Description

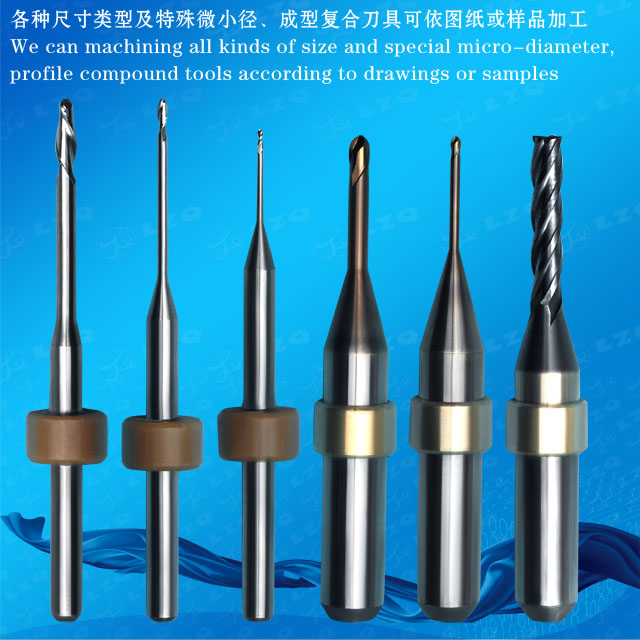

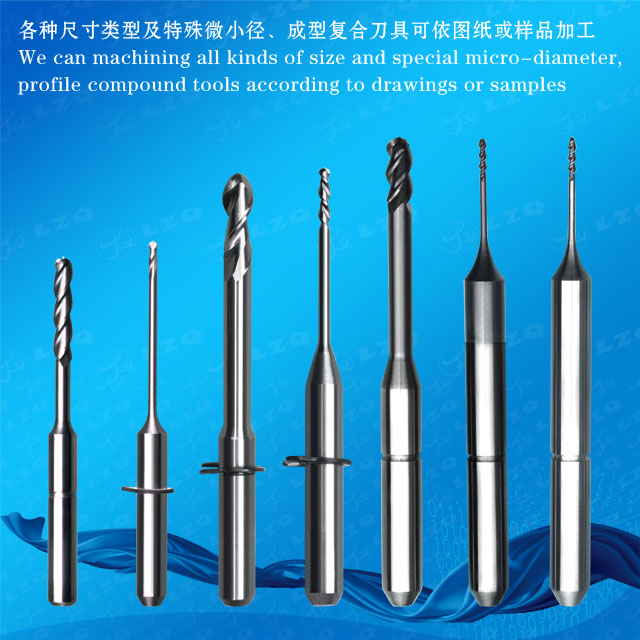

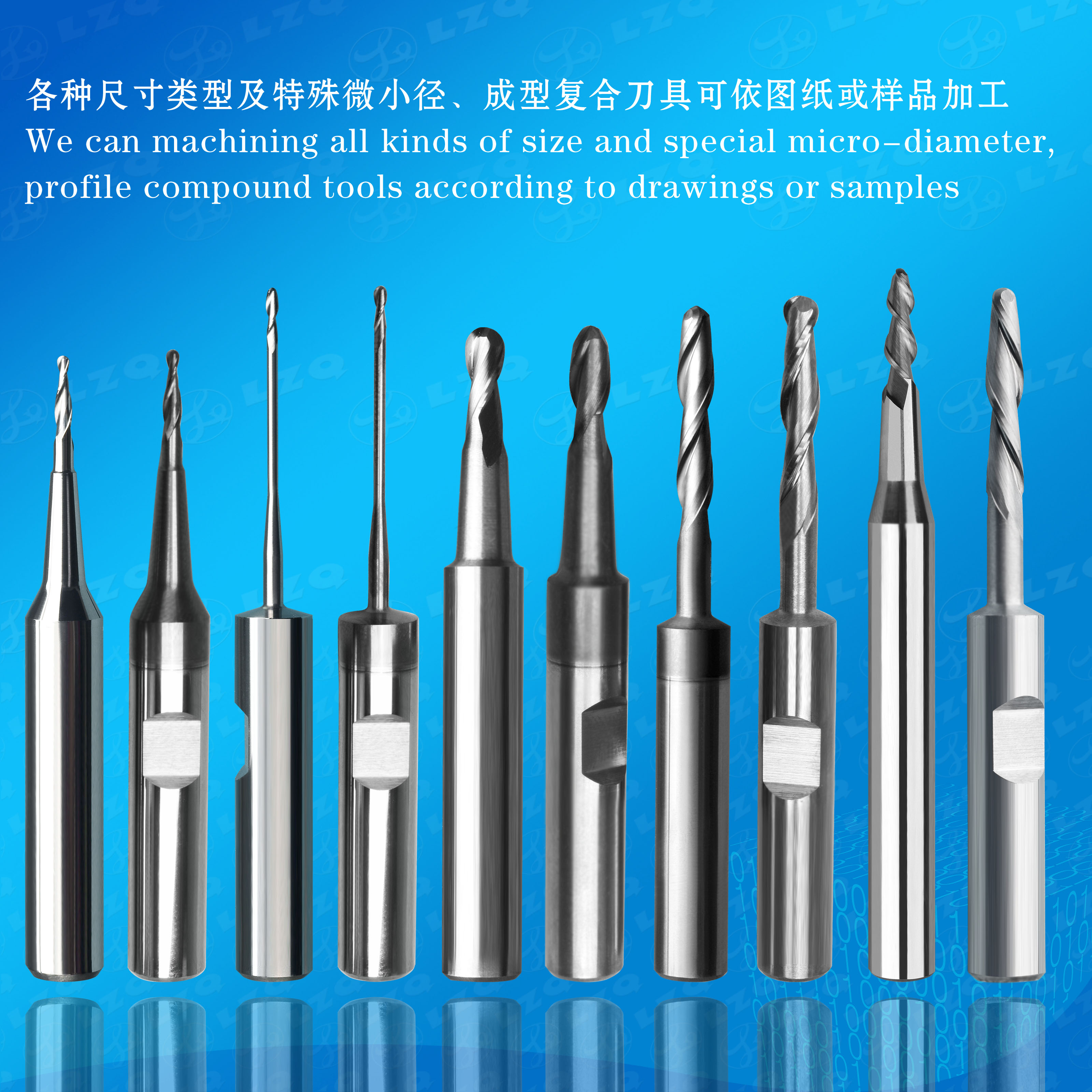

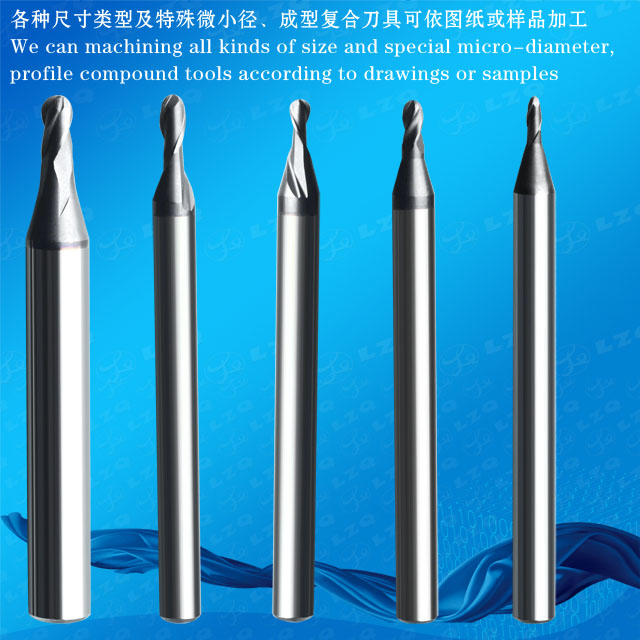

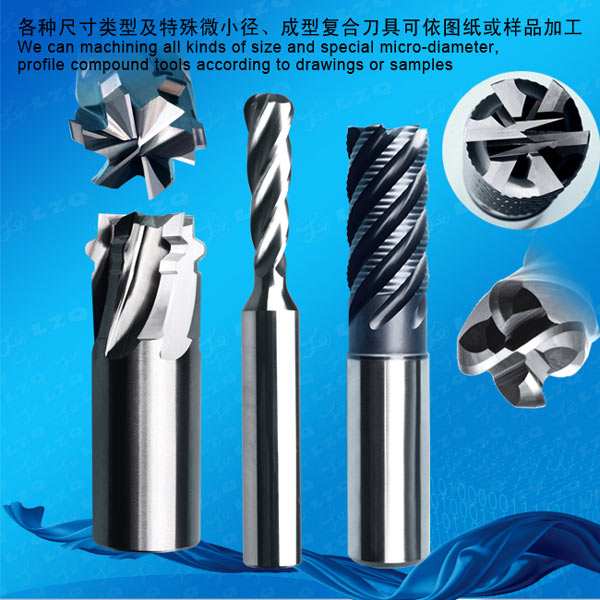

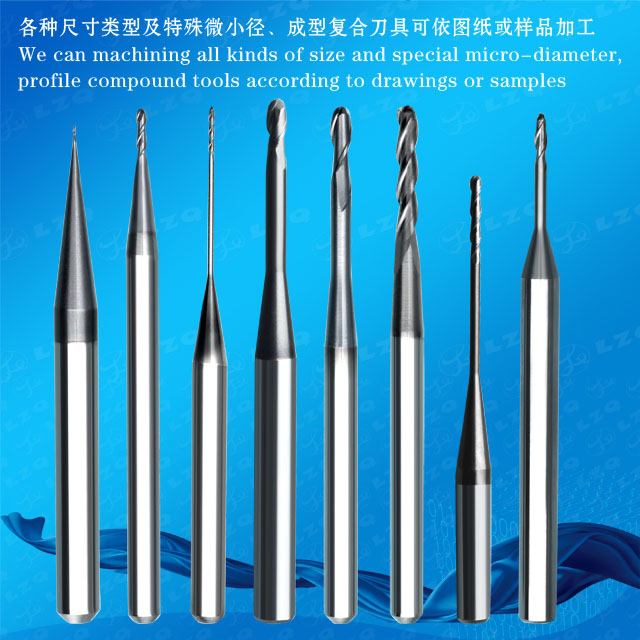

