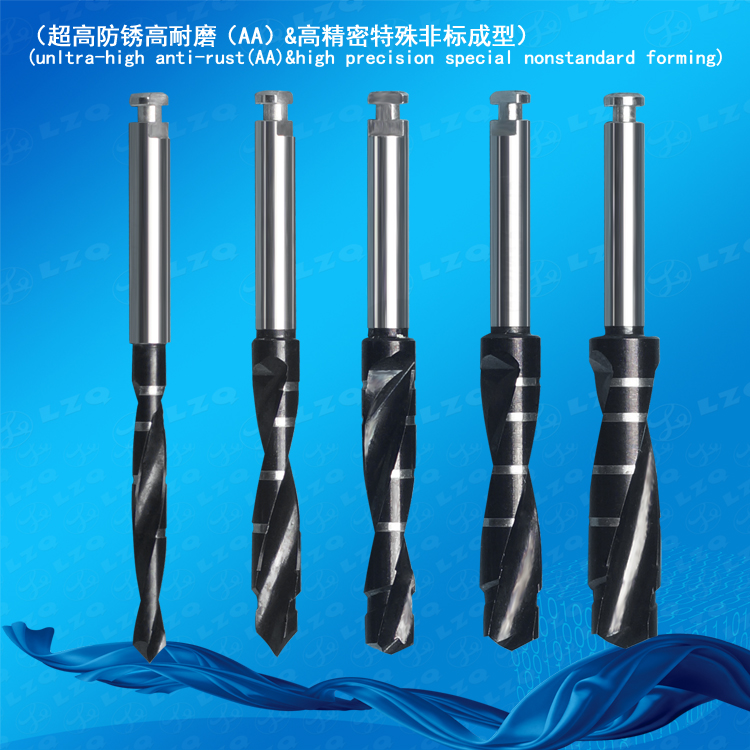

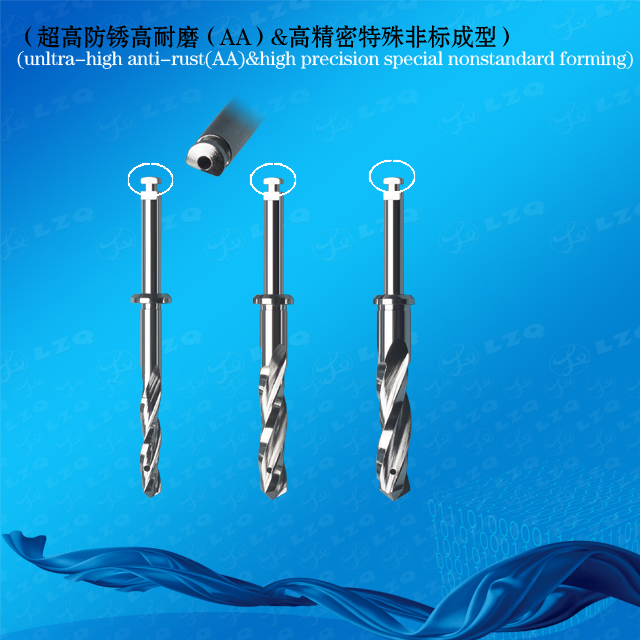

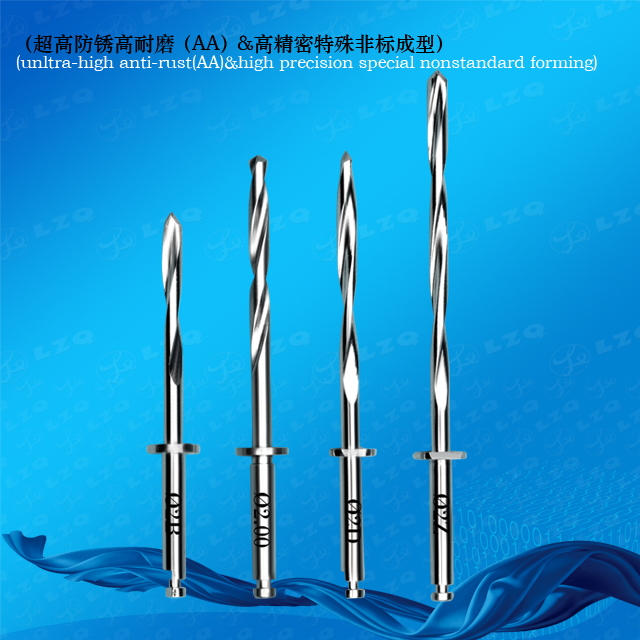

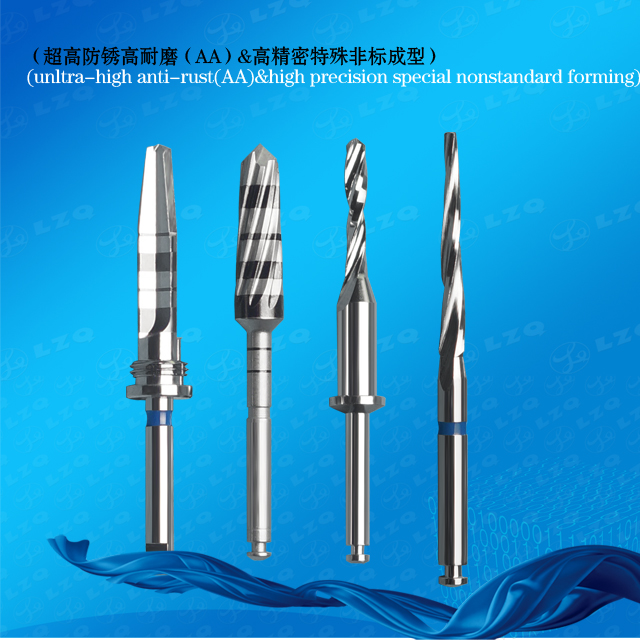

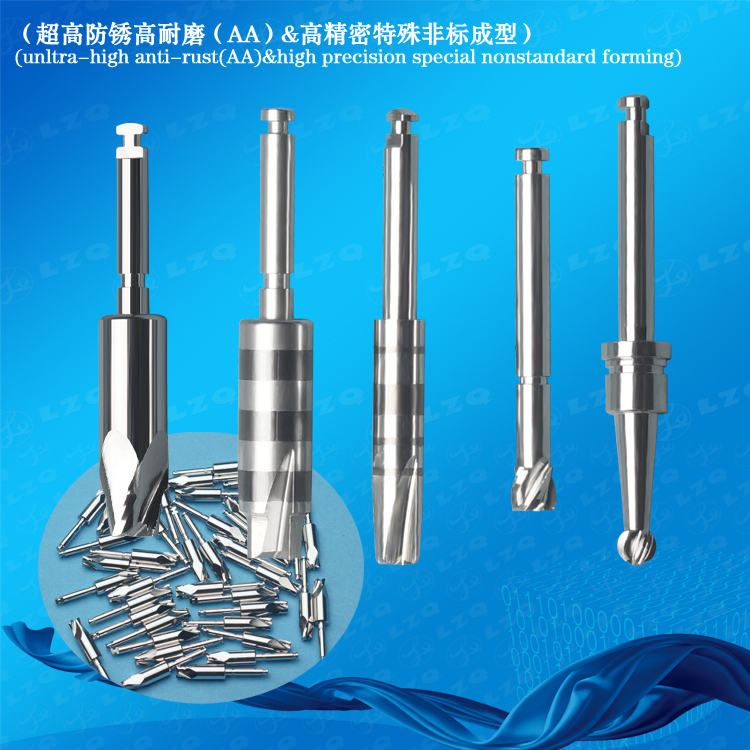

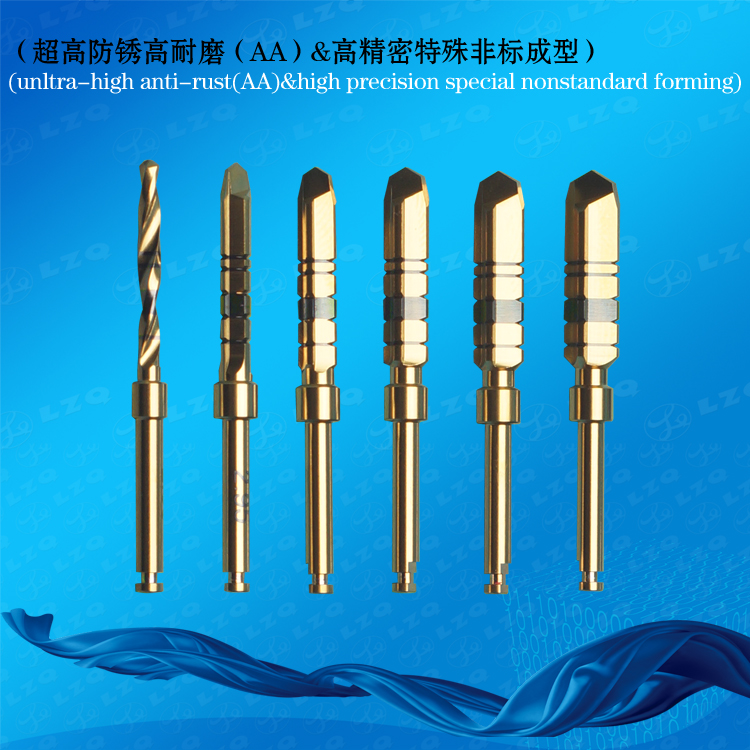

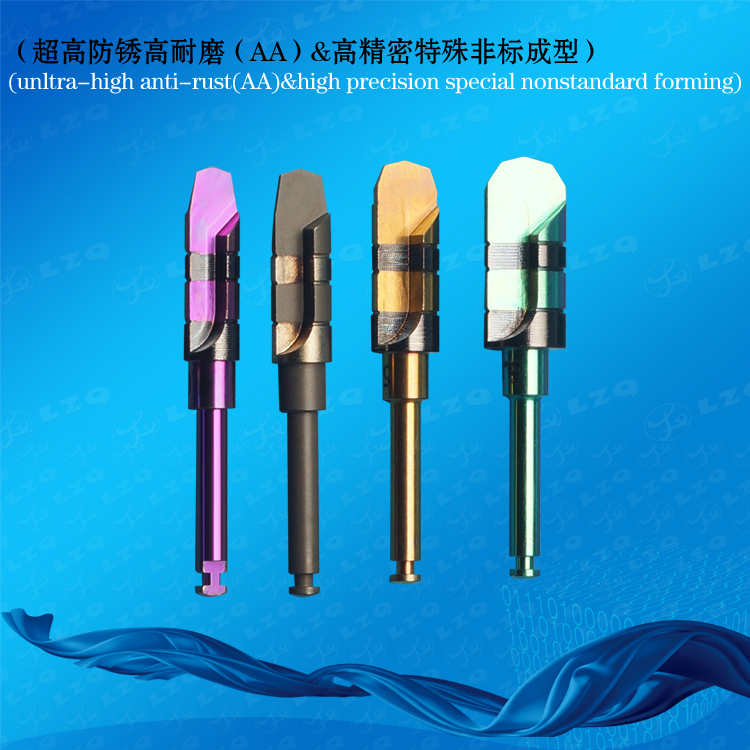

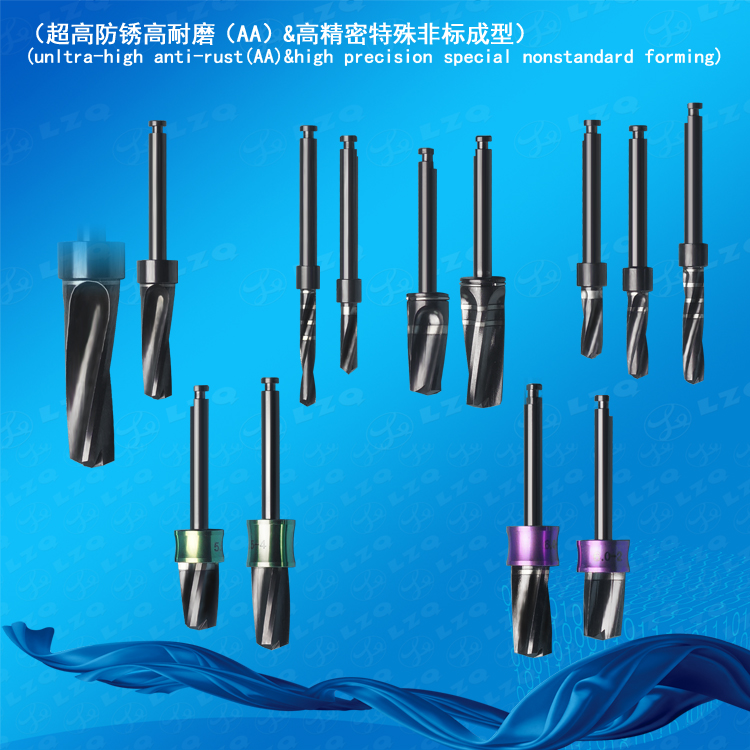

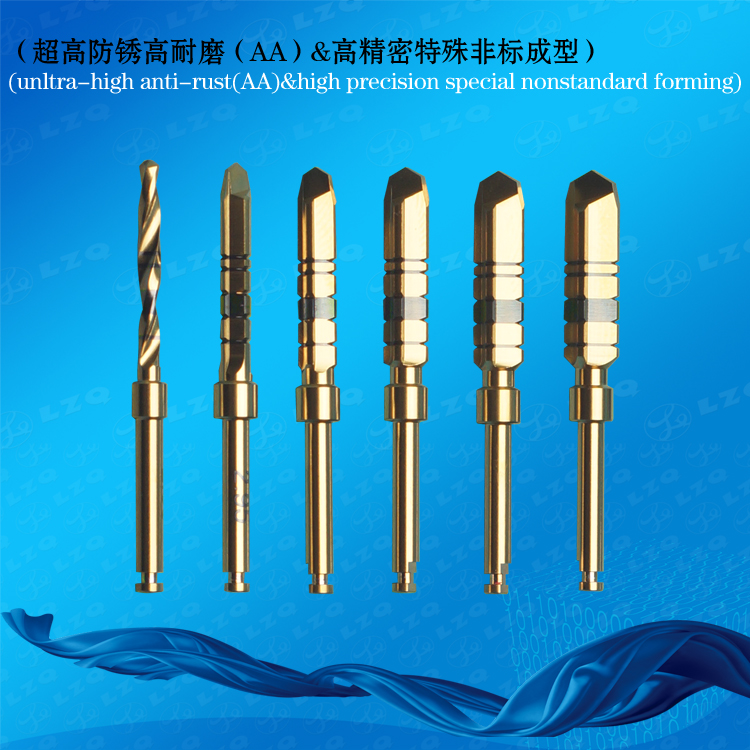

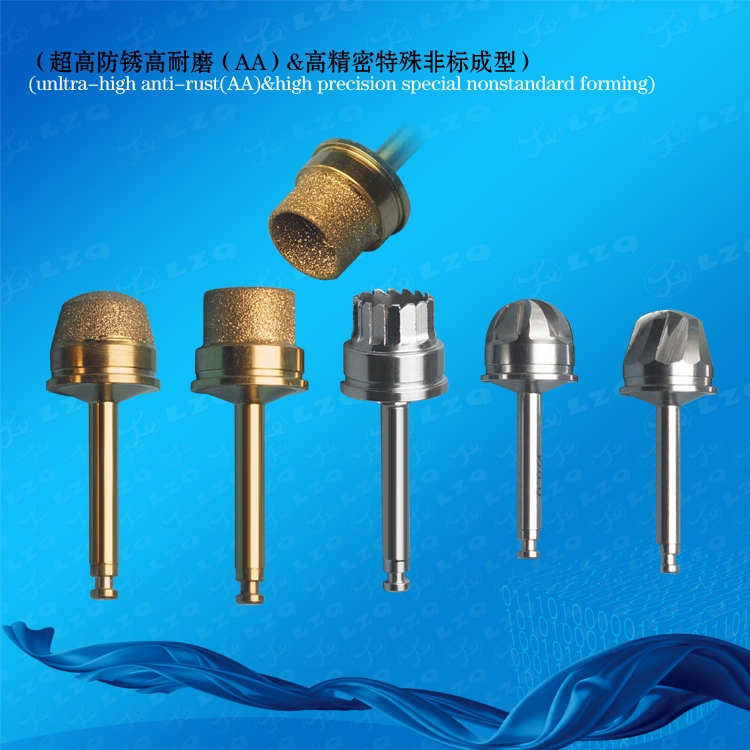

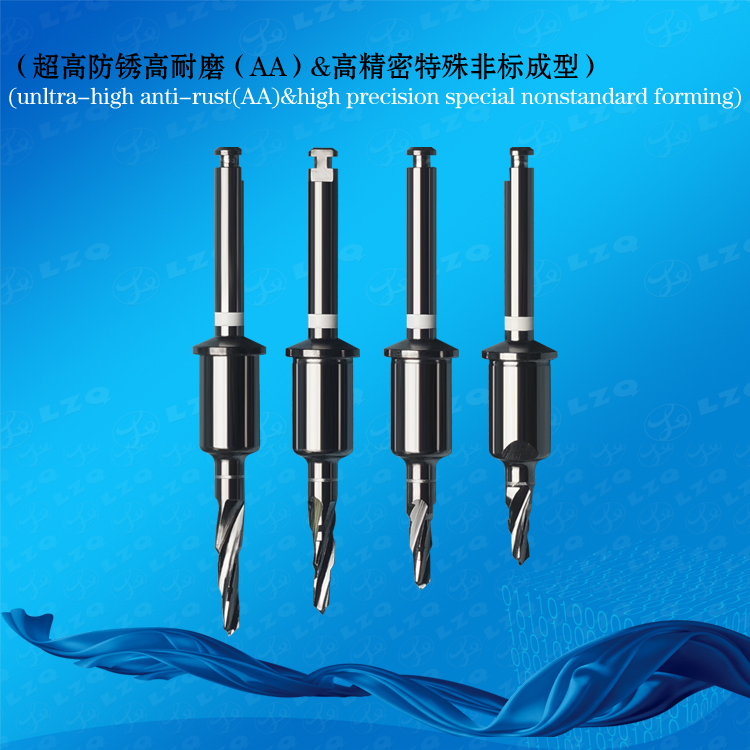

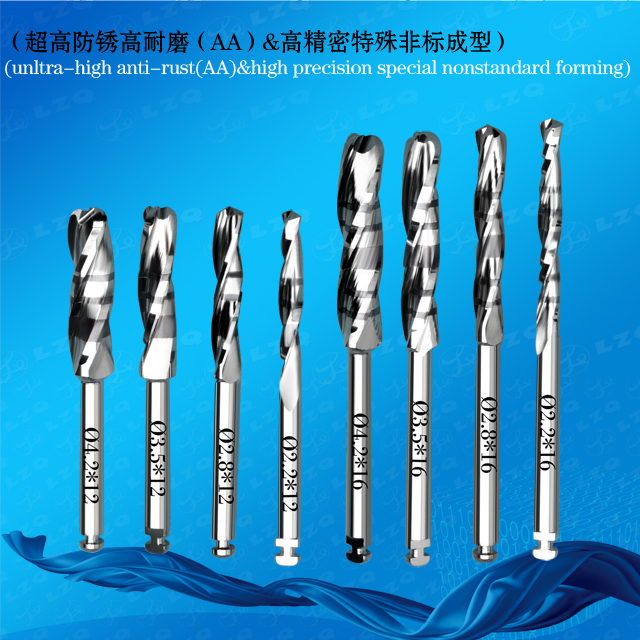

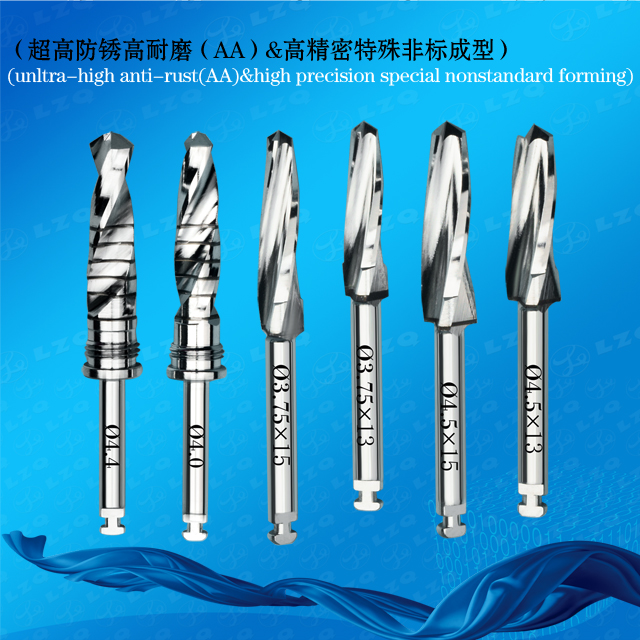

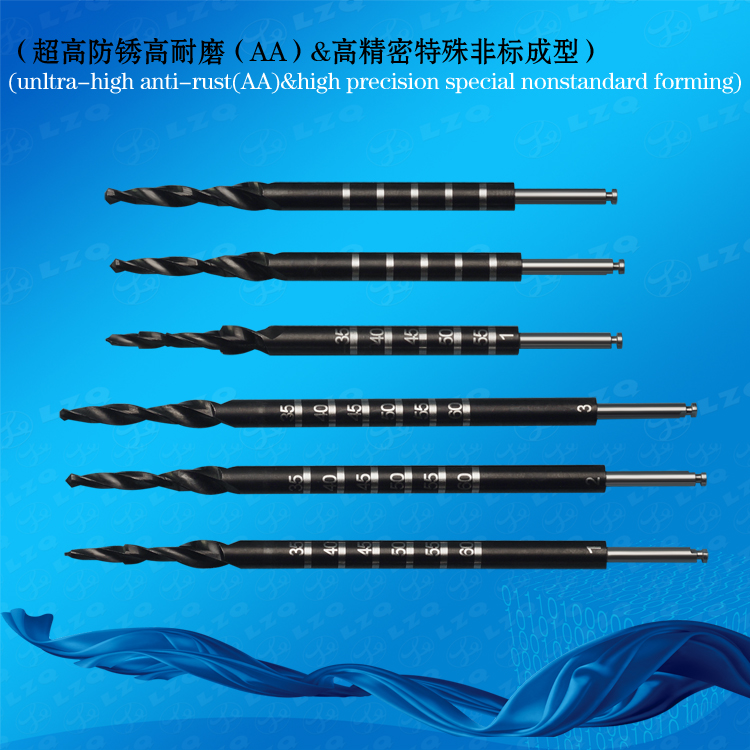

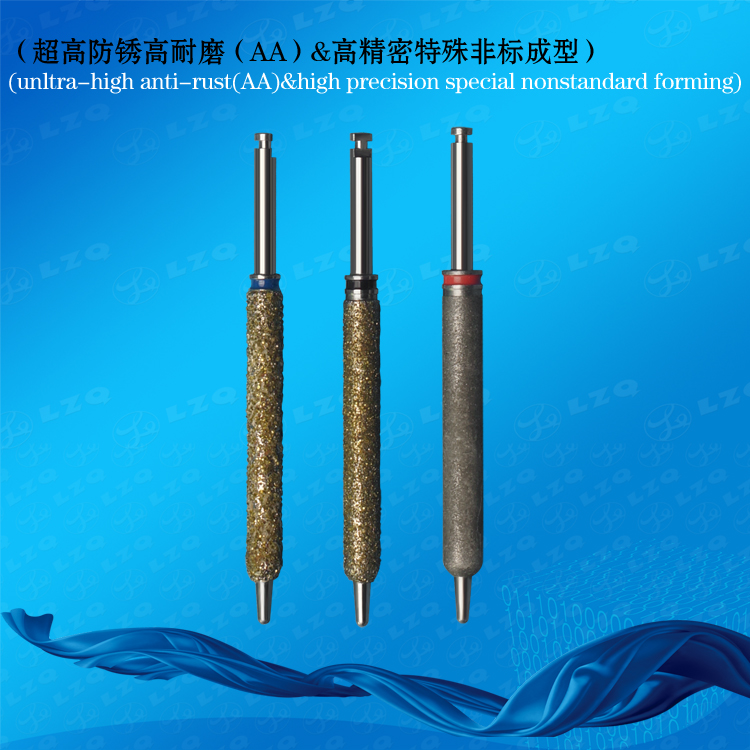

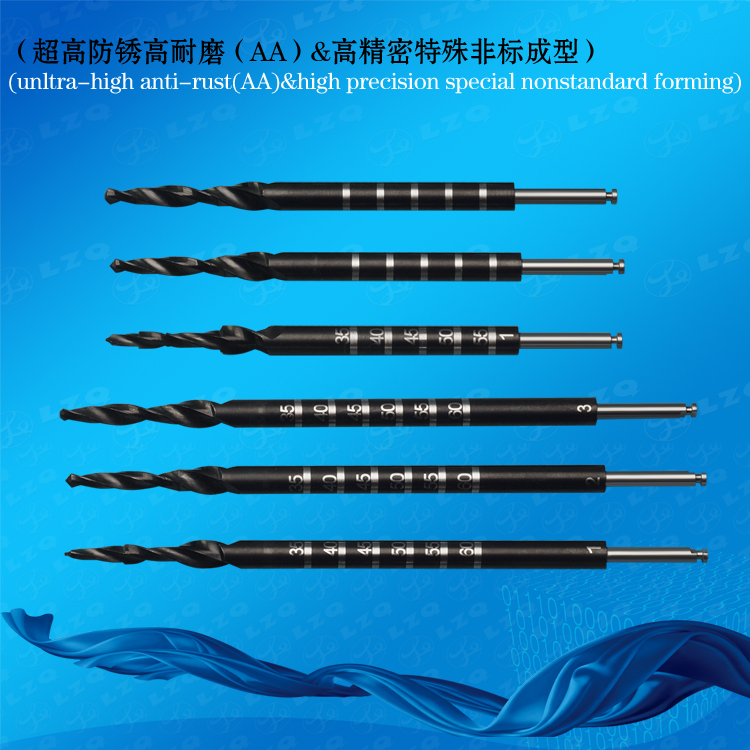

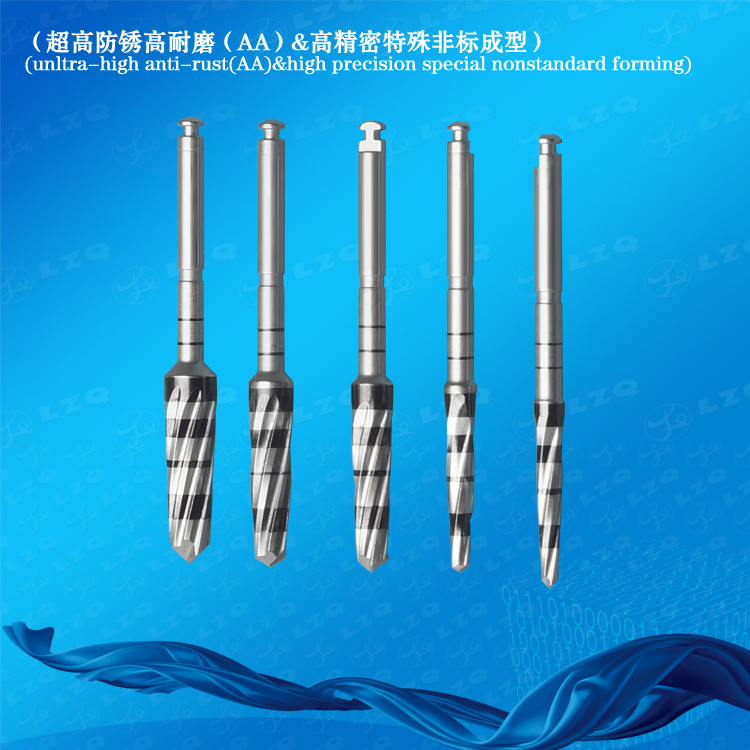

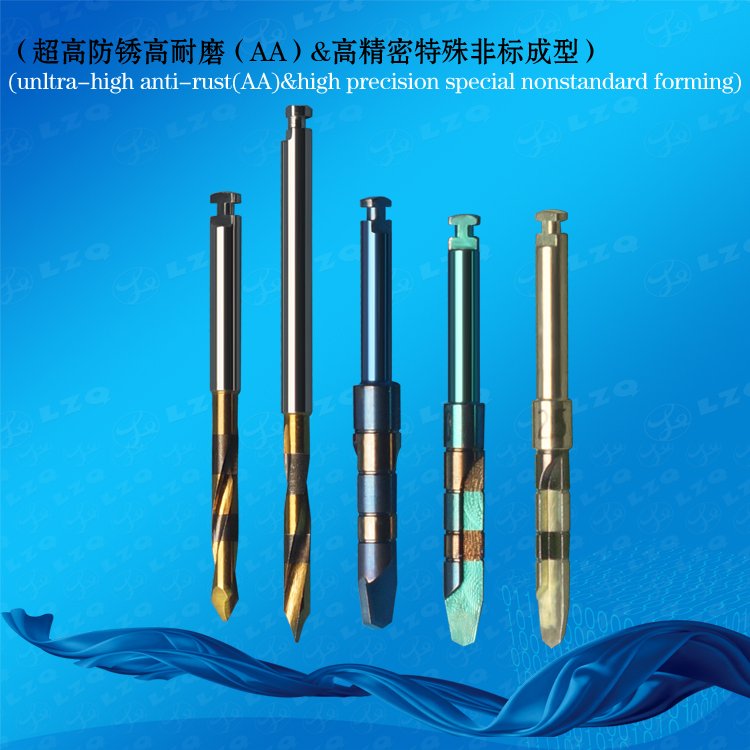

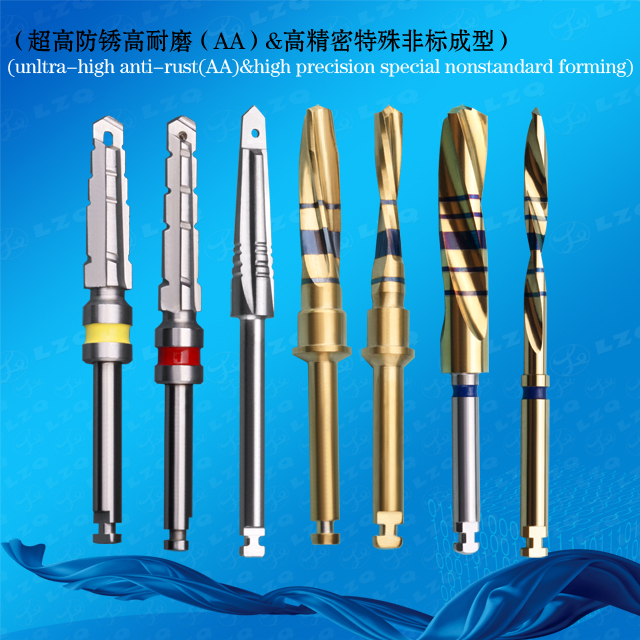

