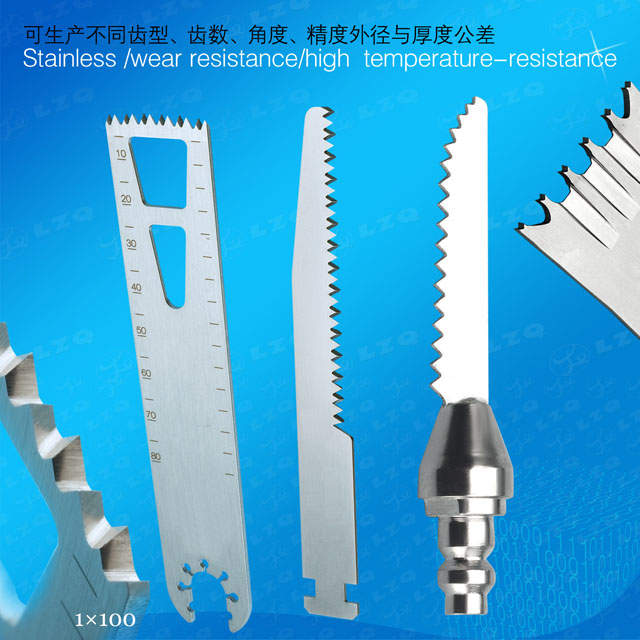

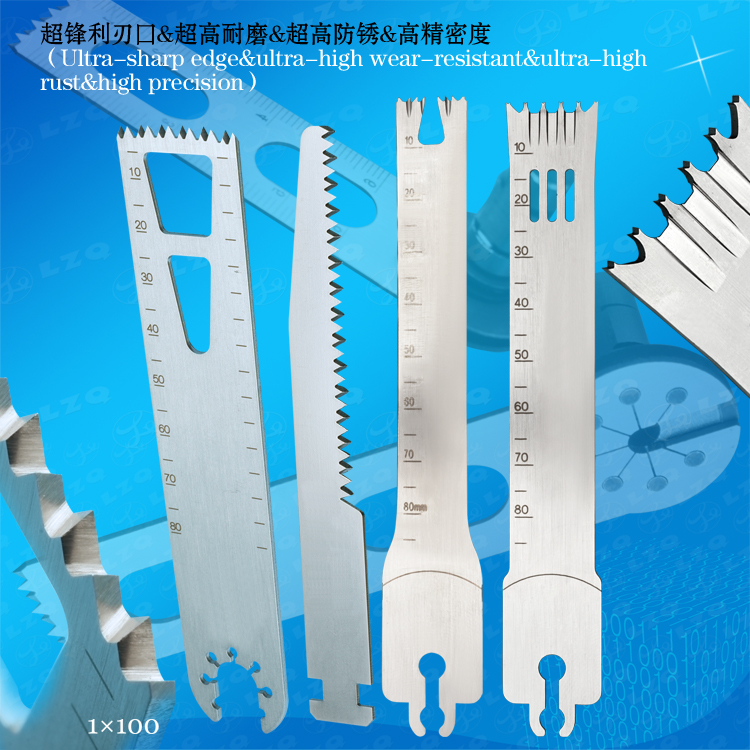

medical bone saw L-05.002.103

一, Product Information

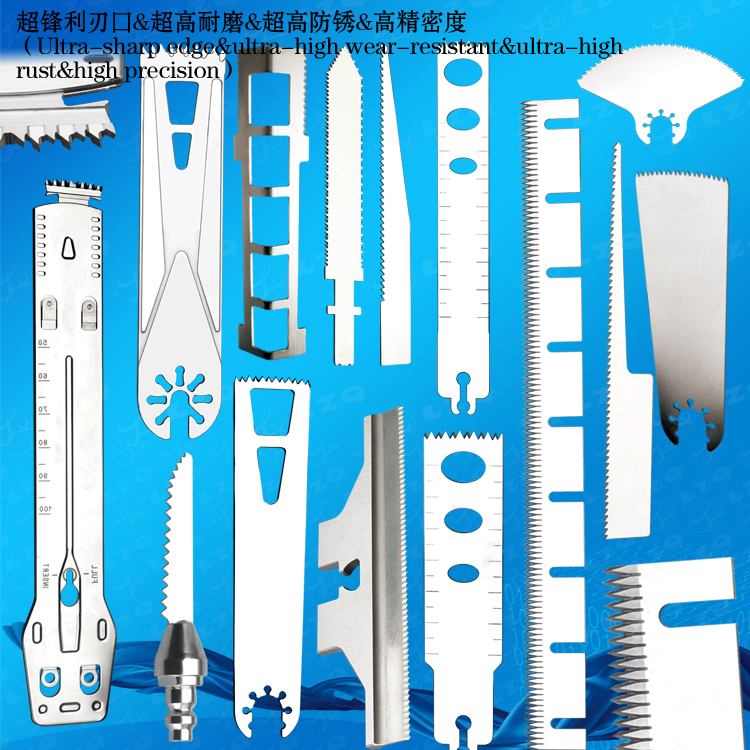

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance.