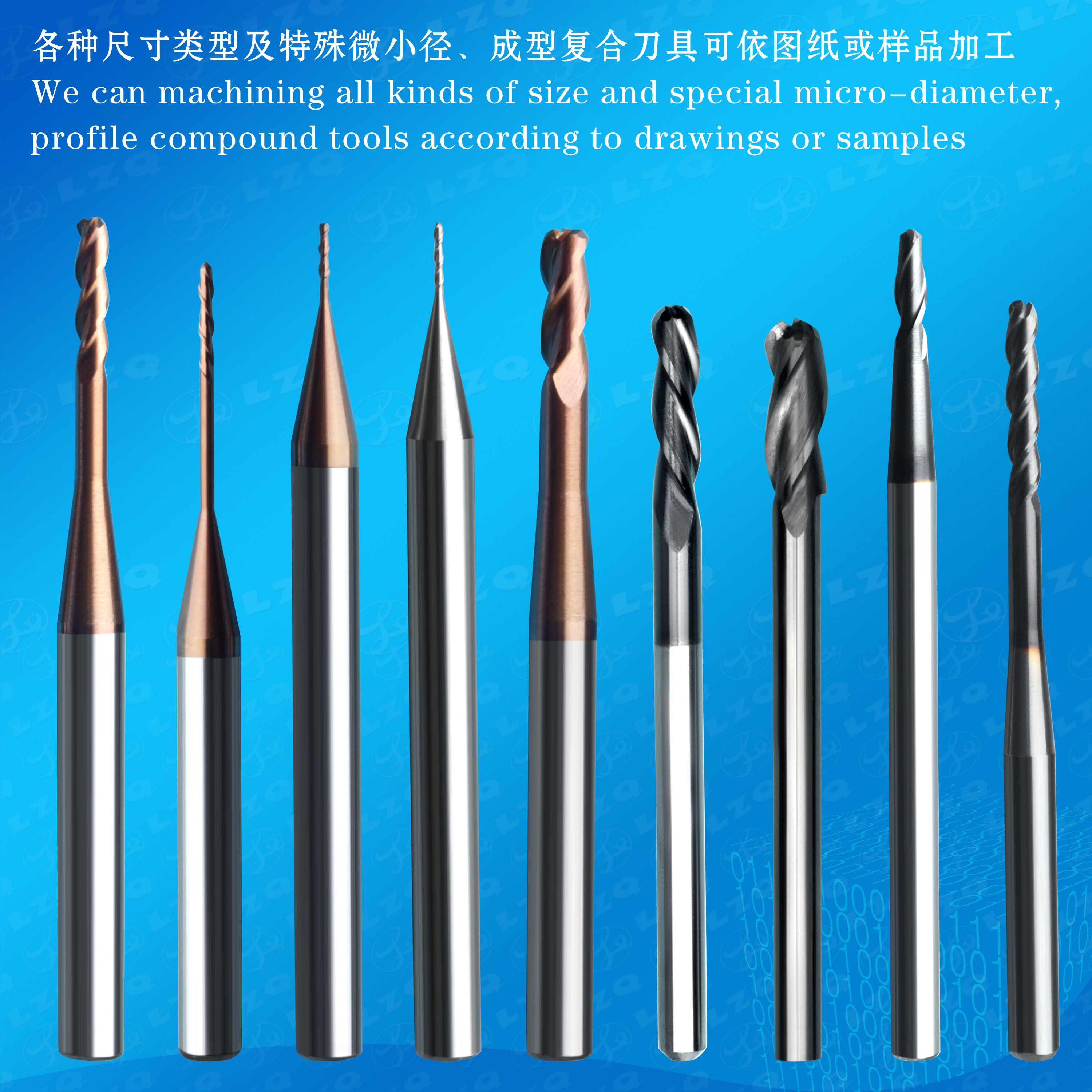

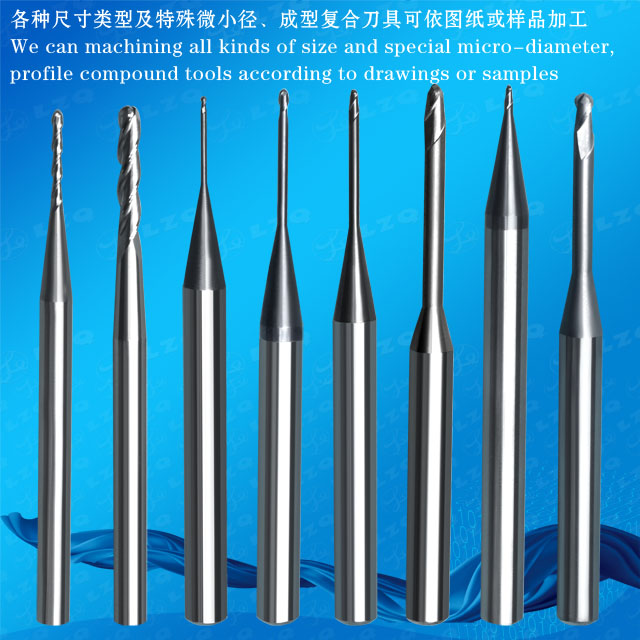

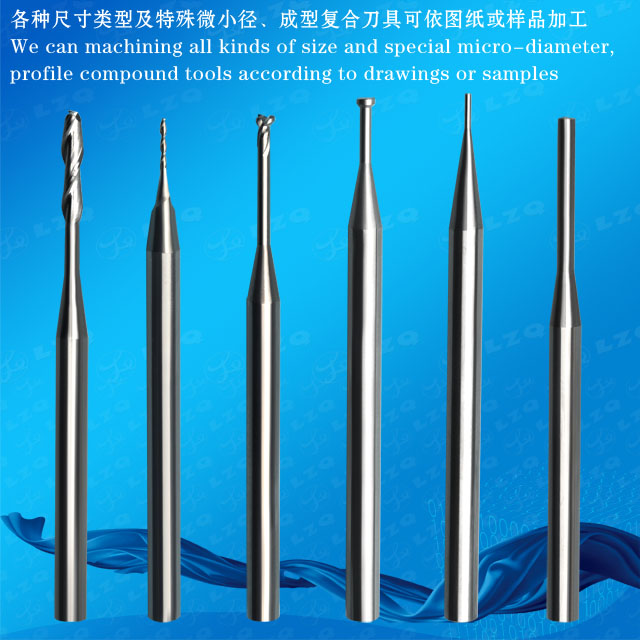

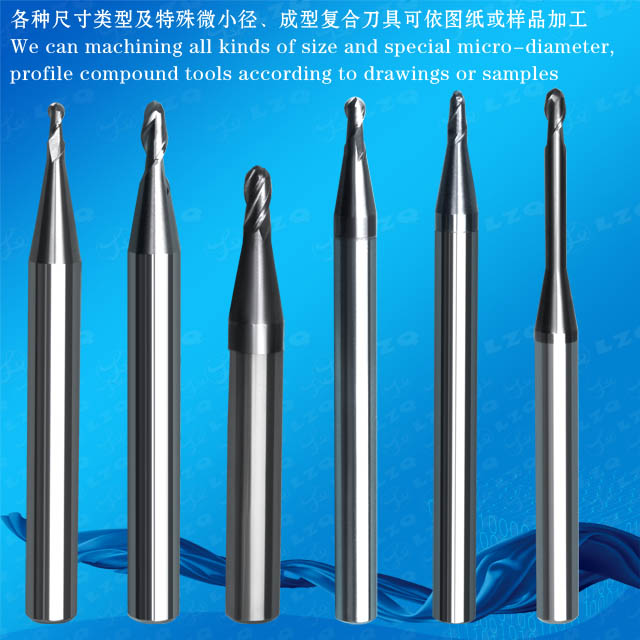

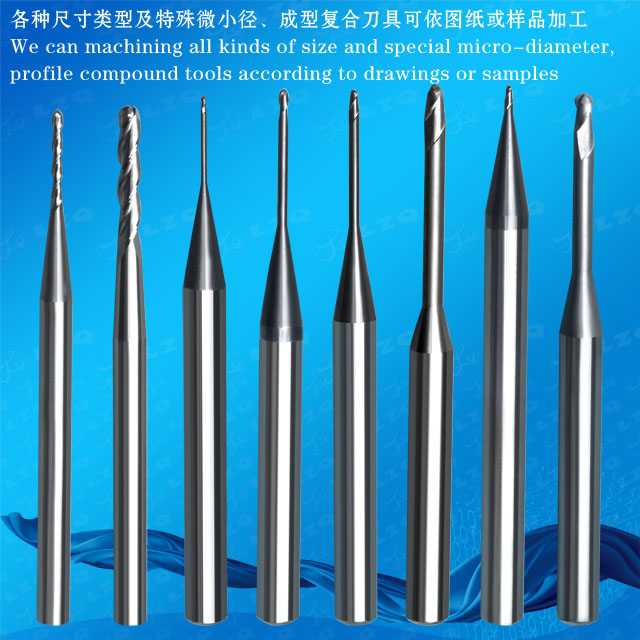

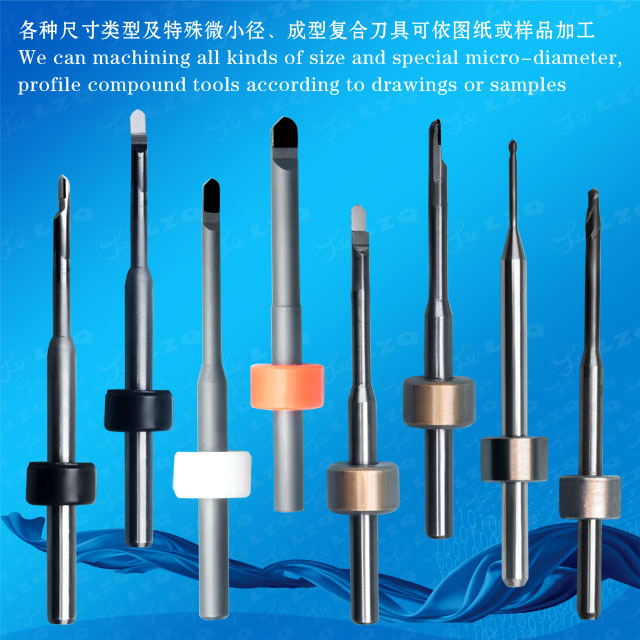