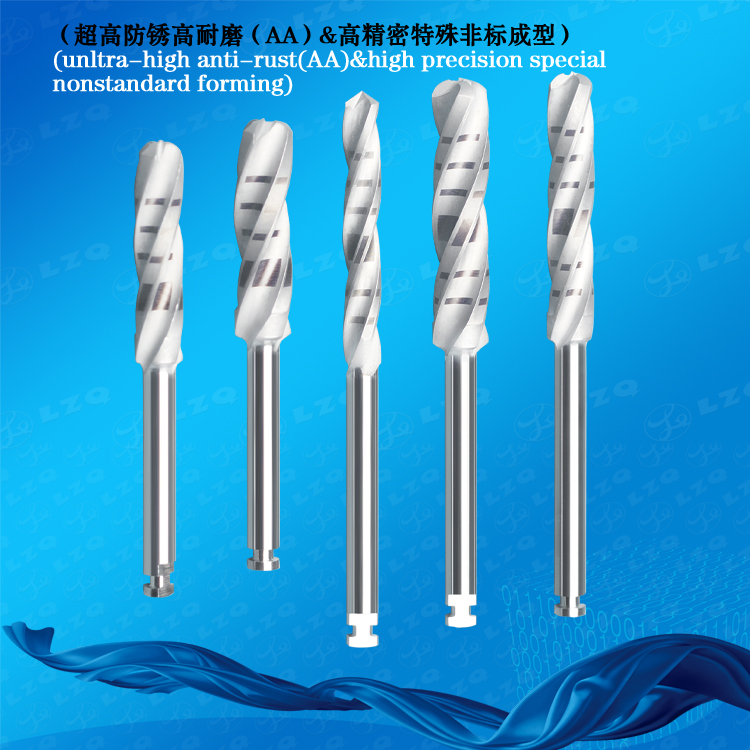

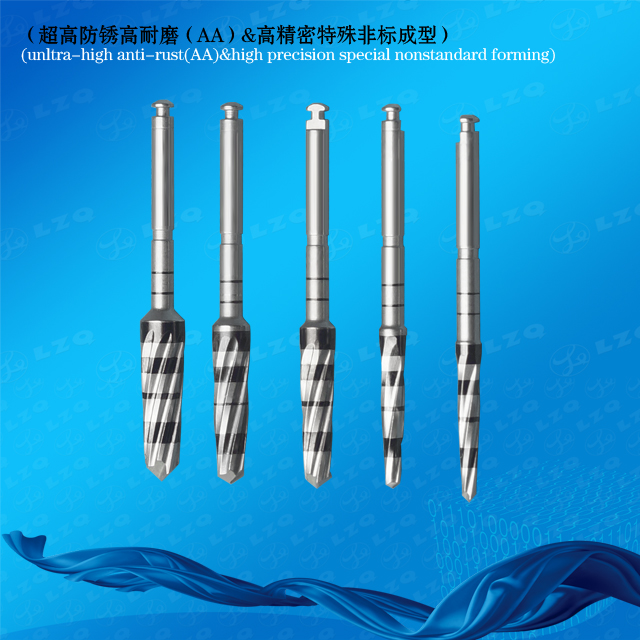

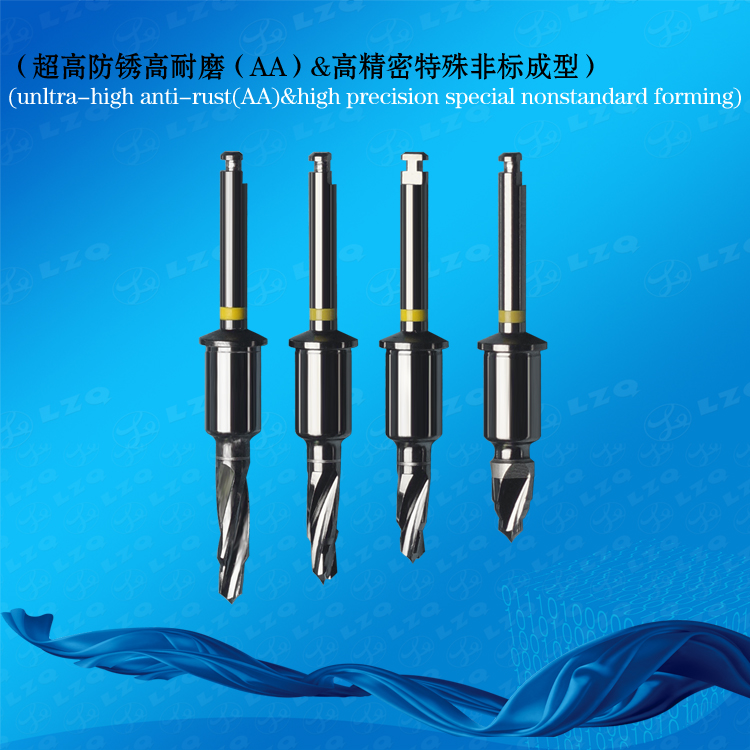

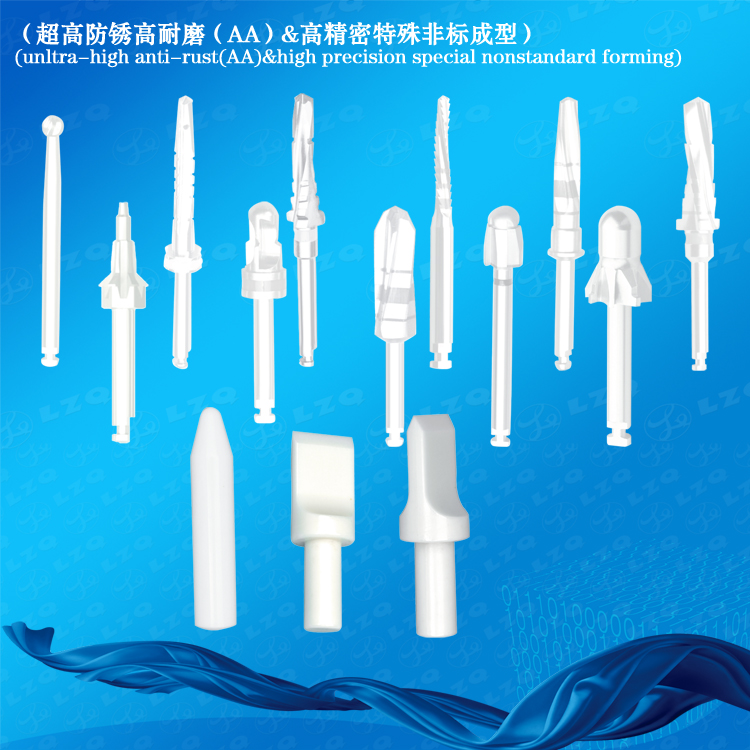

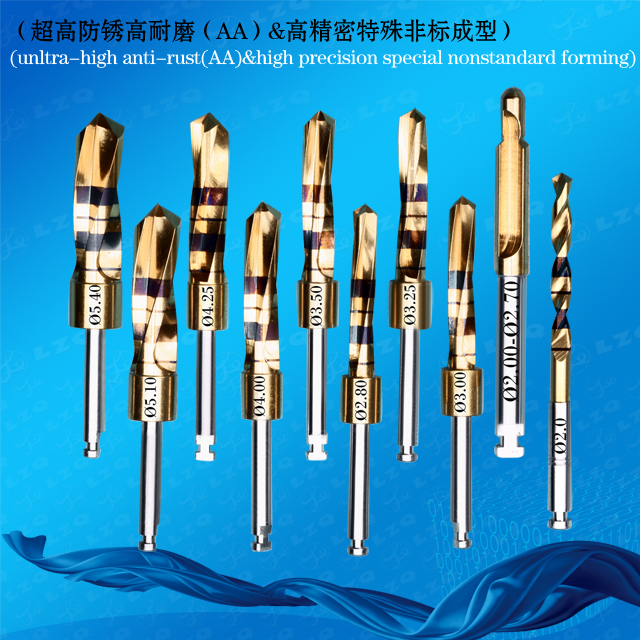

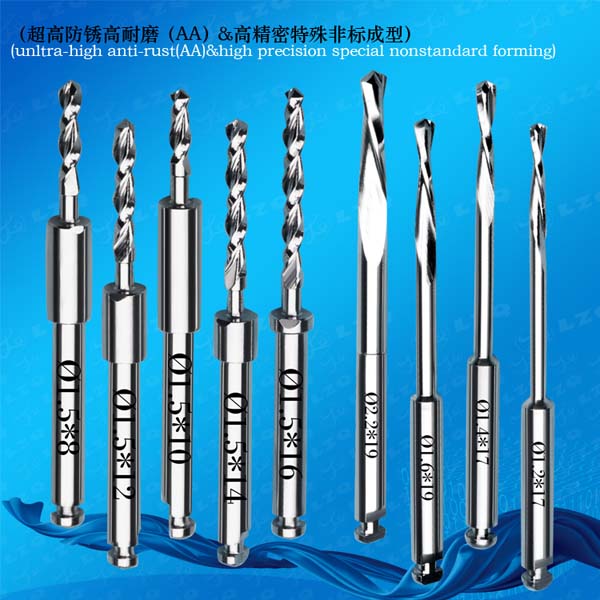

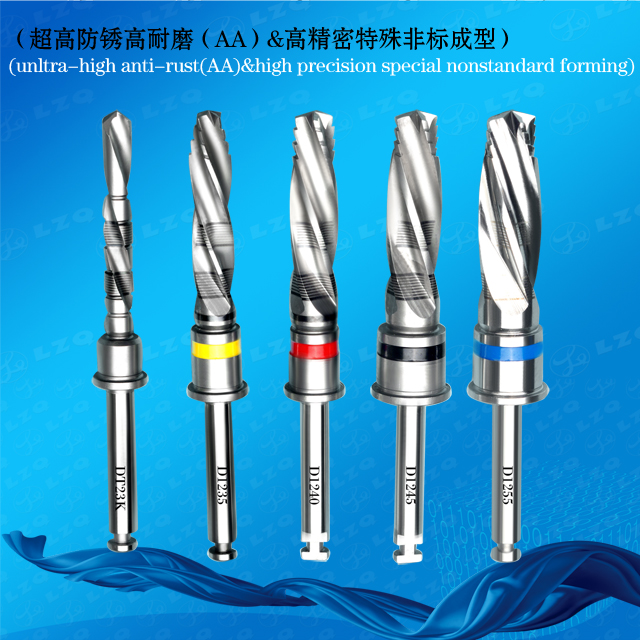

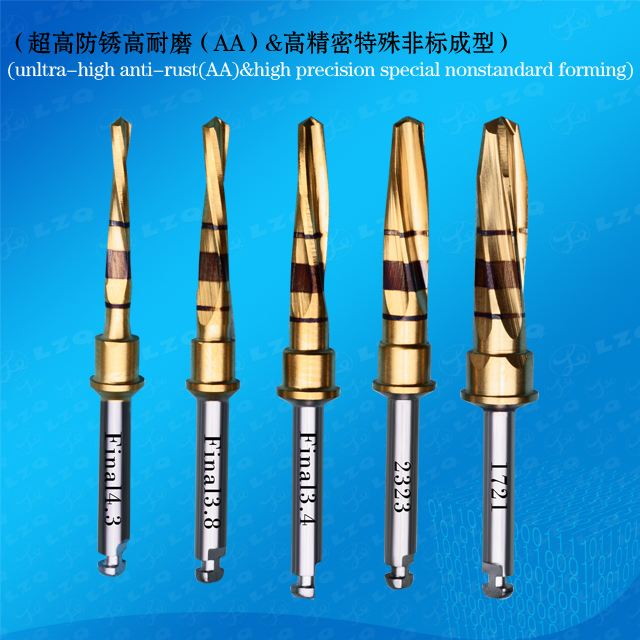

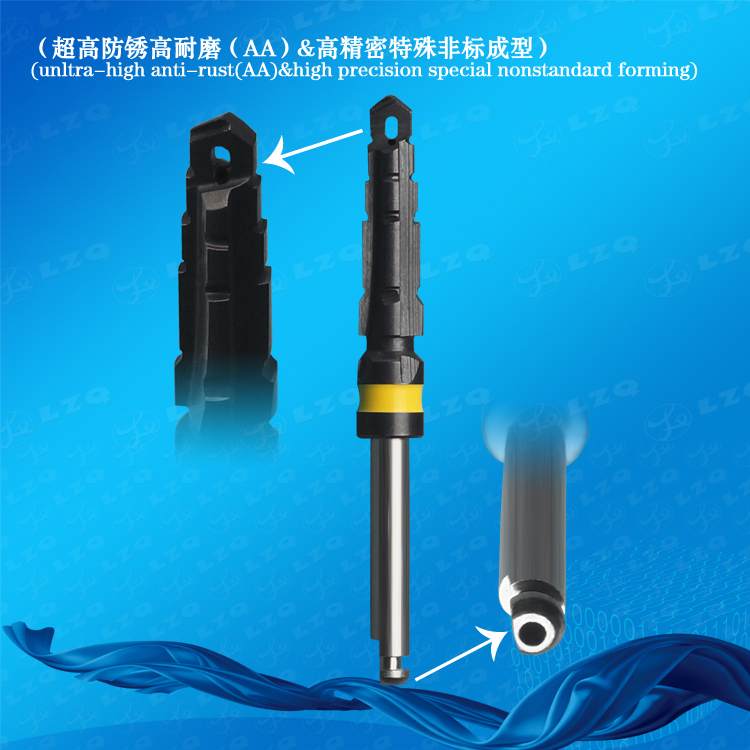

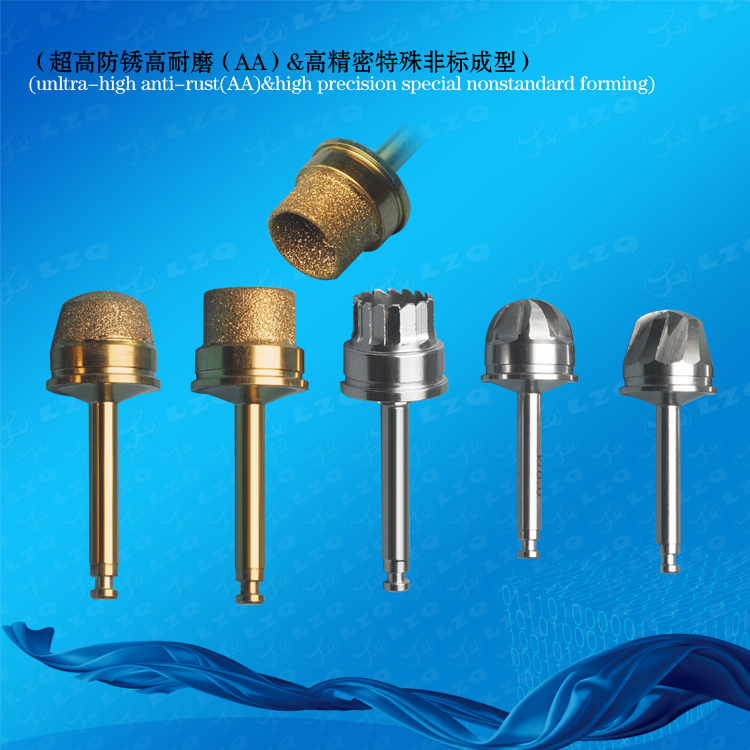

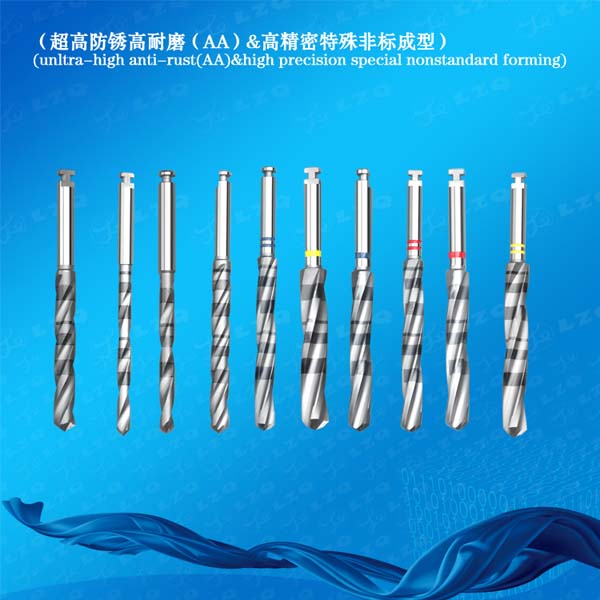

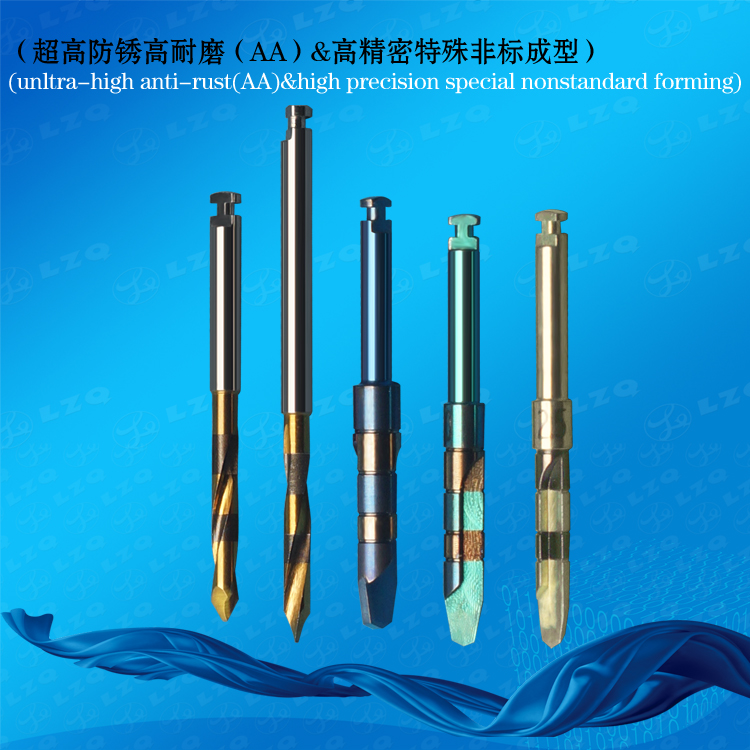

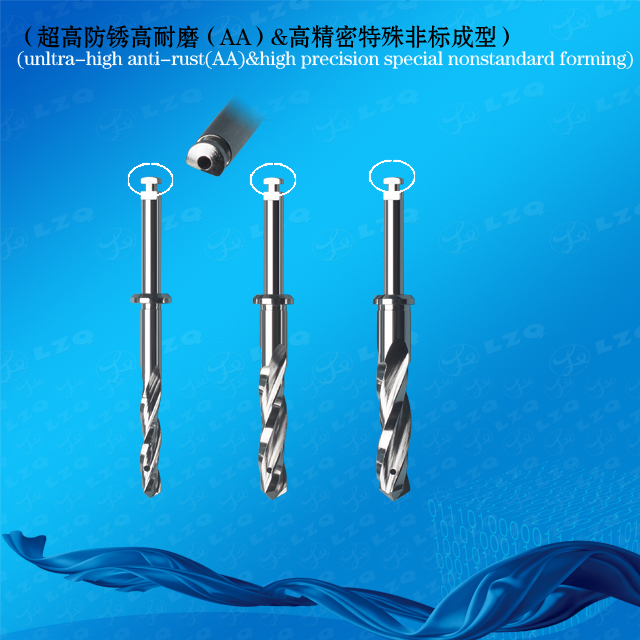

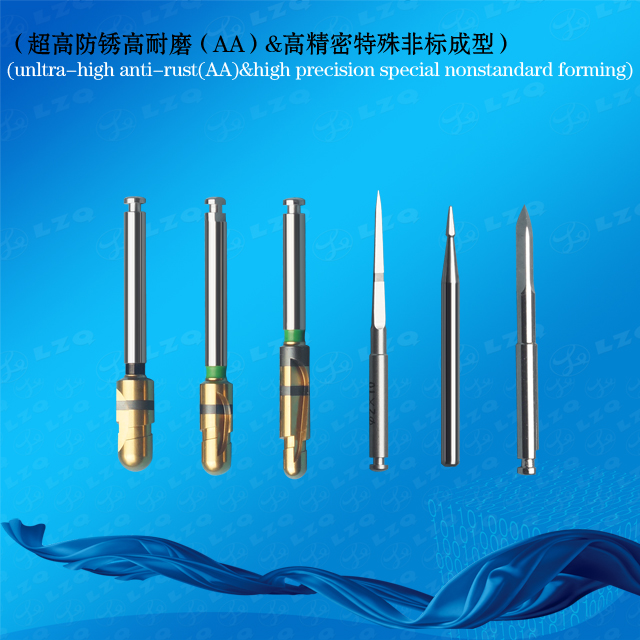

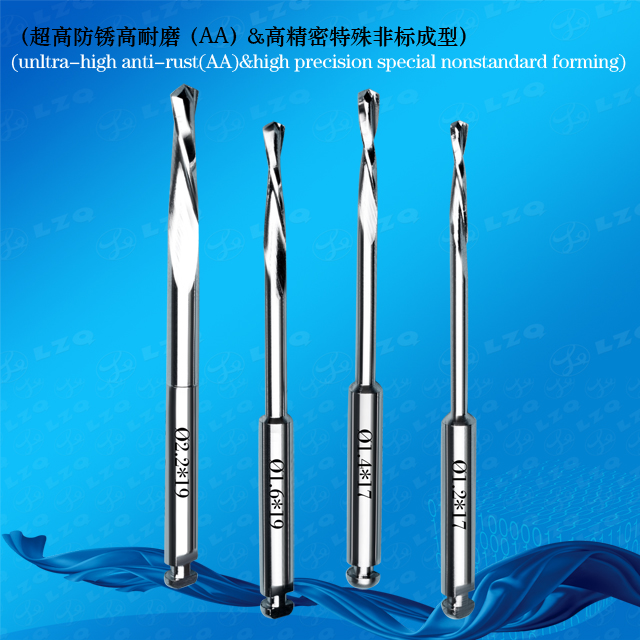

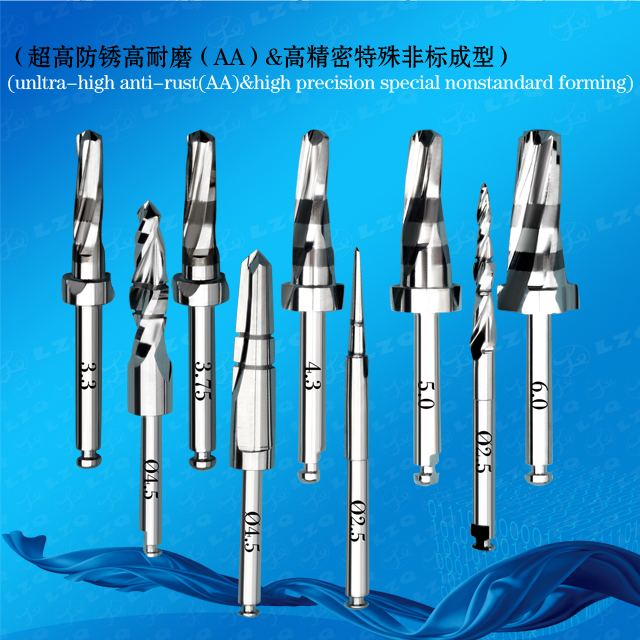

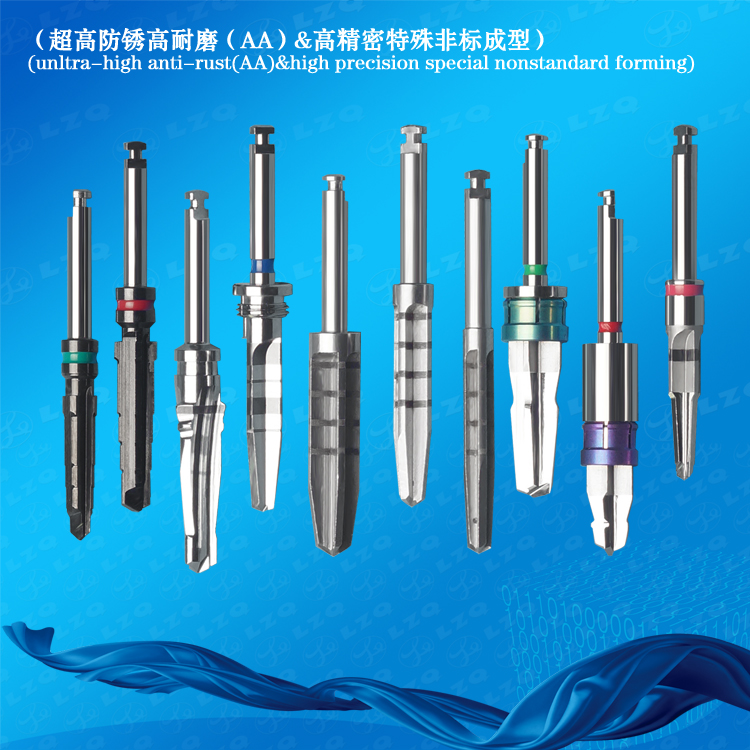

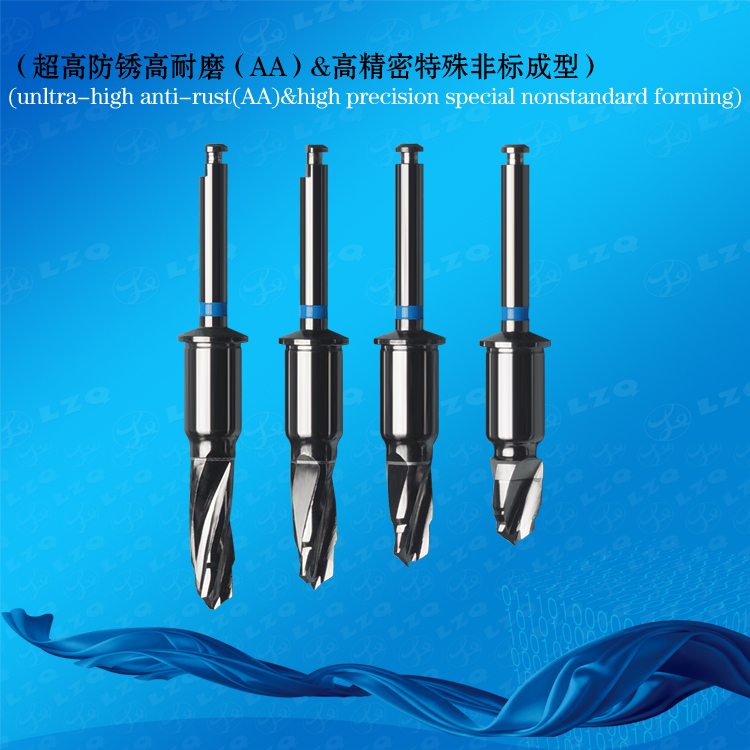

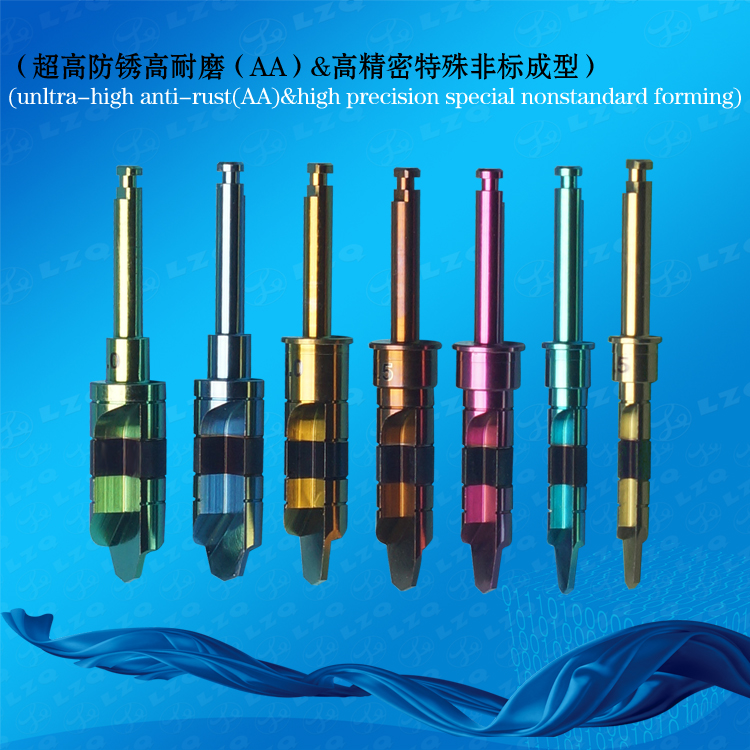

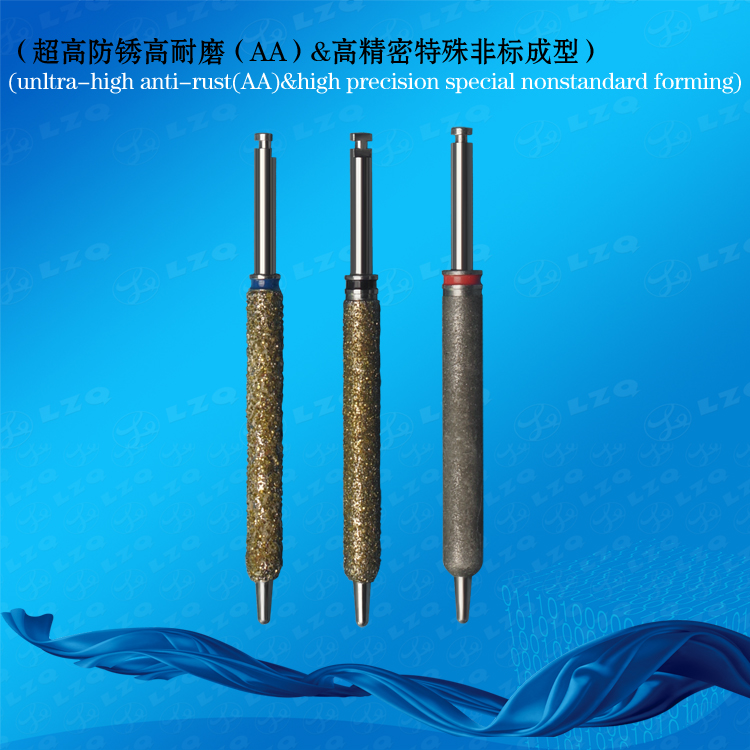

