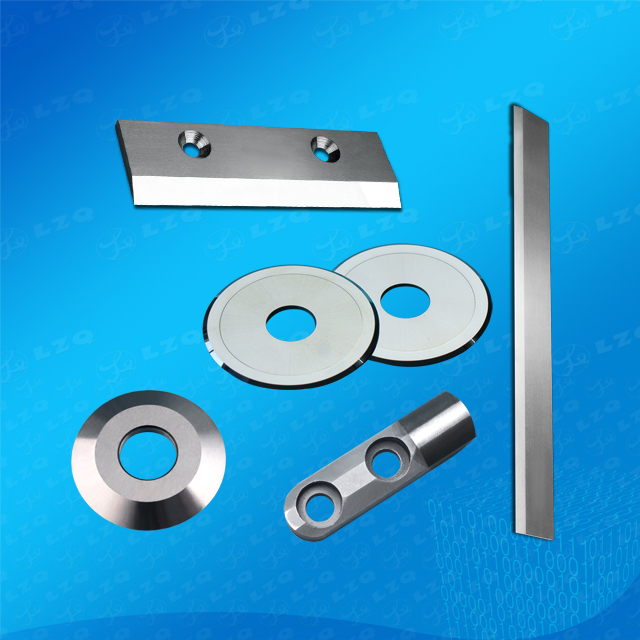

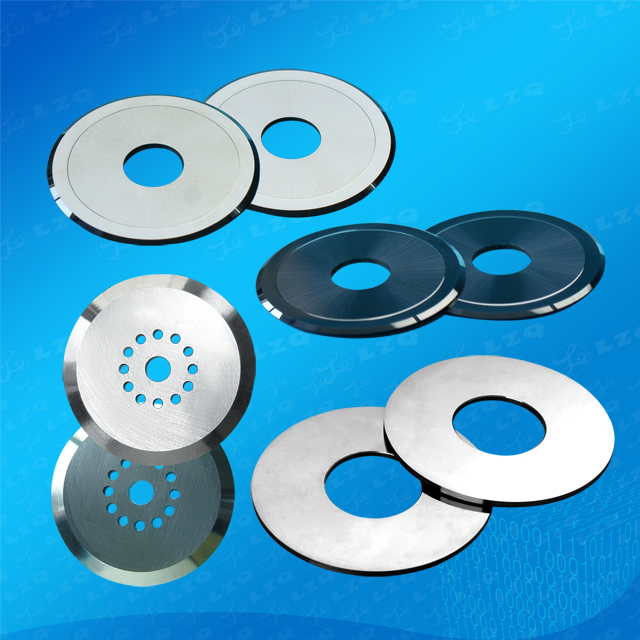

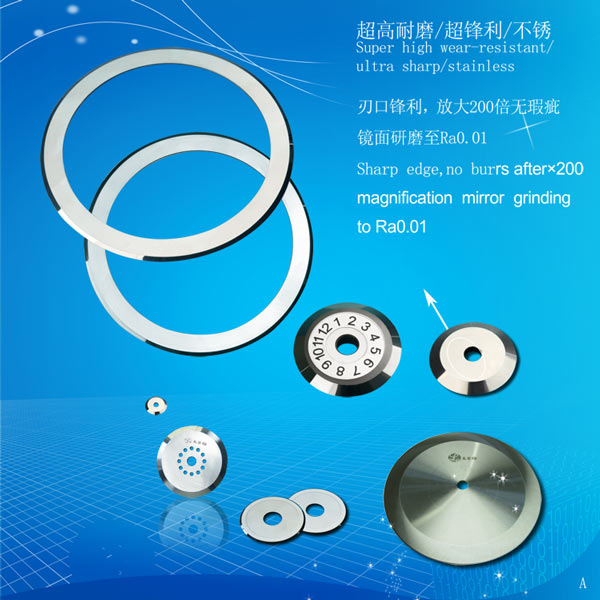

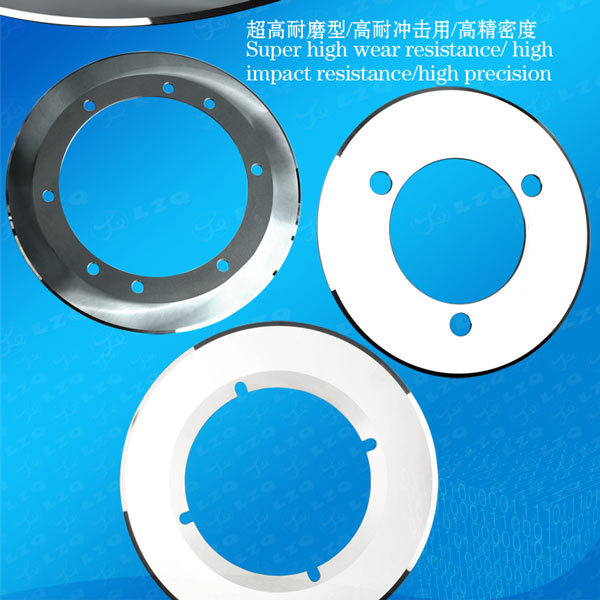

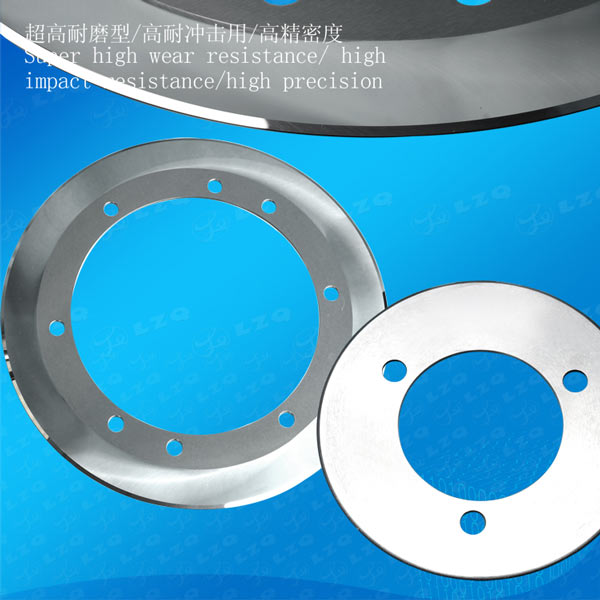

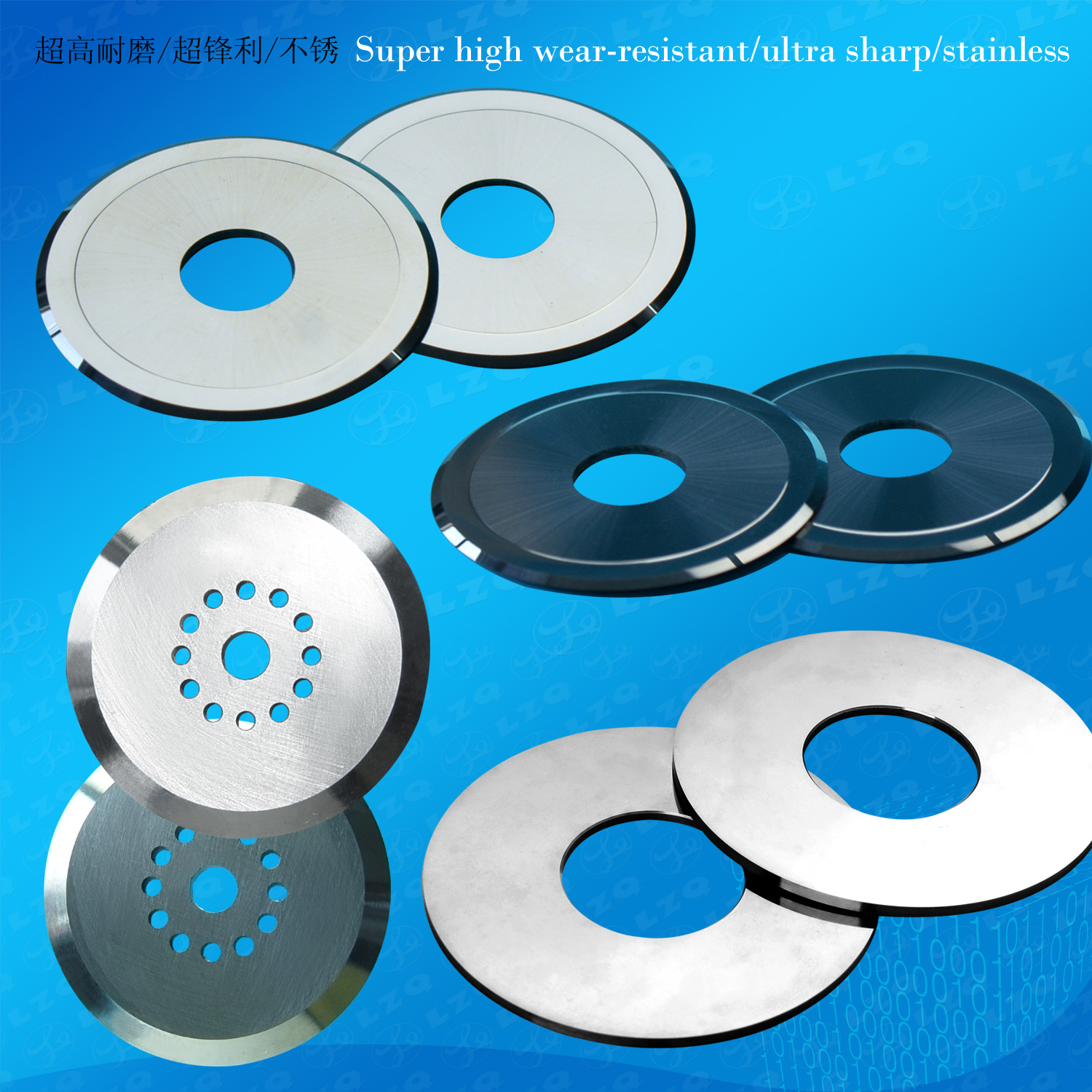

cutting wheels for glass carbide cutting wheels float glass cutting wheels

High Quality Cutting Wheels

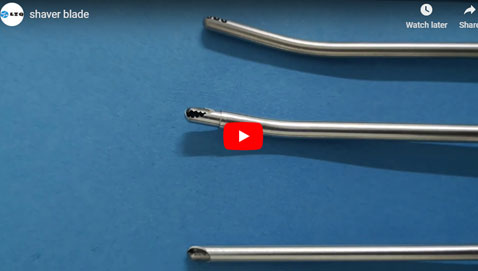

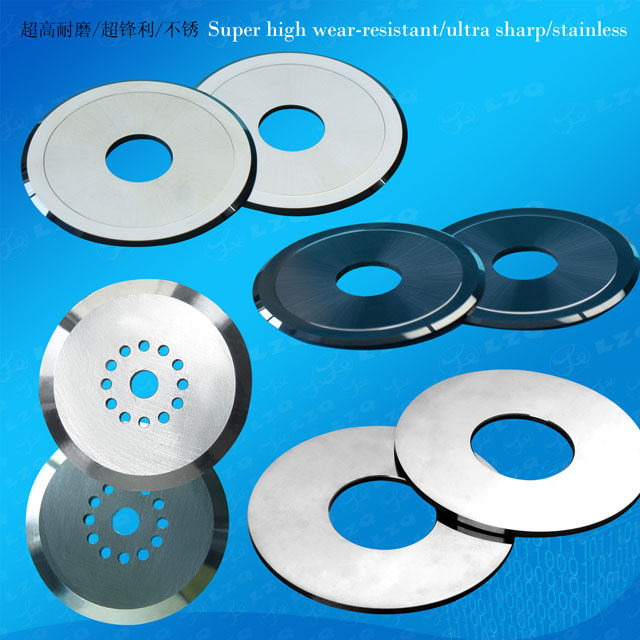

Equipped with state-of-the-art technology, LZQ produces cutting wheels for a wide variety of applications. Whether for float, drawn, thin or thick glass, special glass like display or borosilicate glass, LZQ provides carbide, PCD, coated and microstructured cutting wheels to meet your requirements. High Quality; Reliable and repeatable cutting results

One of the major benefits of the carbide cutting wheels is that it features a service life which is several times longer than the life of conventional steel wheels. Furthermore, the carbide cutting wheels have consistently good cutting properties which provide clean cut edges for different glass thicknesses. A similar development can be seen with PCD (polycrystalline diamond). Best raw materials and outstanding machining The careful selection and analysis of the raw material is the starting point for producing top quality glass cutting wheels. But not only the basic material is critical for the quality of the cutting wheel; tremendous know-how lies in the machining of the wheels. The wheels are ground to perfection. The grind is adapted to suit the later application and results in consistently long service lives and optimal cutting results. The cutting wheels obtain the best running qualities because the holes are hone processed and the side surfaces are fine polished and lapped.