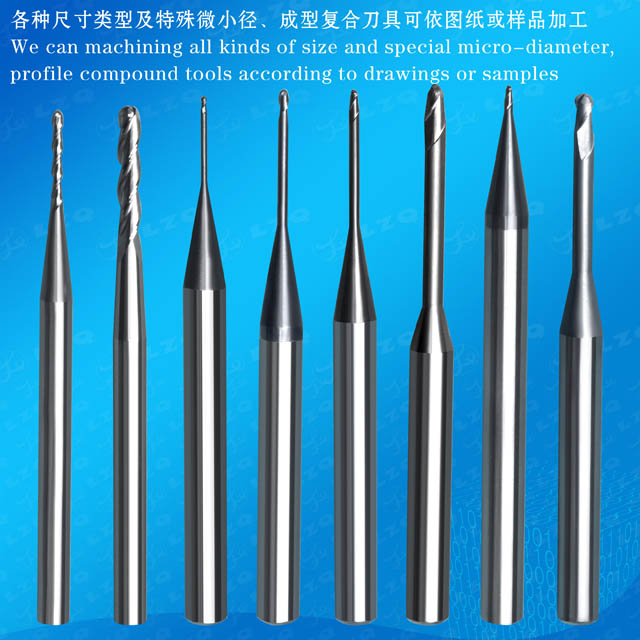

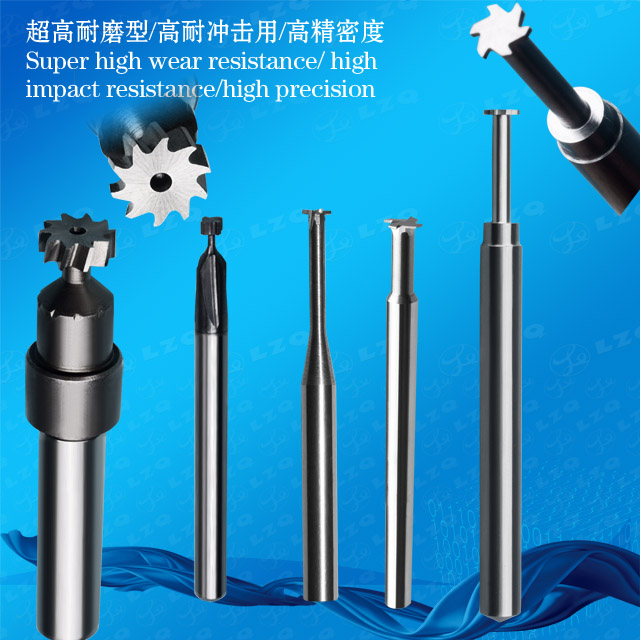

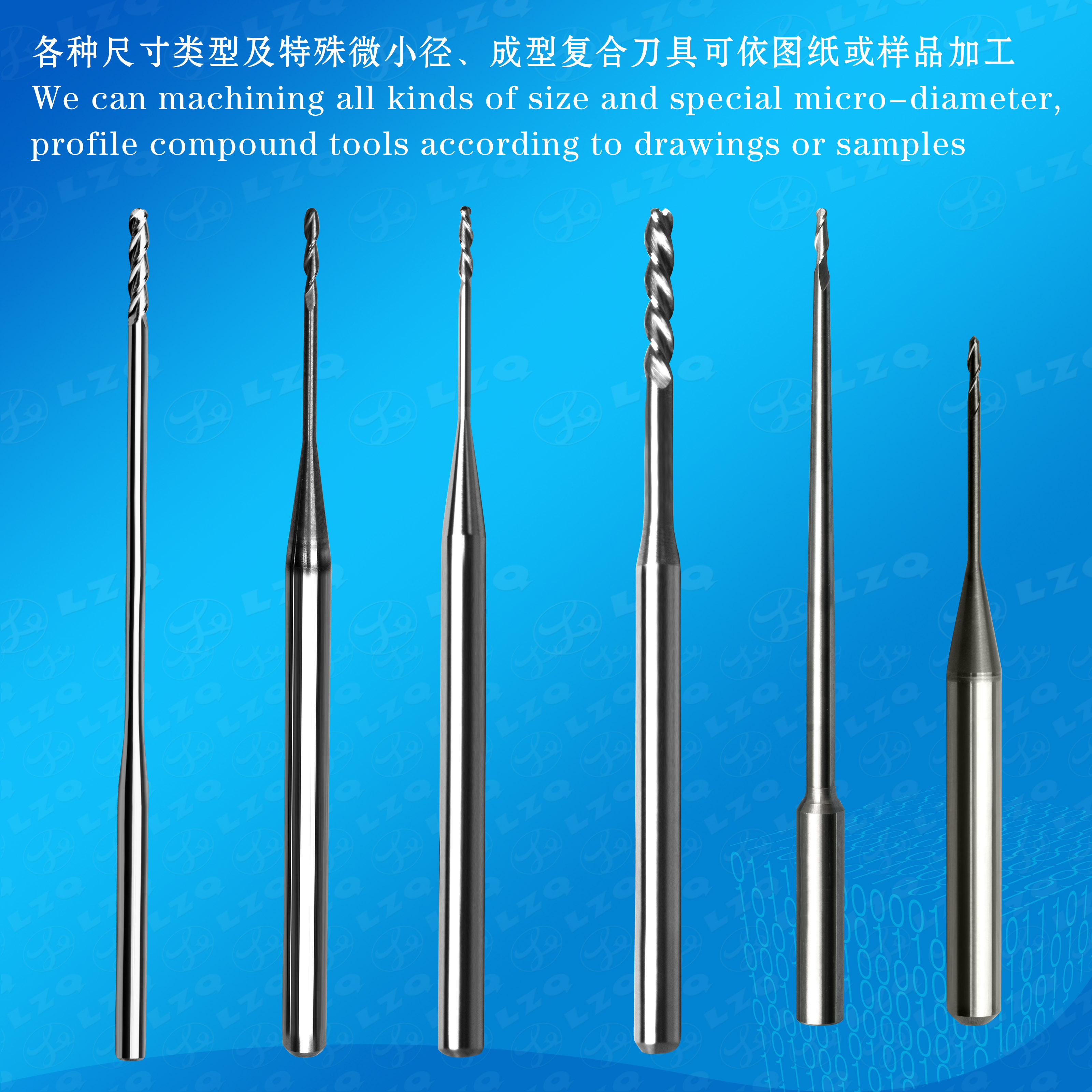

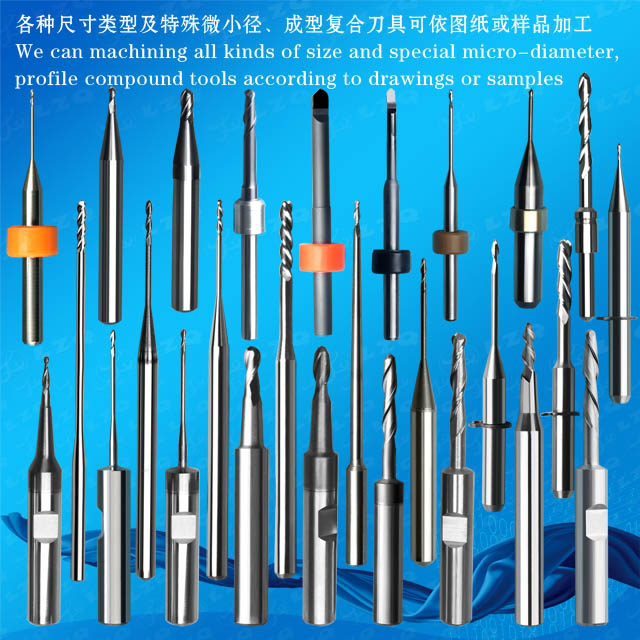

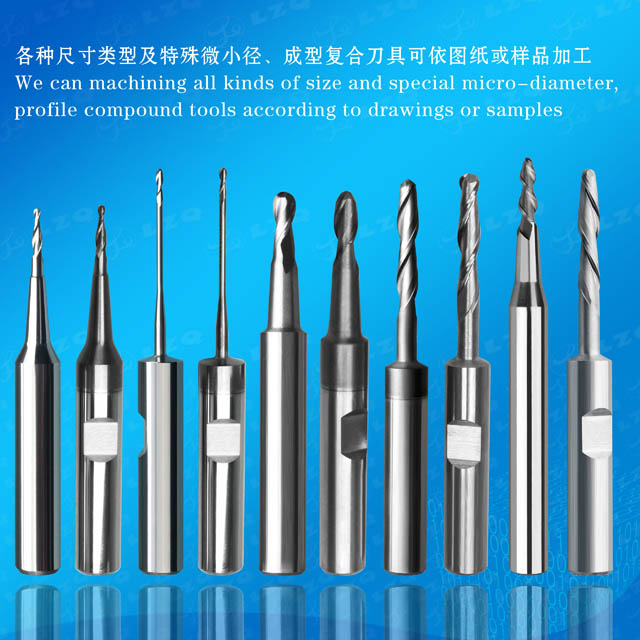