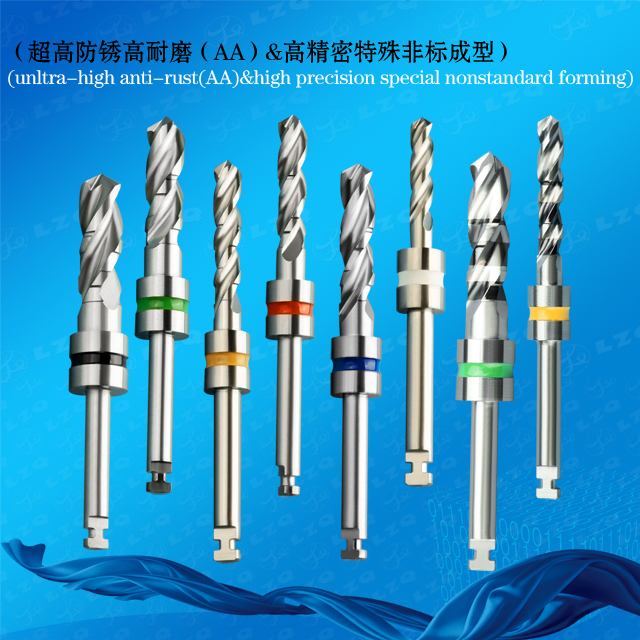

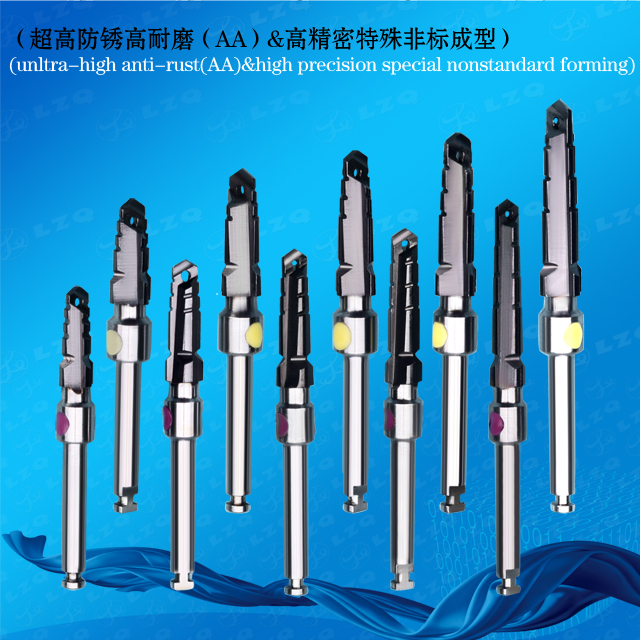

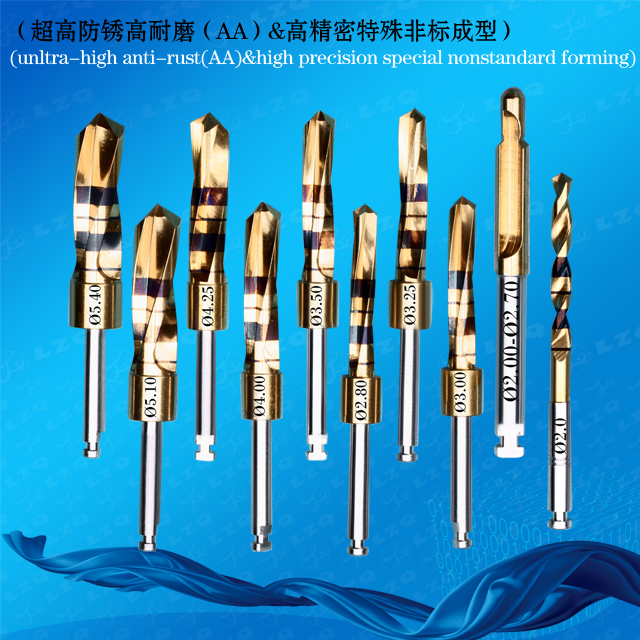

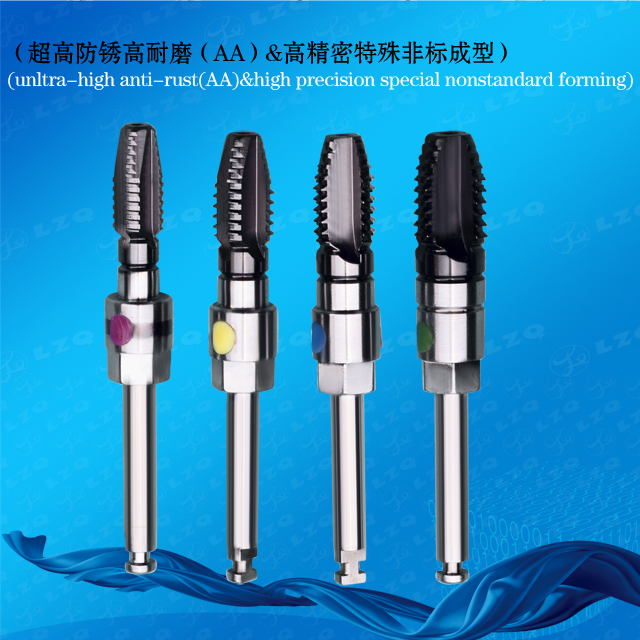

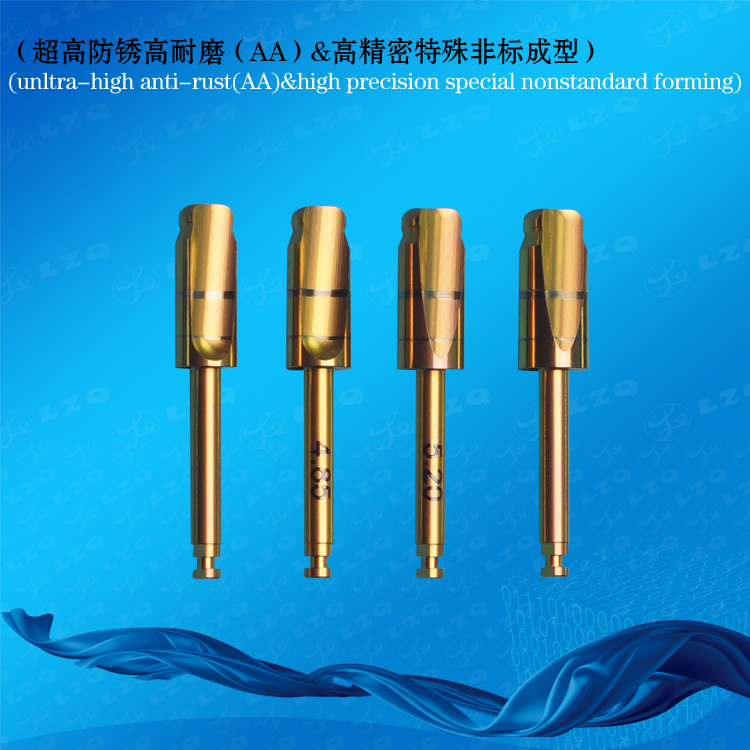

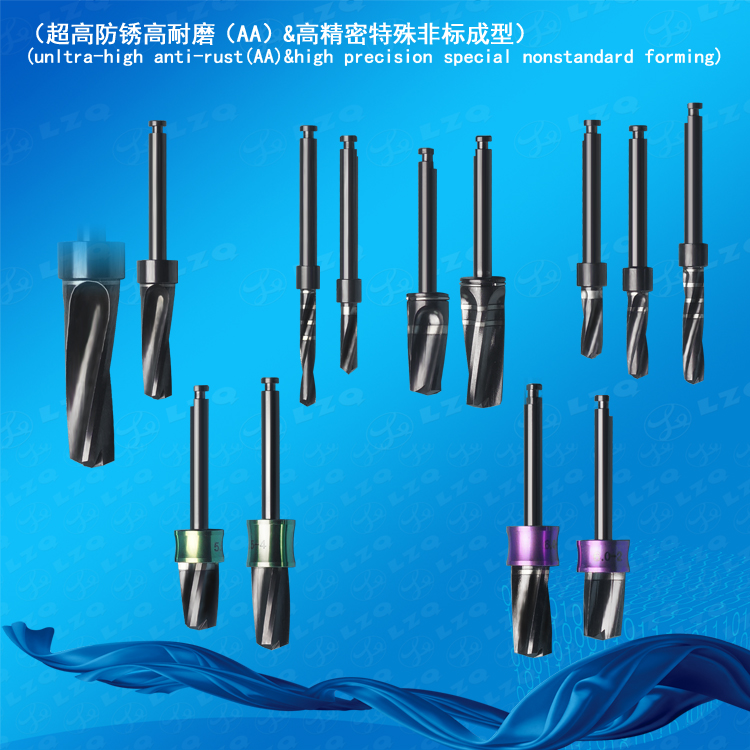

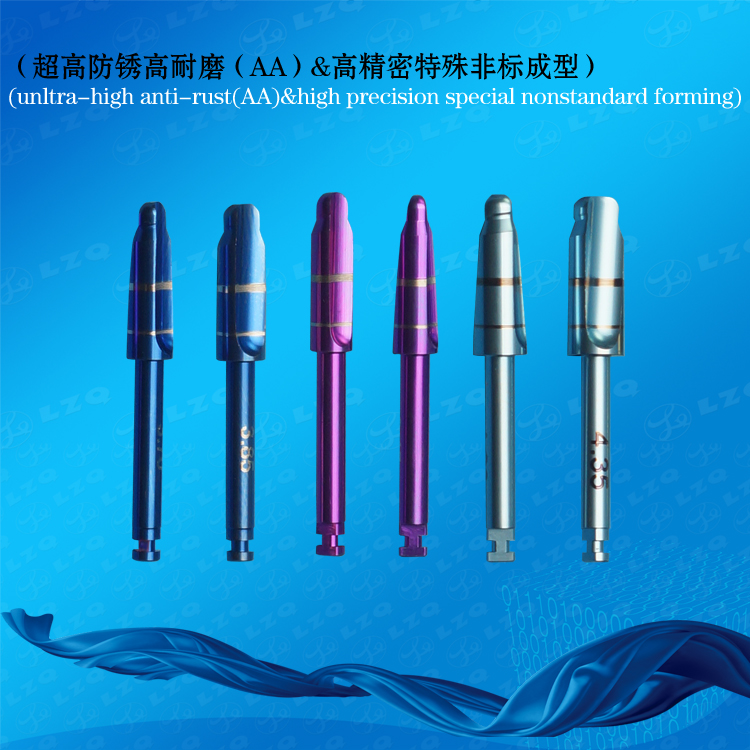

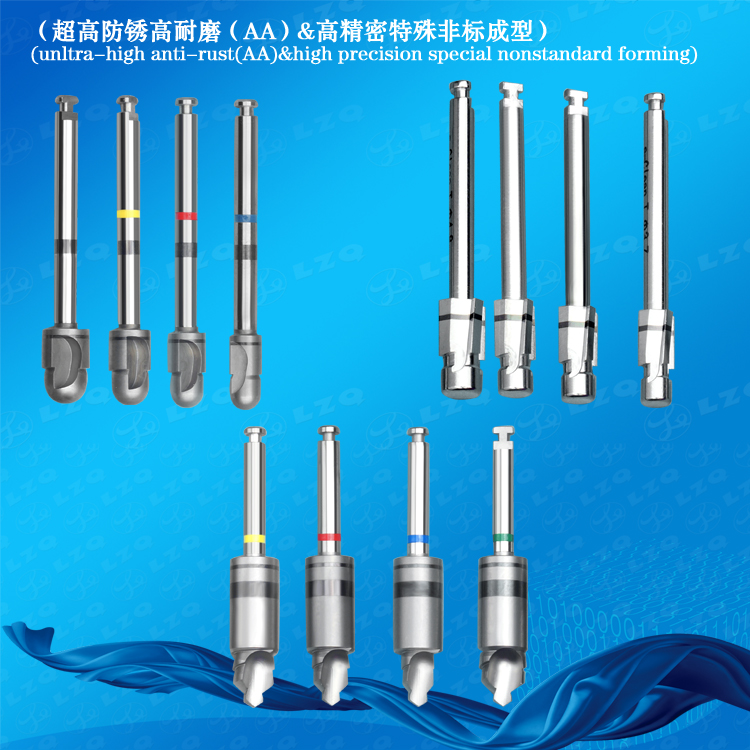

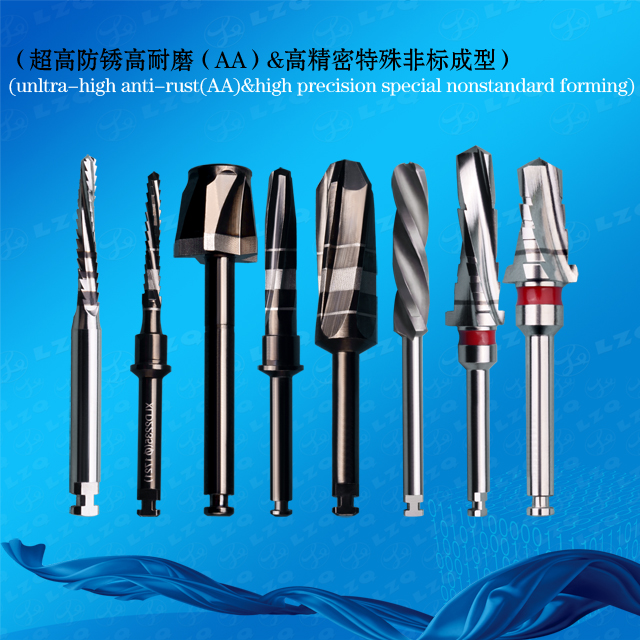

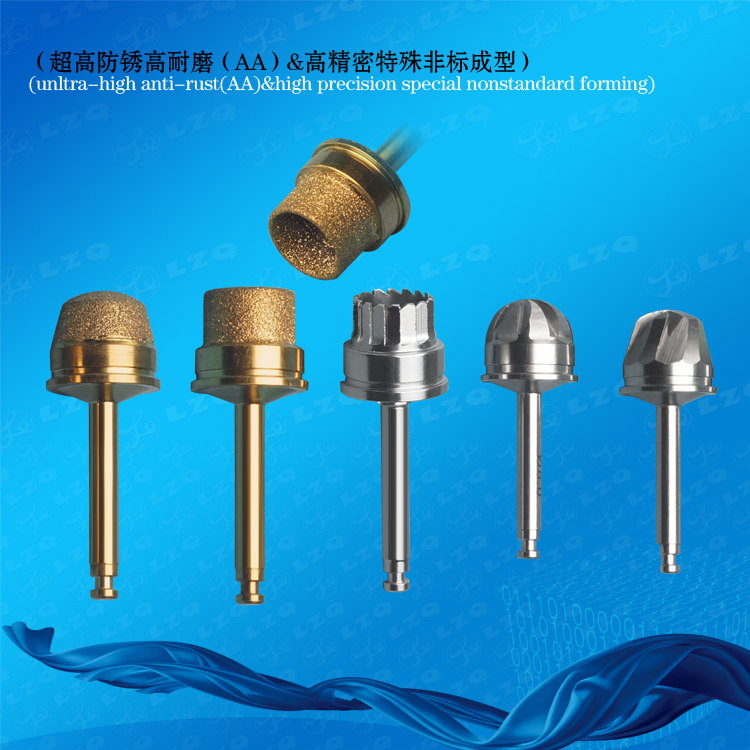

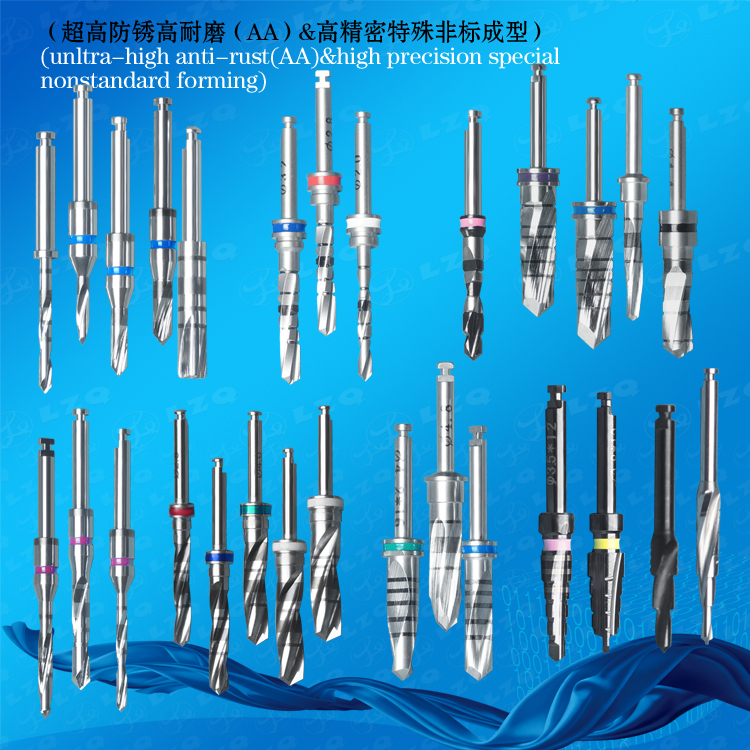

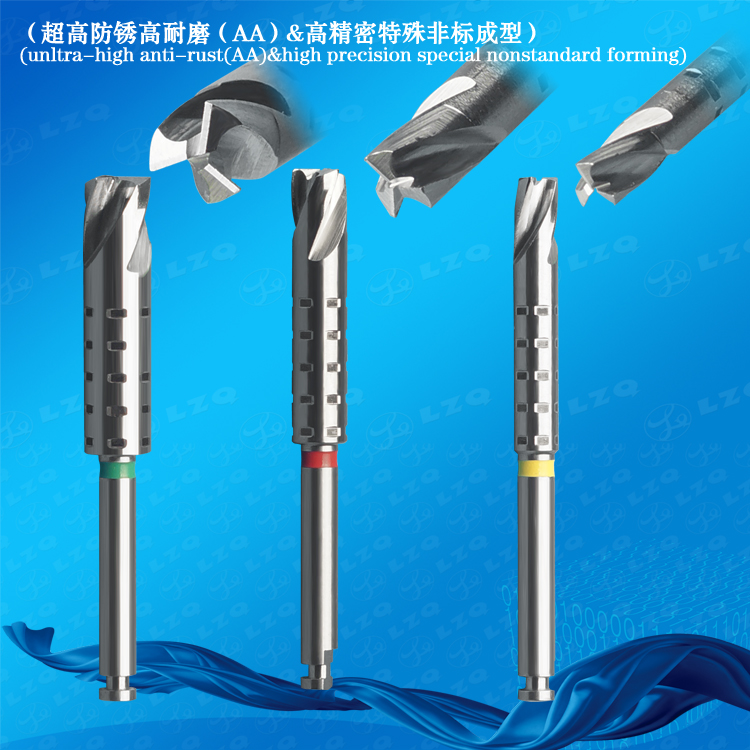

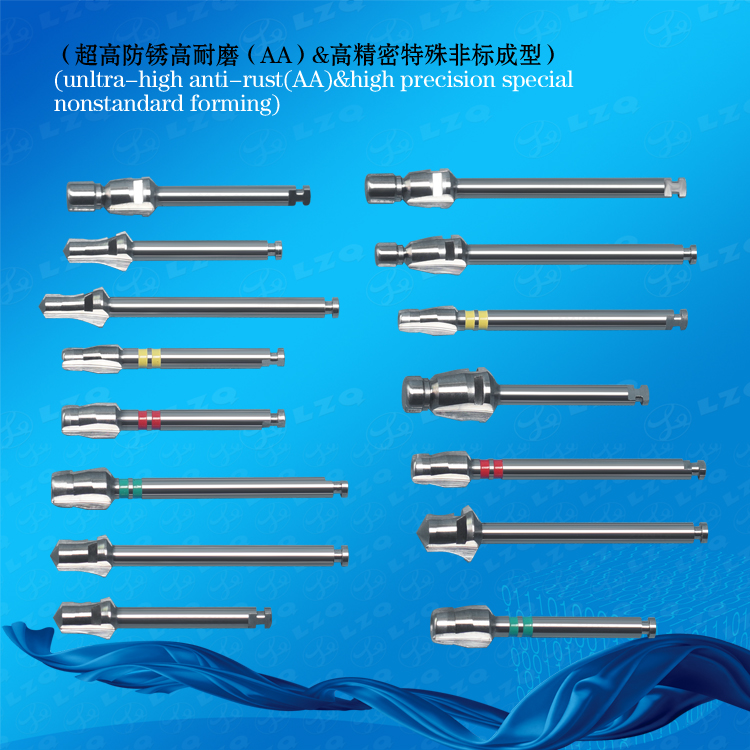

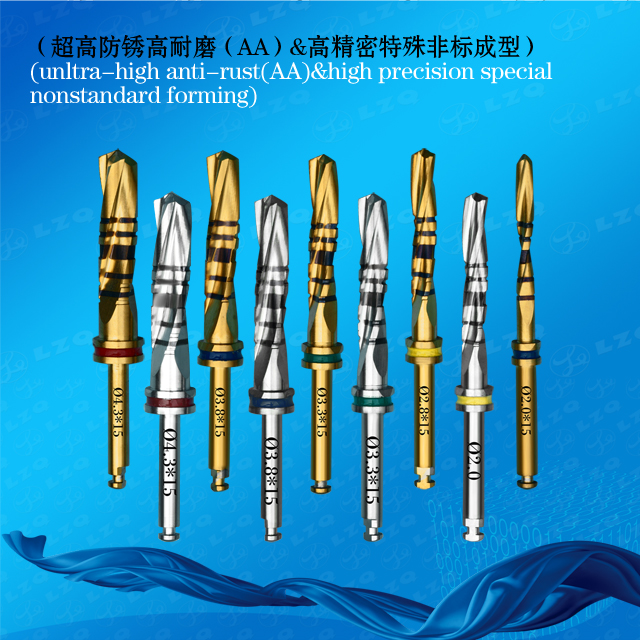

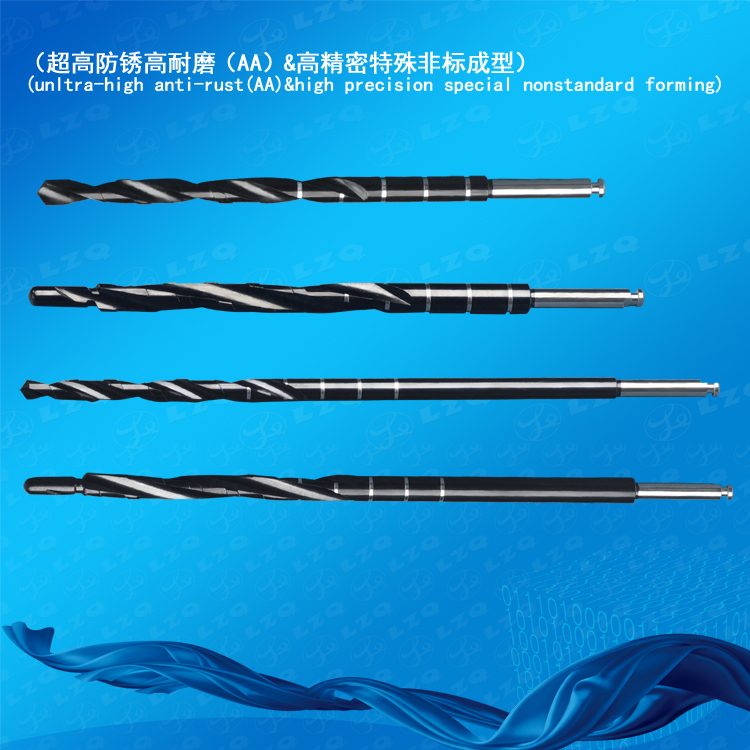

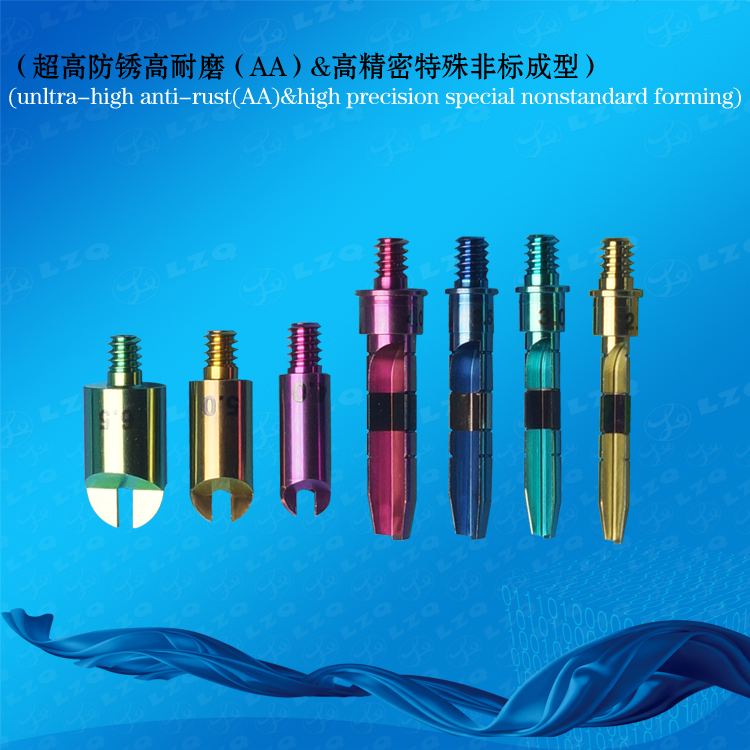

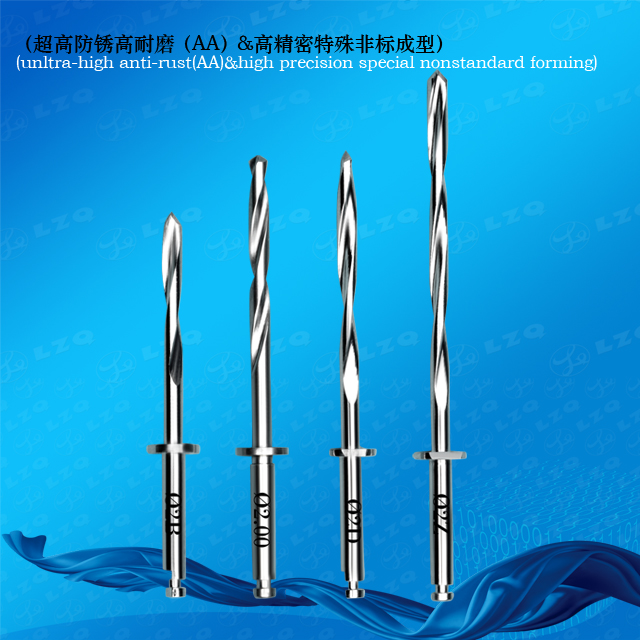

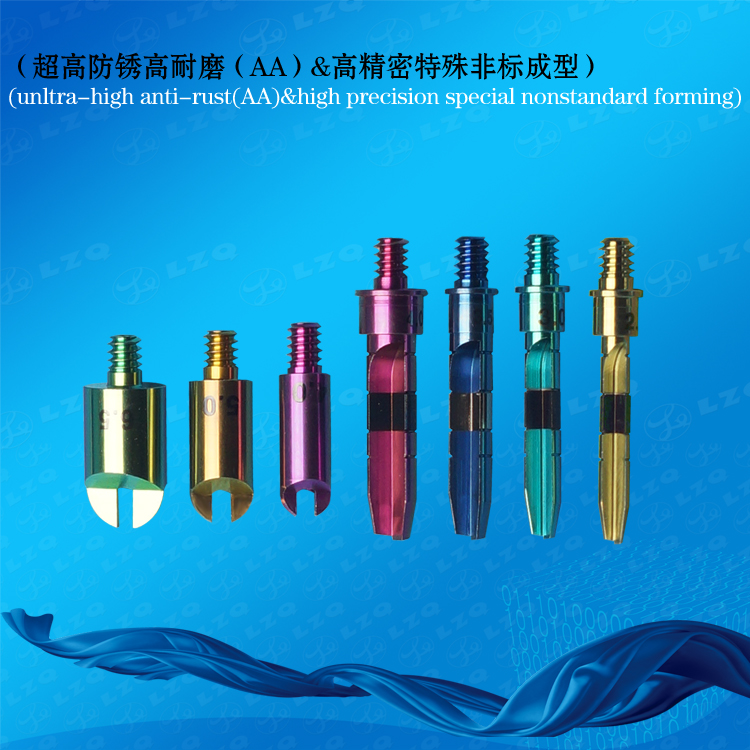

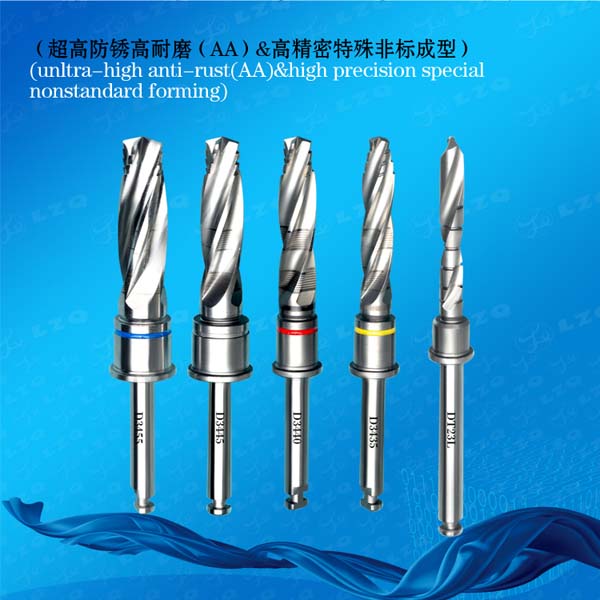