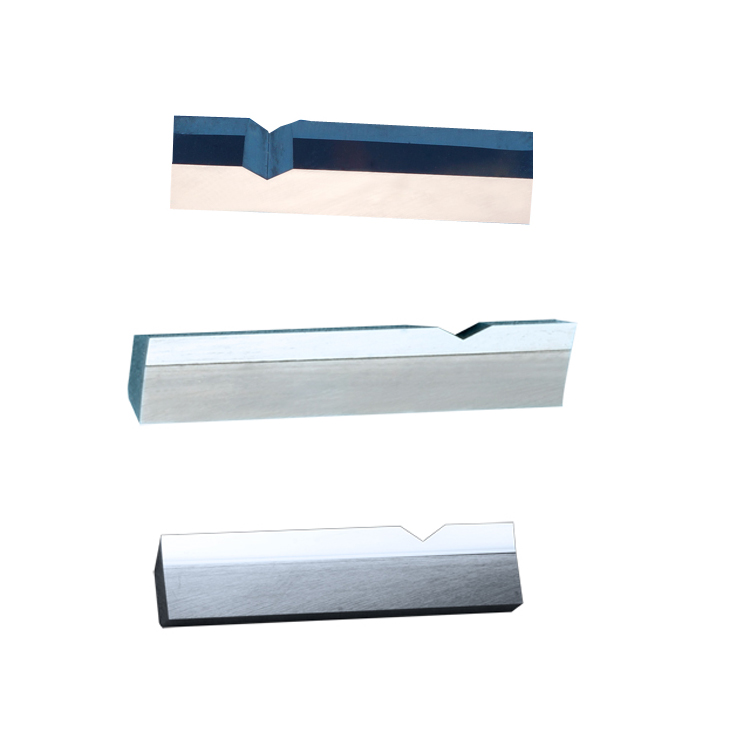

In order to be able to cut glass of different thicknesses and coatings, the cutting wheel must have the optimum cutting angle. Only when the cutting angle is exactly suited to the glass can the best break quality be achieved and the edge damage be reduced to a minimum. Cutting pressure a = Cutting angle (±1°) D = Outside diameter (+0.15 mm/0.0059“-0.30 mm/0.0118“) d = Inside diameter (+ 0.04 mm/0.0016“) t = Wheel thickness (± 0.01 mm/0.0004“) Cutting angles 165° 160° 155° 150° 145° 140° 135° 130° 125° 120° 115° 110° When cutting glass, the right combination of cutting pressure and cutting angle is very important to keep the score as uniform and narrow as possible. A good score looks like a fine, silvery thread. Excessive cutting pressure increases the risk of glass splintering. In this case, the broken edge exhibits a rough pattern with irregularities. Cutting speed Not only the cutting pressure but also the cutting speed is important for a good cut. In general we can say that it is better to cut quickly, because doing so reduces the cutting pressure and allows a blunter wheel angle to be selected. This in turn improves the buildup of tension along the score in the glass and results in better breaking quality.

Due to their special micro-structured cutting edge, these cutting wheels achieve excellent cutting results with minimal cutting pressure, especially when cutting high quality glass types such as sensoric and solar glass, optical filters and quartz glass. In extensive tests, excellent results have also been achieved with borosilicate glass in various thicknesses. Furthermore, float glass as well as glass tubes can be precisely cut. In addition to the universal application fields, the wheels are also suitable for dry cutting, thereby avoiding any contamination from cutting fluids and the resulting time-consuming cleaning. Also can be used in all common float lines. For standard requirements, carbide wheels are available – an even longer service life is achieved with wheels made of PCD. The micro-structure allows tensions to be transmitted into the glass with minimal cutting pressure, resulting in a very easy break of the glass. Due to the structure of the cutting edge, the cutting wheel penetrates as notches into the glass compared to standard wheels which score the glass using their whole circumference. As a result, micro-openings of the fissure are produced precisely in the cutting direction. Accompanying cracks and damages deviating from the score line are effectively avoided and edge damages reduced to a minimum. All cutting wheels are marked with the cutting angle, thus avoiding confusion when they are used.

Especially when cutting laminated safety glass as well as edge cutting at float glass facilities, service lives can be achieved which are at least ten times as long as that of standard cutting wheels.

At float glass facilities achieves over 250 km of cutting performance.

Furthermore, significant savings can be attained in maintenance: As a result of the long service lives, cutting wheels and wheel holders don‘t need to be exchanged as frequently as usual.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