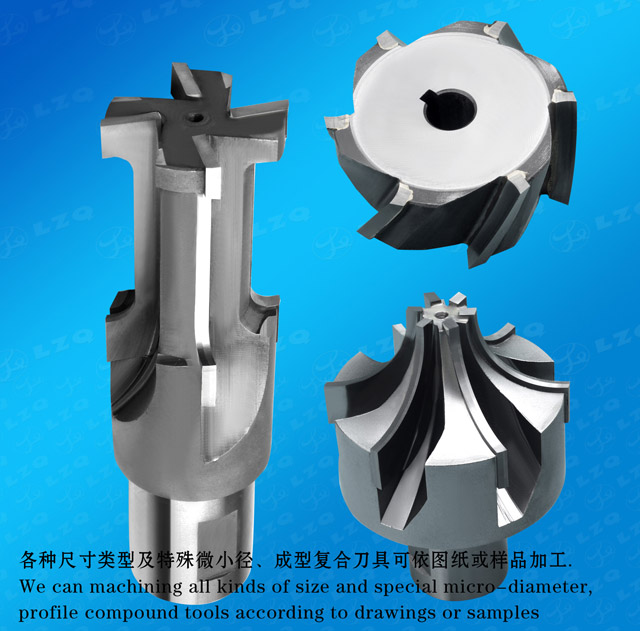

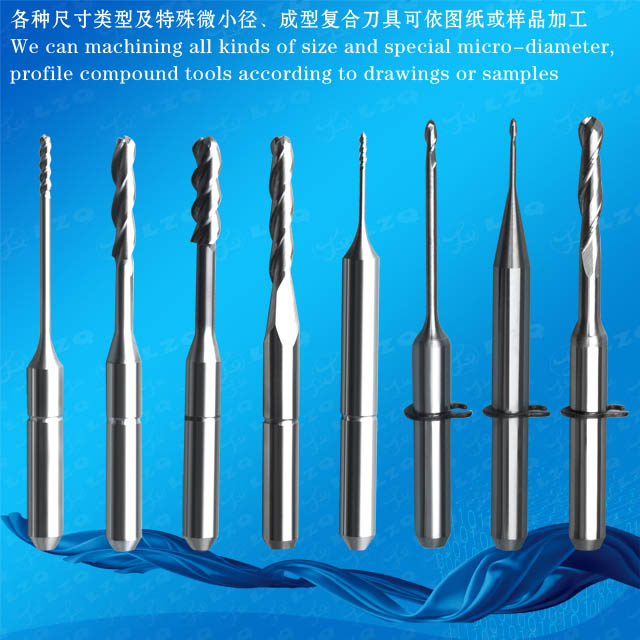

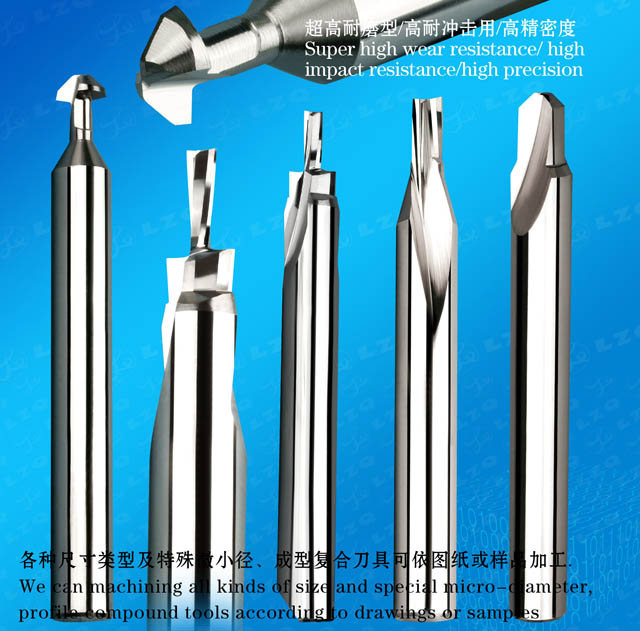

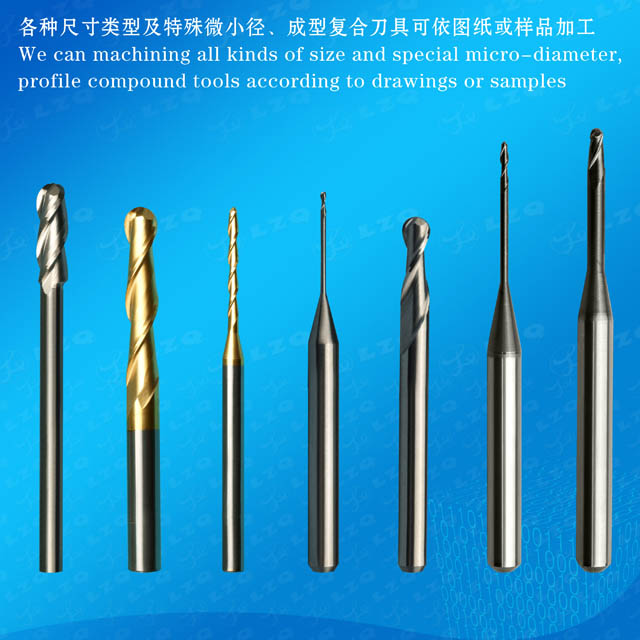

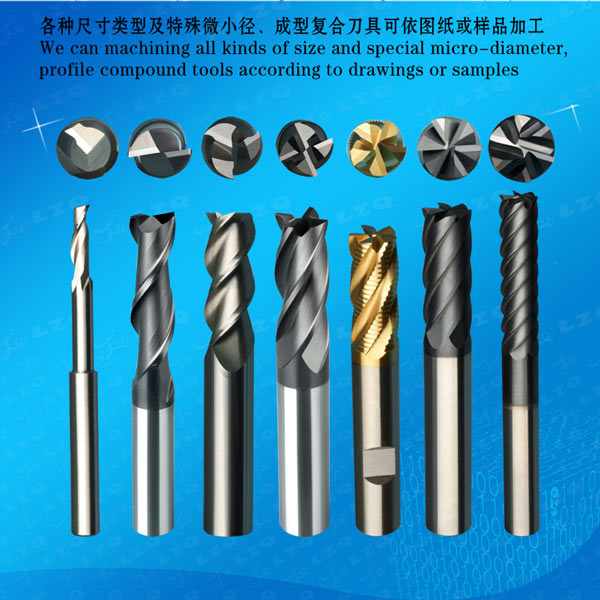

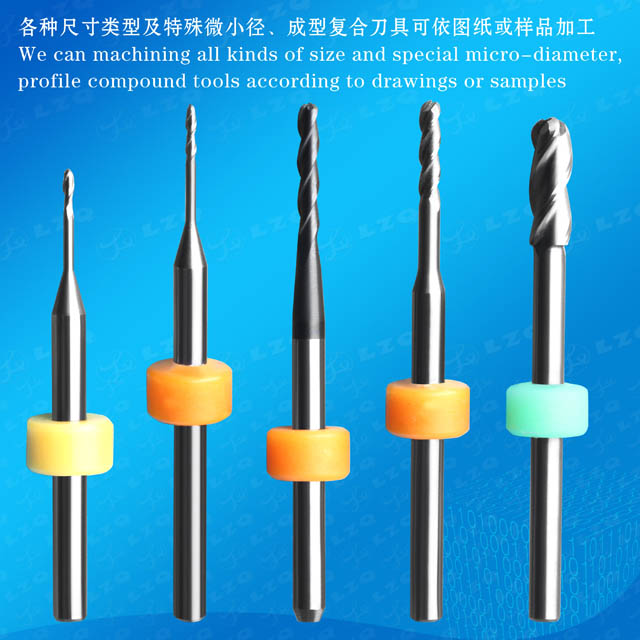