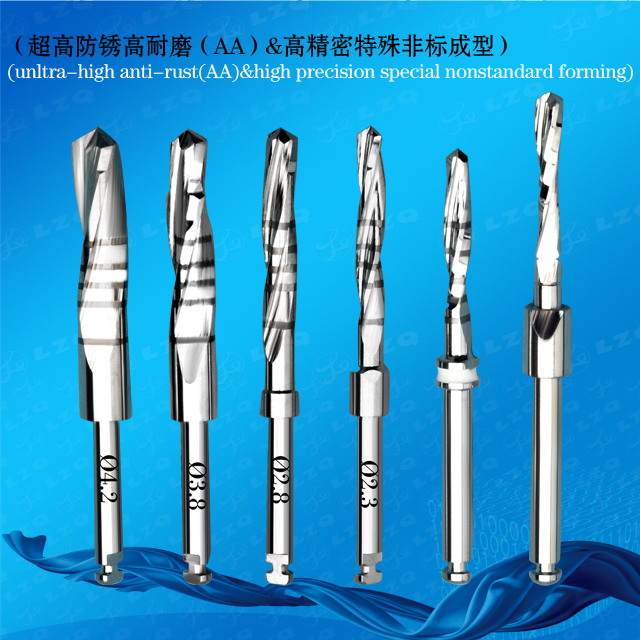

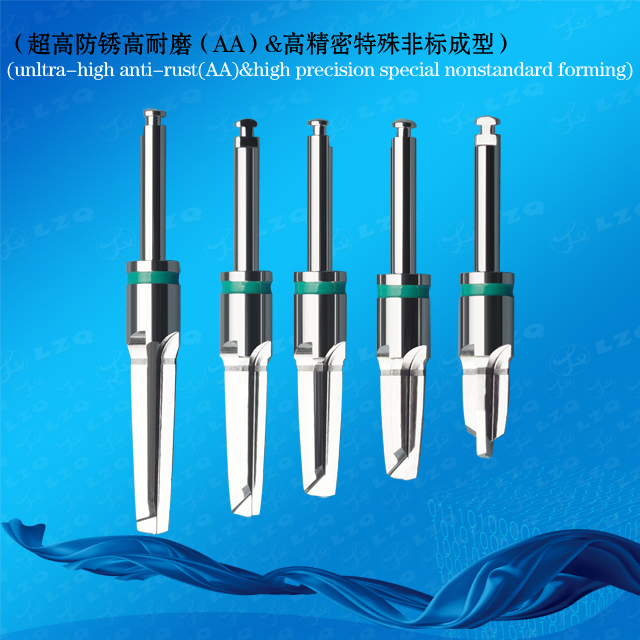

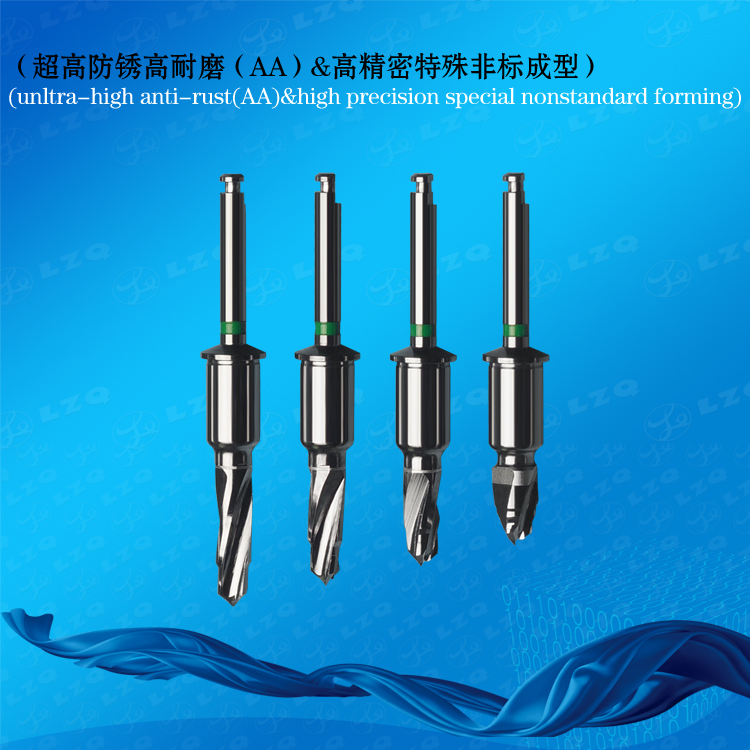

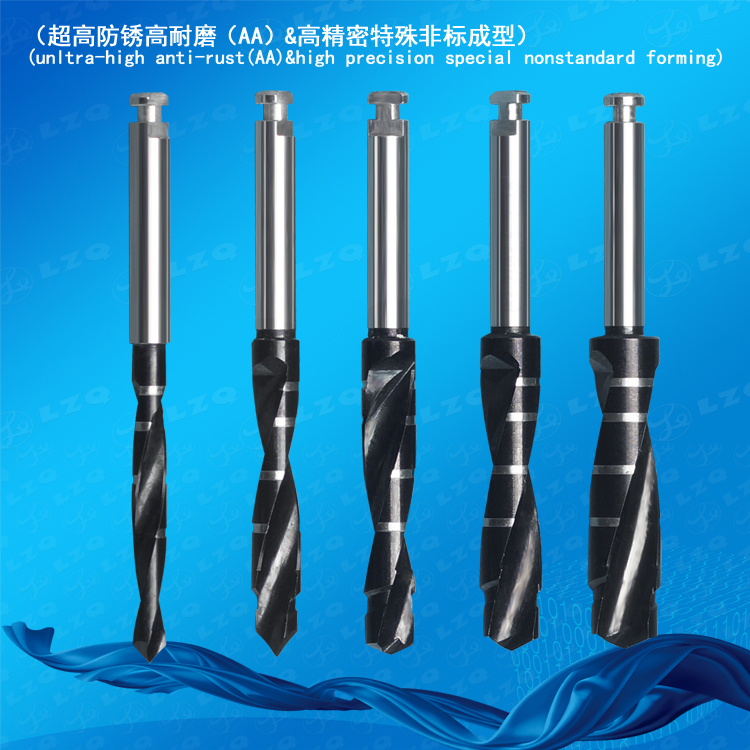

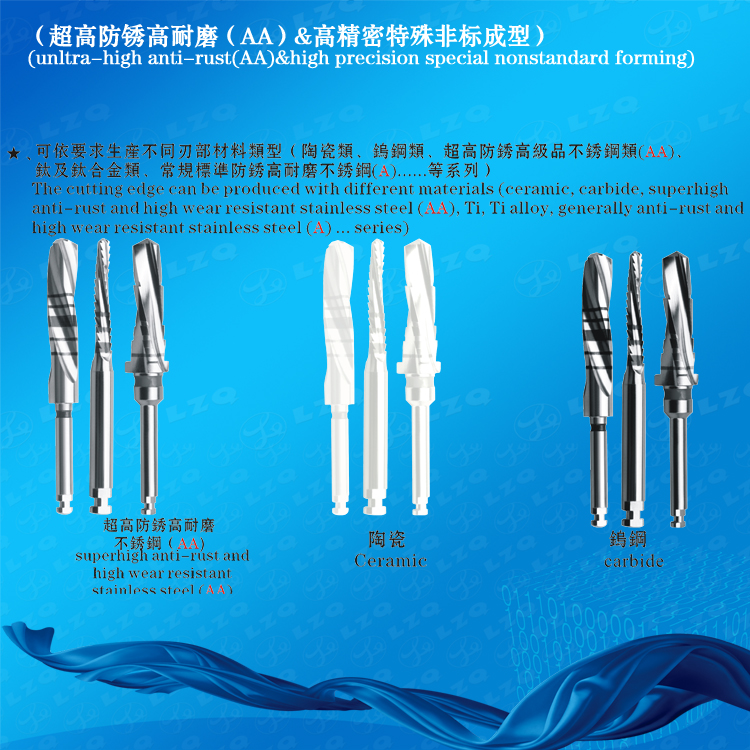

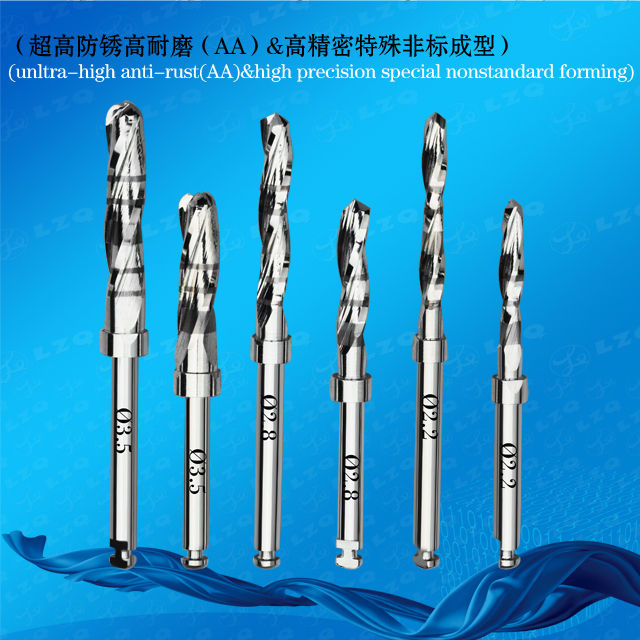

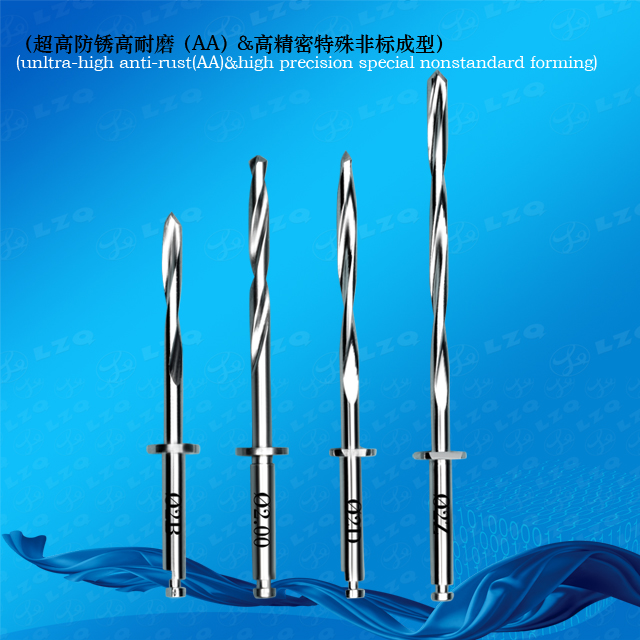

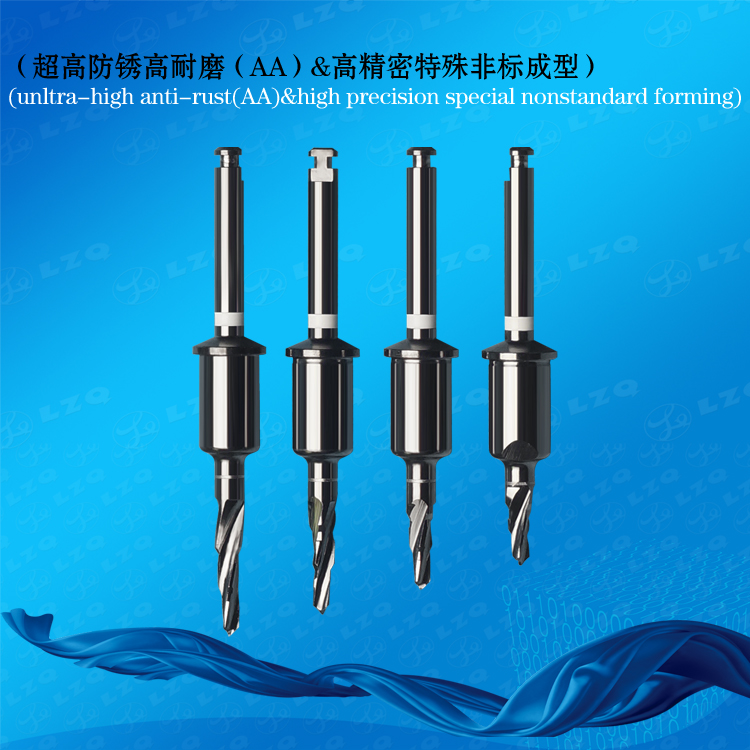

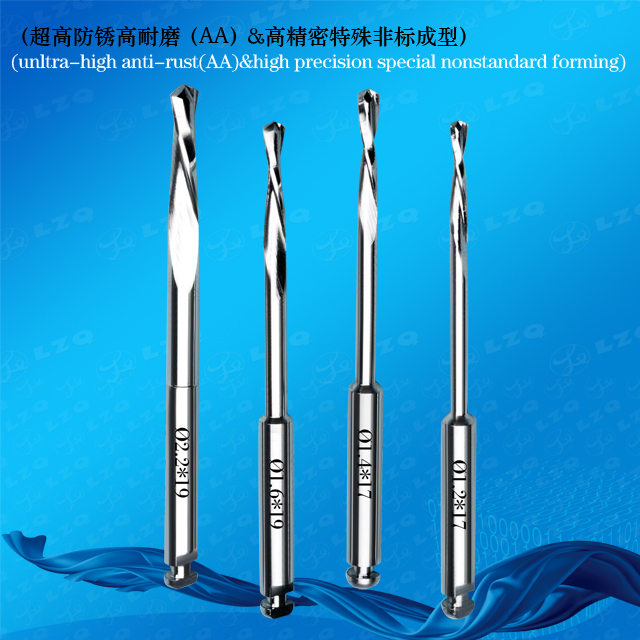

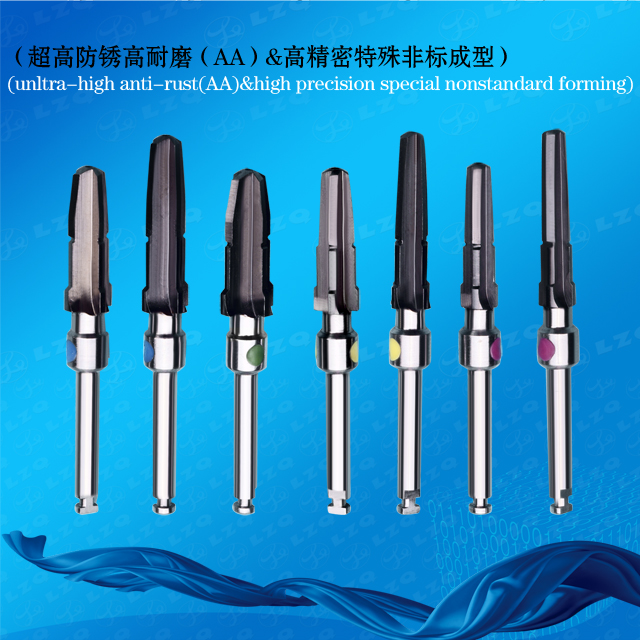

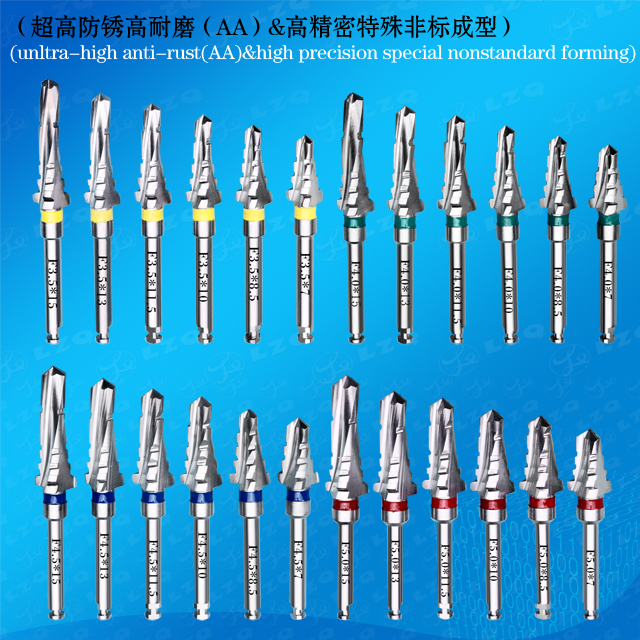

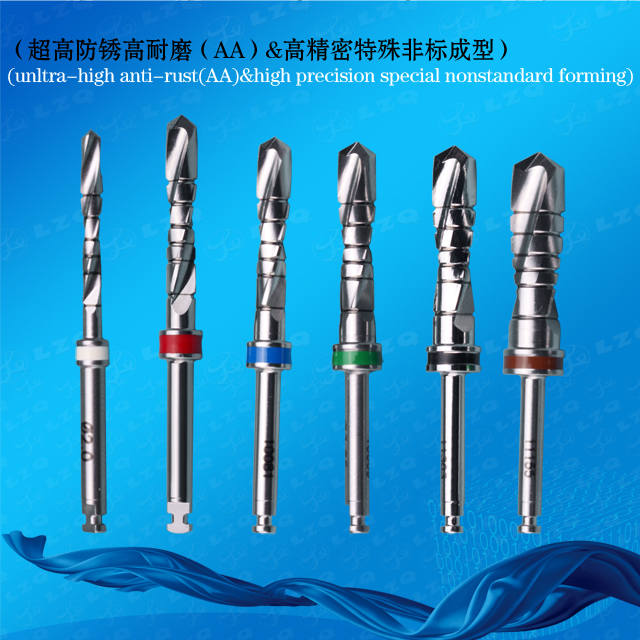

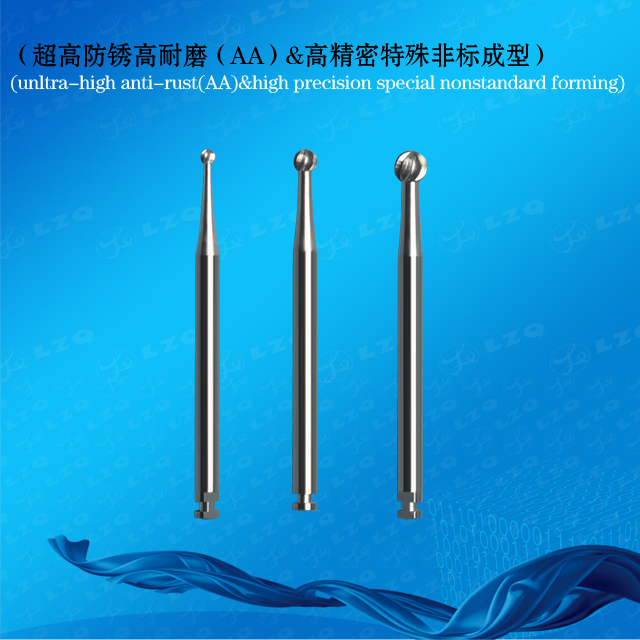

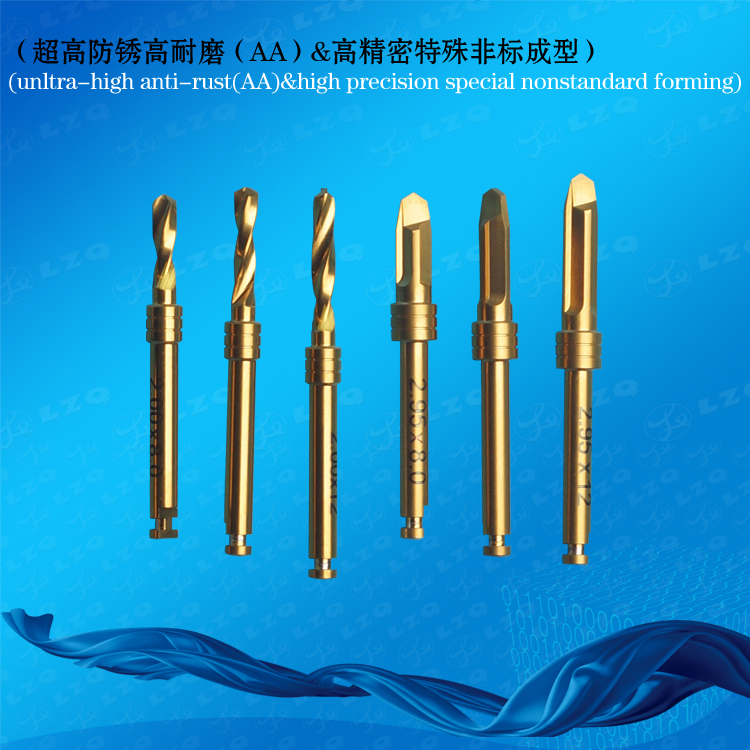

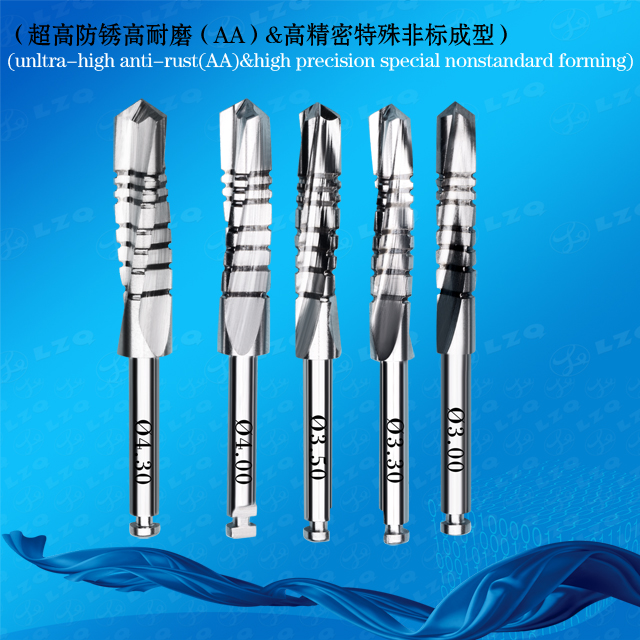

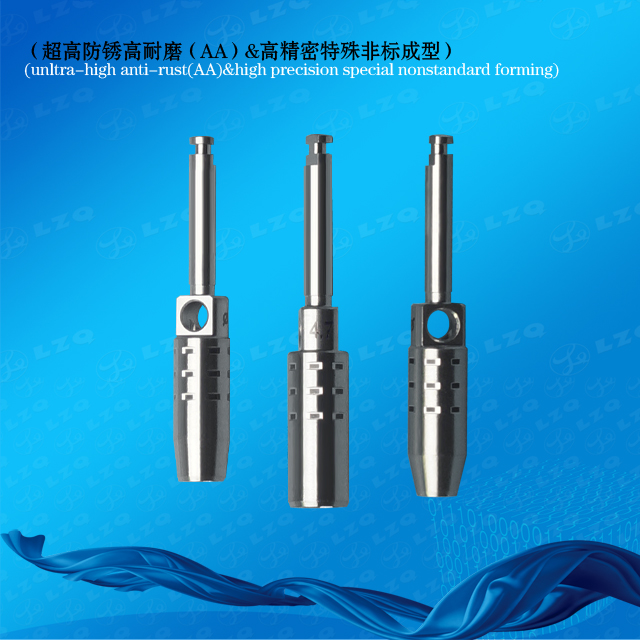

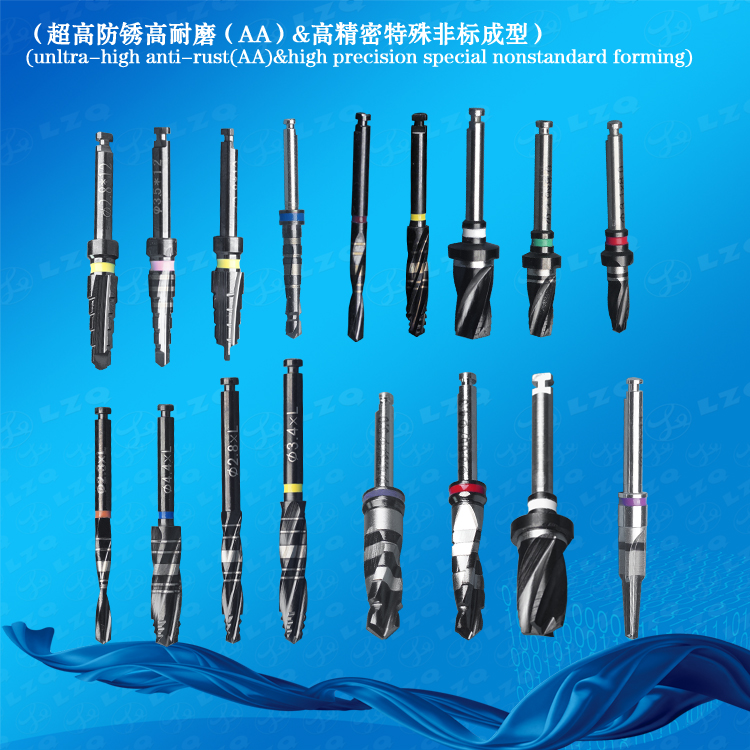

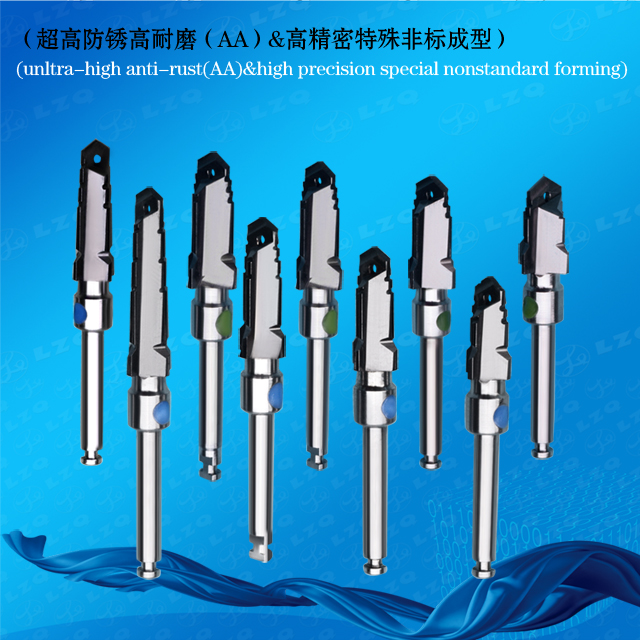

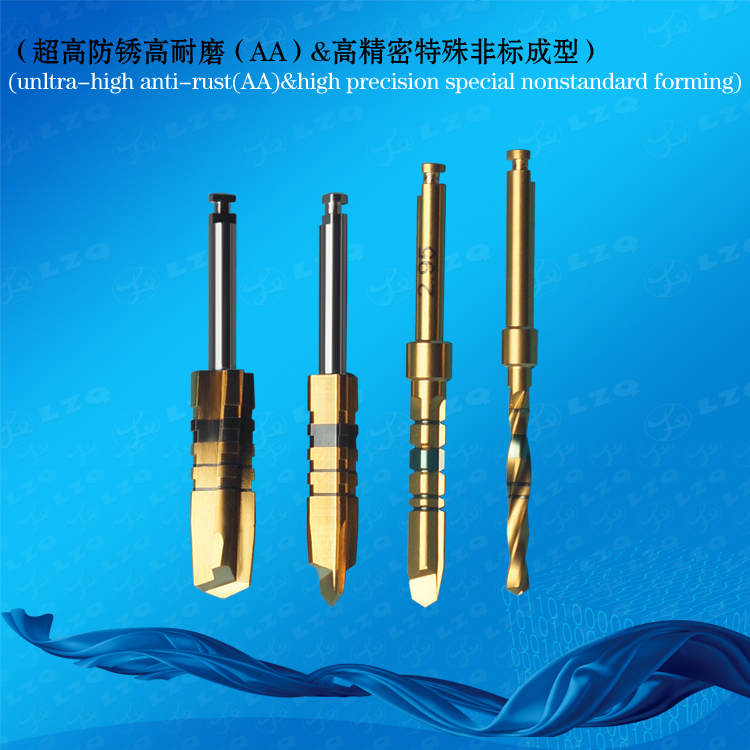

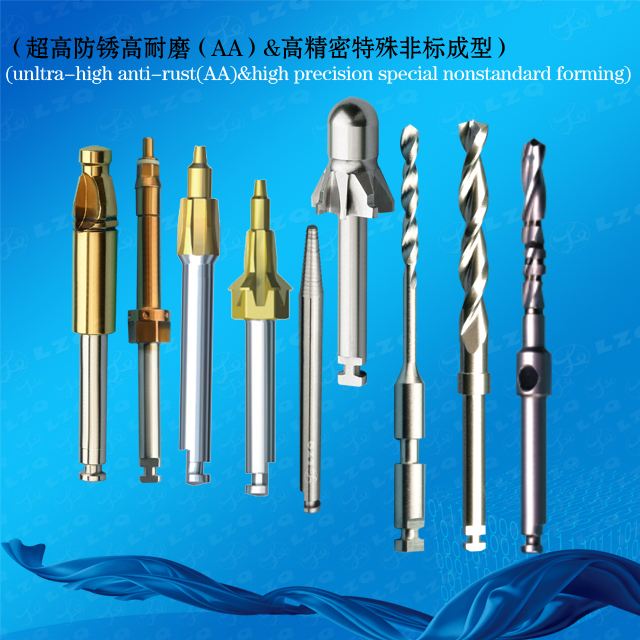