※If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).※

We keep around RMB 30~40 Million turnover stock articles such as raw material ,semi- products, finished products in ordinary year , we are capable to produce according to drawing or sample provided by customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory.

二,Products Description

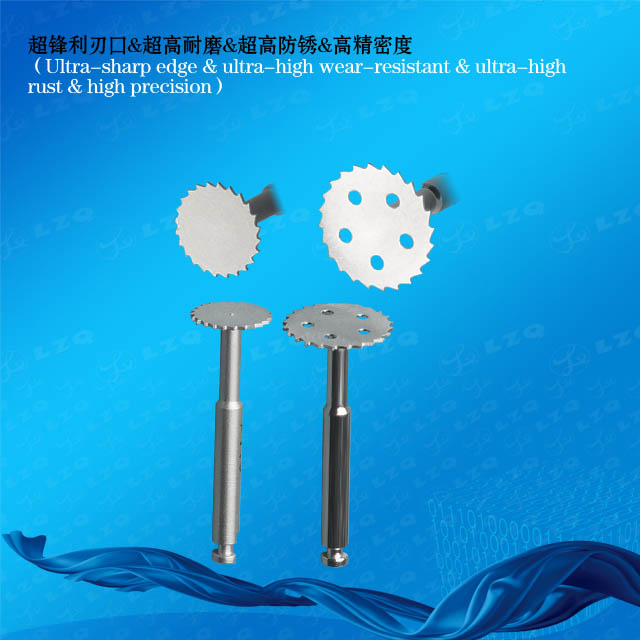

LZQ is an OEM factory for all kinds of medical tools

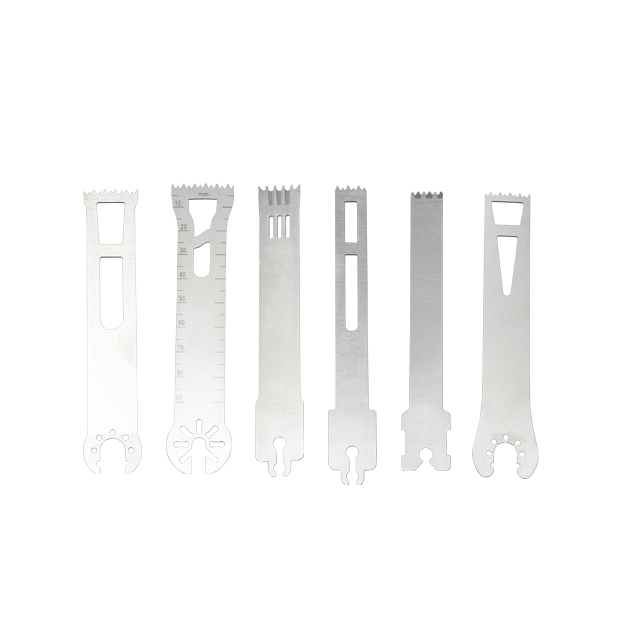

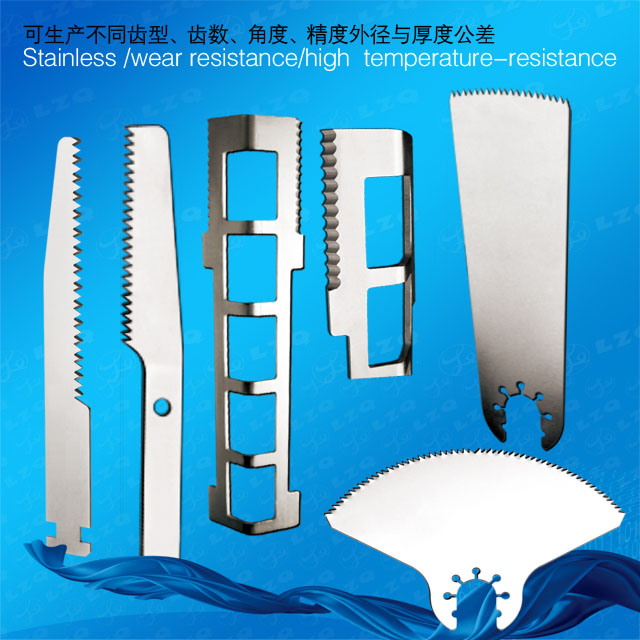

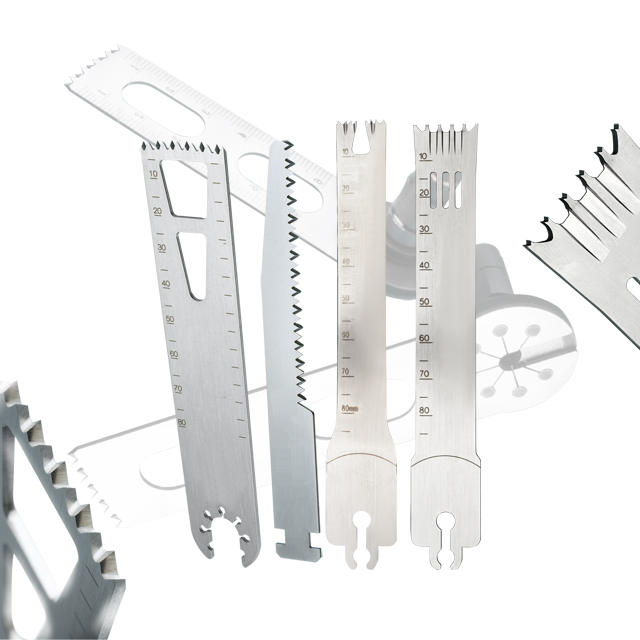

We can produce different shapes of tooth, number of tooth, precision diameter and thickness tolerance.

According to drawings or samples, we can customize ceramic, tungsten steel, stainless steel, titanium alloy, titanium diamond, etc., high-precision combination profile fixture, brazing fixture, wear-resistant accessories, high-precision accessories (3DX technology) molding super Hard, super fine grinding

(Ultra-sharp edge&ultra-high wear-resistant&ultra-high rust&high precision)

Material classification:

1. Ultra-high rust-proof & wear-resistant stainless steel (AA) (HRC54°±2°Section) (regular stock)

2. Conventional standard rust-proof and wear-resistant stainless steel (A)(HRC52°±2°) series Ordinary antirust stainless steel (A) (HRC62°±2°)

3. wavy-edge( we can grind front. reverse side and staggered teeth)

Grinding grade for flute section

AAA: CNC mirror grinding for flute with any shape

A A: CNC finish grinding for flute with any shape

A : CNC common grinding for flute with any shape

Processing way of two flat sides:

1、After heat treatment to hardness HRC62°+2°hard and thick materials can be processed to complicated and step profile shape and size by finish grinding and electric spark EDM, but the cost is high

2、After heat treatment to hardness HRC62°+2°hard material can be processed to double flat sides with any thickness tolerance by finish grinding, but the cost is a litter high.

3、 Stardard thickness material can’t be throug thethe treatment and it is too thin The cost is low.The hardness of material is decided by material factories

4、micro size can use high performance hiah tenacitv carbide CNC mirror surface grindingforming

Processing grade for shank

AAA:Sodick/+GF+WEDM-LS by 3-5 times