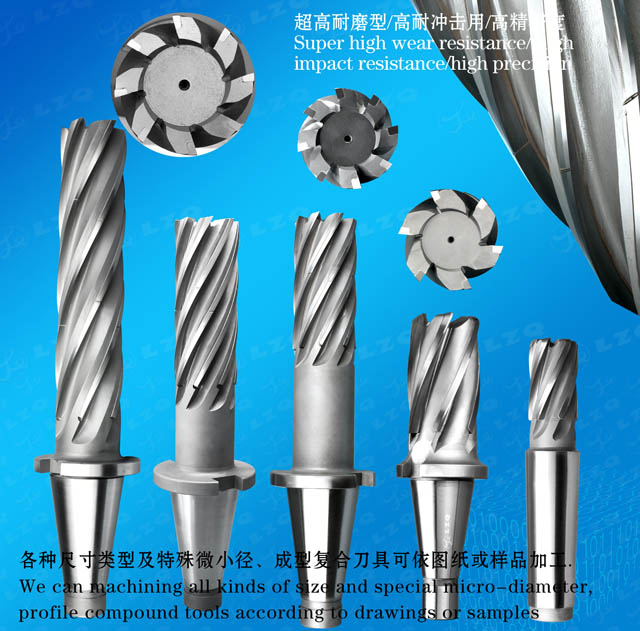

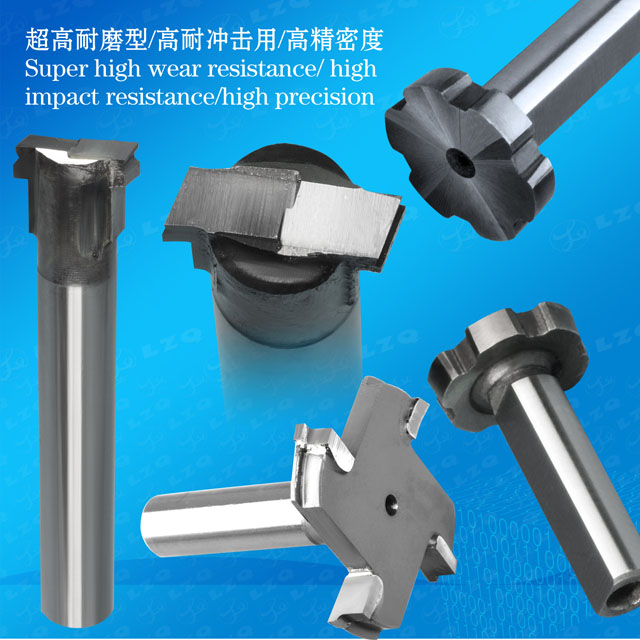

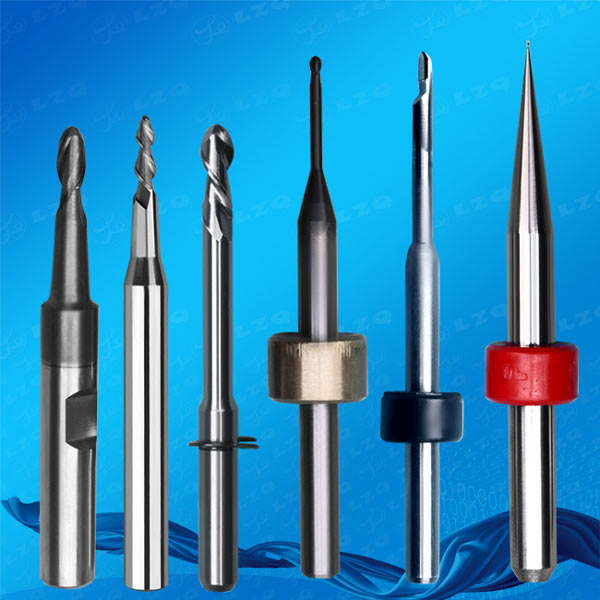

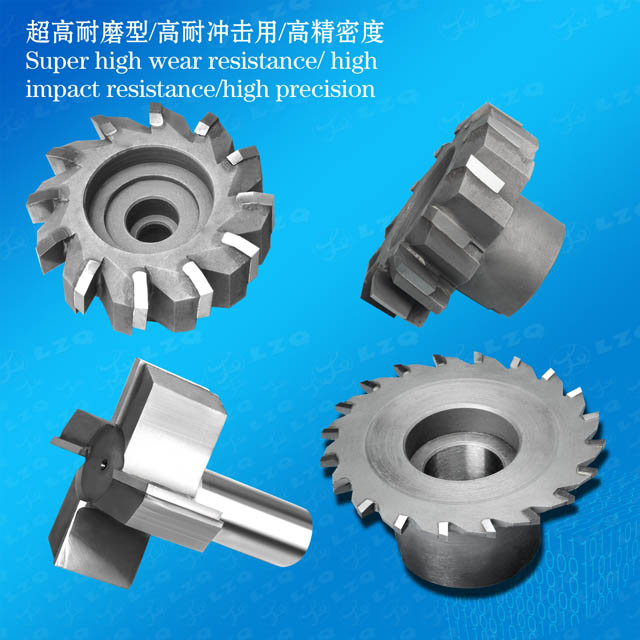

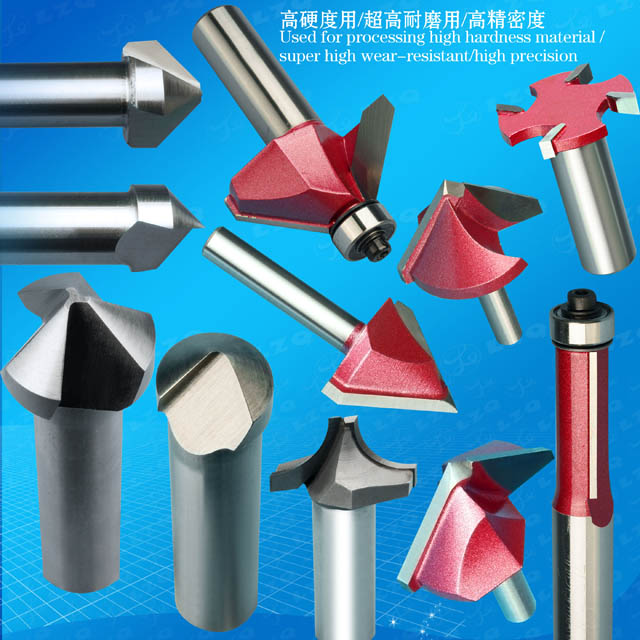

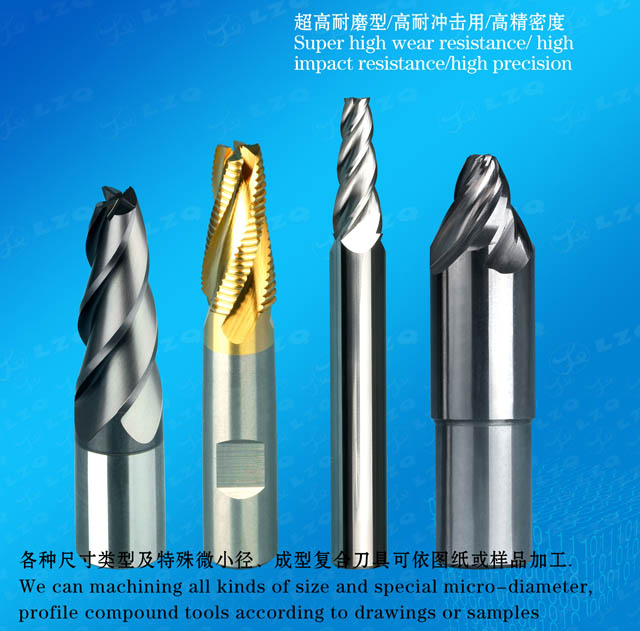