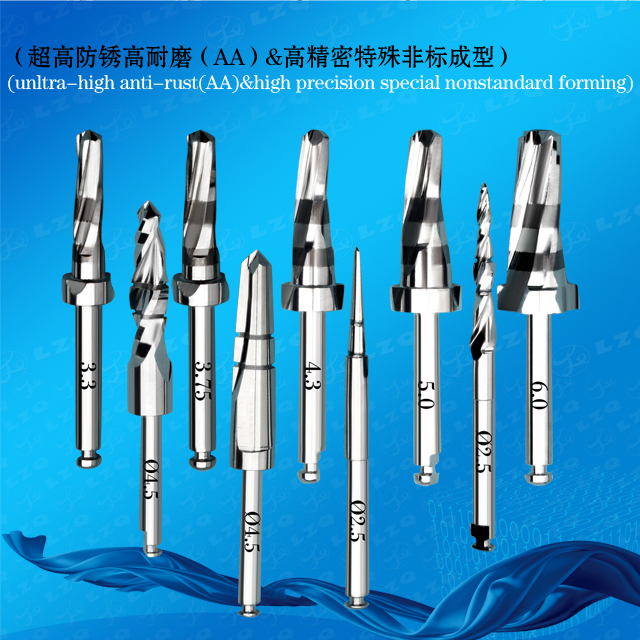

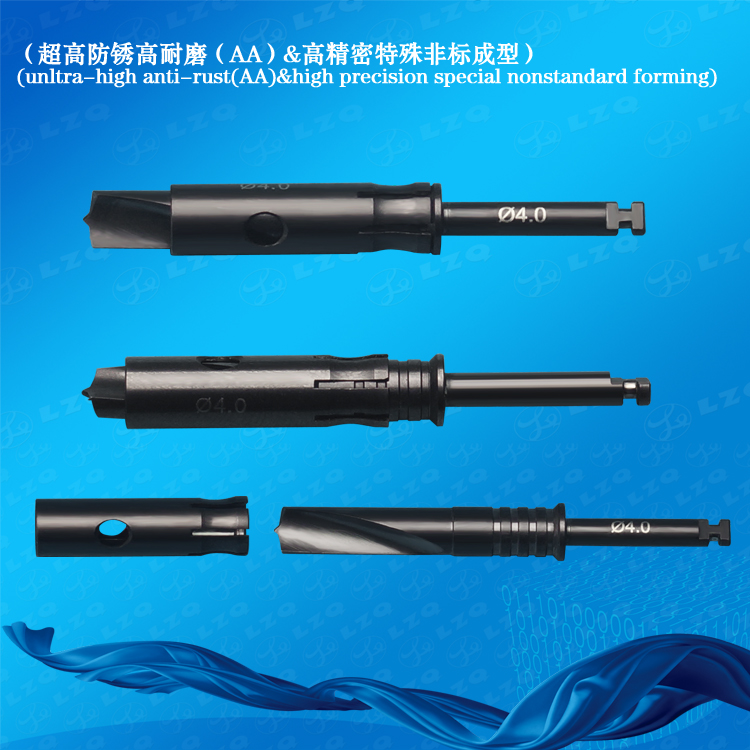

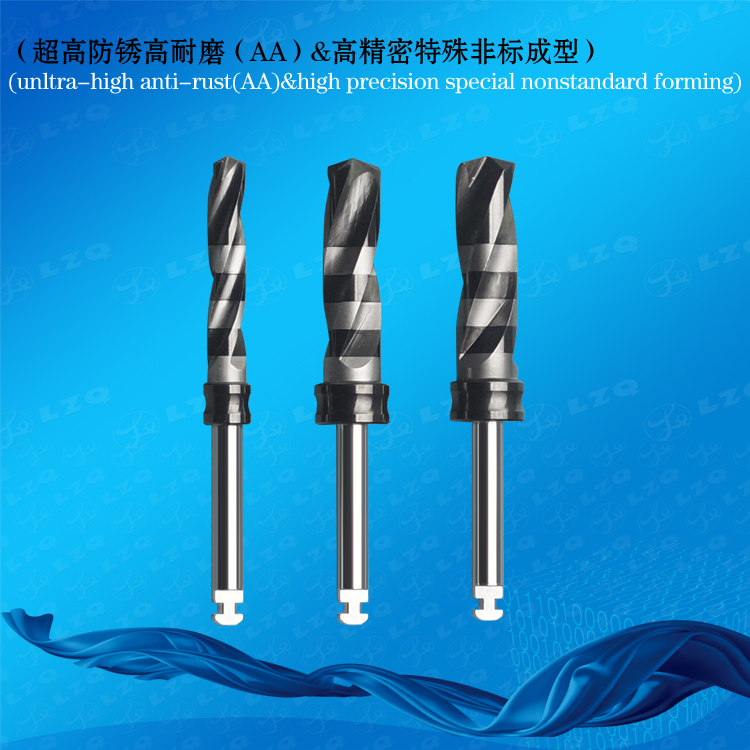

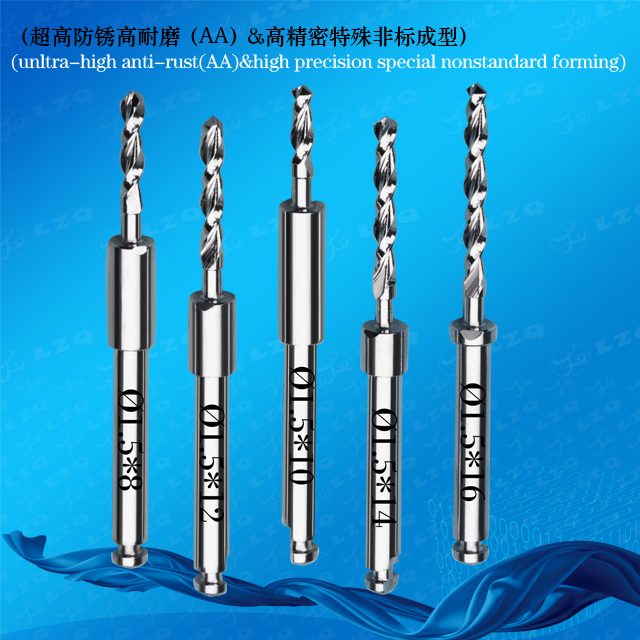

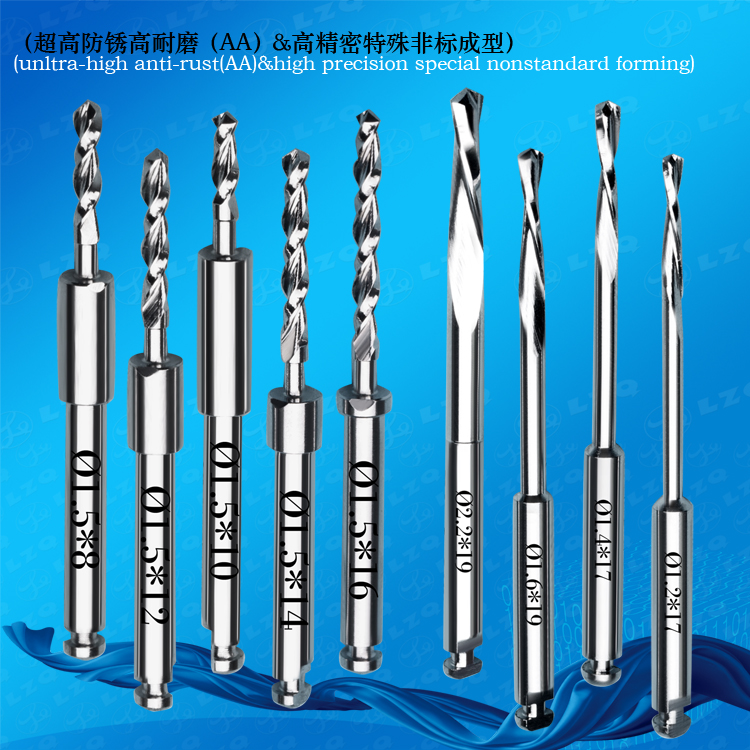

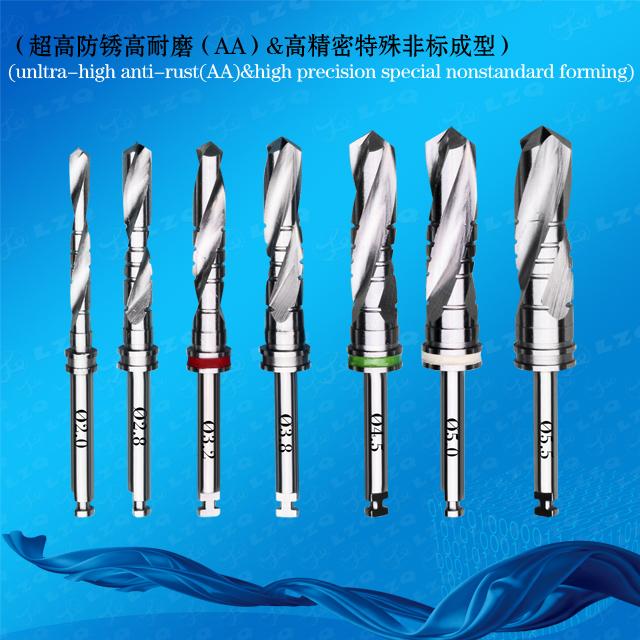

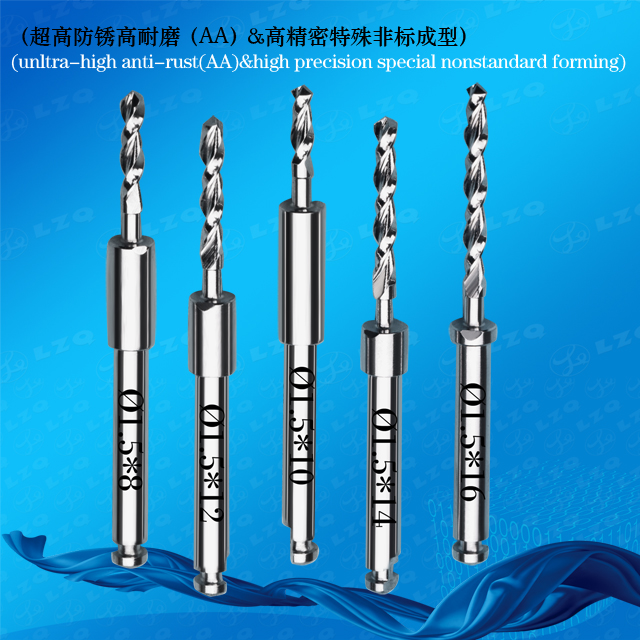

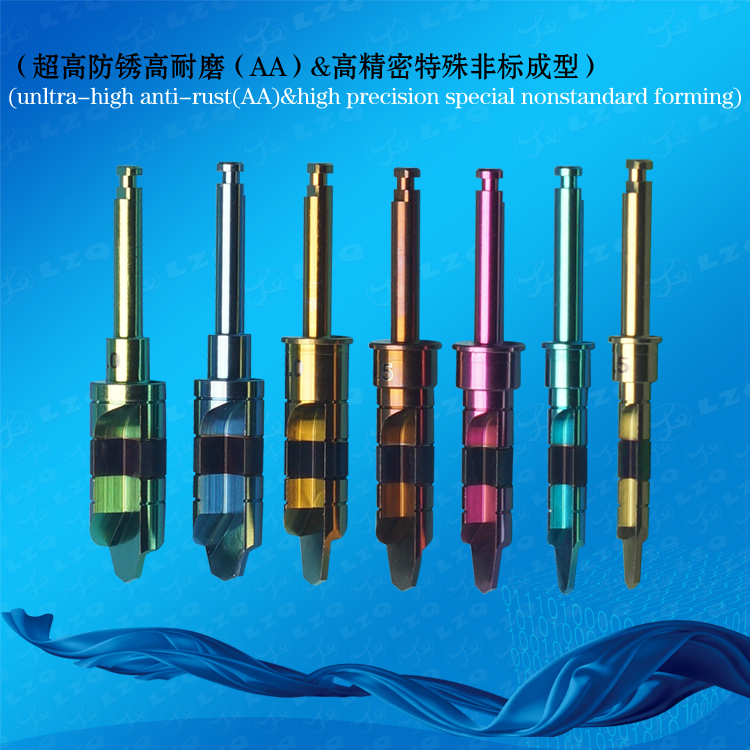

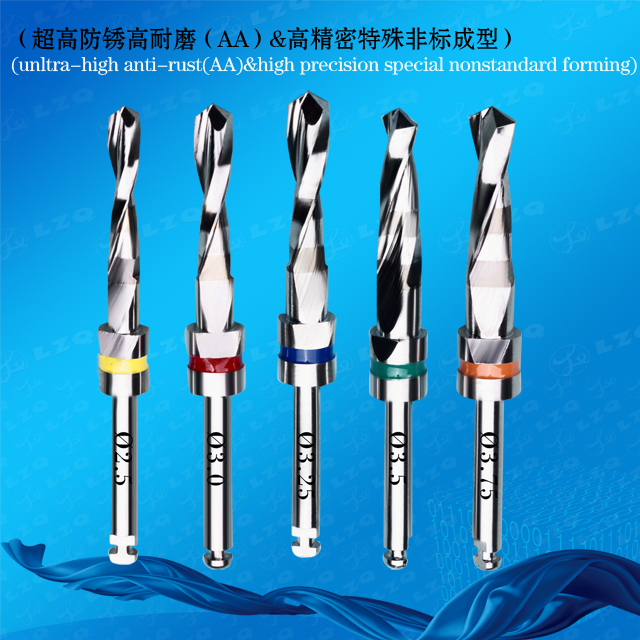

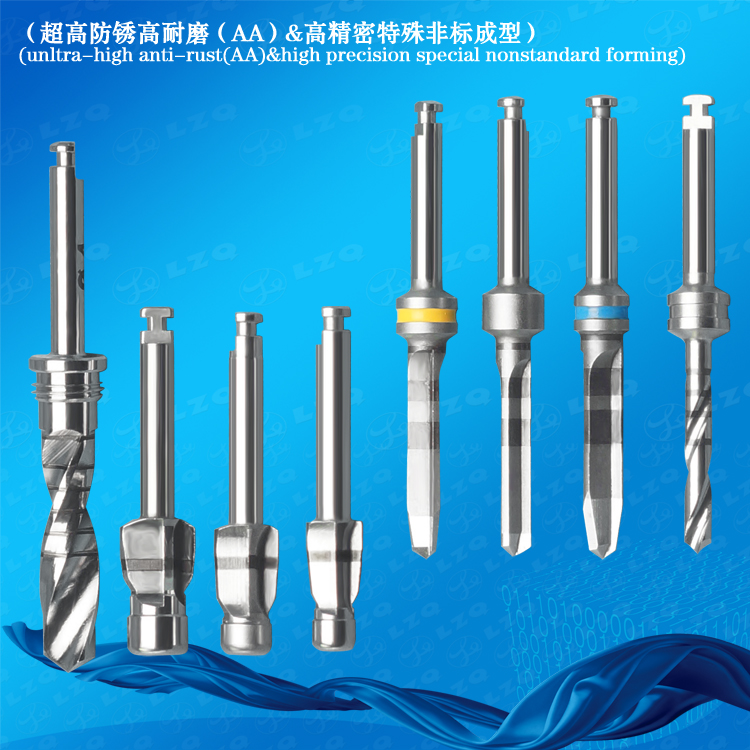

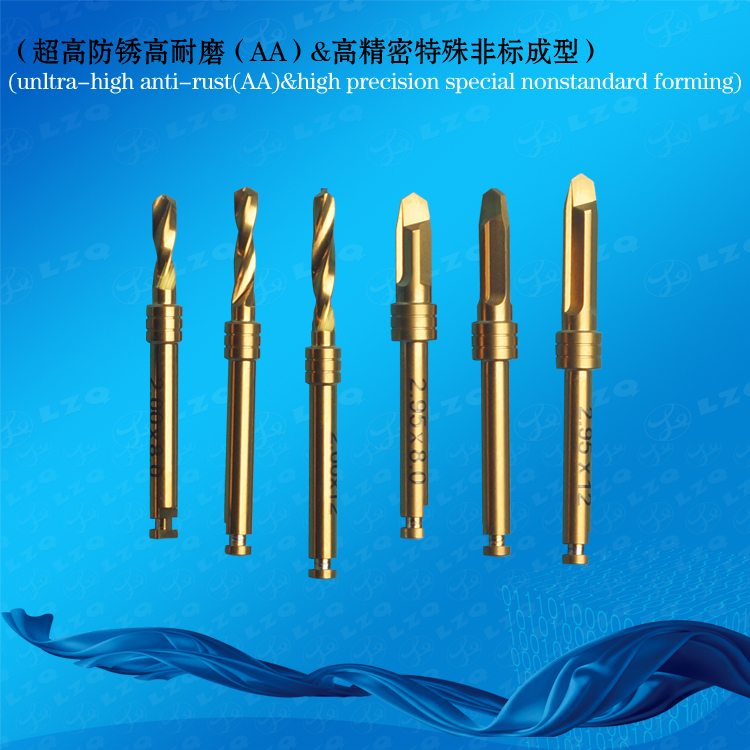

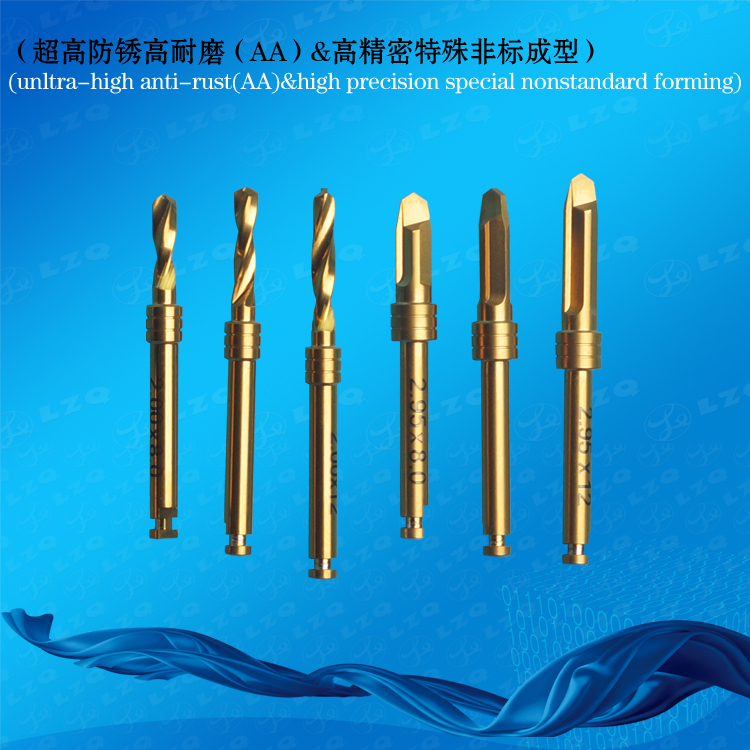

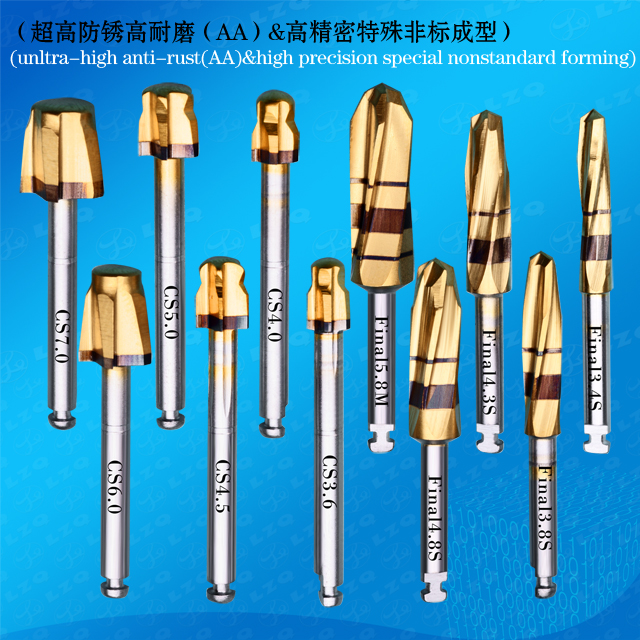

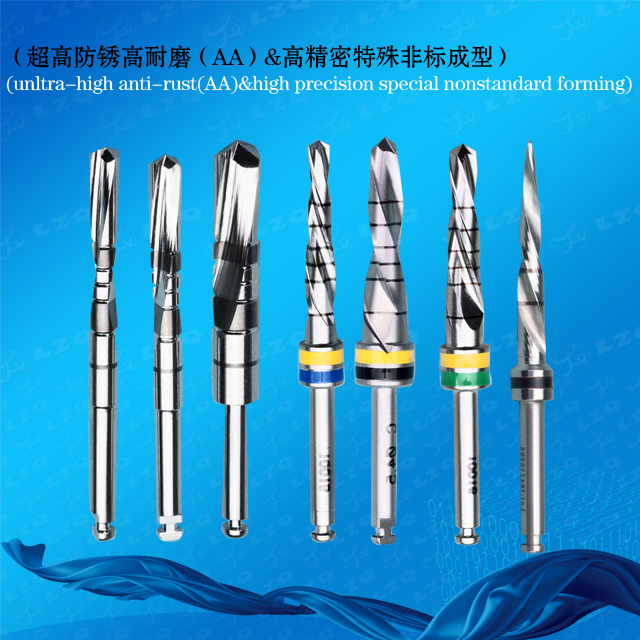

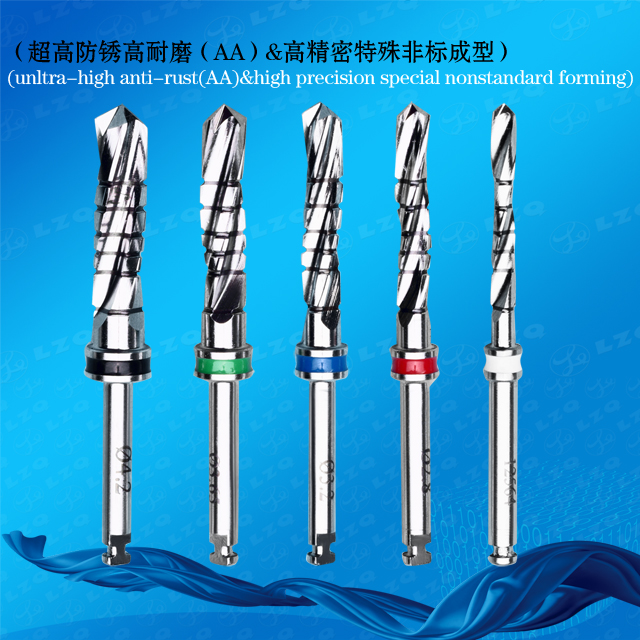

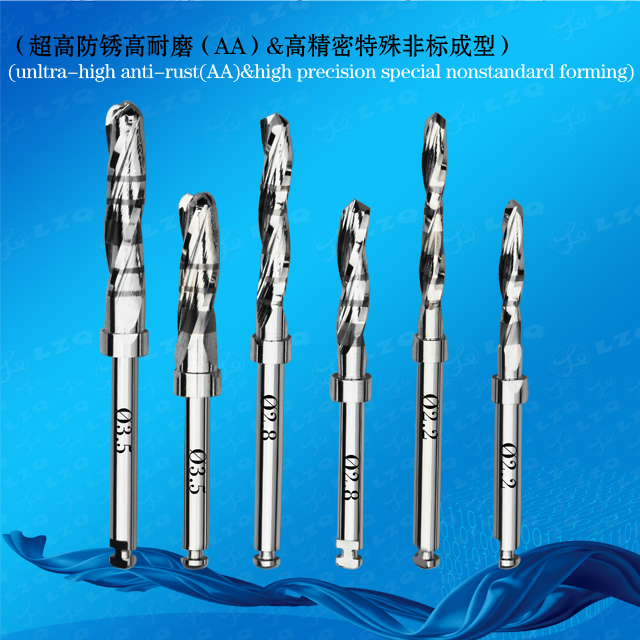

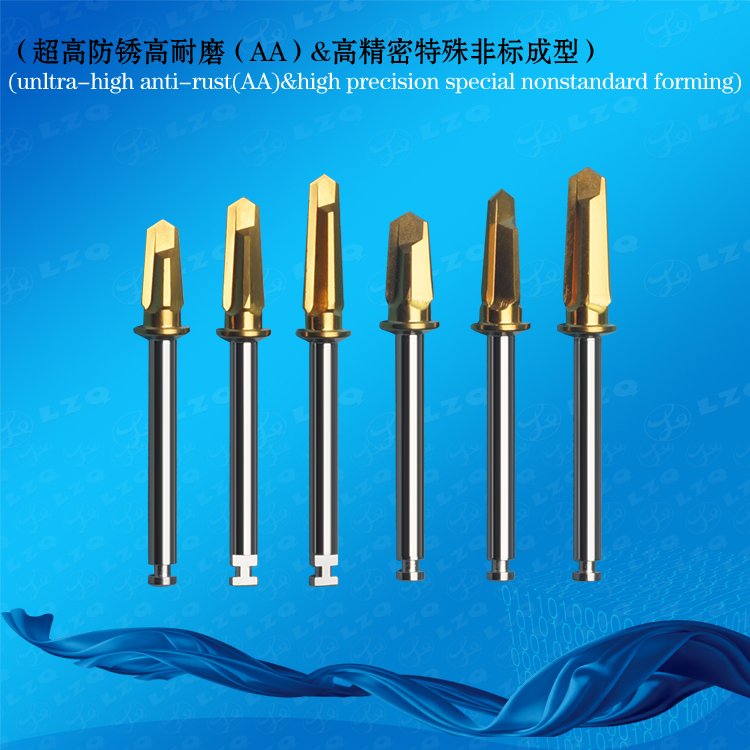

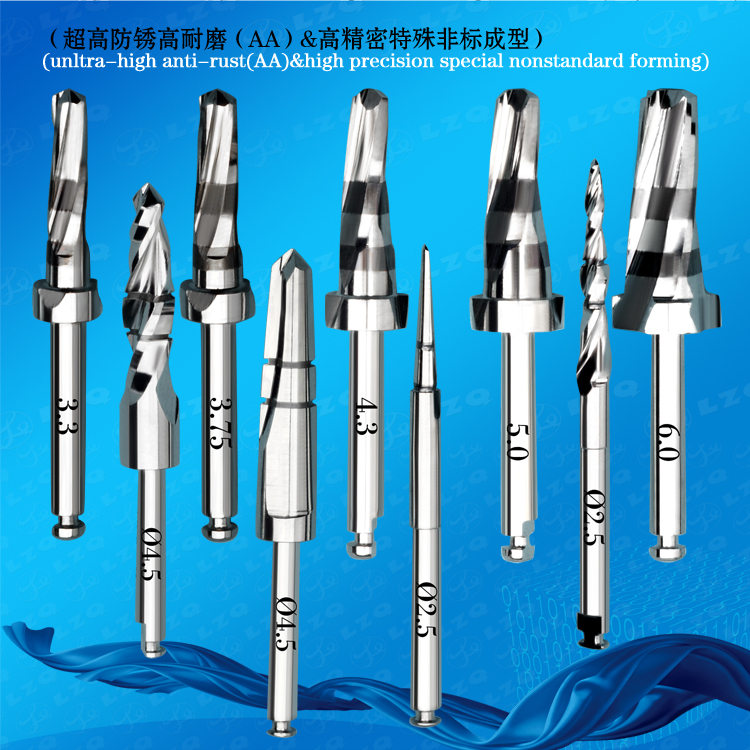

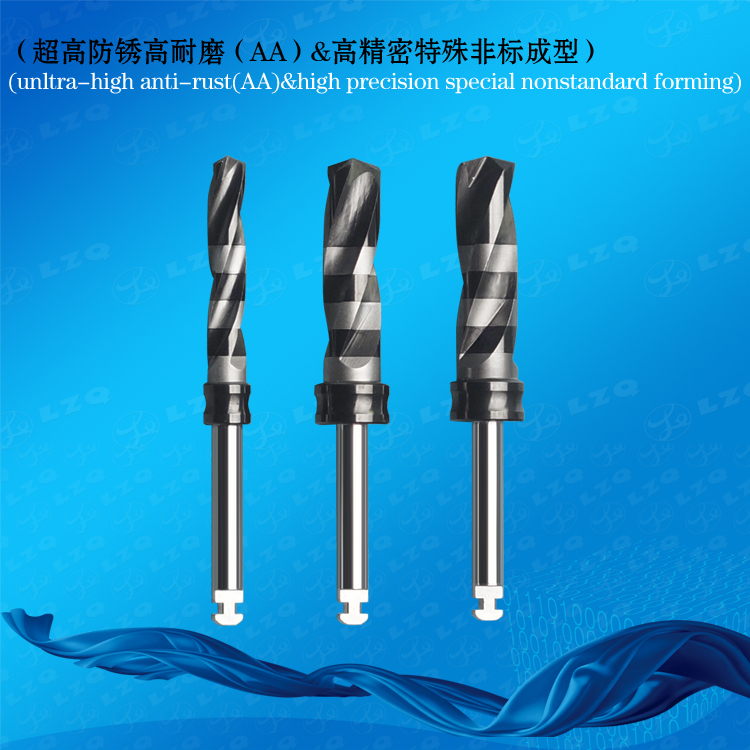