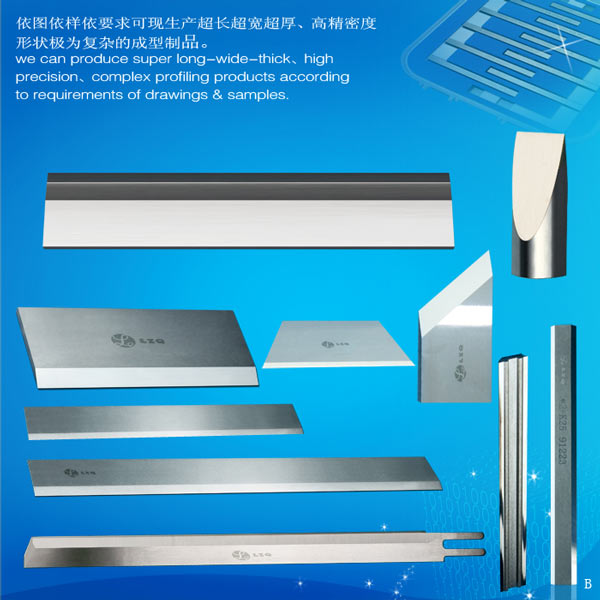

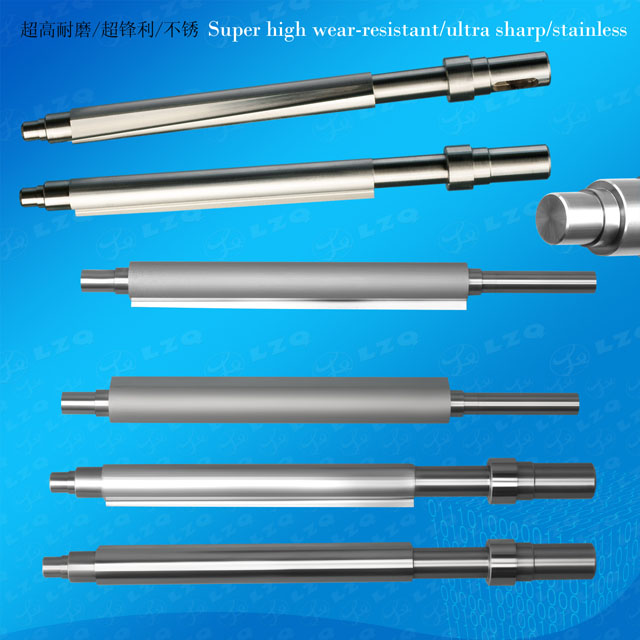

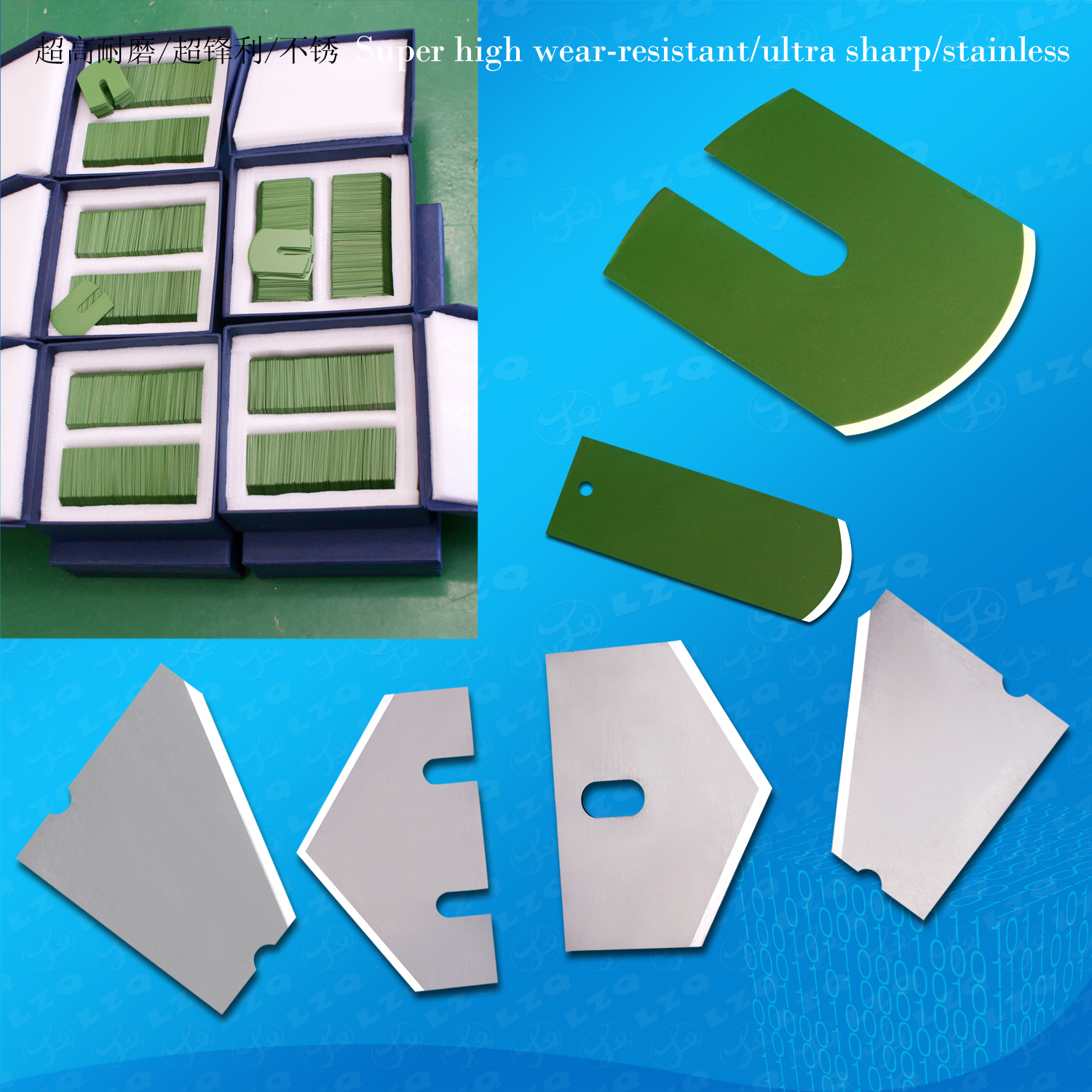

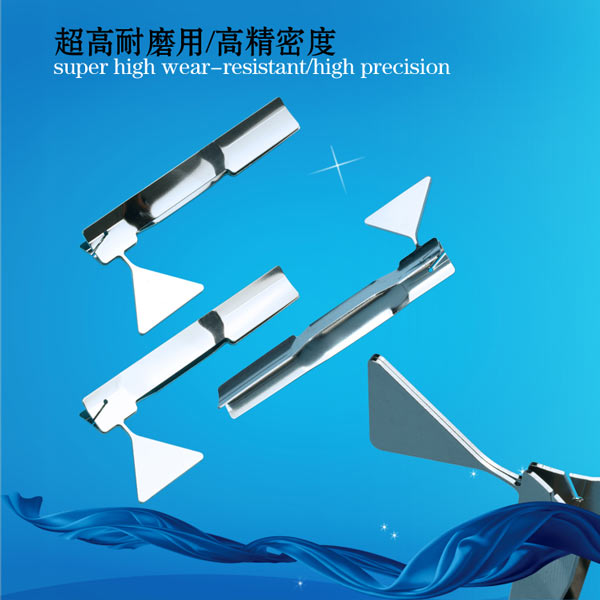

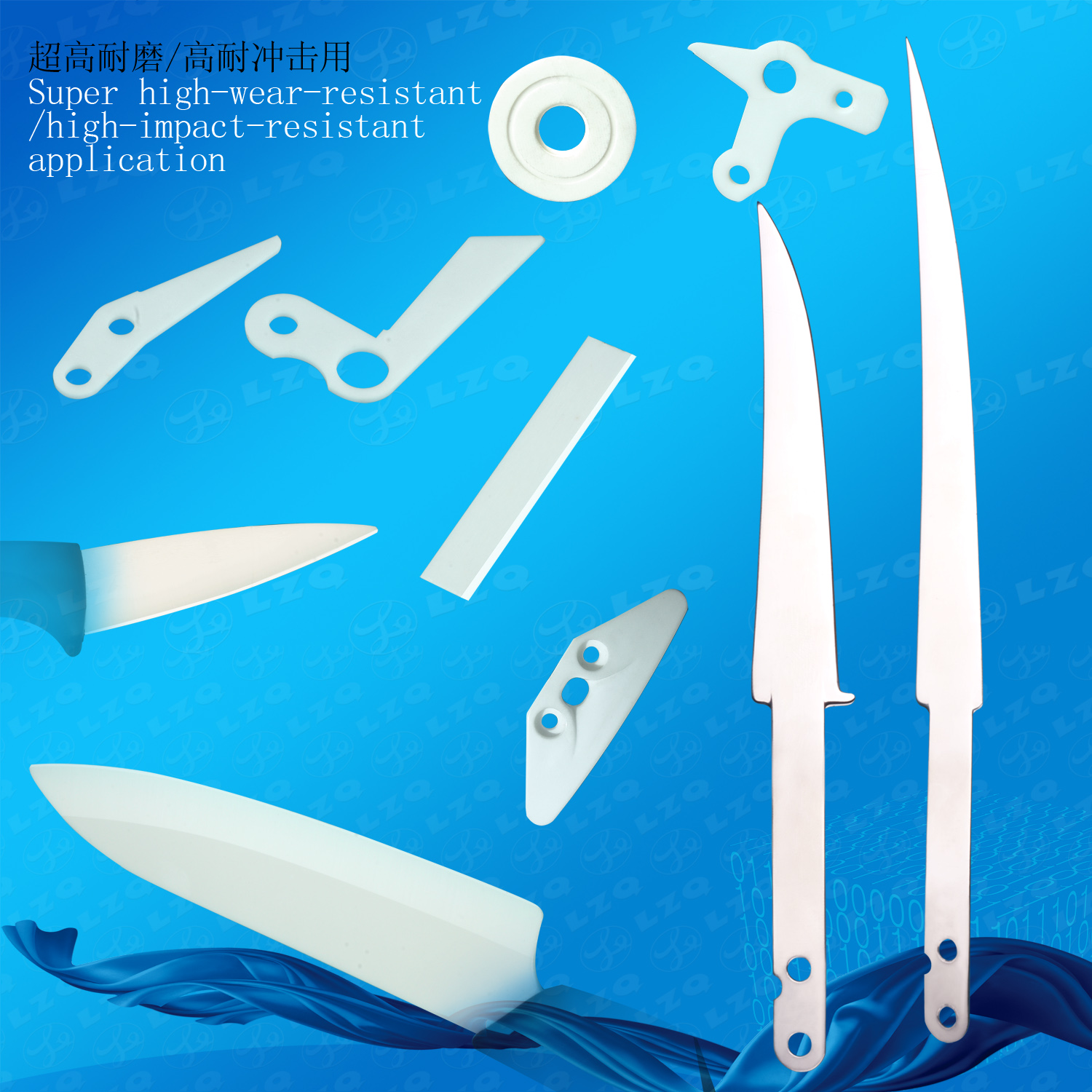

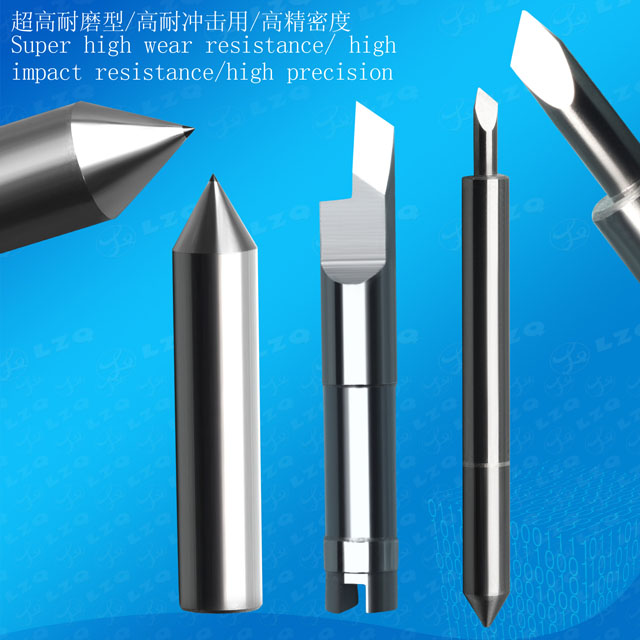

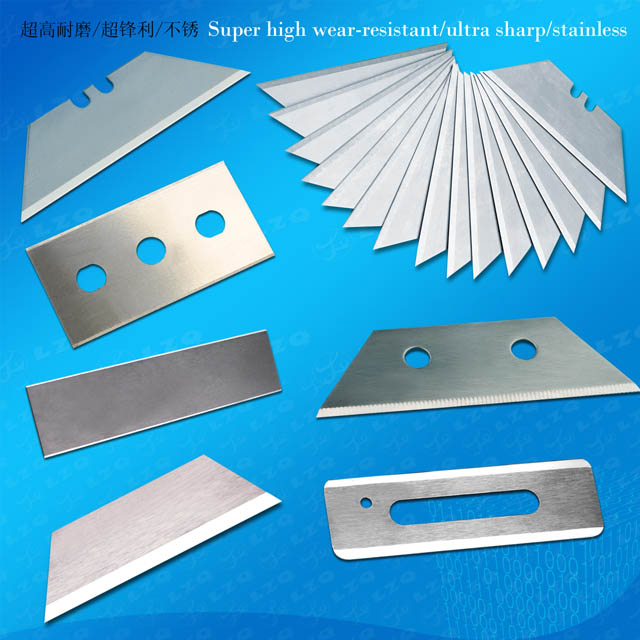

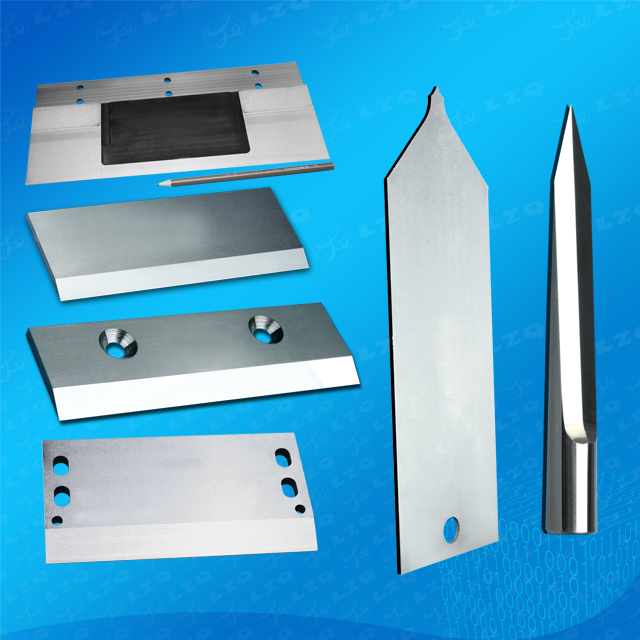