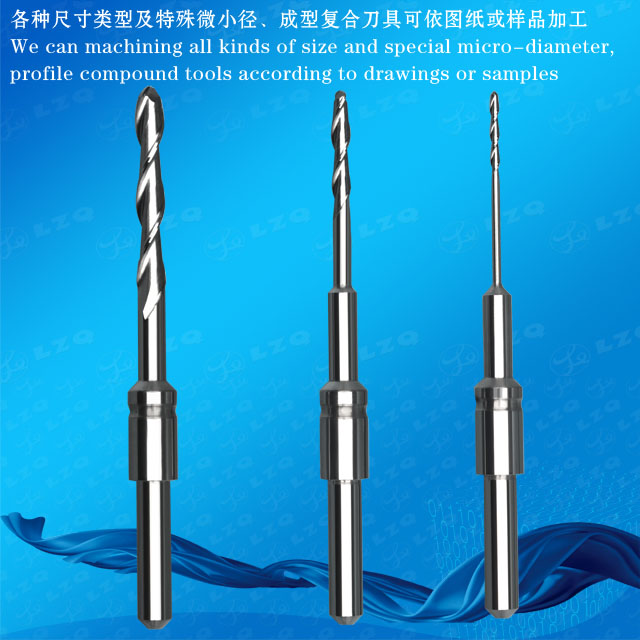

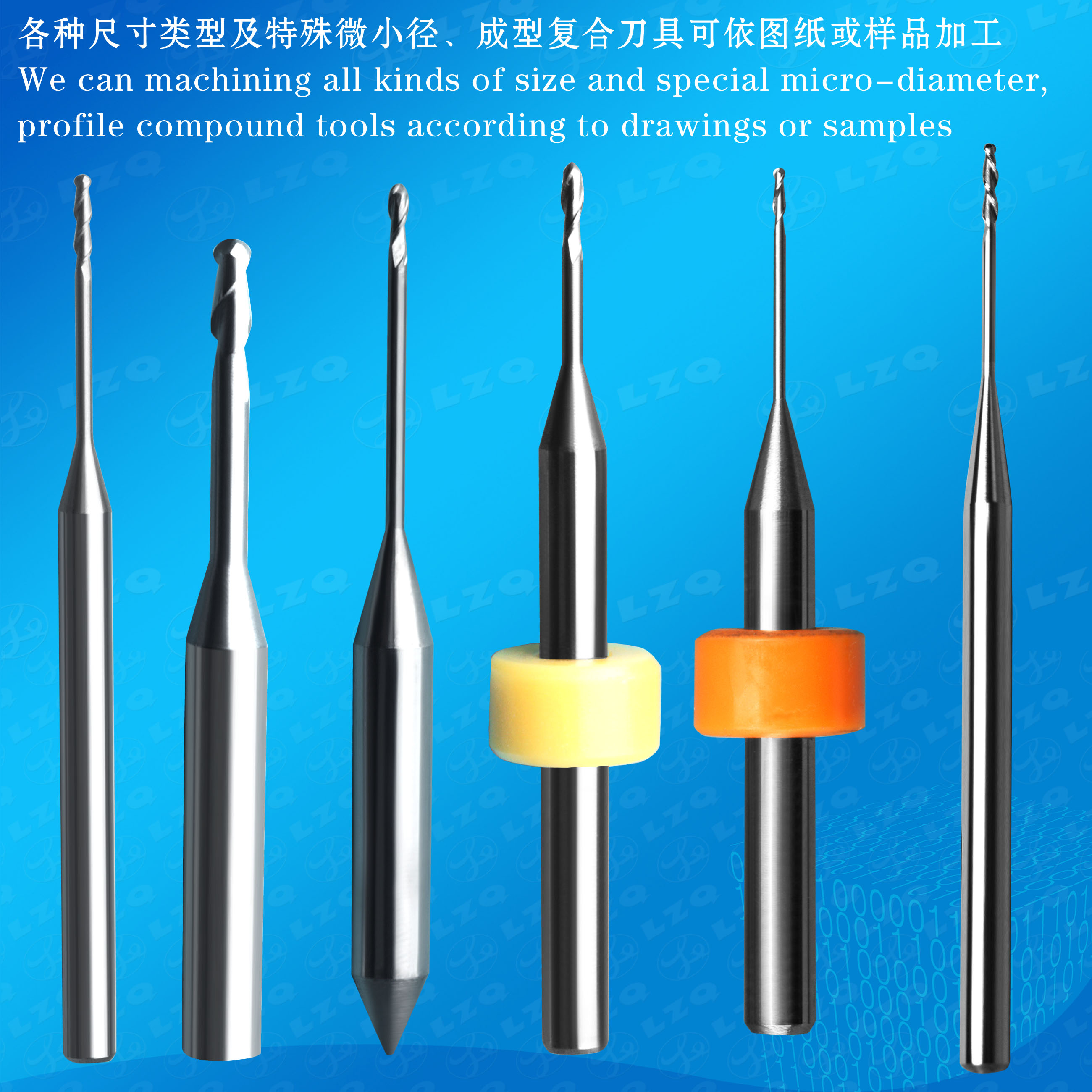

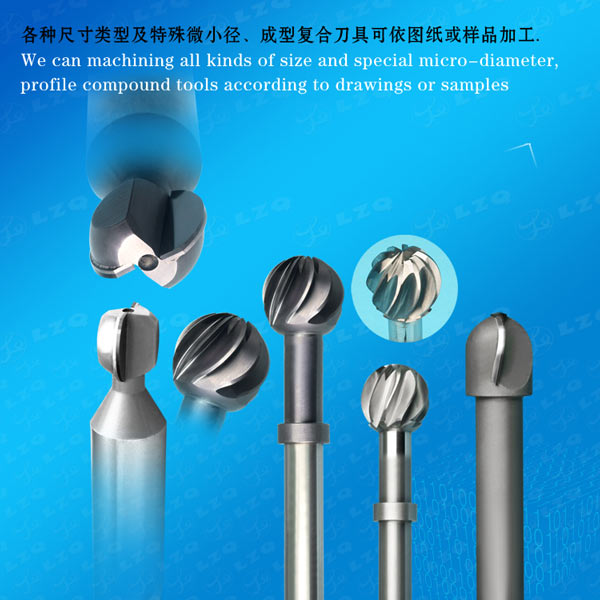

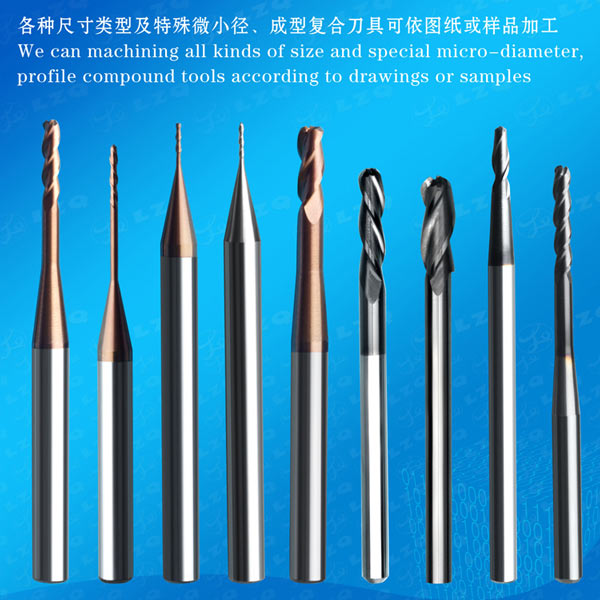

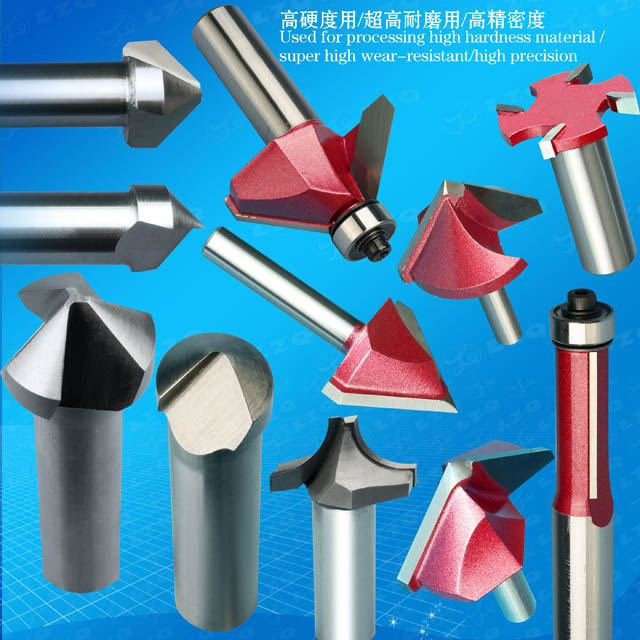

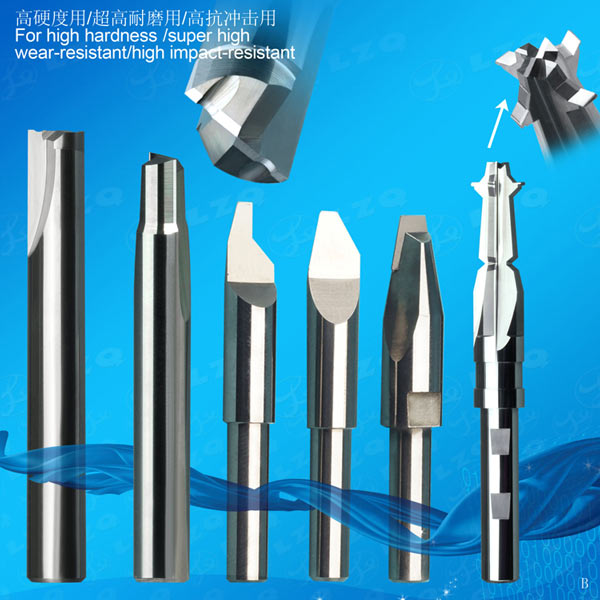