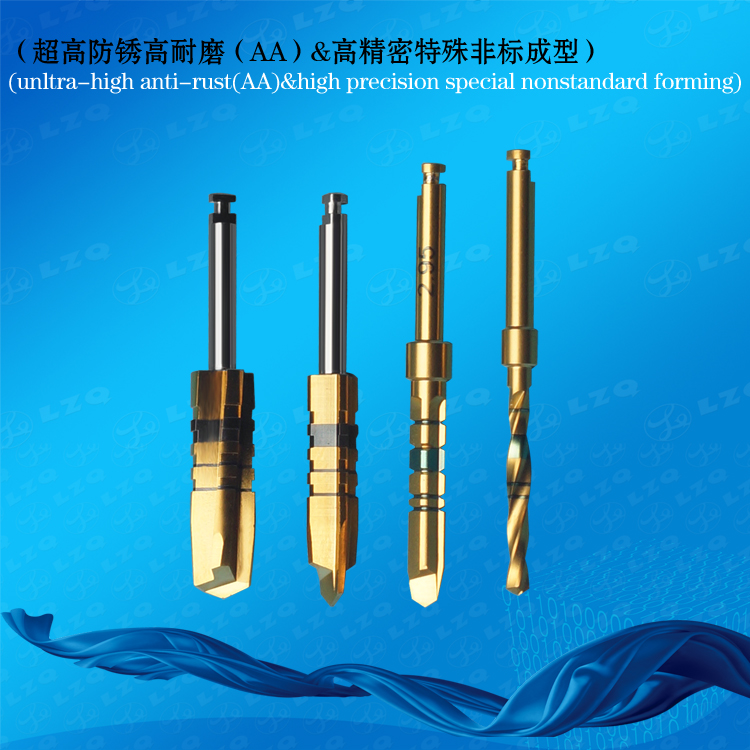

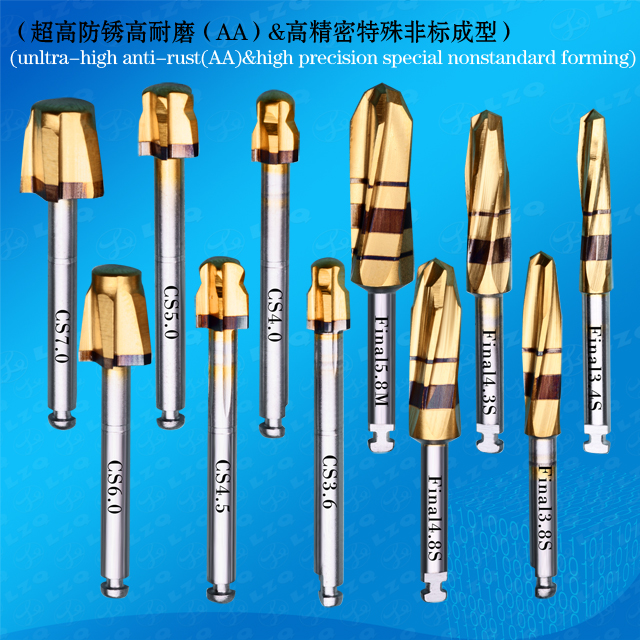

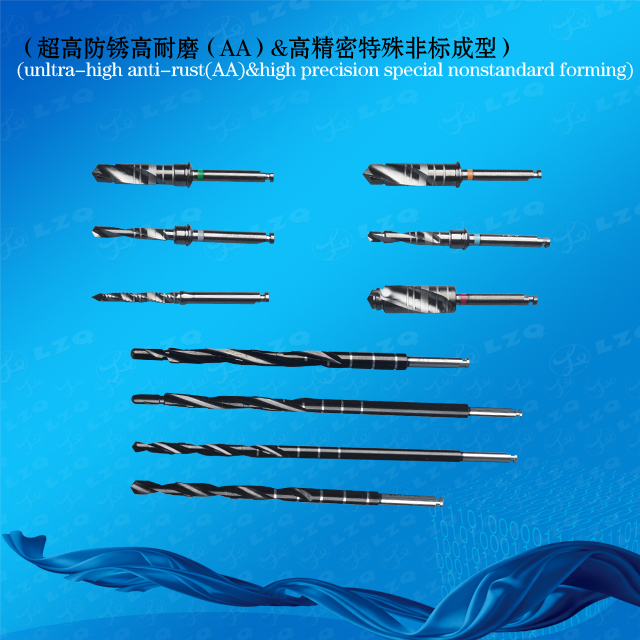

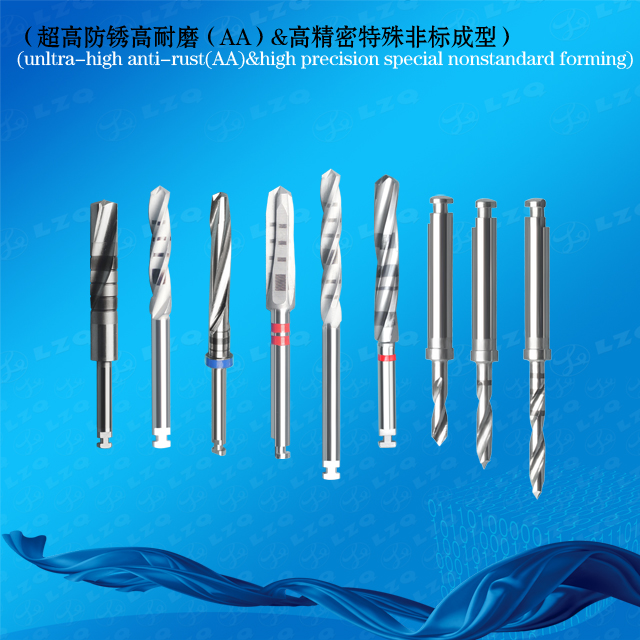

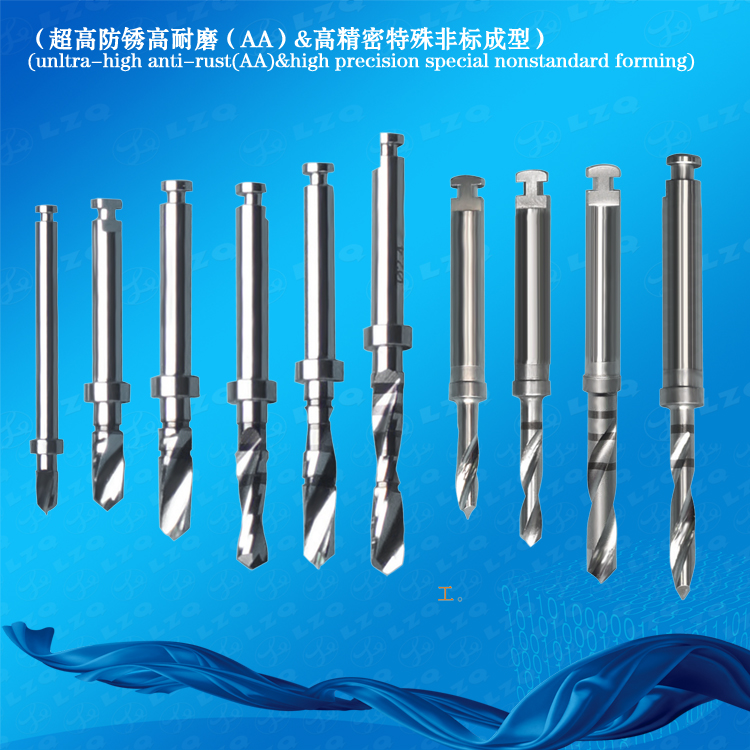

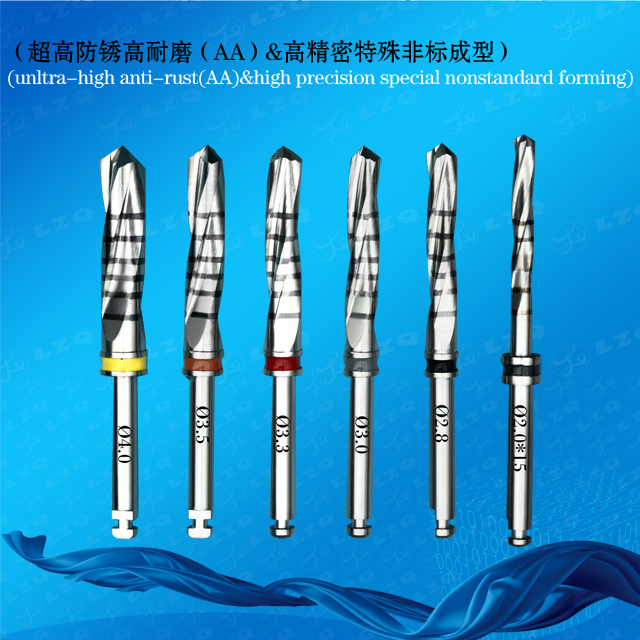

(unltra-high anti-rust(AA)&high precision special nonstandard forming)

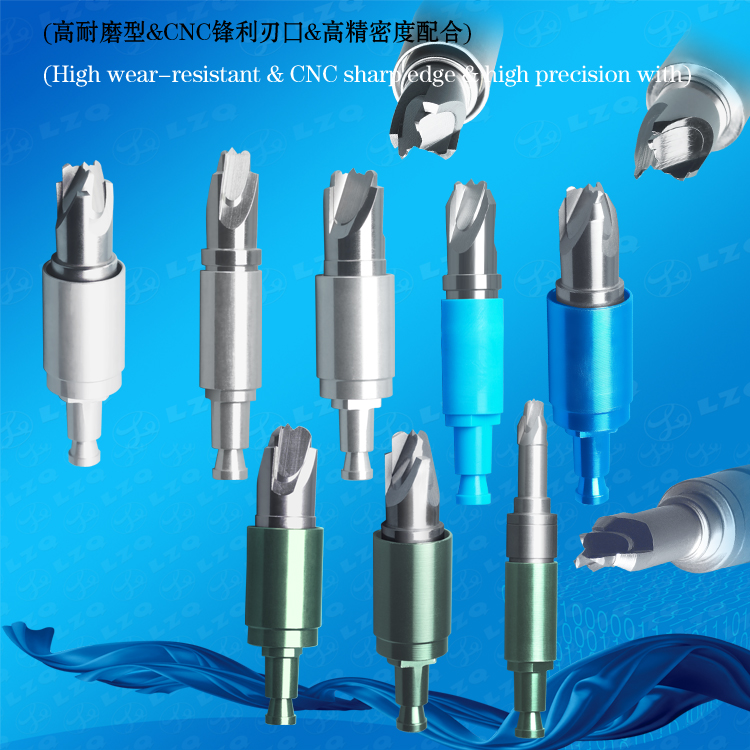

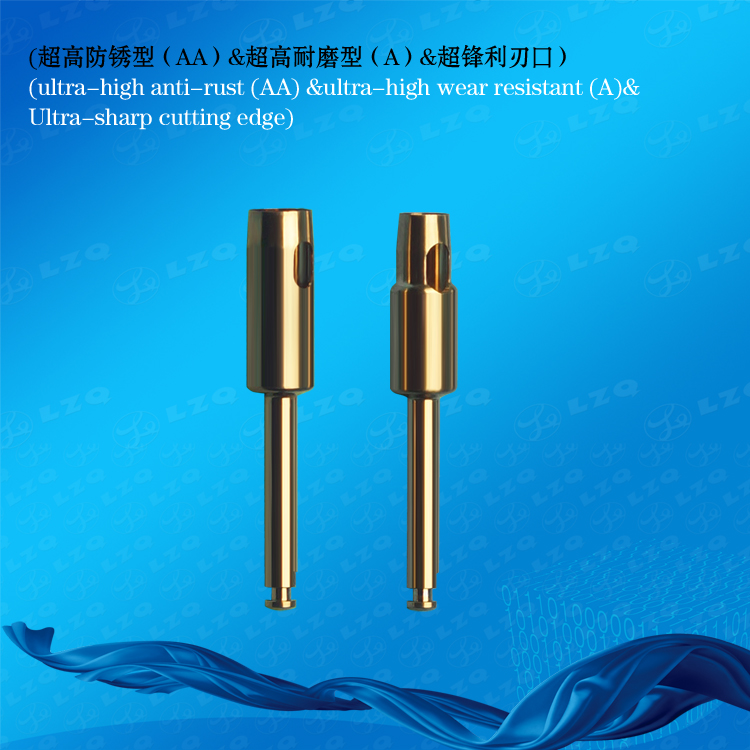

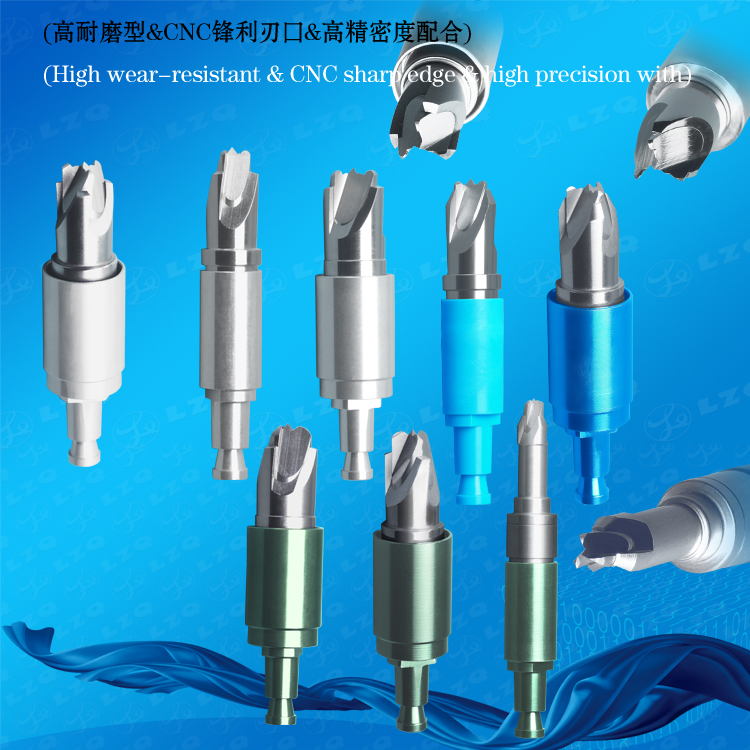

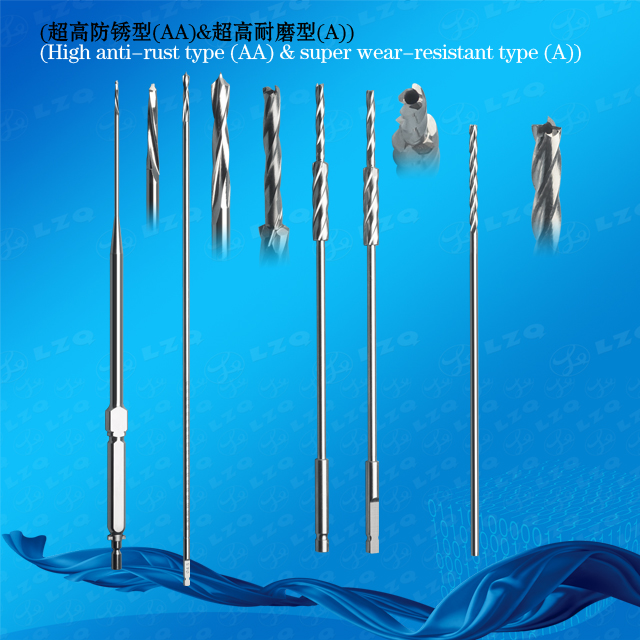

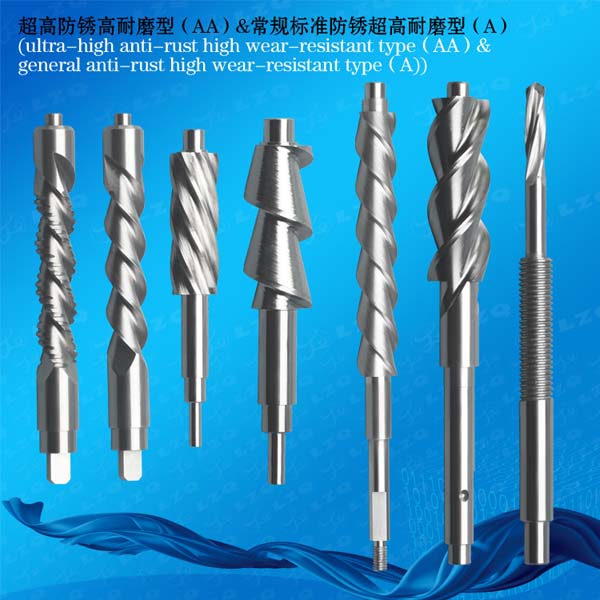

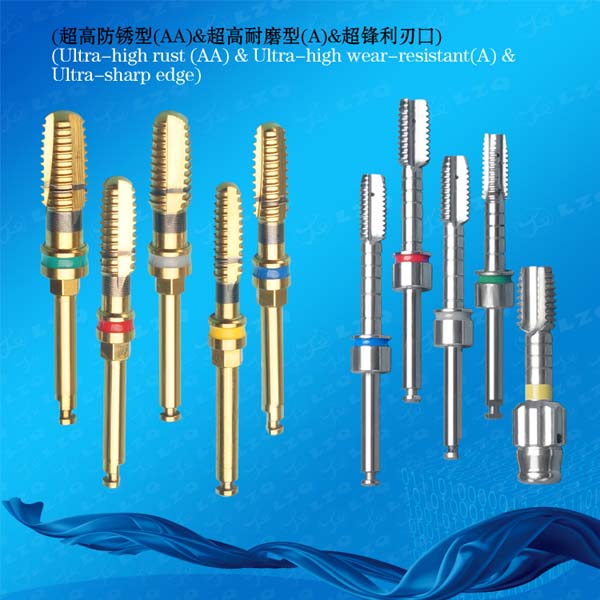

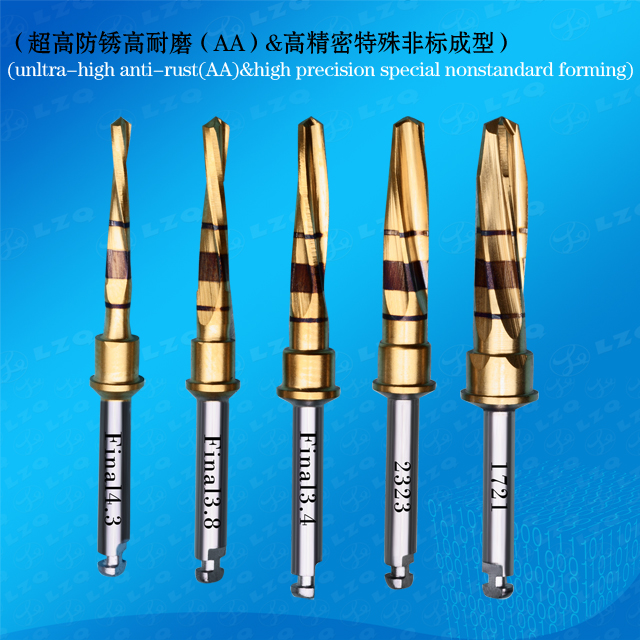

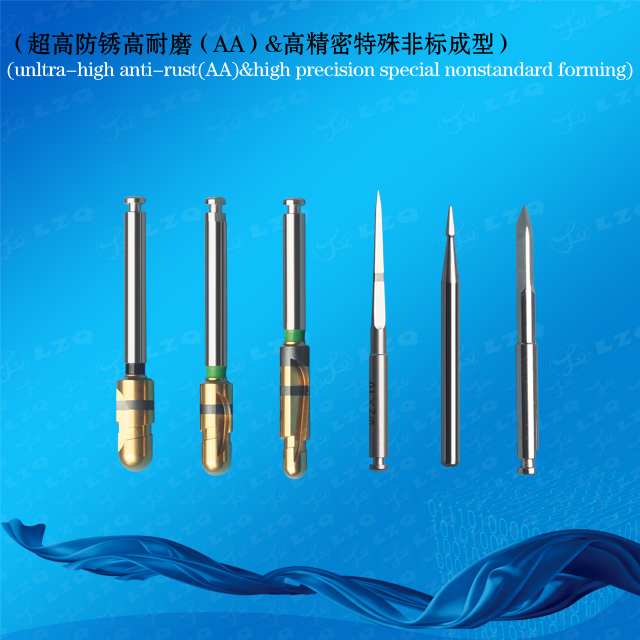

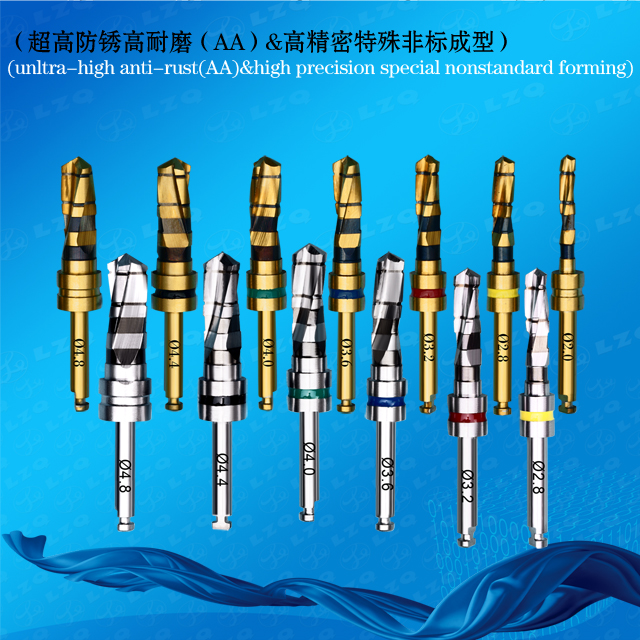

Different colors of coating (mostly Black & Yellow),Different degrees of Matt/Shiny treatment

Material of cutting edge:

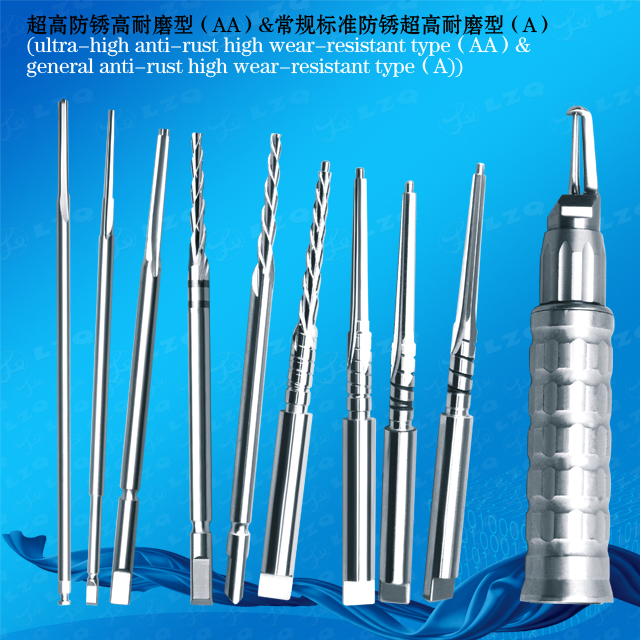

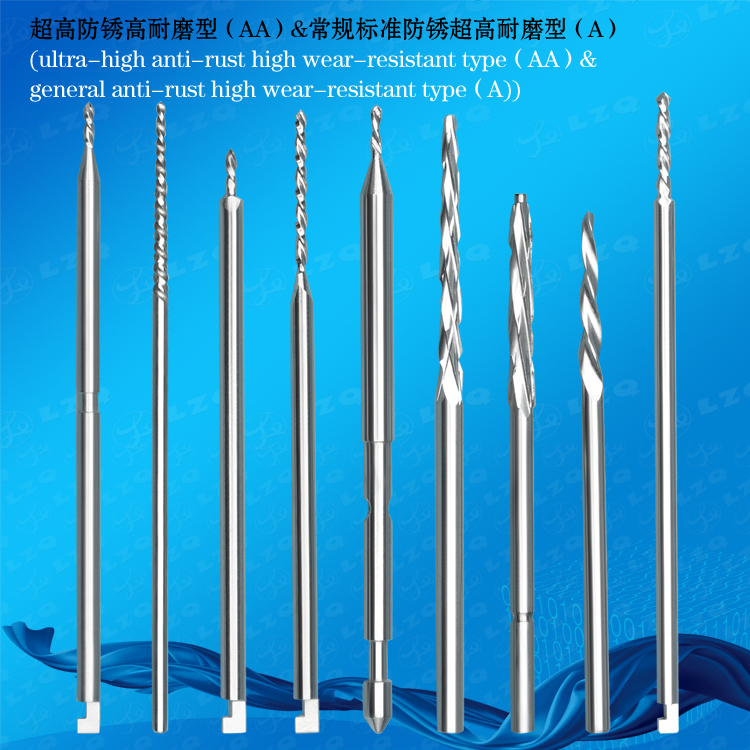

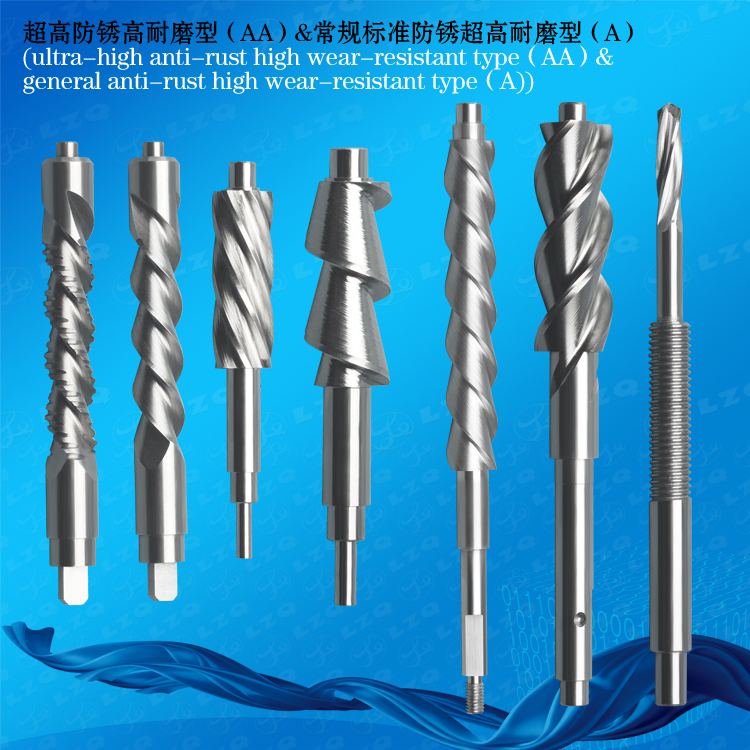

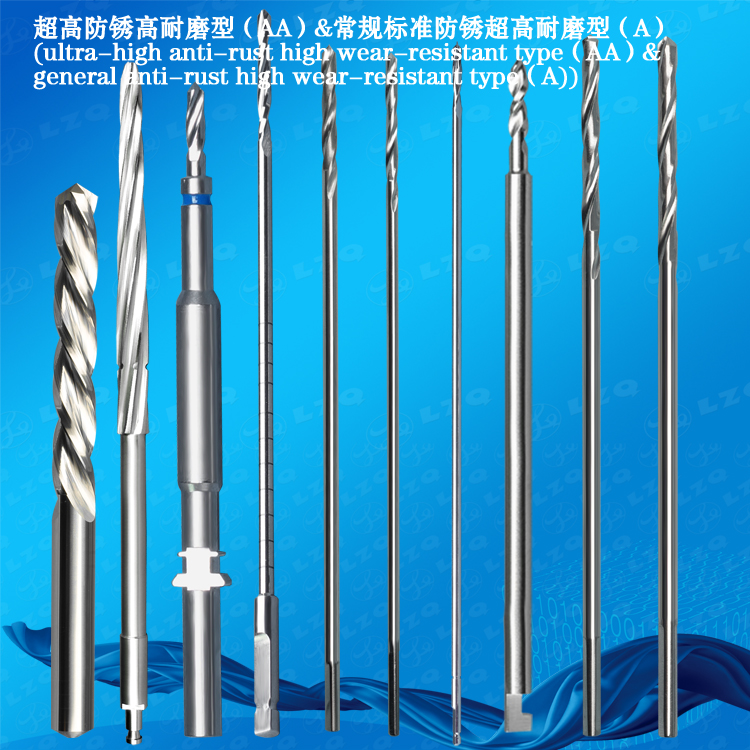

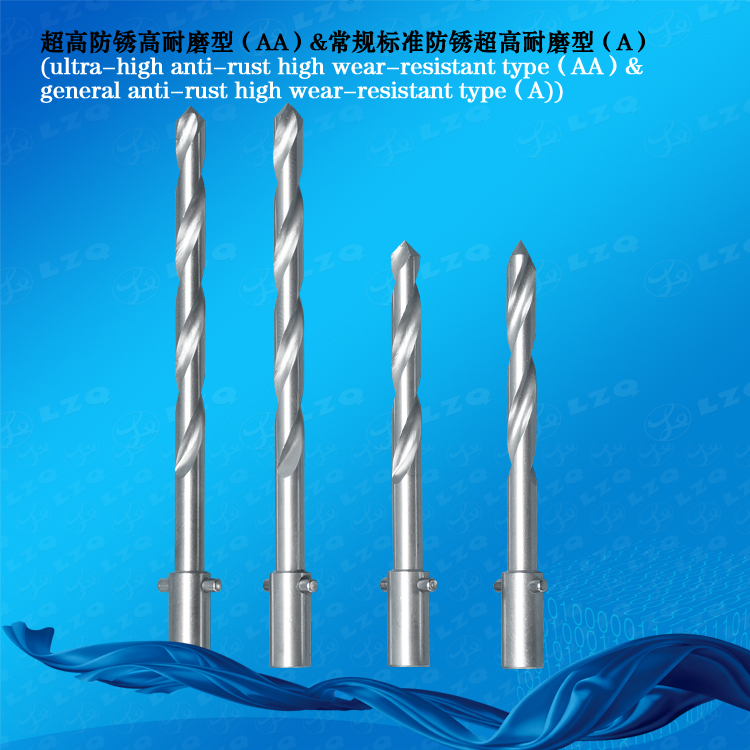

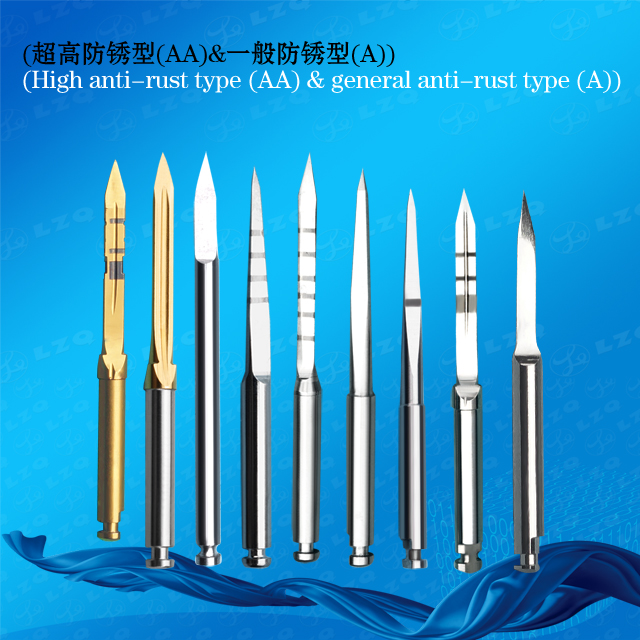

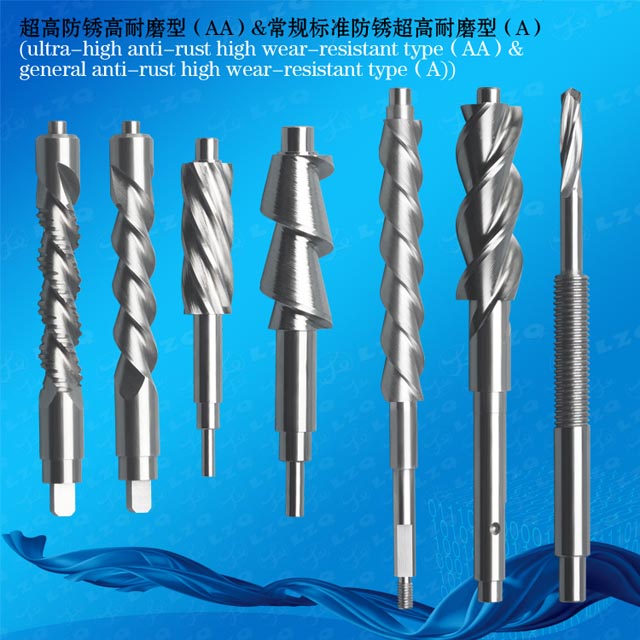

1.Ultra-high anti-rust high wear-resistant stainless steel(AA)(HRC54°±2°Section)(regular stock)

2.General anti-rust high wear-resistant stainless steel(A)(HRC45°~64°Section) series

3.Titanium and Titanium alloy (HRC35°~42°) series

4.Ceramic(HRA85°~94°)series,(HRC67°~84°) series

5.Carbide(HRA81°~94°) series,(HRC60°~84°) series

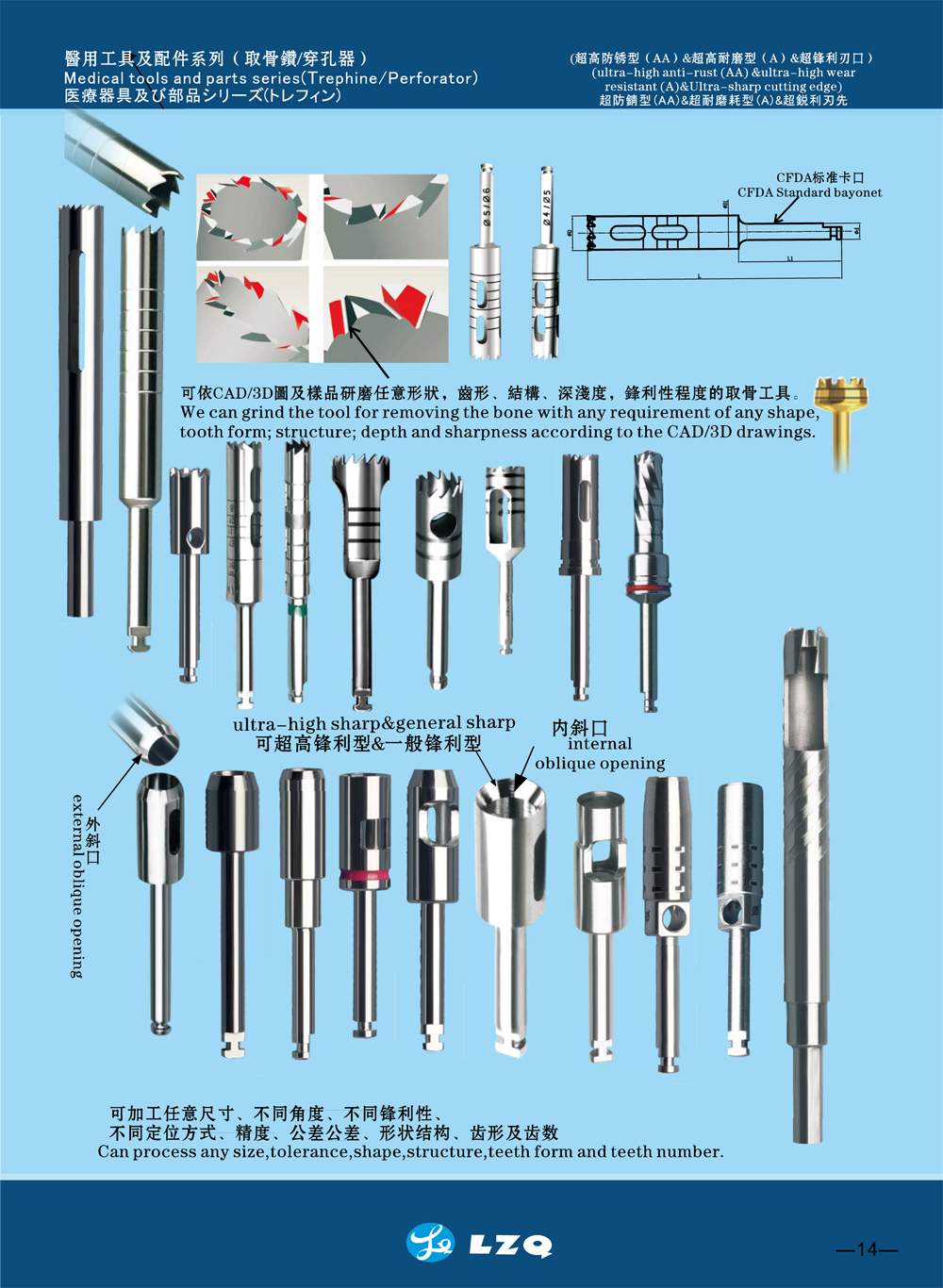

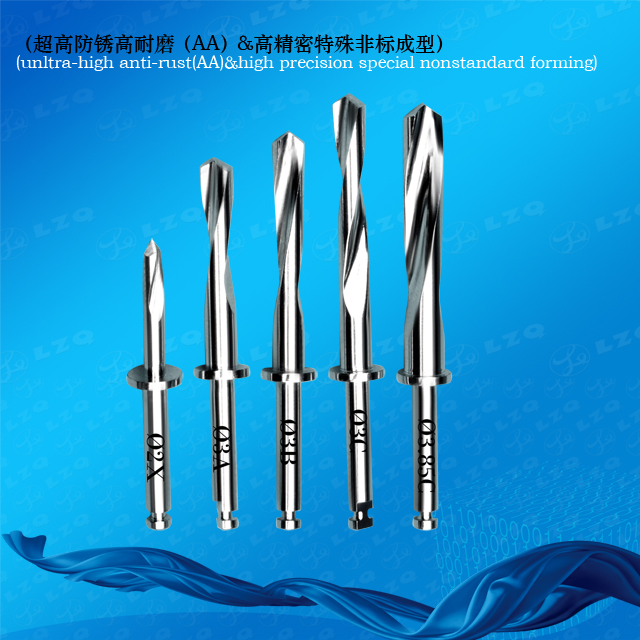

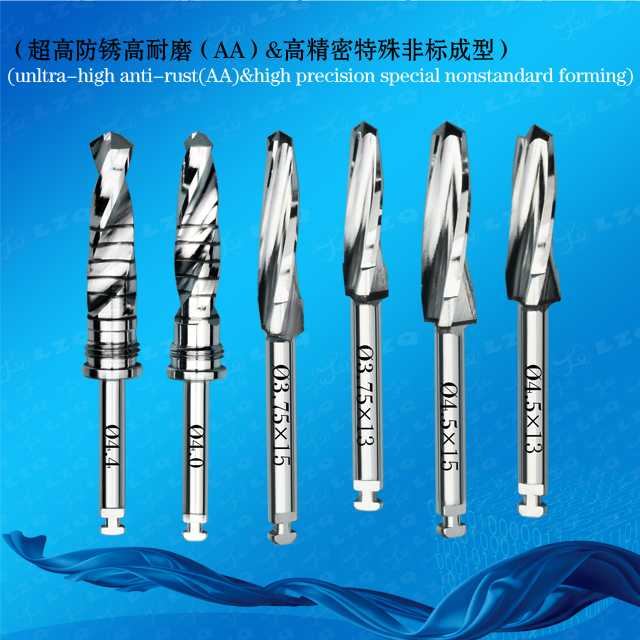

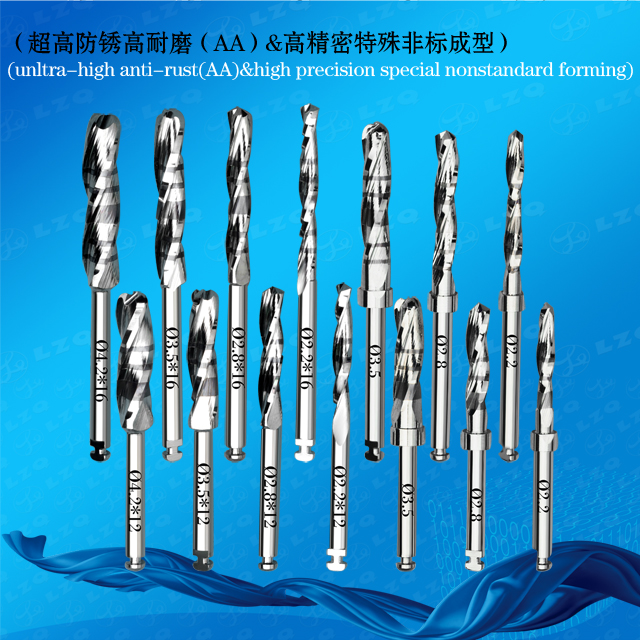

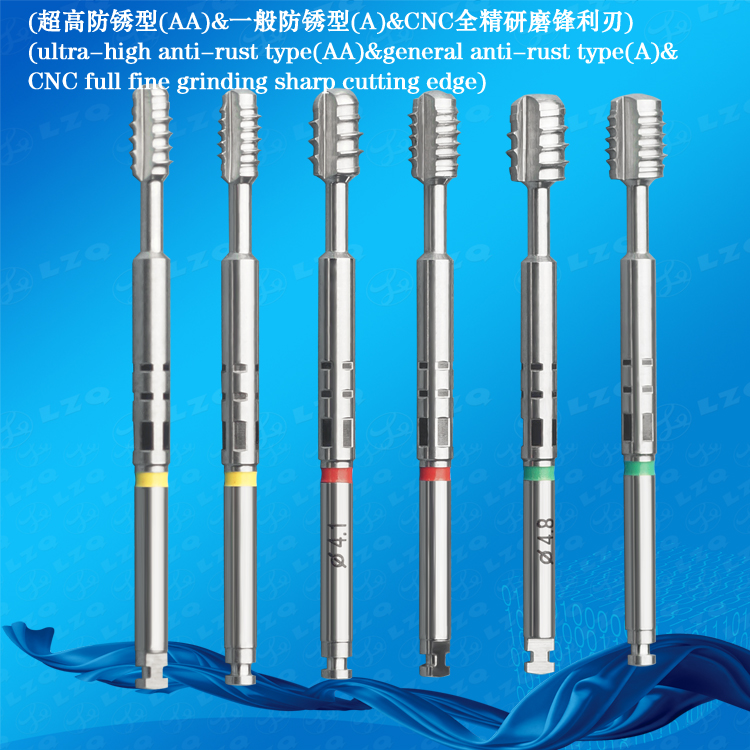

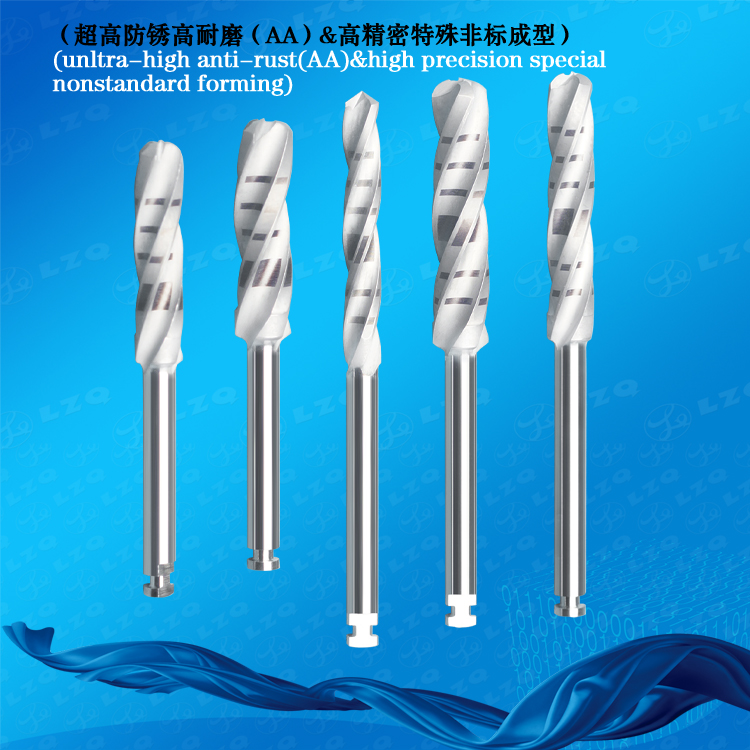

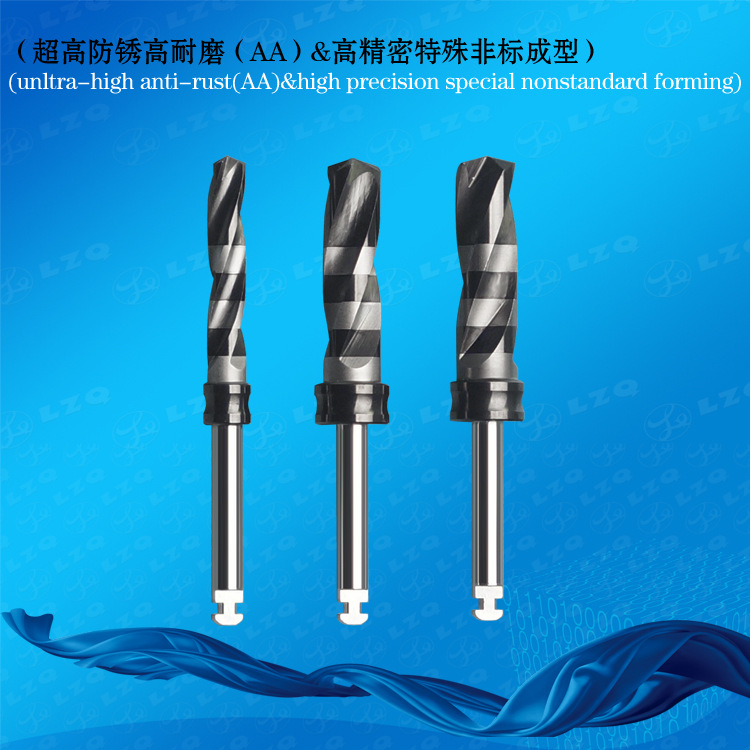

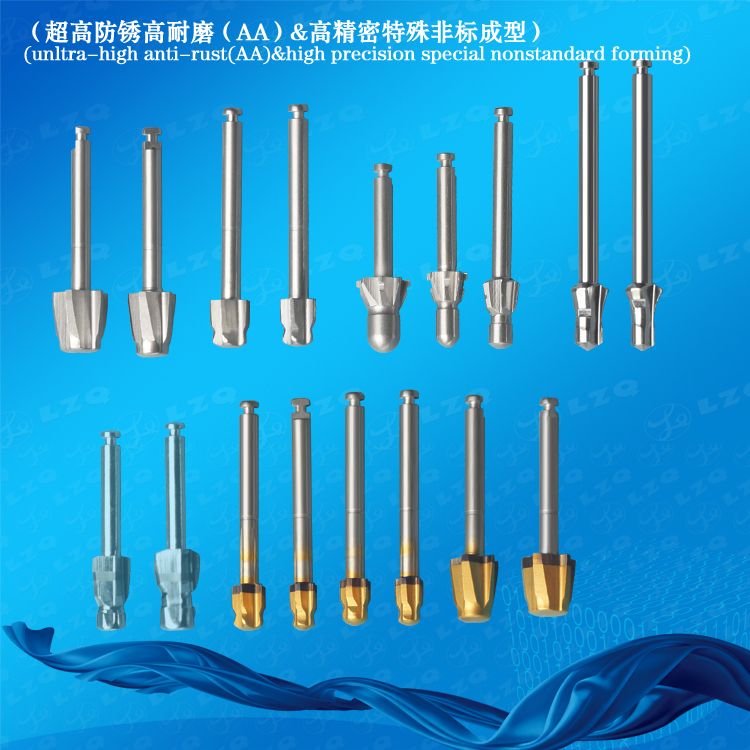

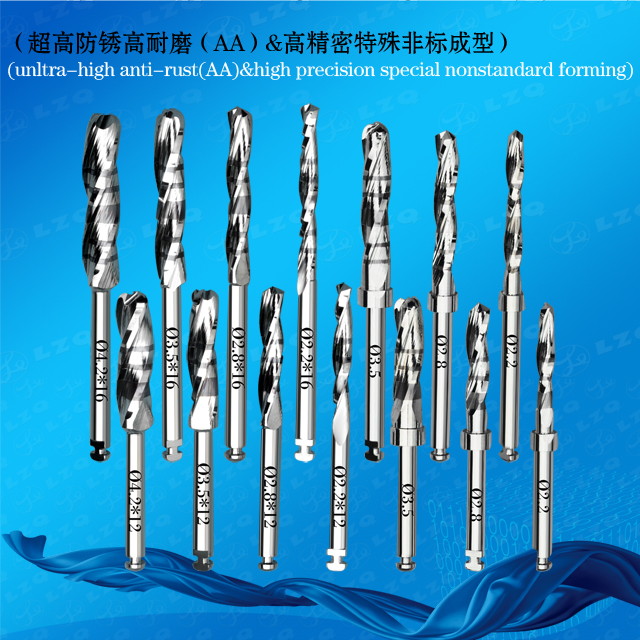

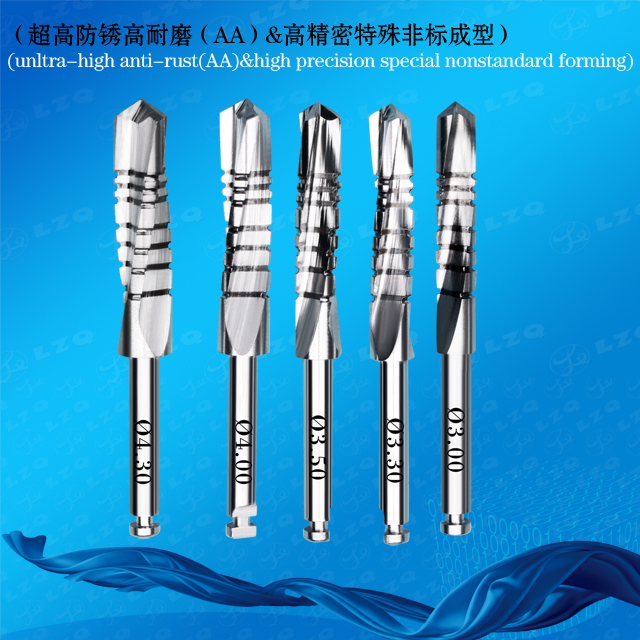

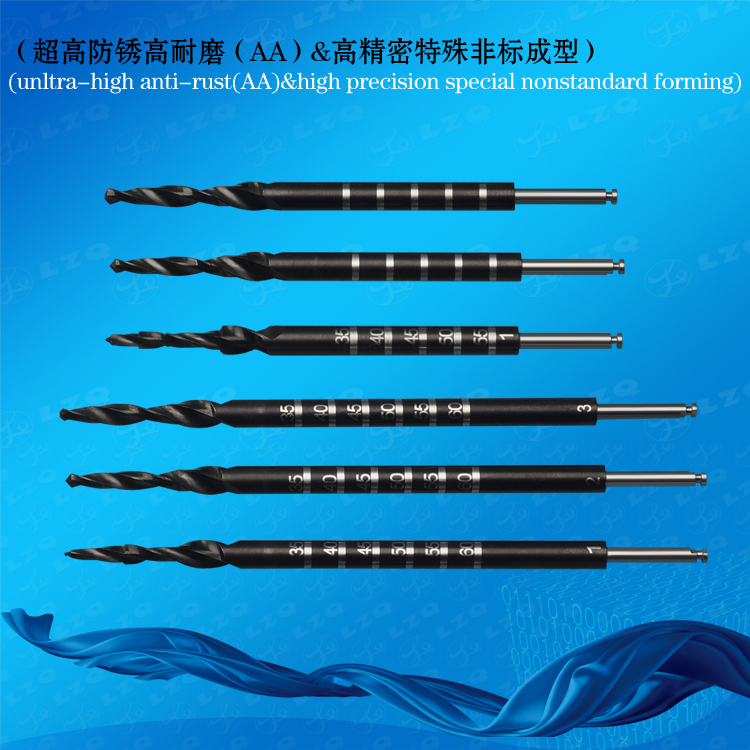

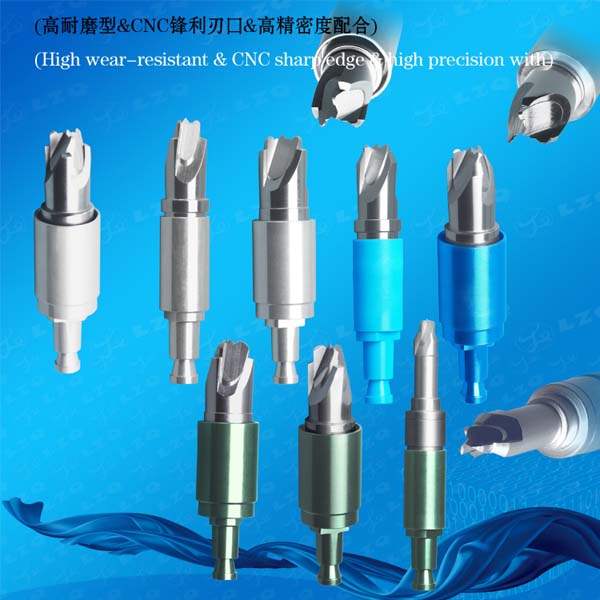

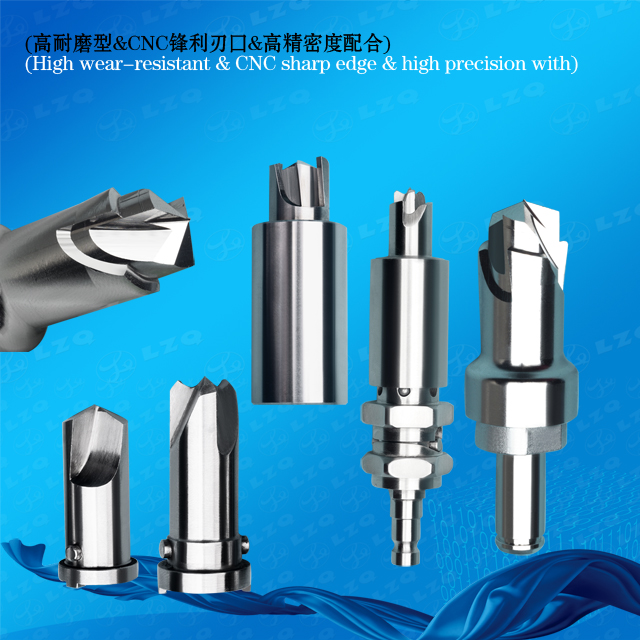

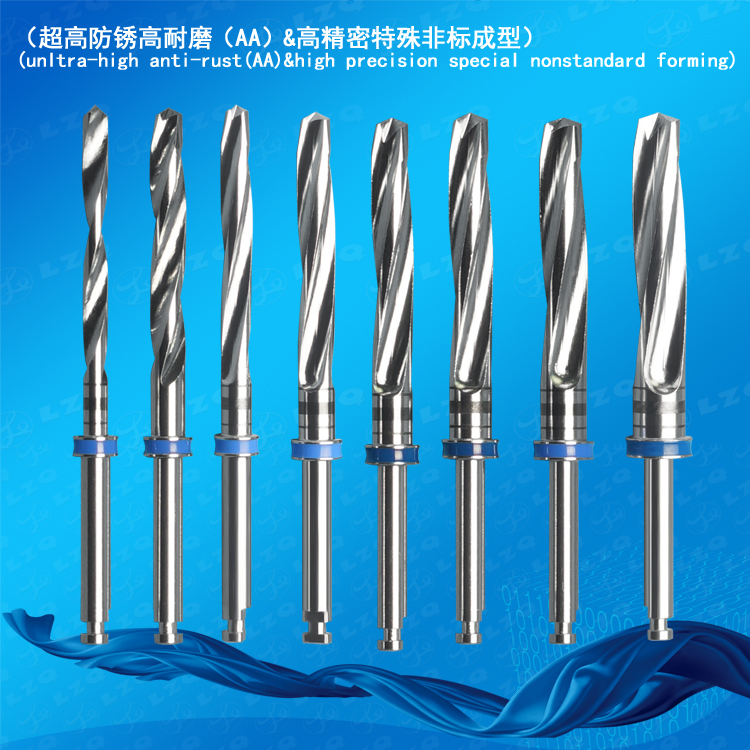

Chip collector, Bone deposition drill and reamer series commonly used for skeletal fragment collection and bone powder accumulation to the crest as reference:

Regular stock material: Ultra-high anti-rust & high wear-resistant stainless steel (AA)(HRC54°±2°Section)

Deep groove to top, chip accumulation to the crest. (It can be with black, yellow, full matt, full shiny, partial matt + partial shiny and other surface treatment)

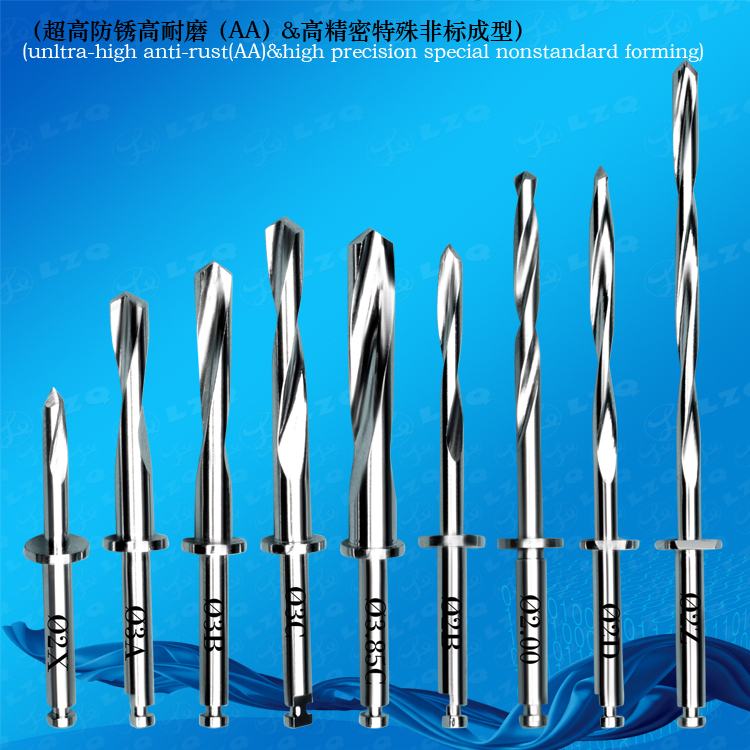

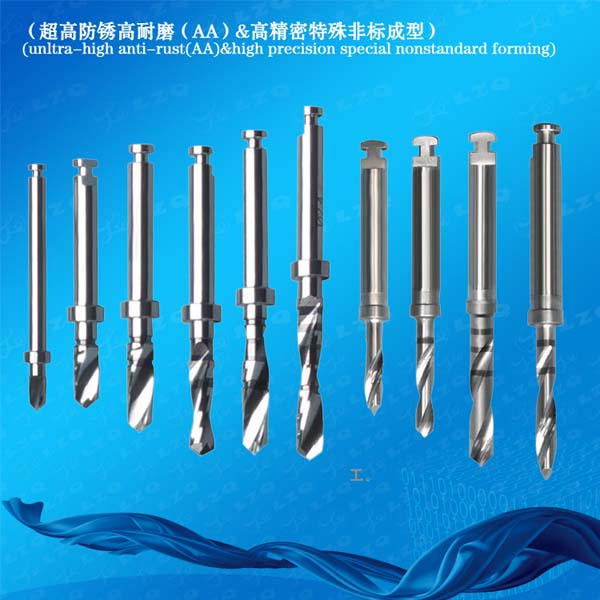

① 2-flute commonly-used specification: Any size series of edge diameter between Φ0.80mm~Φ5.50mm

3-flute commonly-used specification: Any size series of edge diameter betweenΦ0.80mm~Φ7.95mm

4-flute commonly-used specification: Any size series of edge diameter between Φ2.0mm~Φ7.95mm

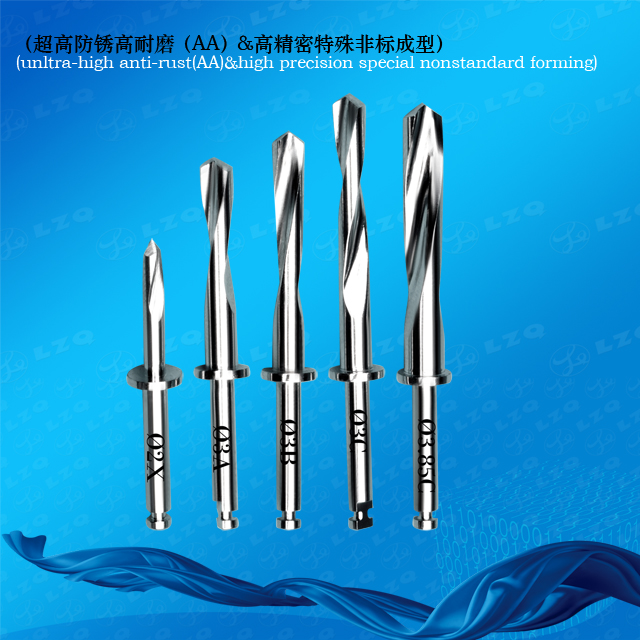

② The series with regular number of flutes, but cutting length up to 55mm and total length

up to 65mm, processed with any step, taper angle, shape, sharpness requirements.