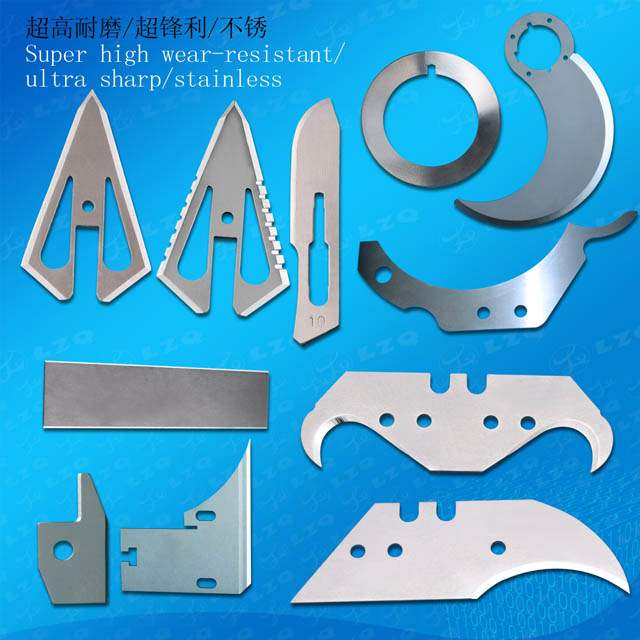

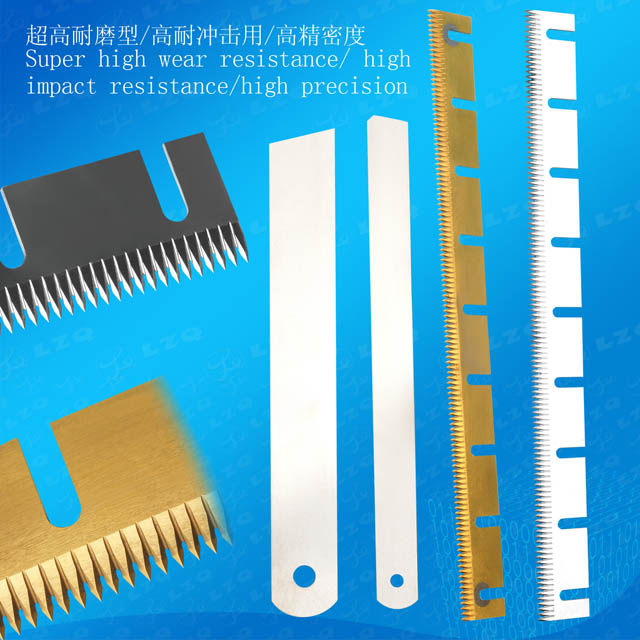

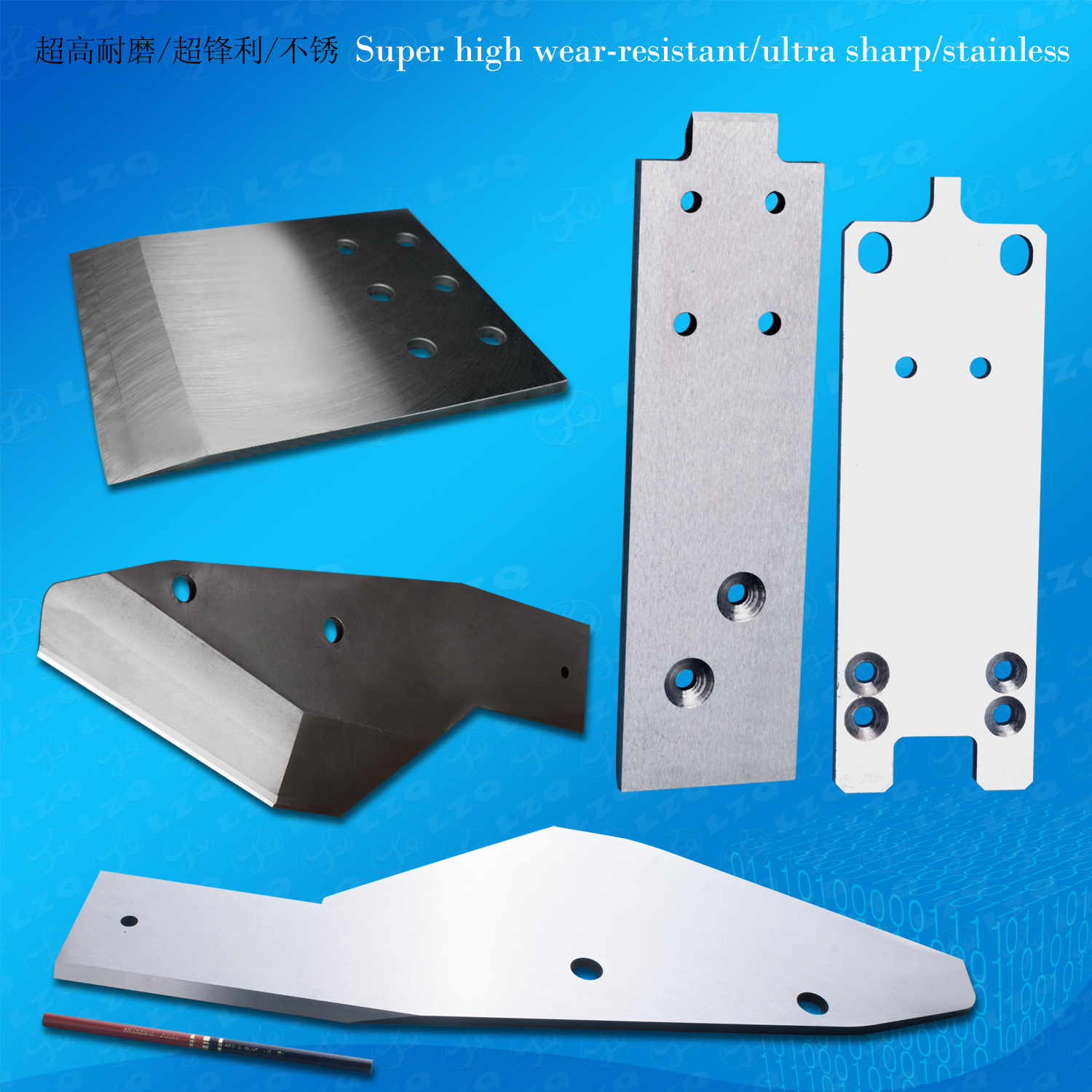

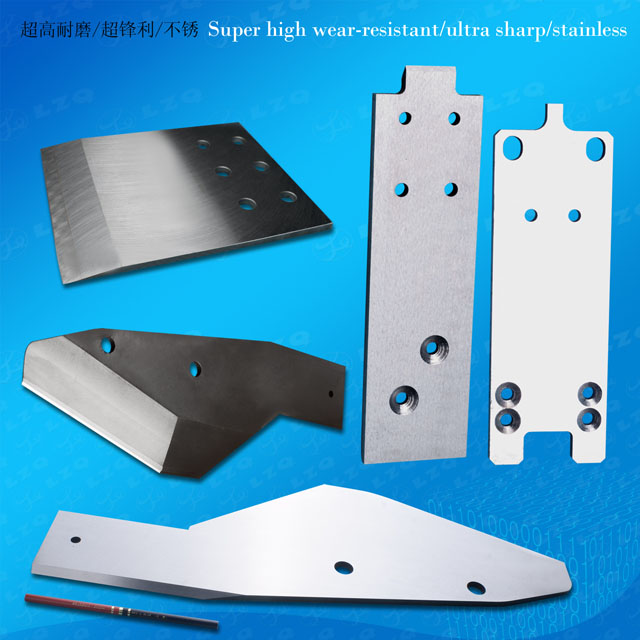

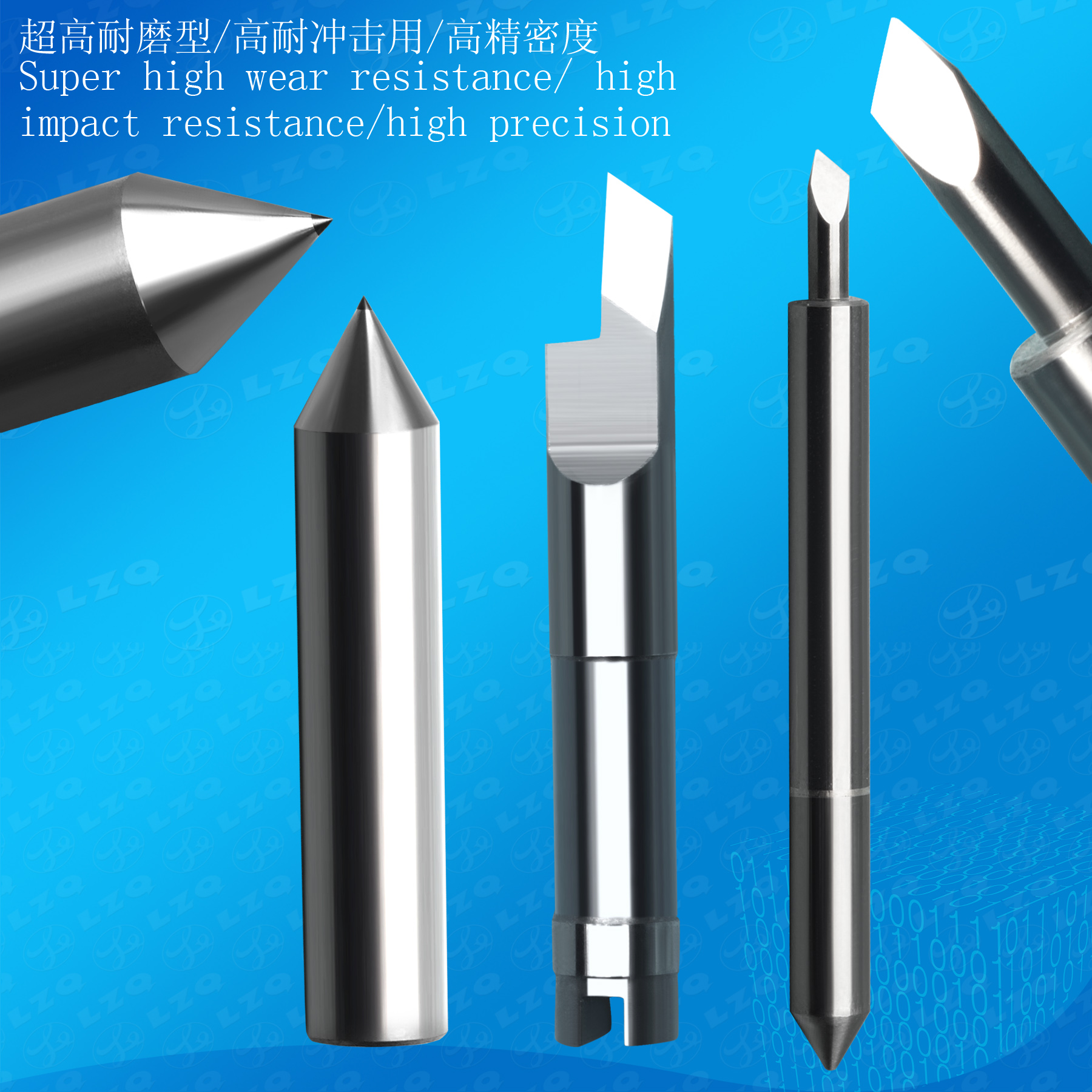

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

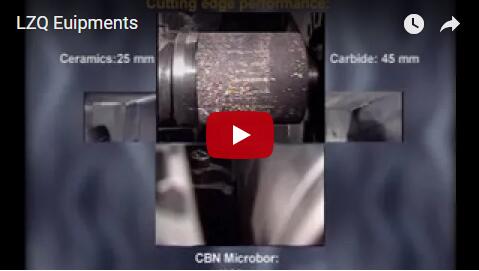

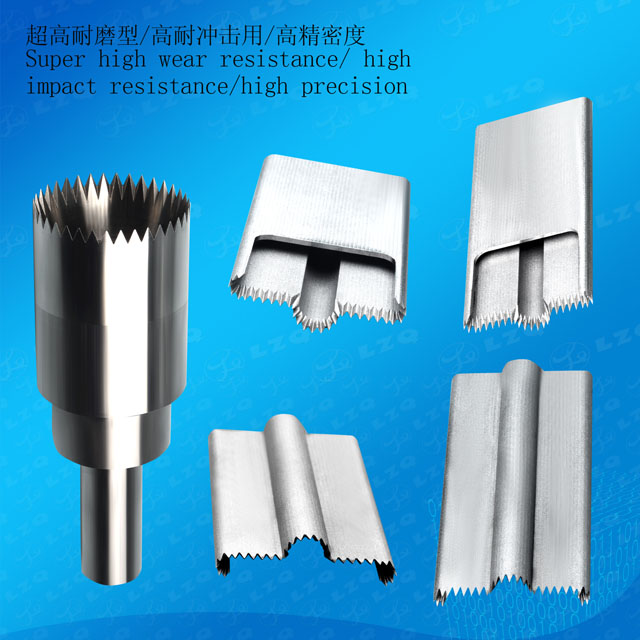