A A:Sodick/+GF+WEDM-LS1-2 times

A :process with carbide mould by high precision punching shear

B :process with common mould by precision punching shear

The cost of products includes: grinding grades of cutting edge+ processing grades of shank+ processing way of two flats=combine final products with different application, effect, grade and cost-performance If meet the assembly space demand, saw tooth can be customized with different thickness, width, tooth shape, number of teeth, angle, sharpness.

We ca in make tools with any material, any shape,special kind special type,abnormal shapeand precision and tolerance by mirror surface grinding according to your drawings or samples

三,Material / Characteristics

ASTM440Mod

(Super-high rust-proof stainless steel A+) (hardened HRC60°±2°Section)

Ultra-high anti-rust, high-sharpness and super-high wear-resistant stainless steel, with super-high wear resistance (super high hardness) performance and high standards of rust and corrosion resistance. It has a service life of 2 ~ 3 times longer than that of general stainless steel. The cutting edge keeps for a super-long time of cutting sharpness. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 300 hours, which meet FDA high standard. If for repeated use, it is recommended to clean and dry it in time after every surgery.

Wide range of applications. With excellent abrasion resistance and sharpness, it can be used to produce extremely complex, high-precision handle shapes and formed super-sharp edge structures.

. ASTM440PH . Type 440C . UNS S44004PH . ASTM F899 :

(Ultra-high rust-proof stainless steel AA) (hardened HRC54 ° ± 2 ° Section)

Ultra-high anti-rust & high wear-resistant , high hardness, high impact, high toughness stainless steel, with excellent anti-rust capability, corrosion resistance, wear resistance (high hardness) performance and ideal impact resistance.. Its excellent corrosion resistance is comparable to TYPE 304 Stainless steel; and its rust resistance is closer to alloy for surgical implant. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 1000 hours. Wide range of applications, quite good and stable quality, which can be used to produce extremely complex, high-precision shank shapes and profile ultra-sharp edge structures.