② The conventional 10°~12°helical edge can be sharp, burnishing, passivated, or

front-sharp but rear-blunt.

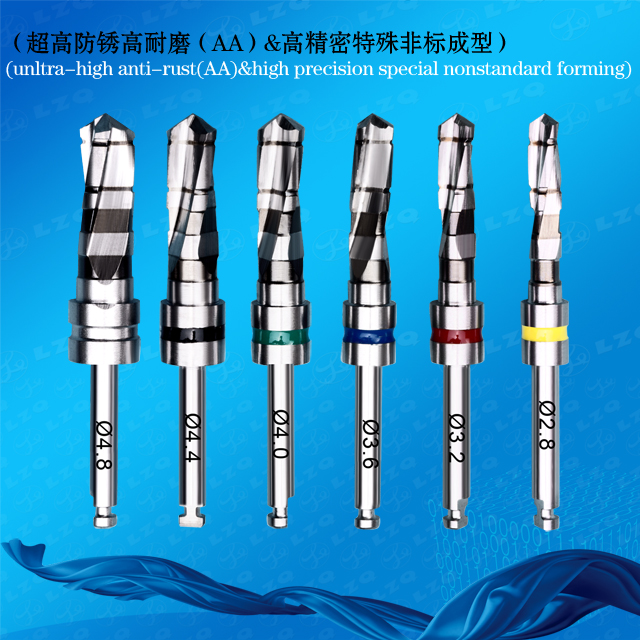

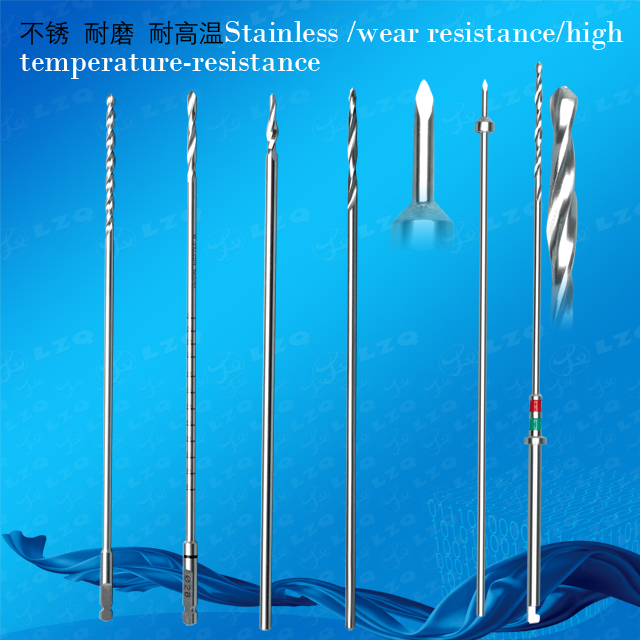

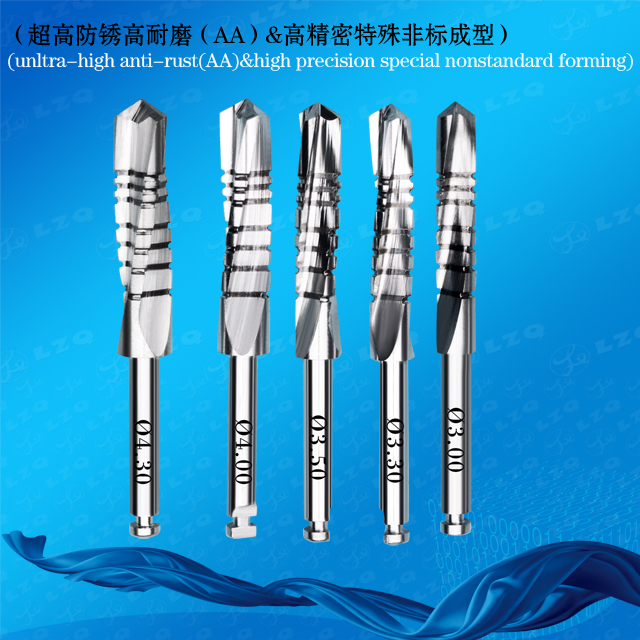

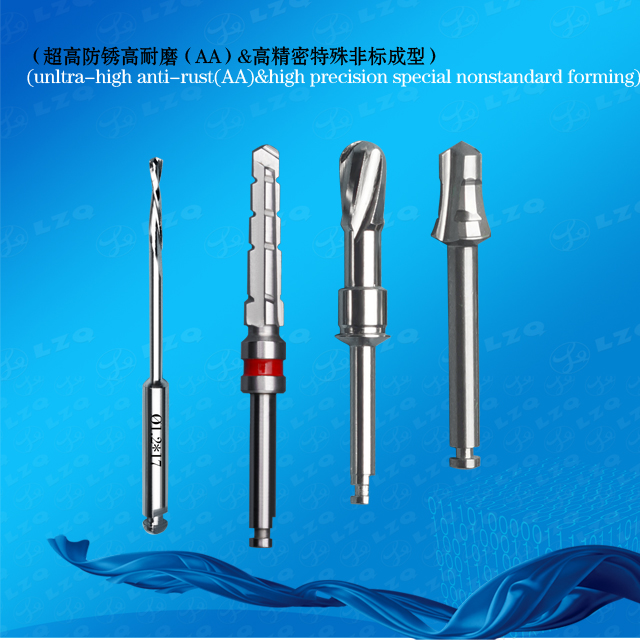

1. Commonly-used edge diameter: any size series between Φ0.80mm~Φ7.95mm

2. Conventional cutting length up to 55mm series,and total length up to 65mm, processed with any step, taper angle, shape, sharpness requirements

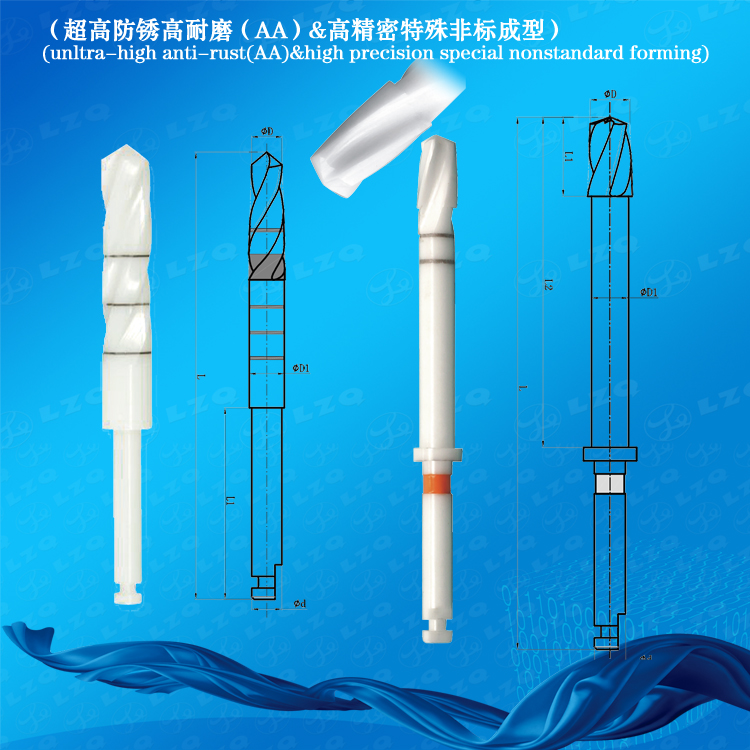

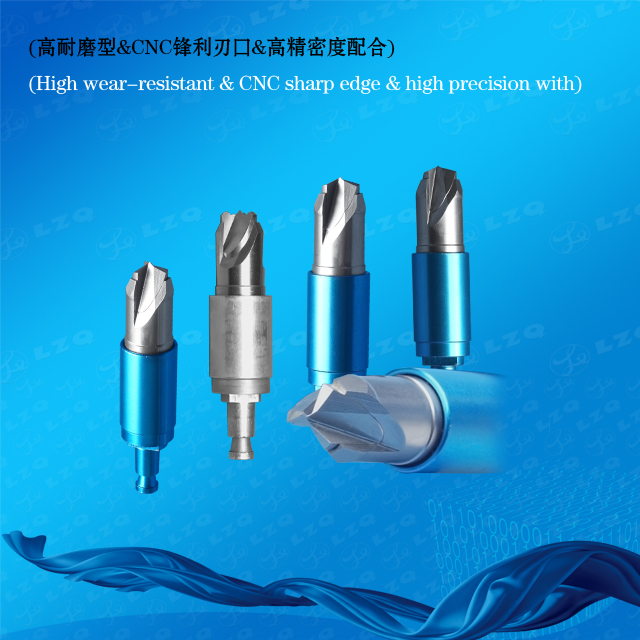

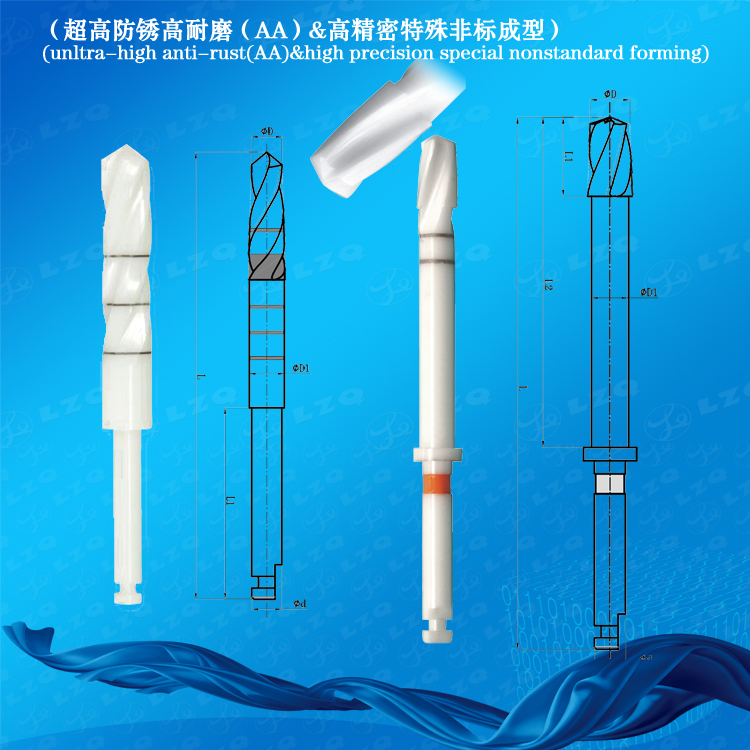

We can produce with super hard and super finish grinding and satisfy your requirement of any type of shank, web thickness, width of chip flute,land, drill tip,inner cooling hole, structure of cutting edge, angle of cutting edge, degree of sharpness of cutting edge, and the dimension tolerance can be up to ±0.003mm (3μm)

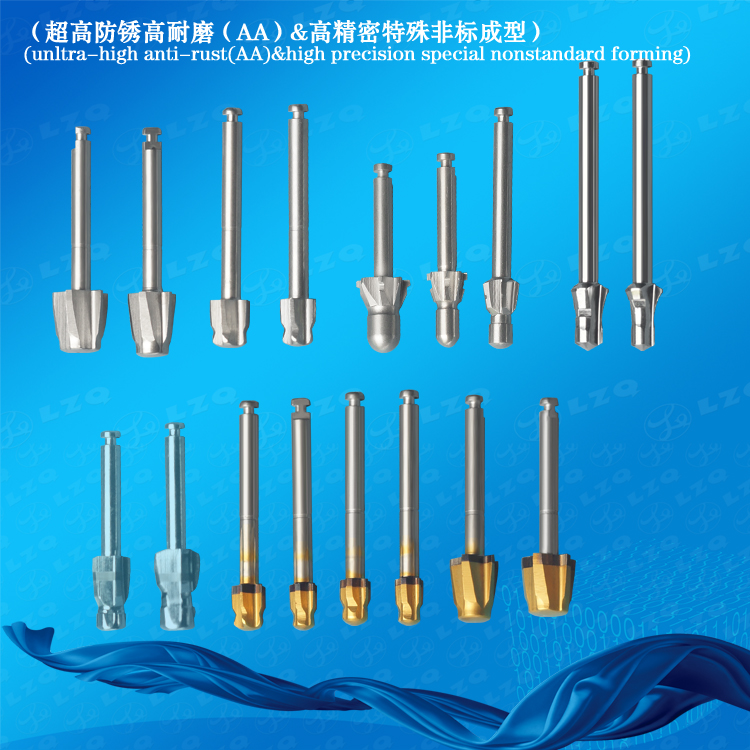

The cutting edge can be produced with different materials (ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

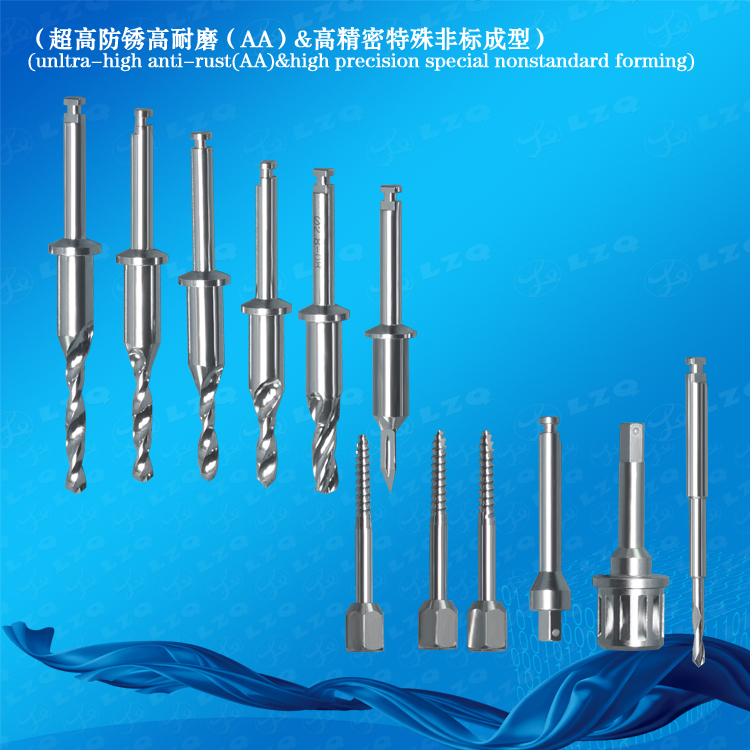

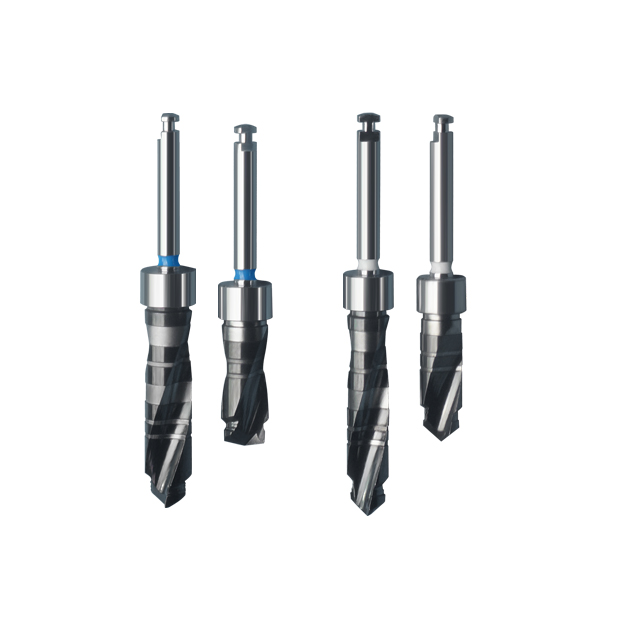

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shapes, structures, etc.

They can be high precisely and high hard ground to mold with materials such as ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, etc

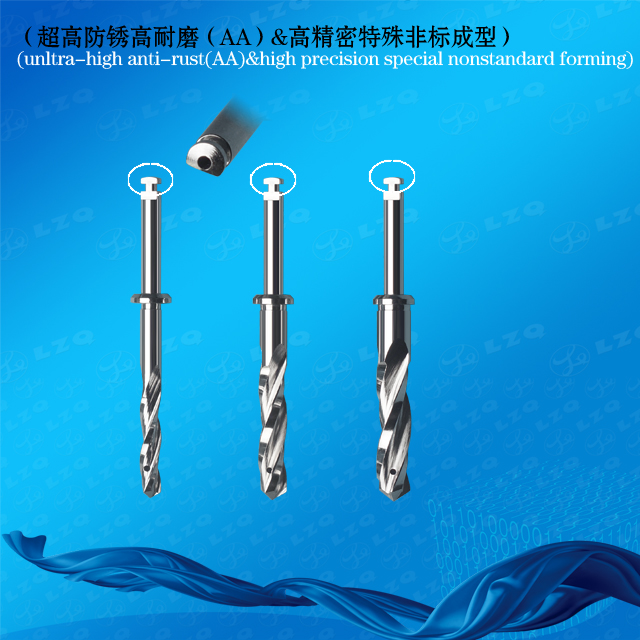

With or without penetration, hollow & hollow core inner hole process with different grades.

Any angle and type of drill tip

Any way of land and drill land

Any web thickness, width of chip flute and depth.

Any structur of cutting edge with size tolerance up to 0.003mm(3um).

Any angle of cutting edge with supper sharp type, generally sharp, a little dull type…

Different colors of coating(mostly black & yellow), different degress of matt/shiny treatment

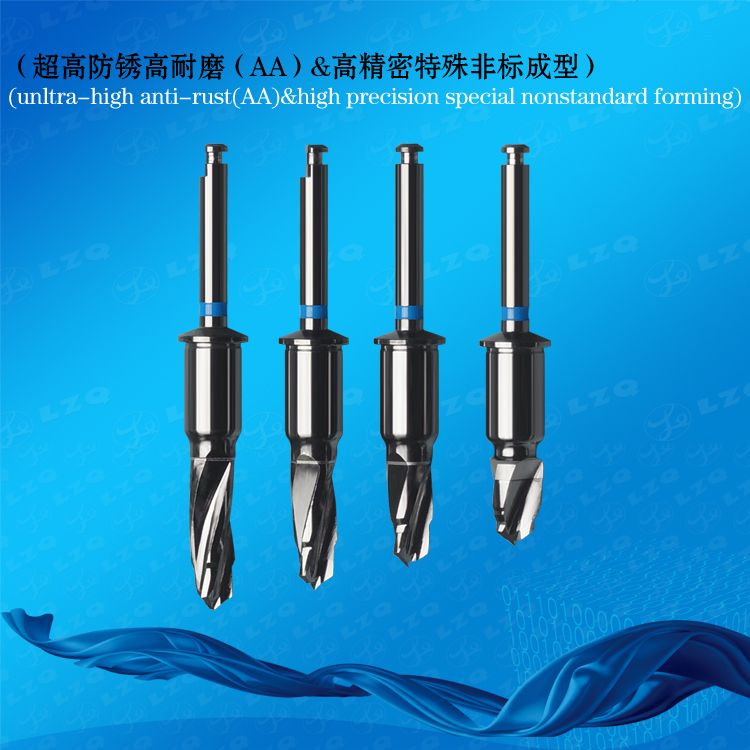

※ Cutting edge machining grades:

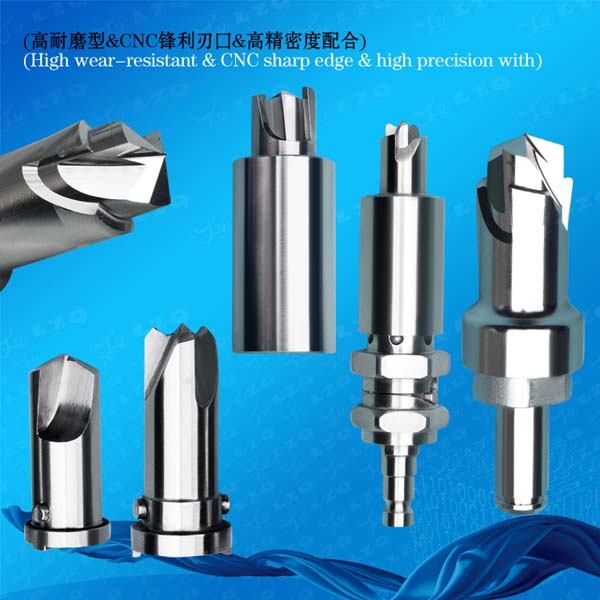

Class AAA: CNC super hard grinding wheel, mirror surface grinding for any shape of cutting edge.Concentricity, runout, cylindricity≤0.003mm(3μm),any sharpness of cutting edge.

Class AA: CNC super hard grinding wheel, finish grinding for any shape of cutting edge.Concentricity, runout, cylindricity ≤0.008mm(8μm),any sharpness of cutting edge.

Class A: CNC super hard grinding wheel, general grinding for any shape of cutting edge.Concentricity, runout, cylindricity≤0.012mm(12μm),any sharpness of cutting edge.

Class B: CNC lathe work + heat treatment + polishing treatment, worse sharpness of cutting edge.Concentricity, runout, cylindricity(0.10~0.20mm)(100/μm~200/μm).

Characteristics

Application domain: For implantology

Material:

(Ultra-high rust-proof stainless steel AA) (hardened HRC54 ° ± 2 ° Section)

Ultra-high anti-rust & high wear-resistant , high hardness, high impact, high toughness stainless steel, with excellent anti-rust capability, corrosion resistance, wear resistance (high hardness) performance and ideal impact resistance.. Its excellent corrosion resistance is comparable to TYPE 304 Stainless steel; and its rust resistance is closer to alloy for surgical implant. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 1000 hours. Wide range of applications, quite good and stable quality, which can be used to produce extremely complex, high-precision shank shapes and profile ultra-sharp edge structures.

Applied for high-end medical standard: AMS 5936 . MMPDS-01 . ASTM A693

ASTM A564 . ASTM F899-12

The Vitro (cytotoxicity) test verifies that the material does not have any potential cytotoxicity and therefore can safely contact human tissue, body fluids or blood, and meets all relevant allergy and skin irritation test standards.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

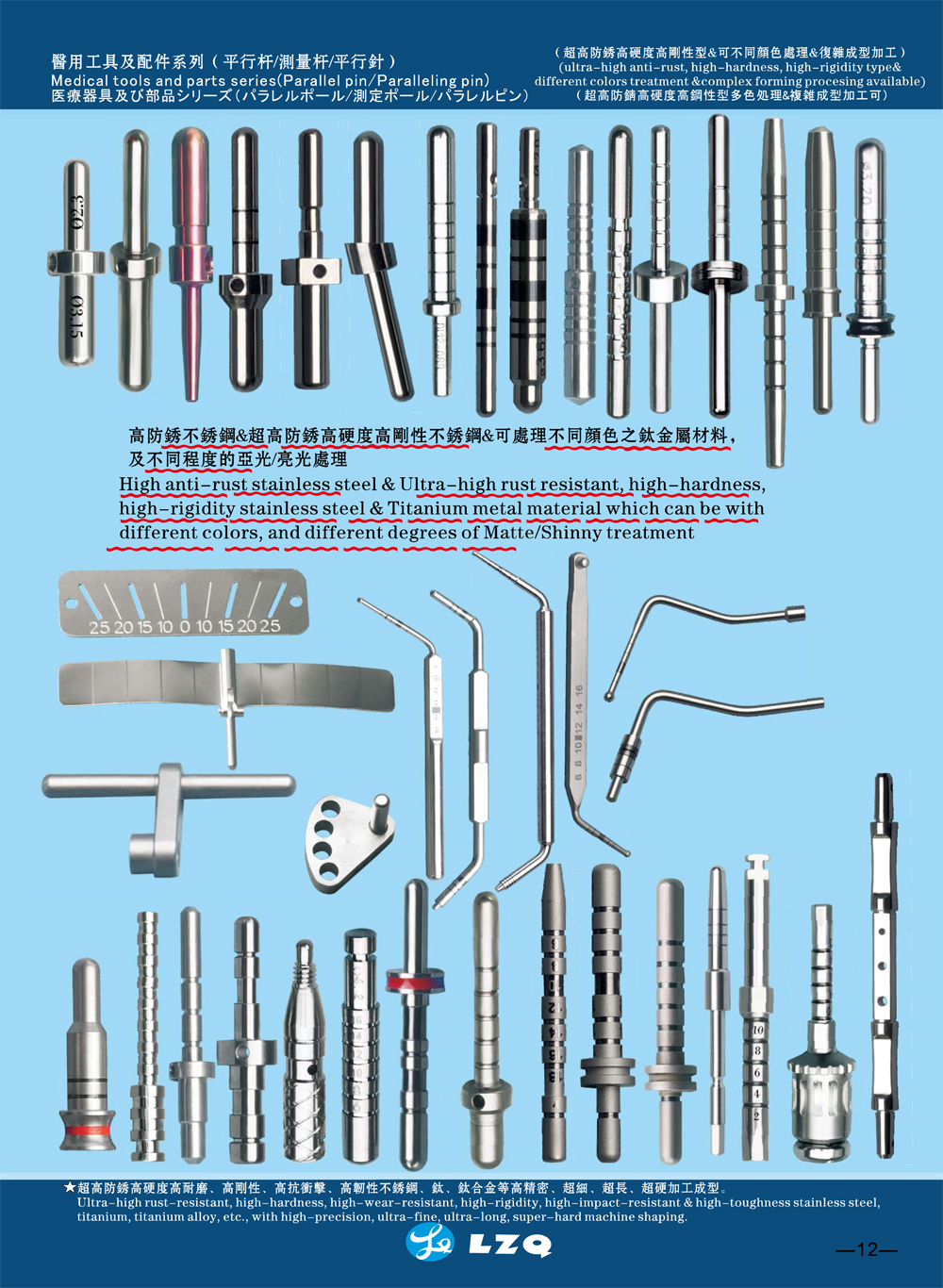

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.