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

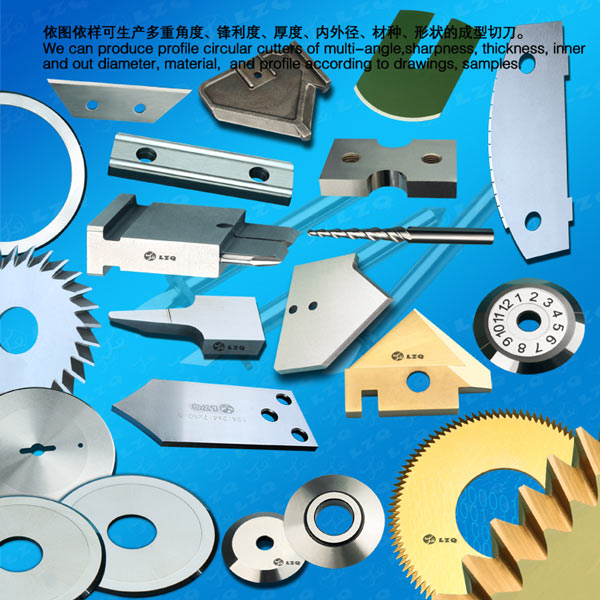

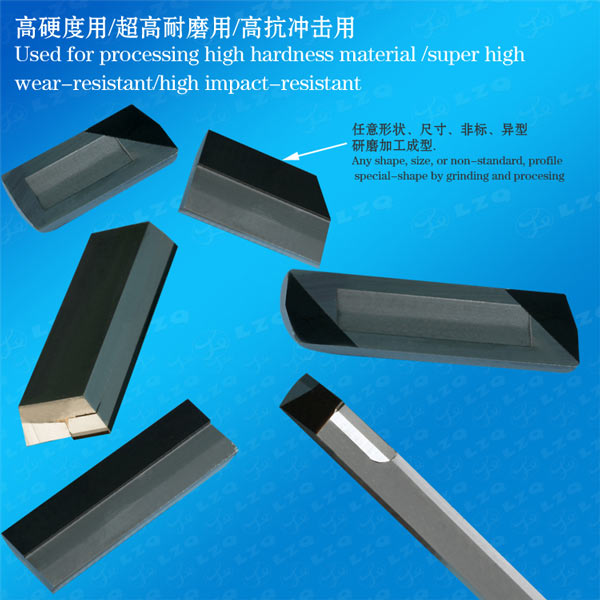

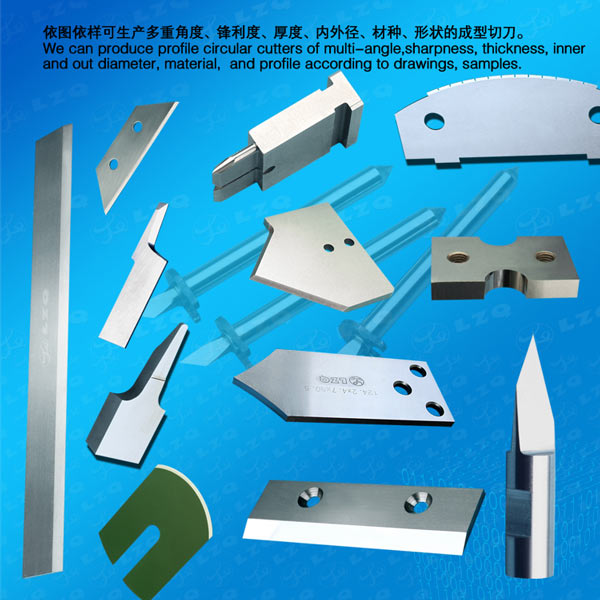

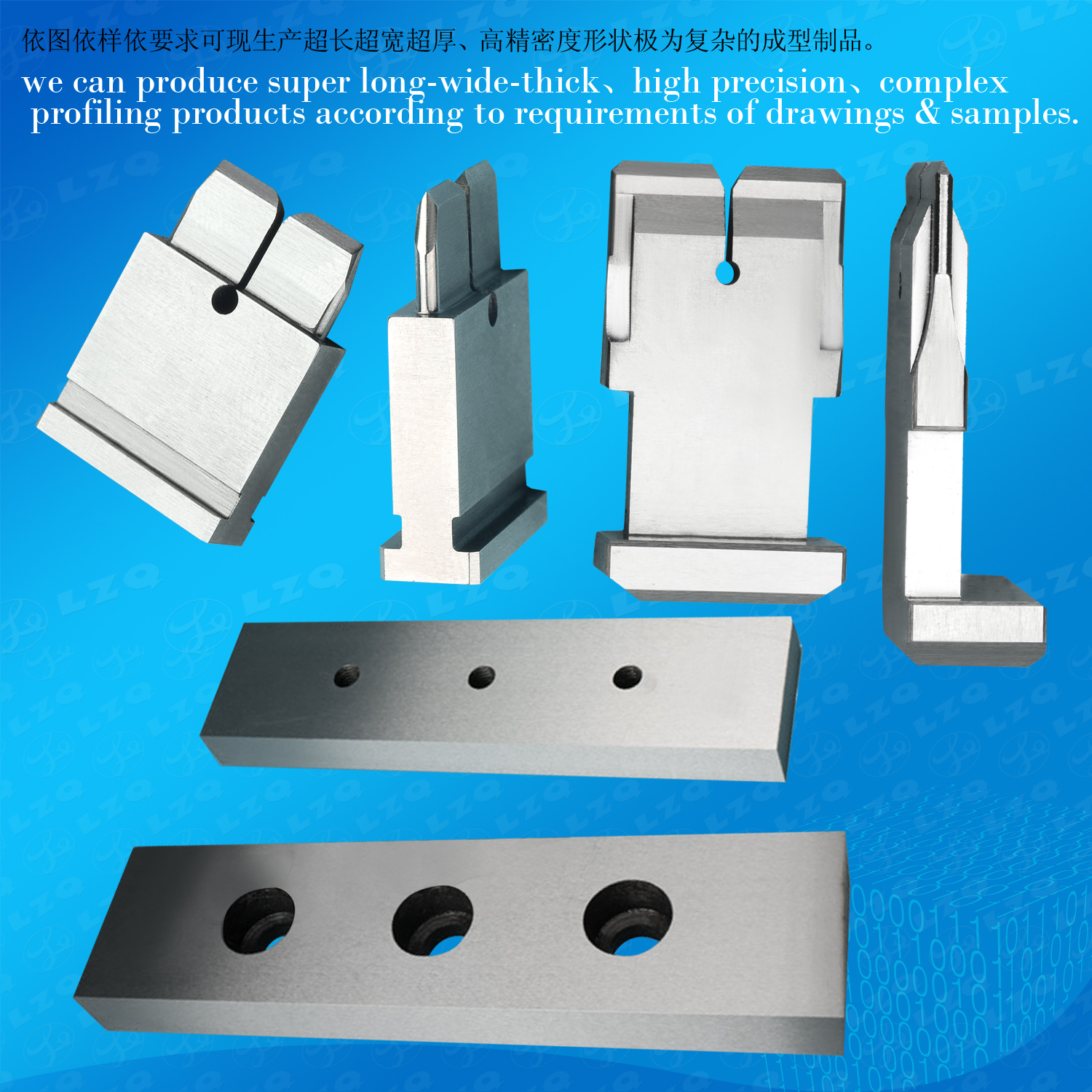

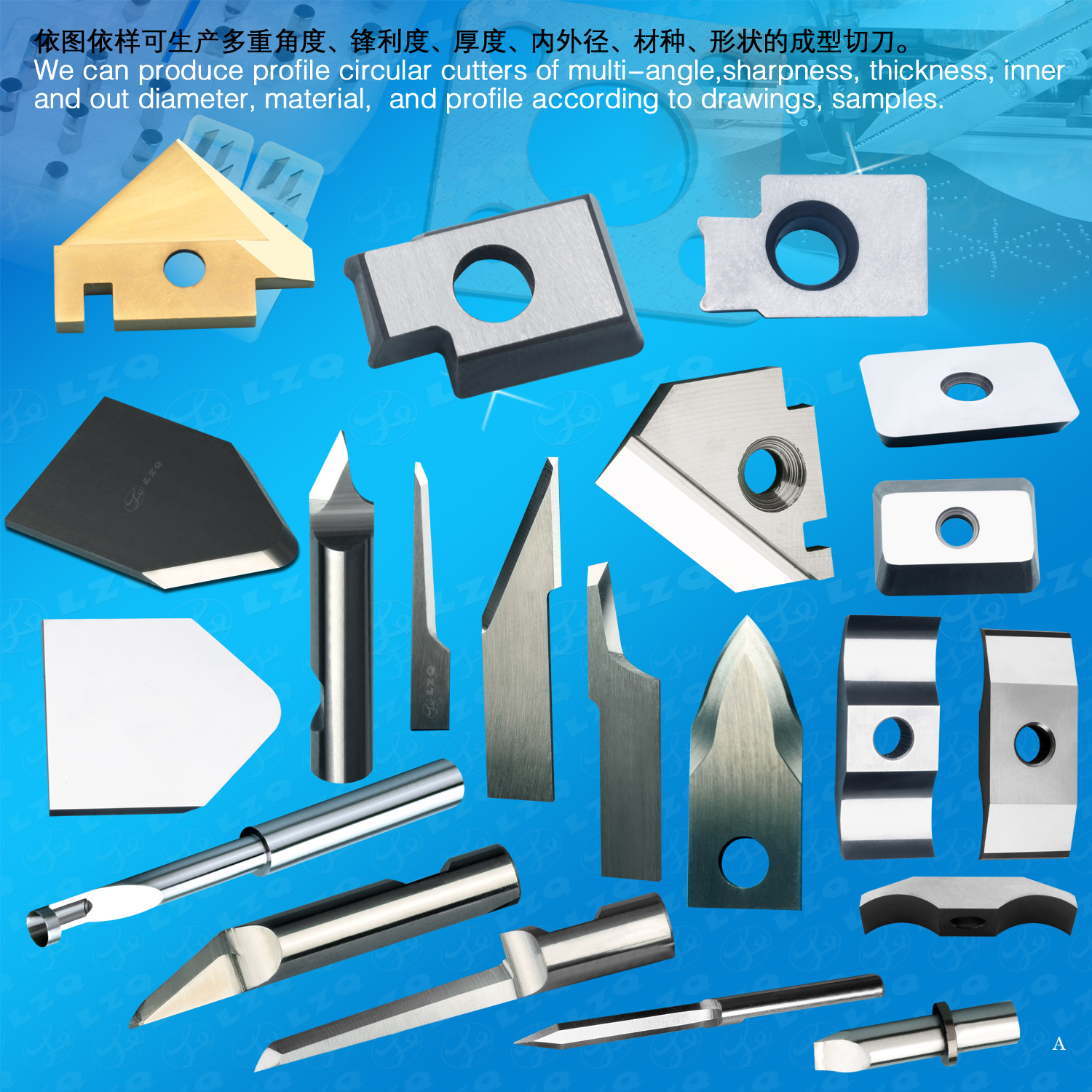

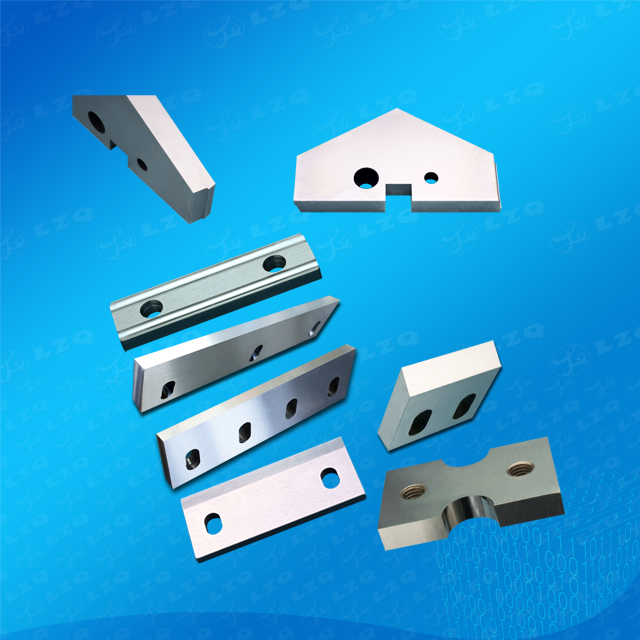