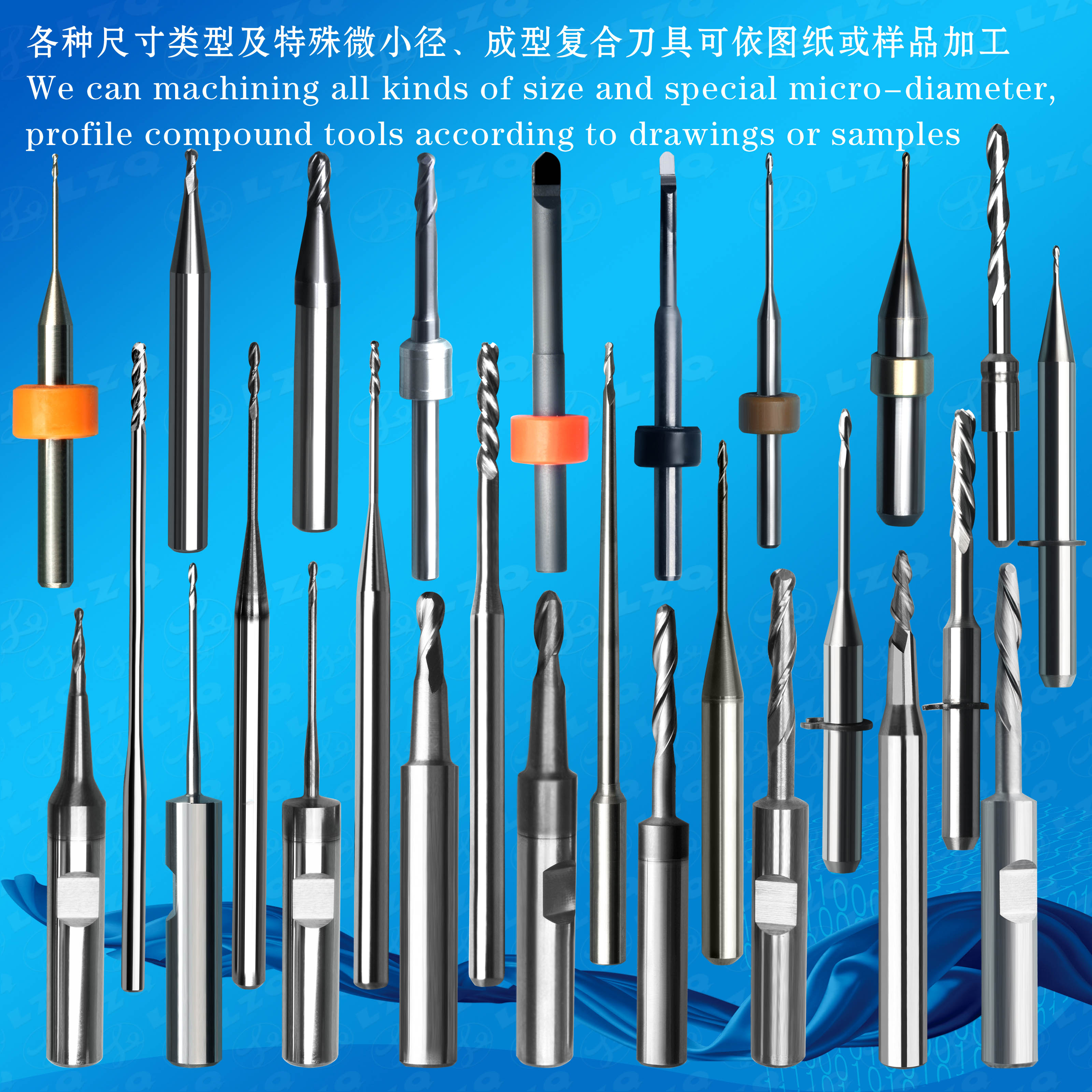

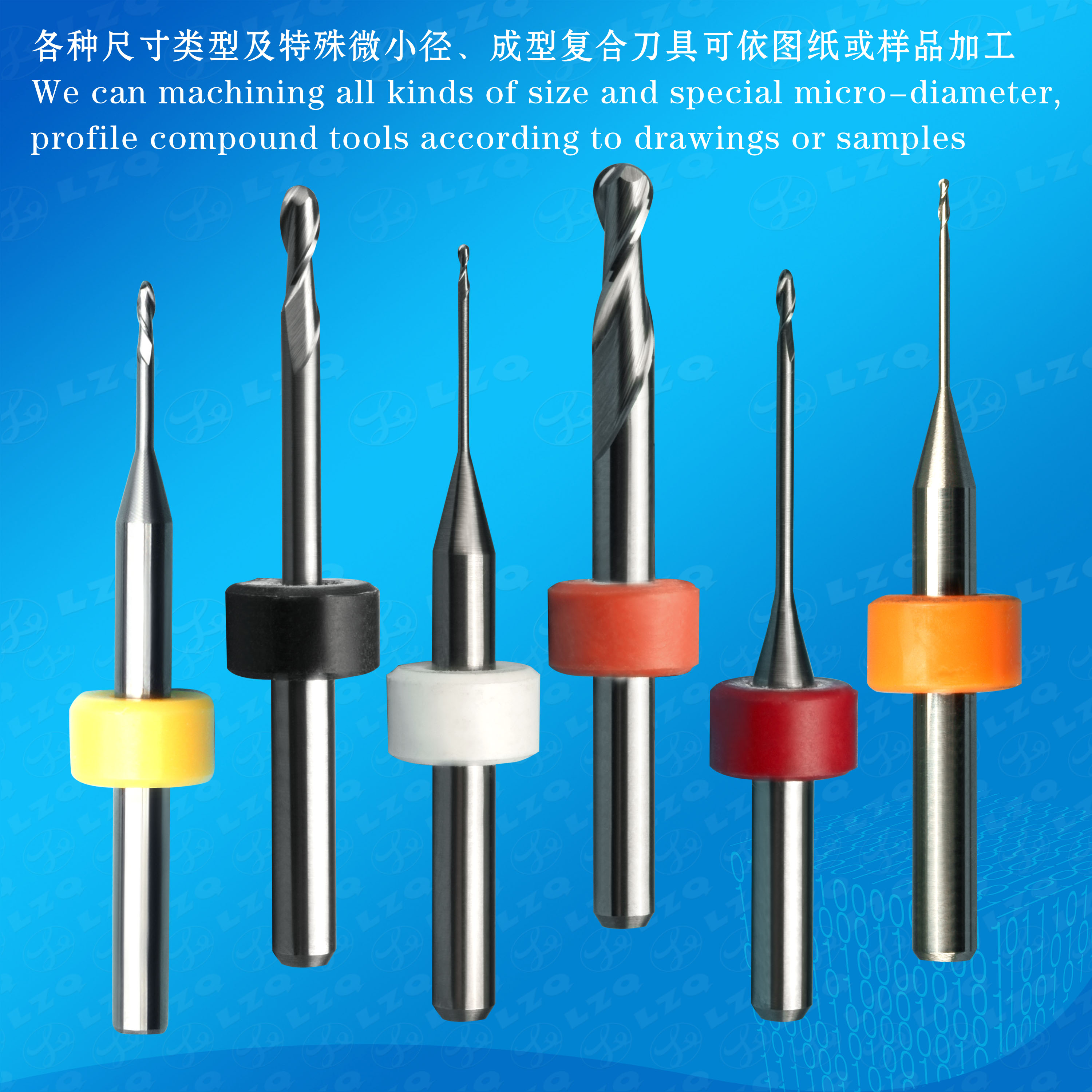

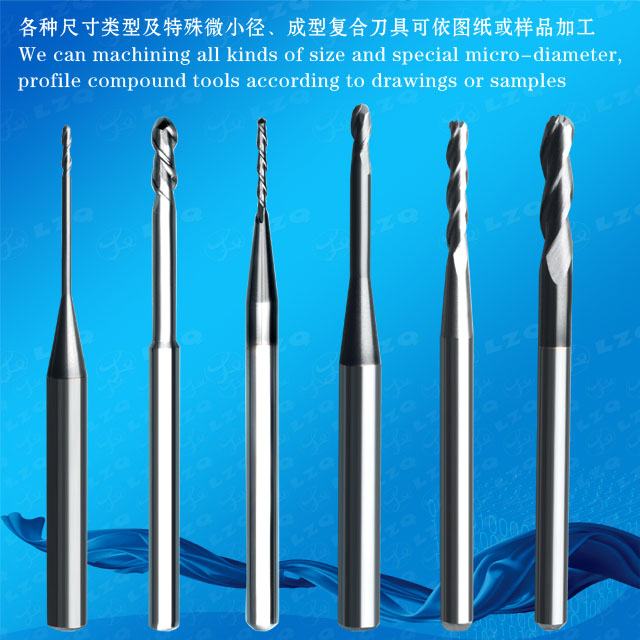

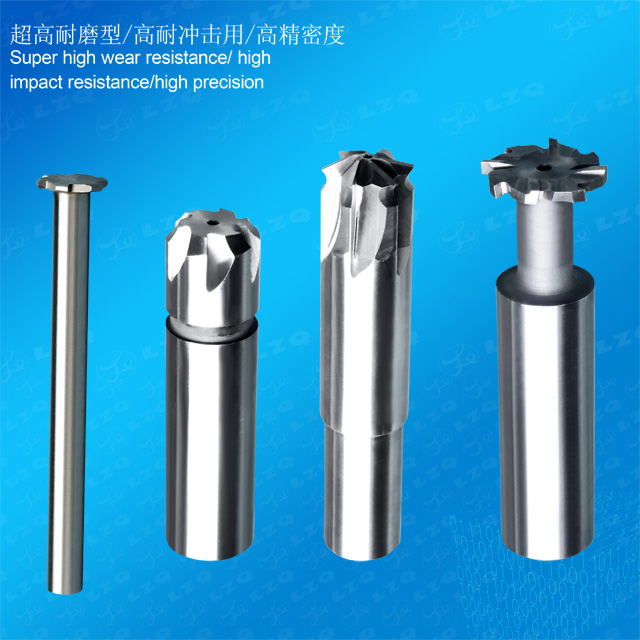

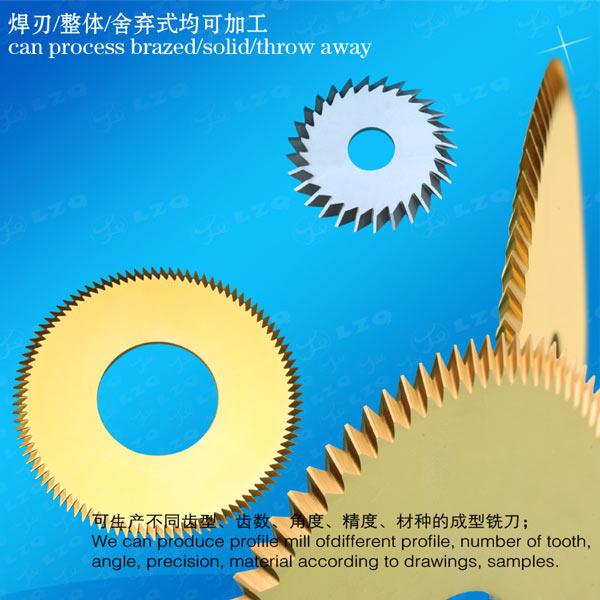

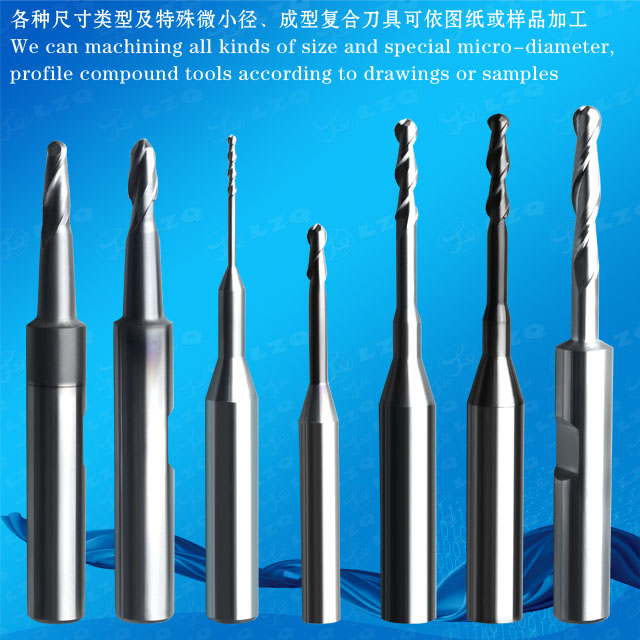