Applied for high-end medical standard: AMS 5936 . MMPDS-01 . ASTM A693 ASTM A564 . ASTM F899-12

The Vitro (cytotoxicity) test verifies that the material does not have any potential cytotoxicity and therefore can safely contact human tissue, body fluids or blood, and meets all relevant allergy and skin irritation test standards.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

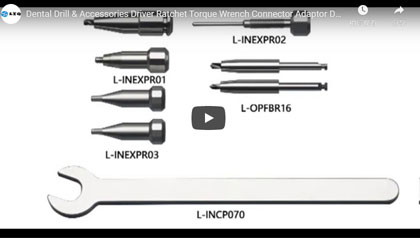

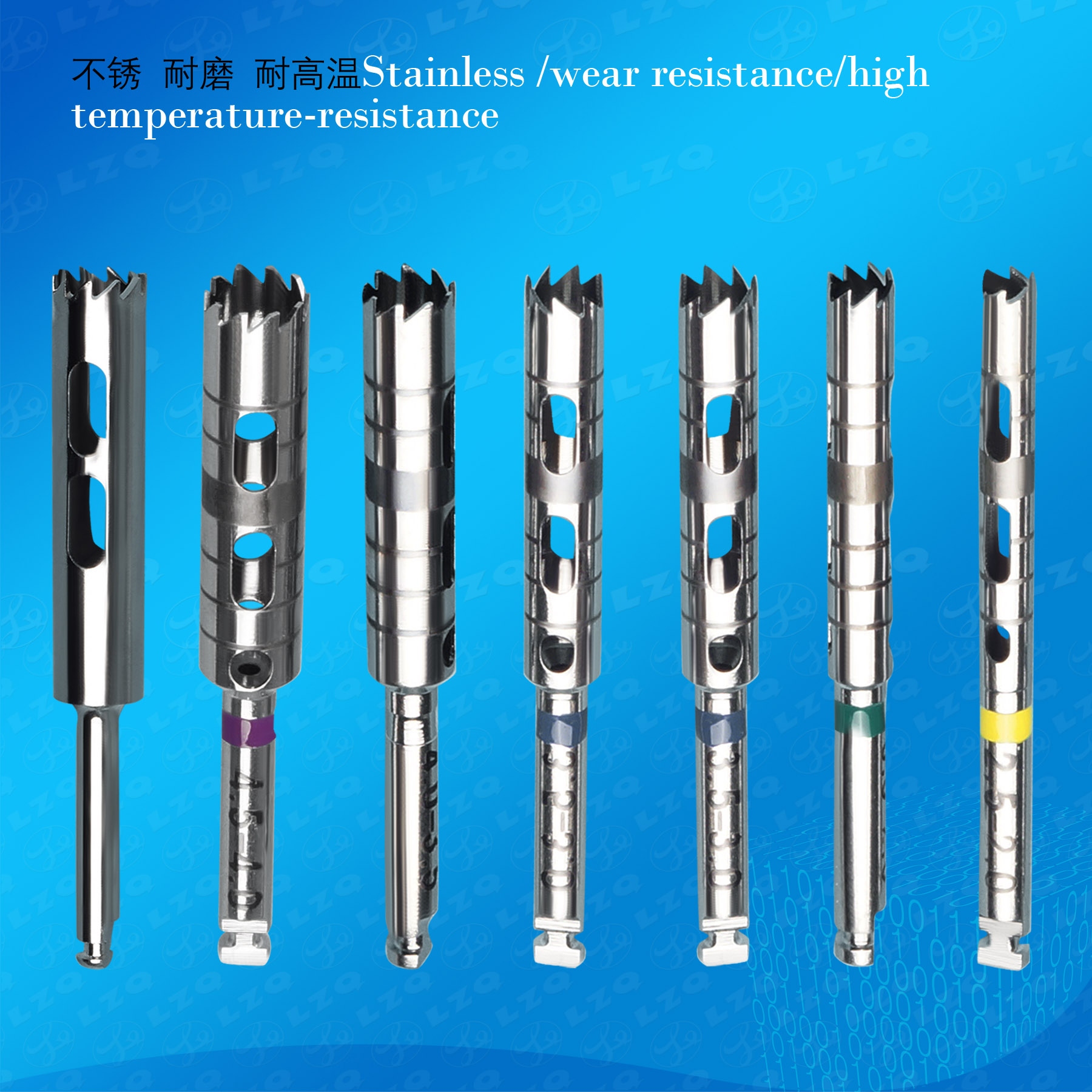

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.