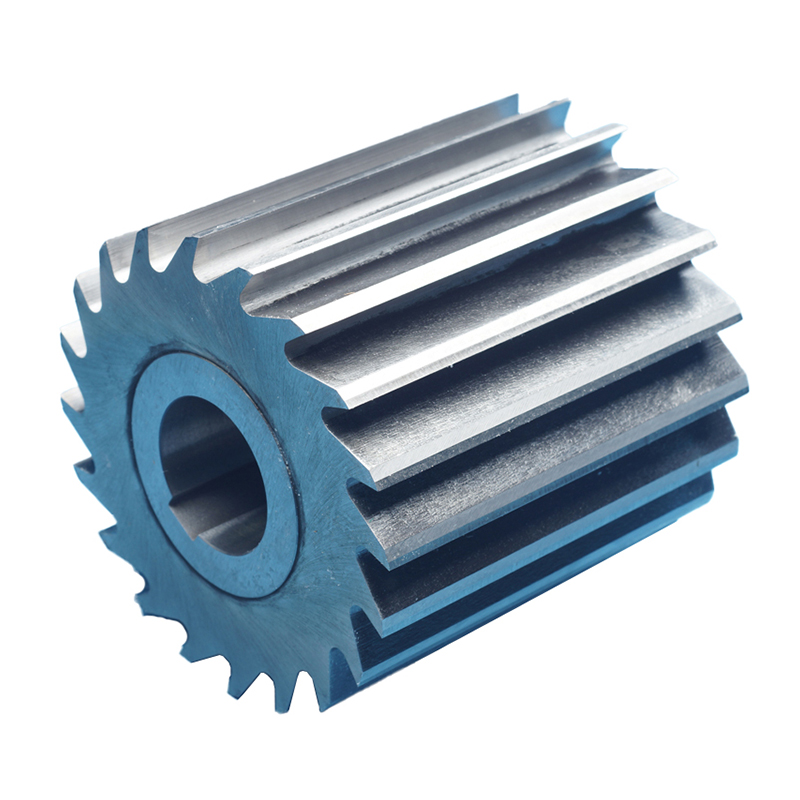

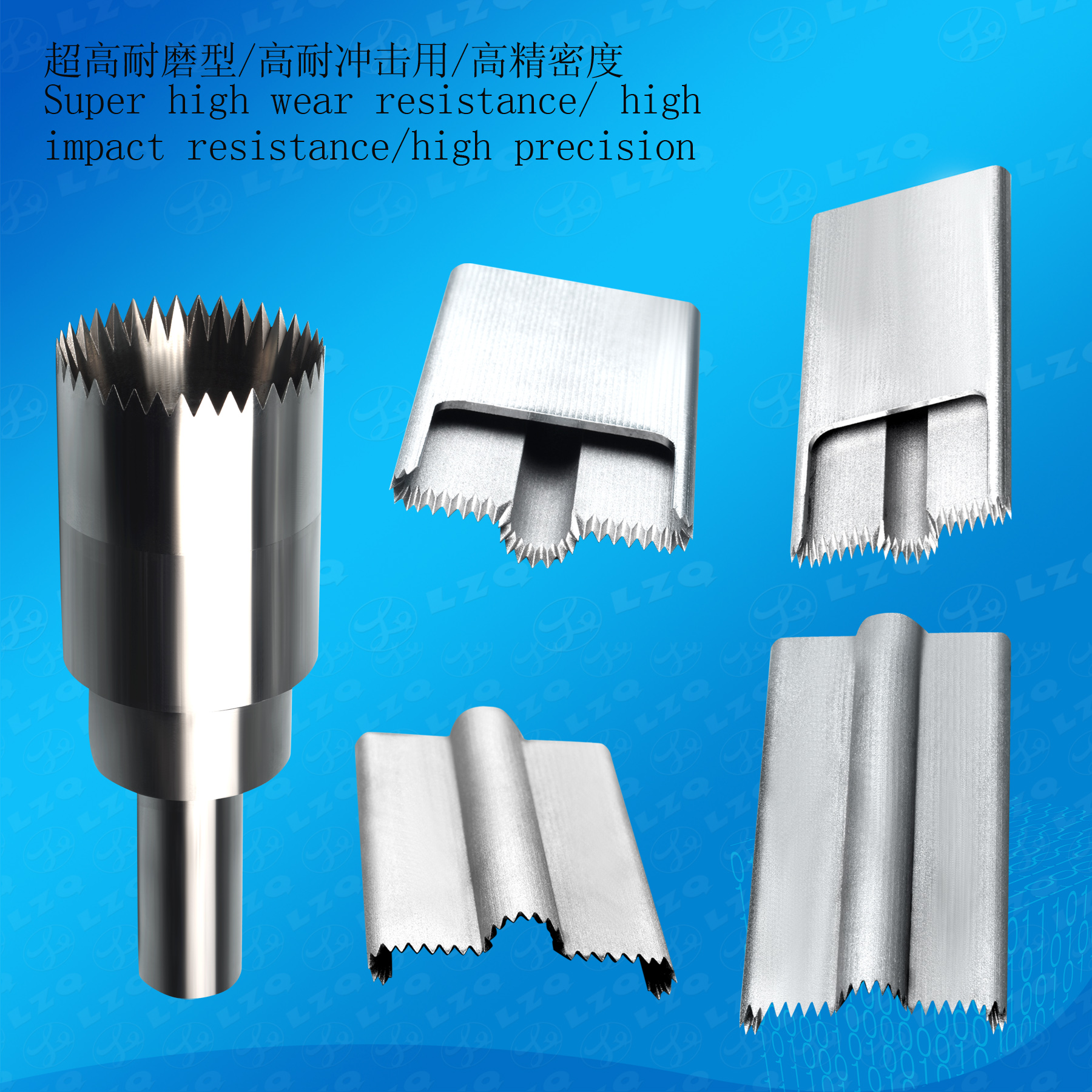

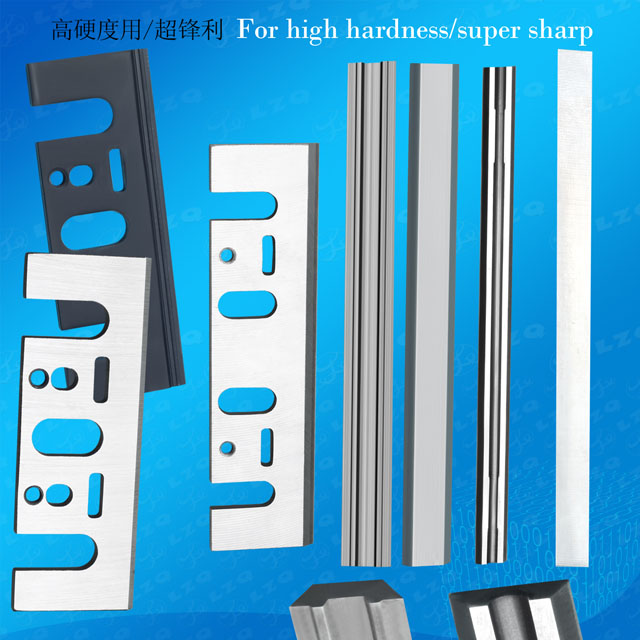

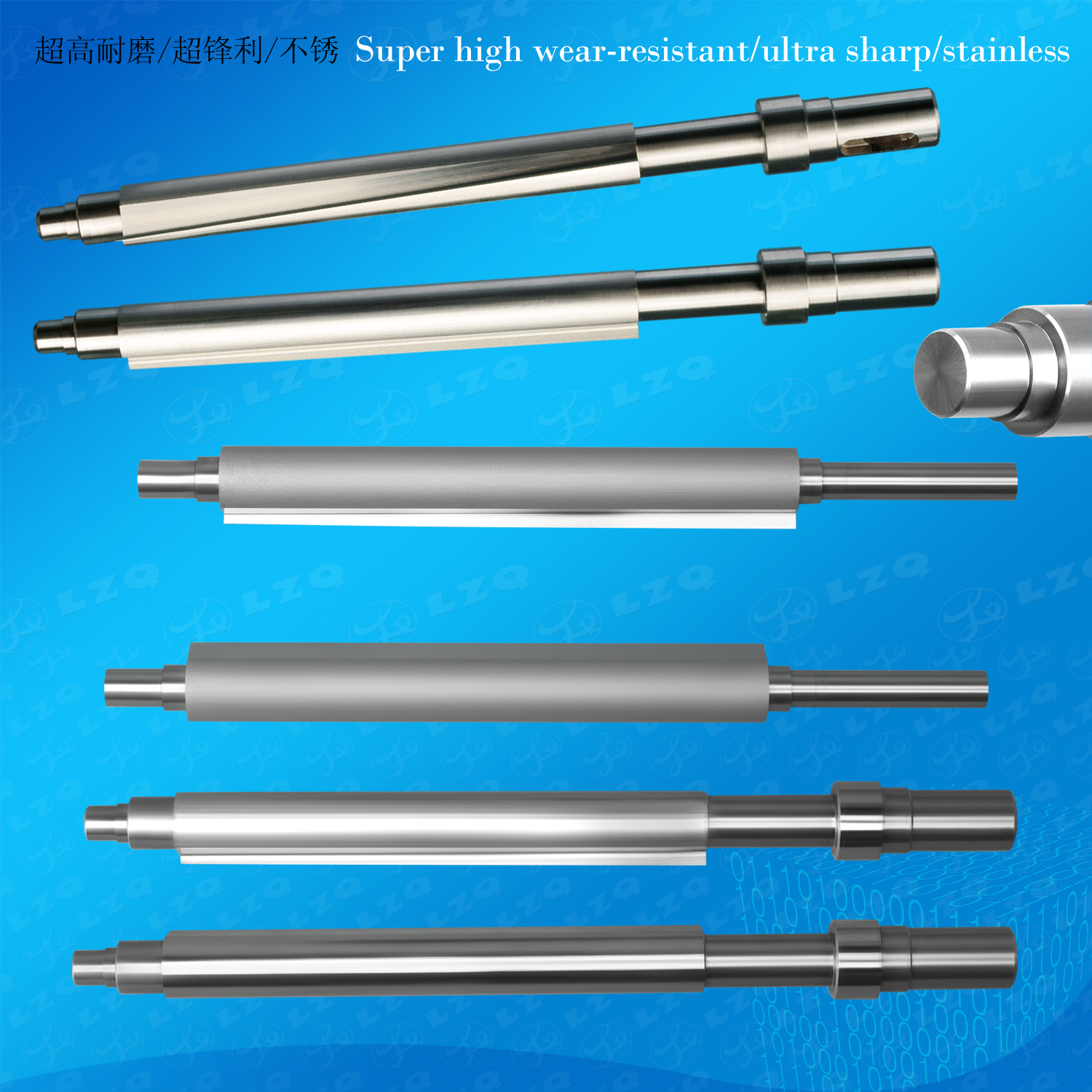

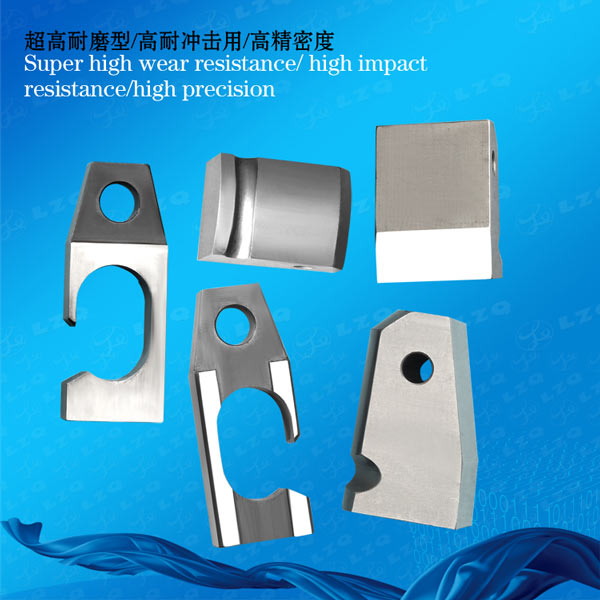

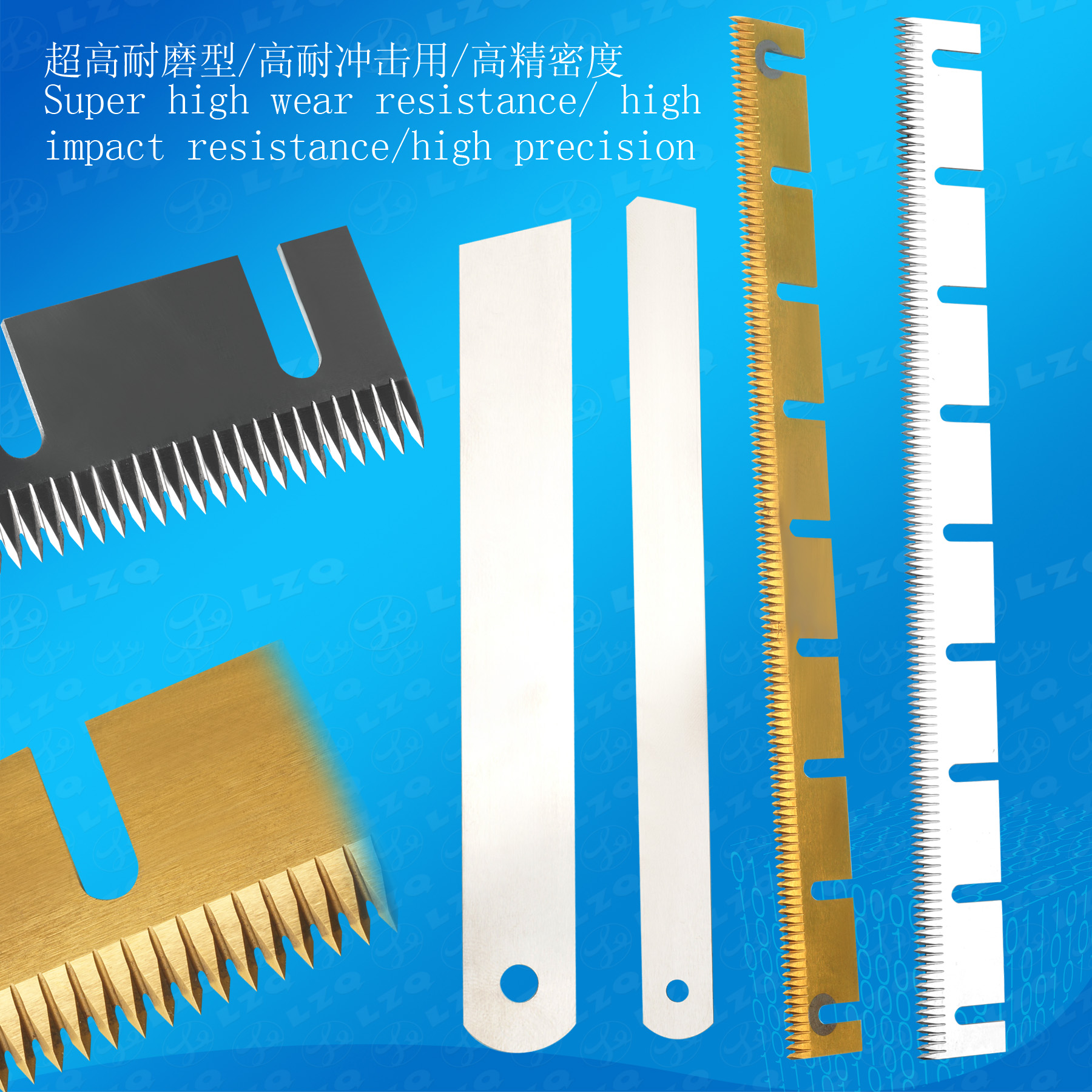

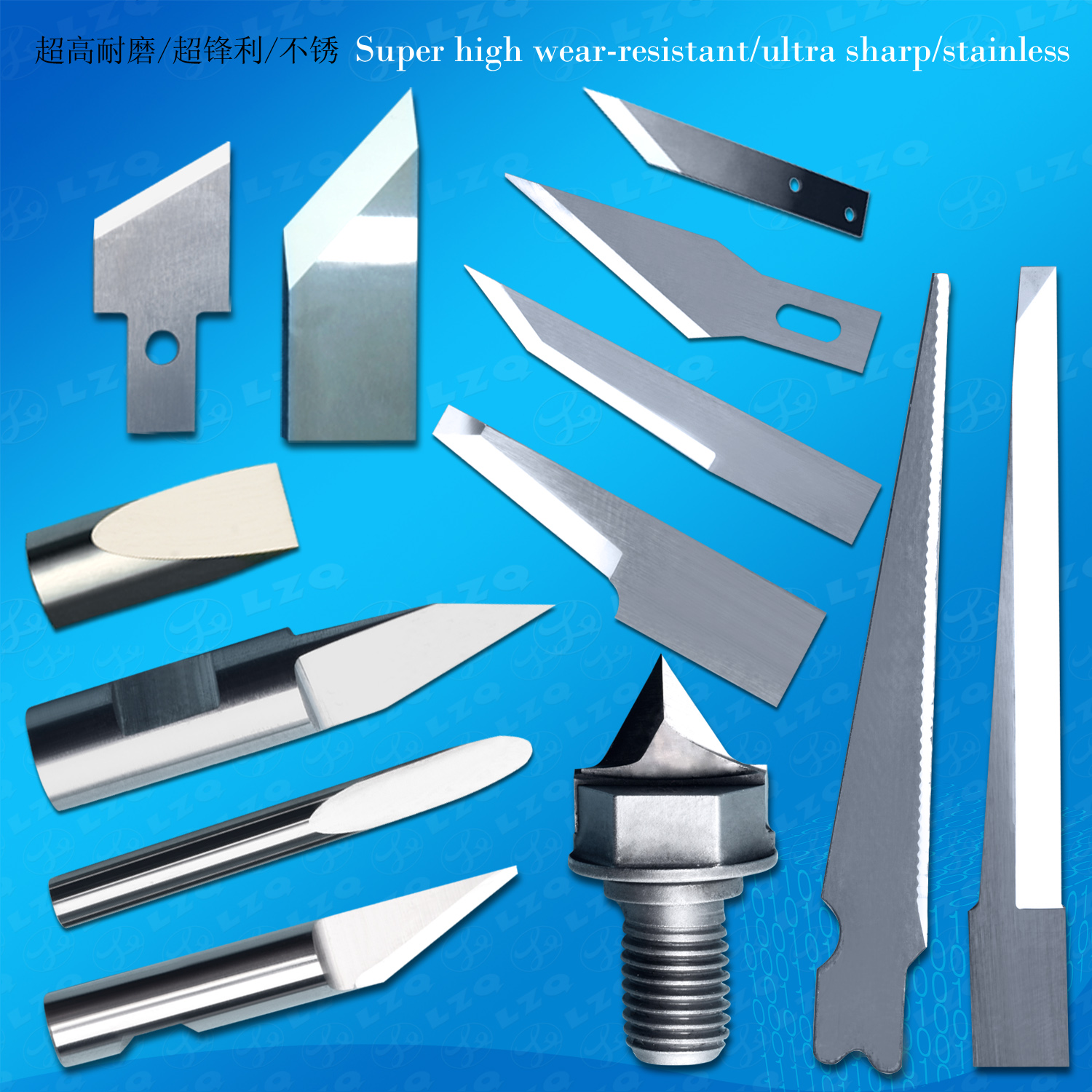

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

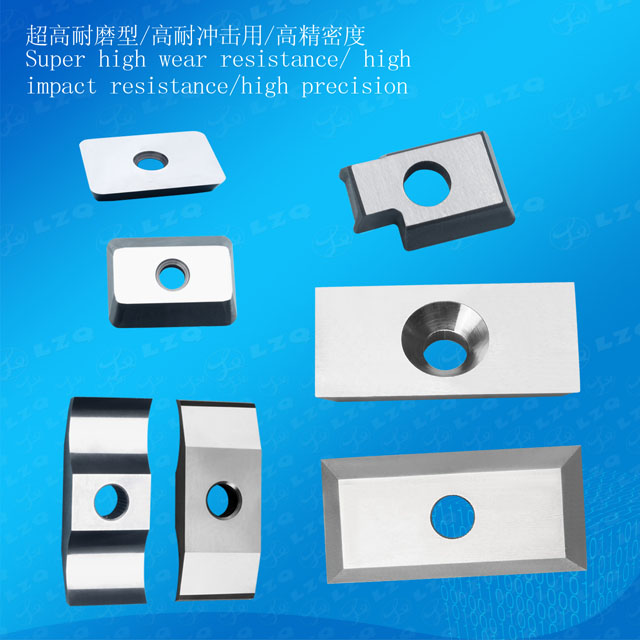

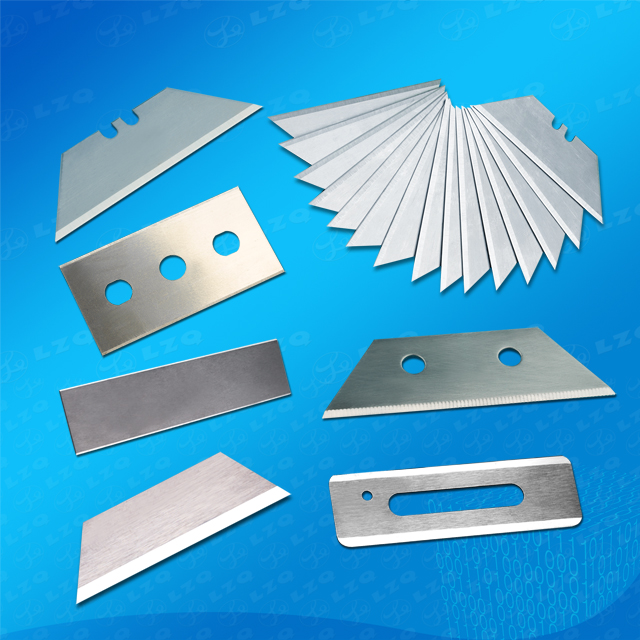

Cutting Tools

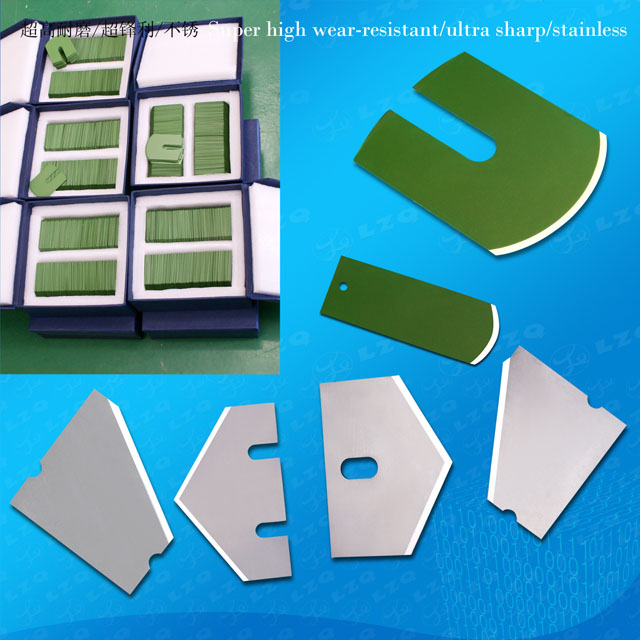

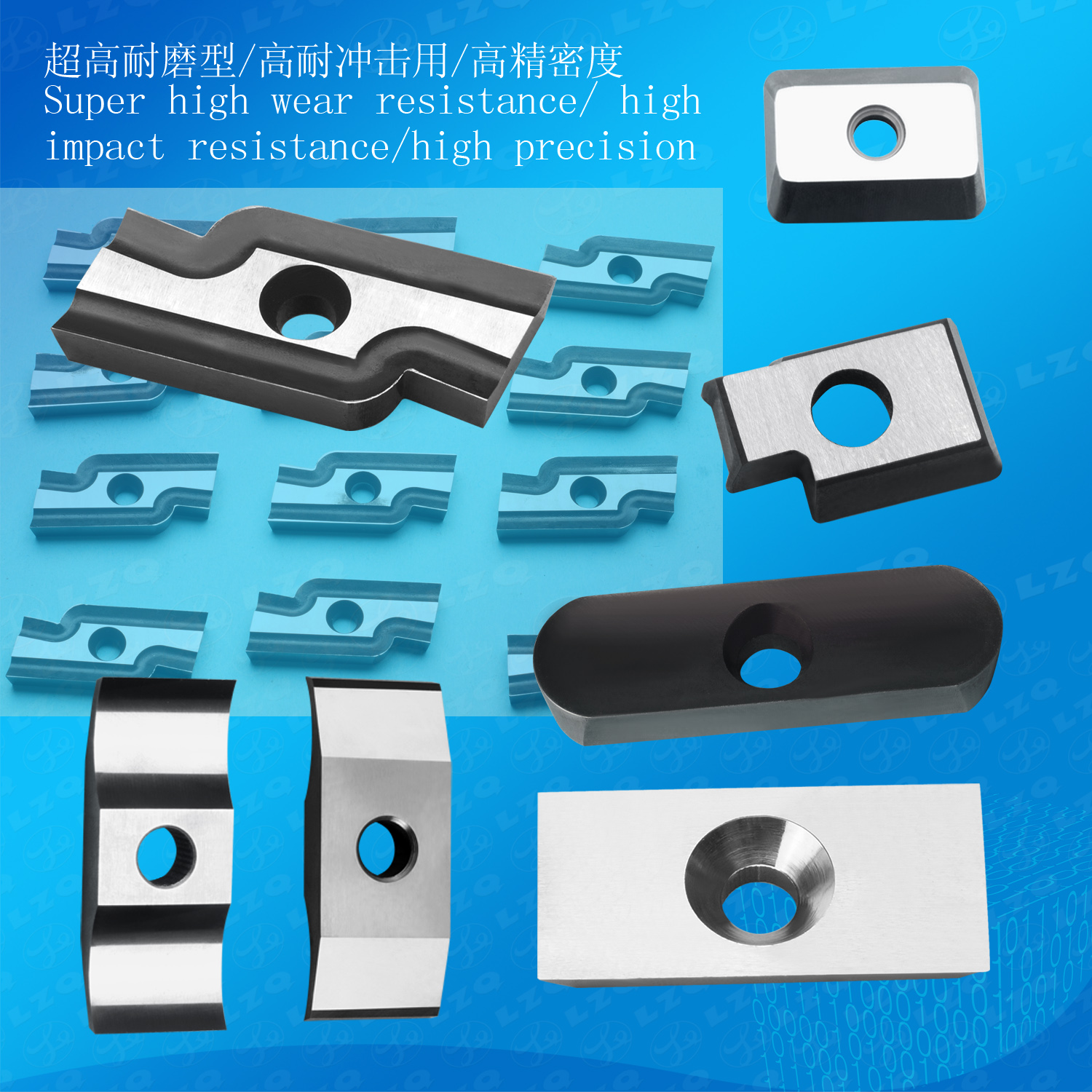

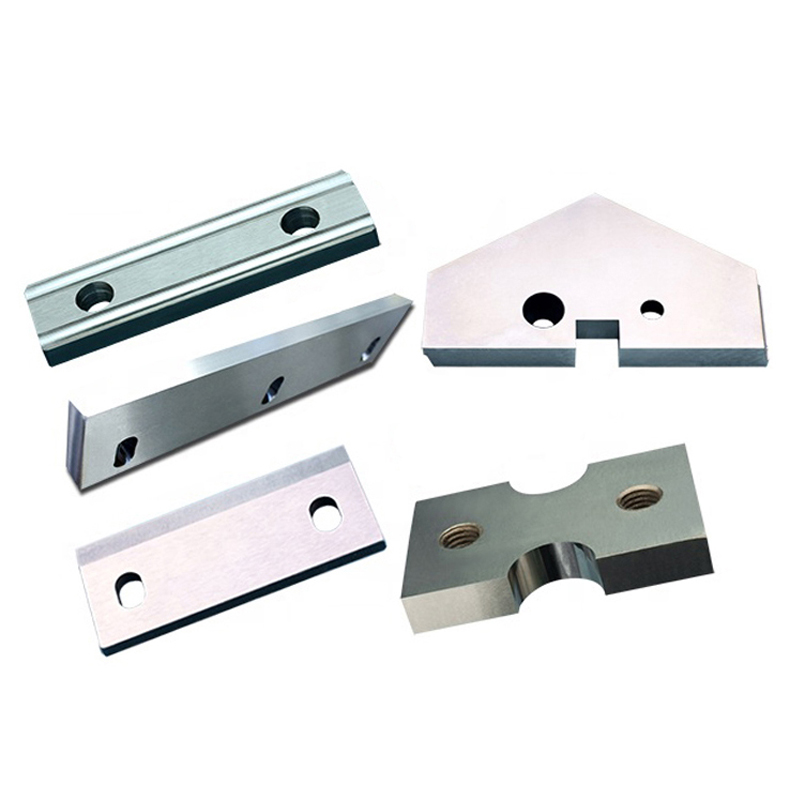

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

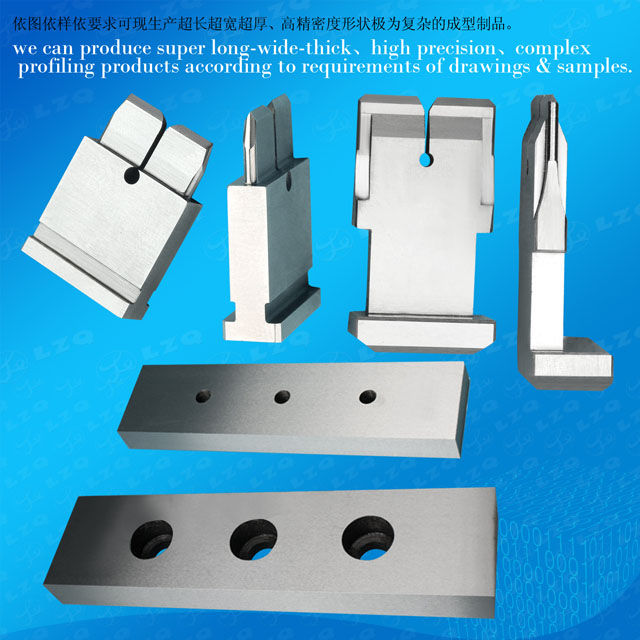

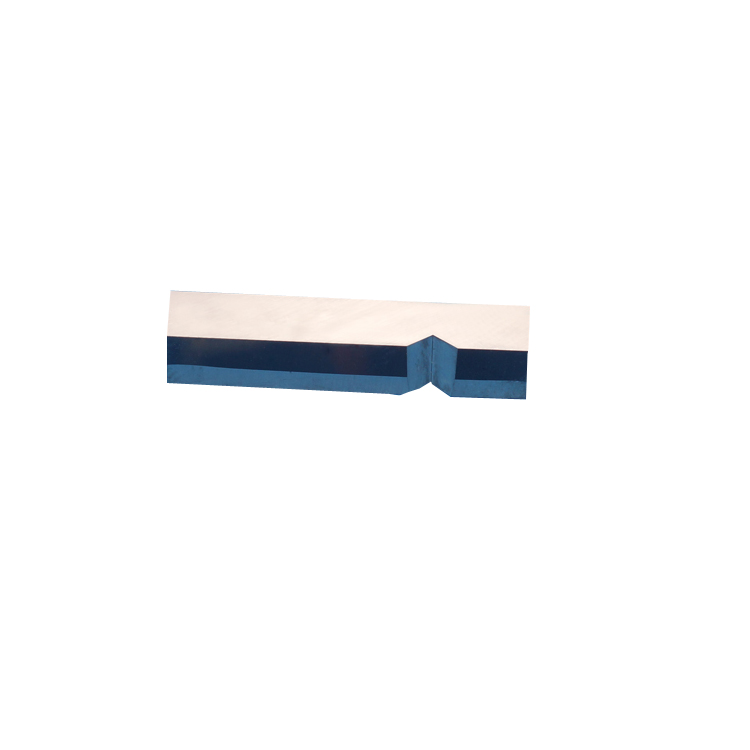

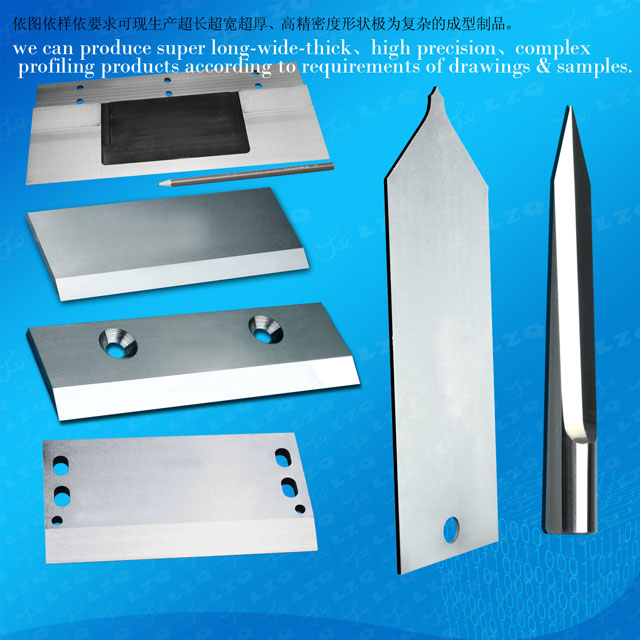

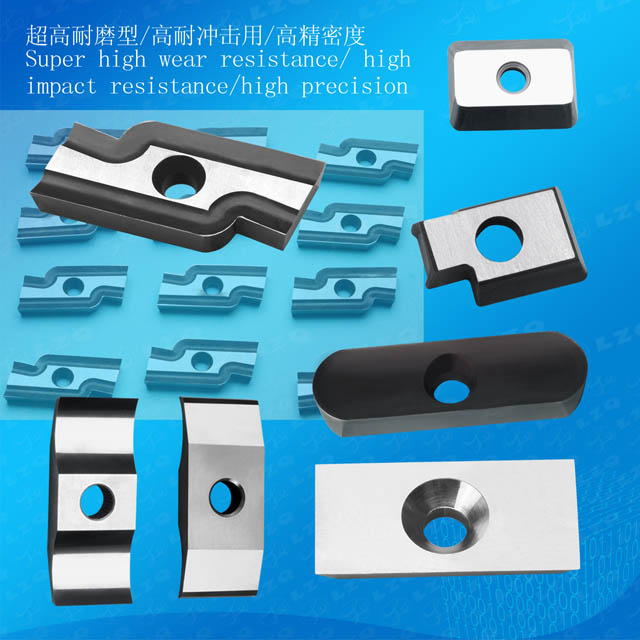

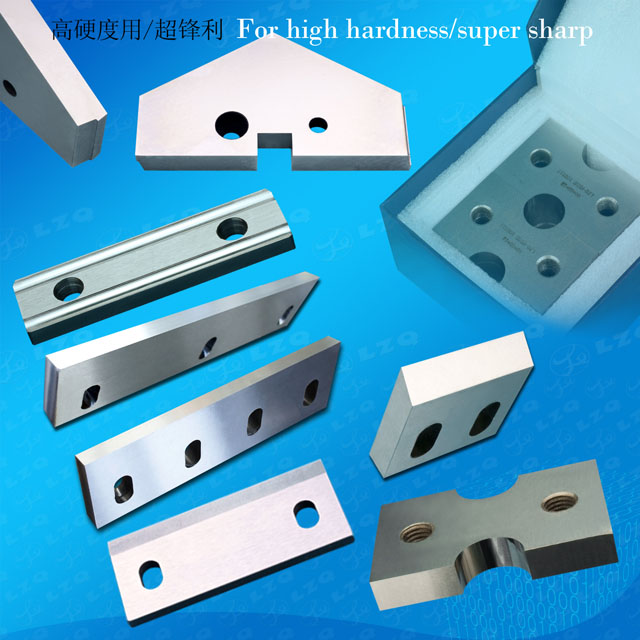

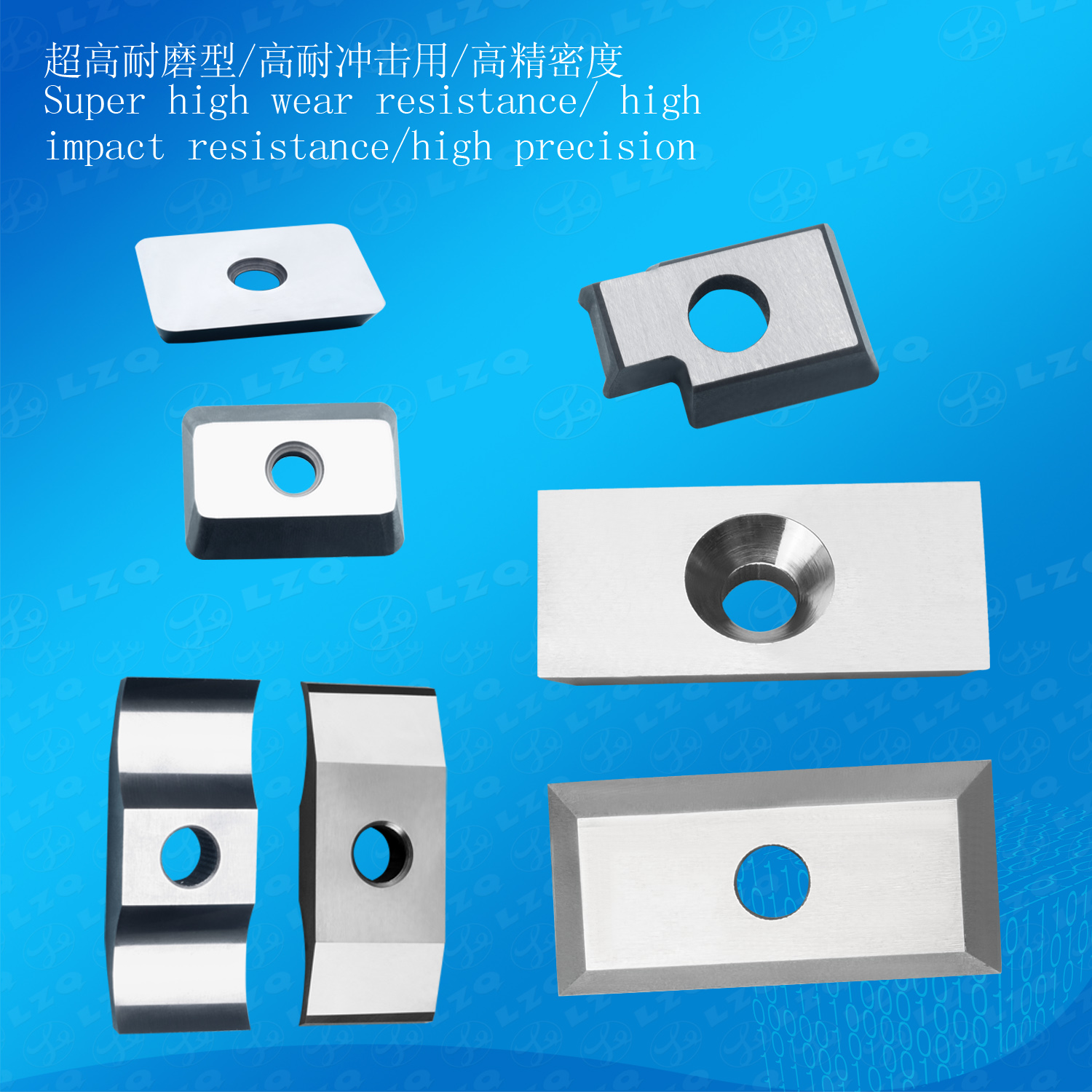

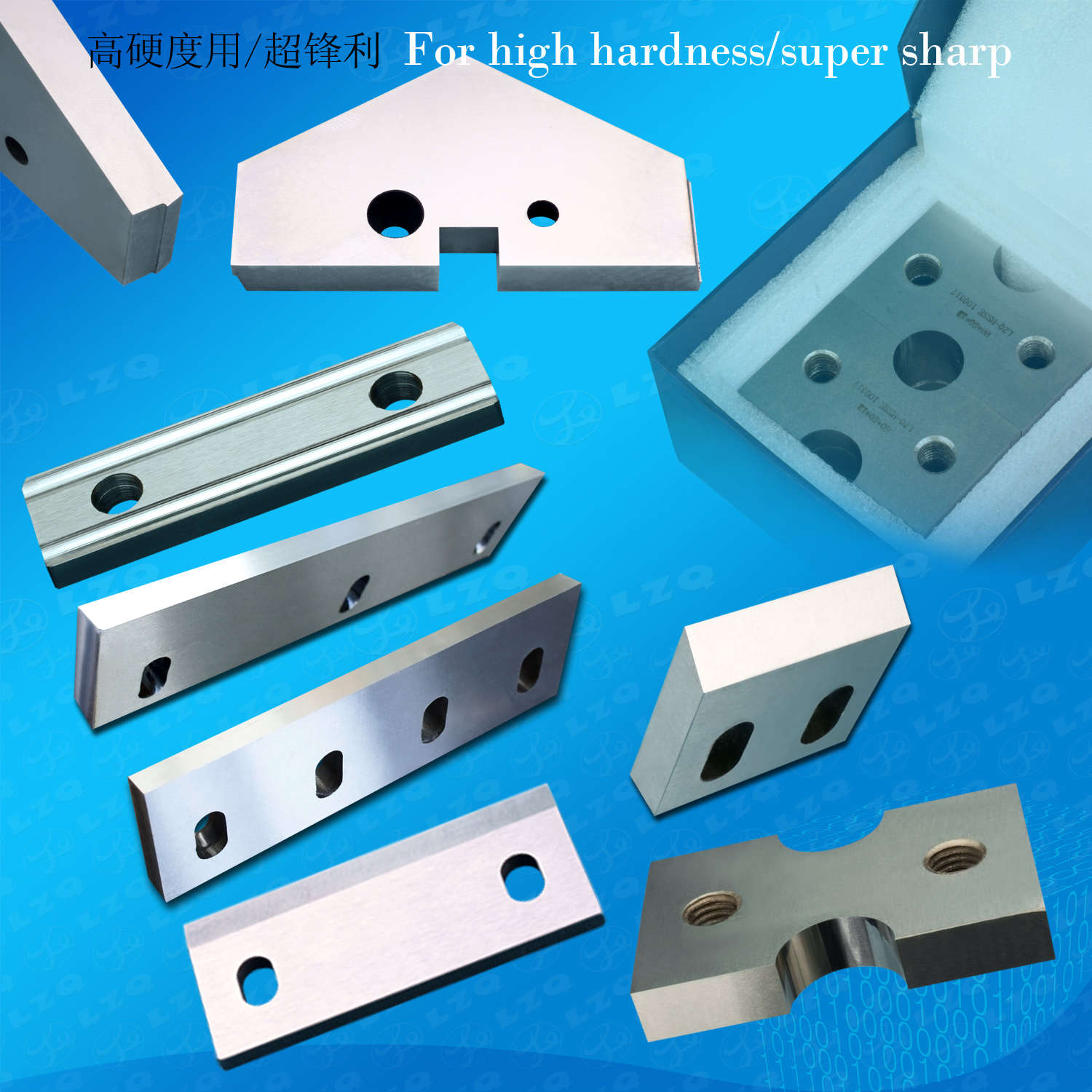

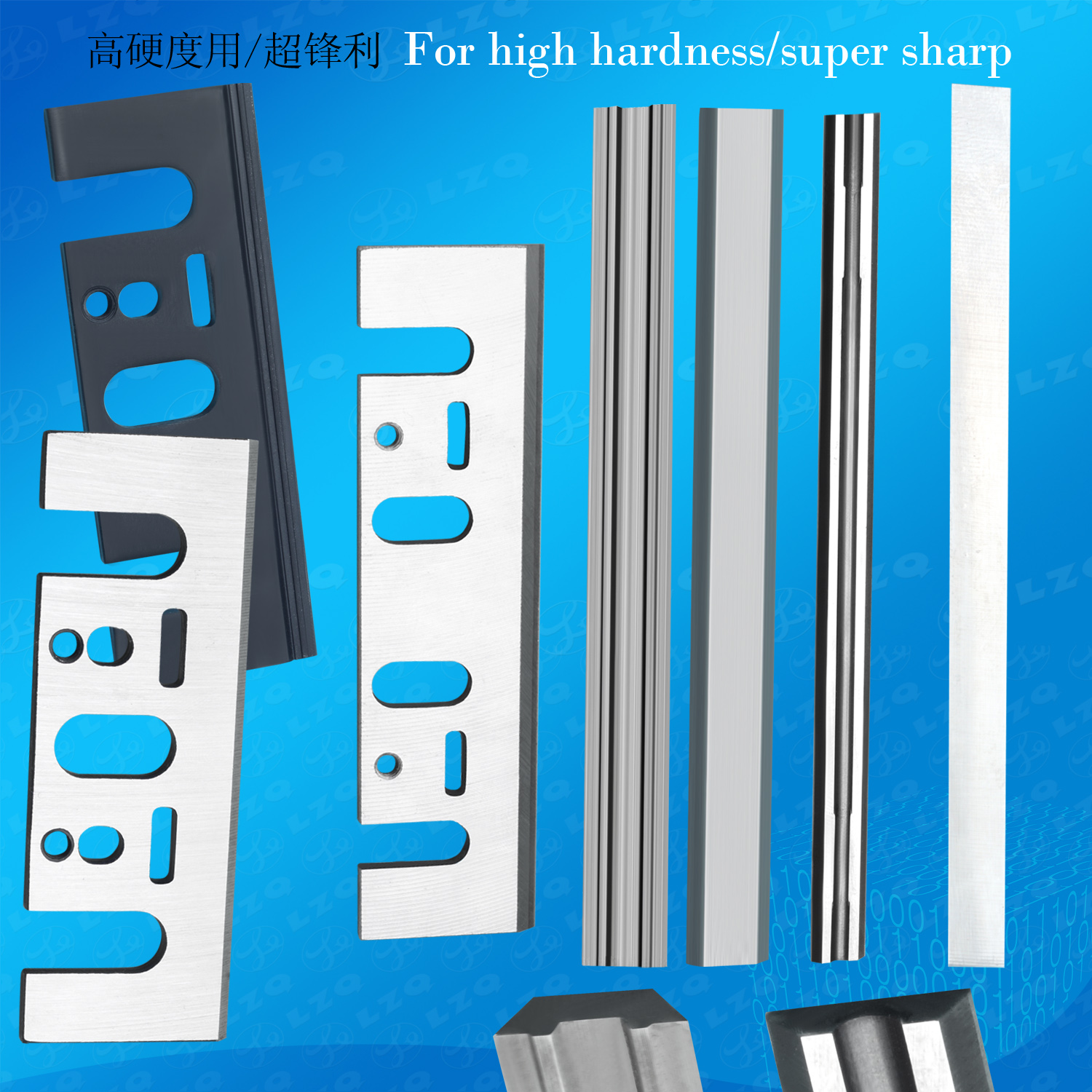

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.