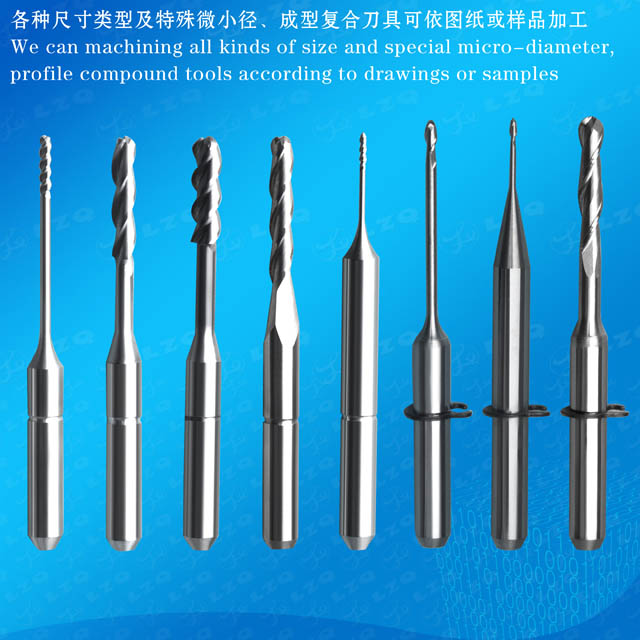

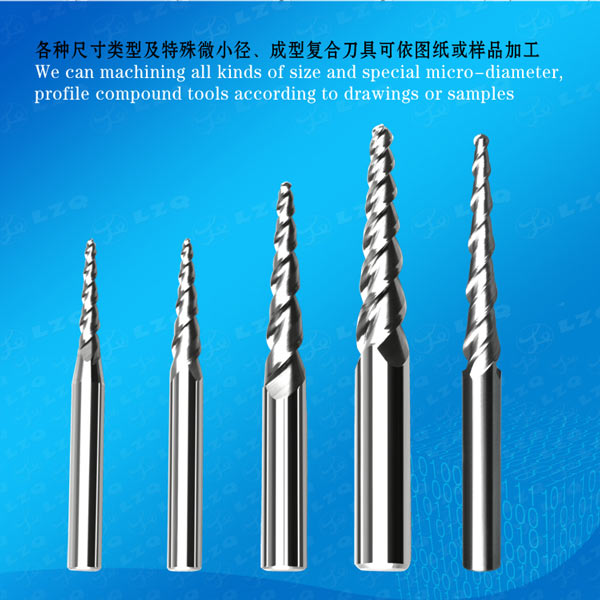

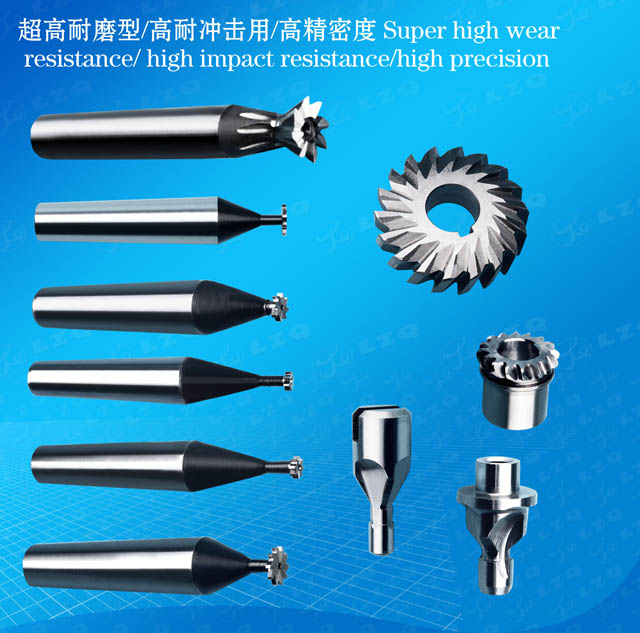

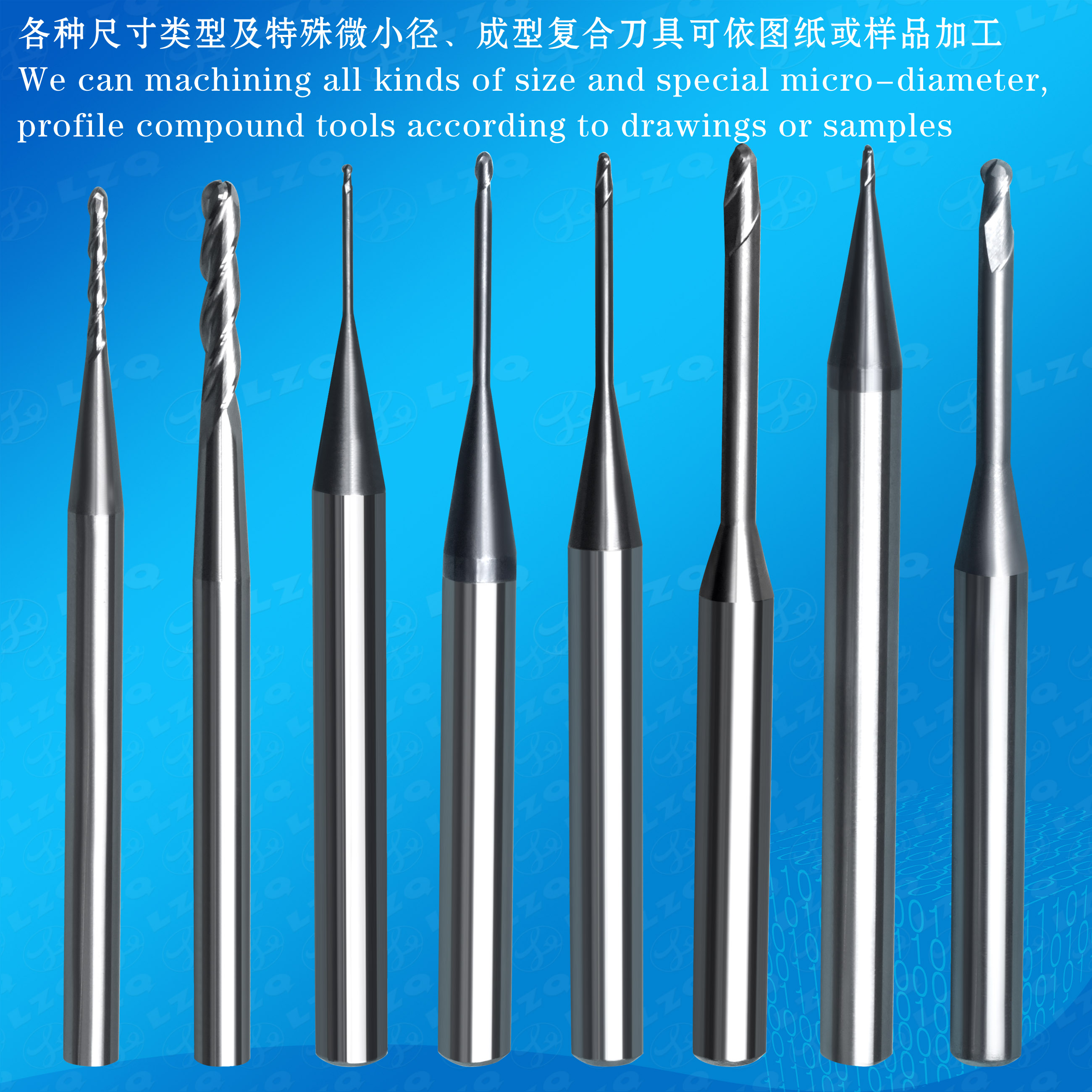

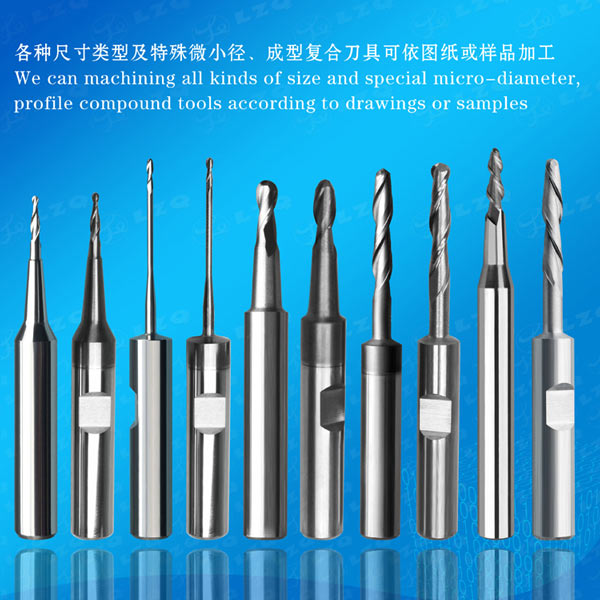

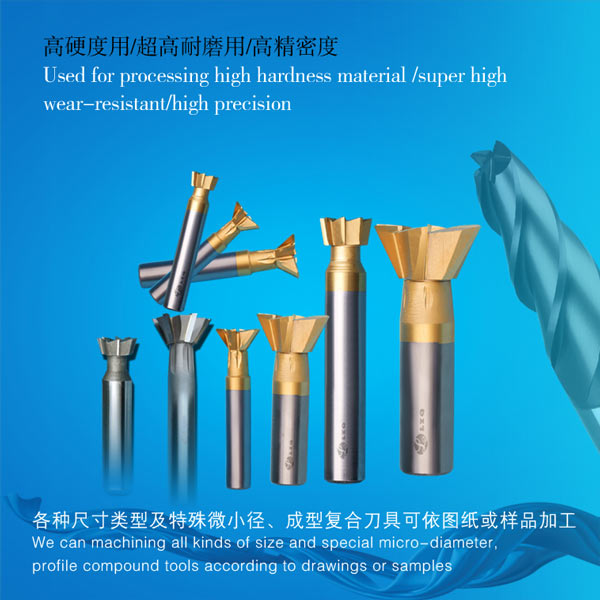

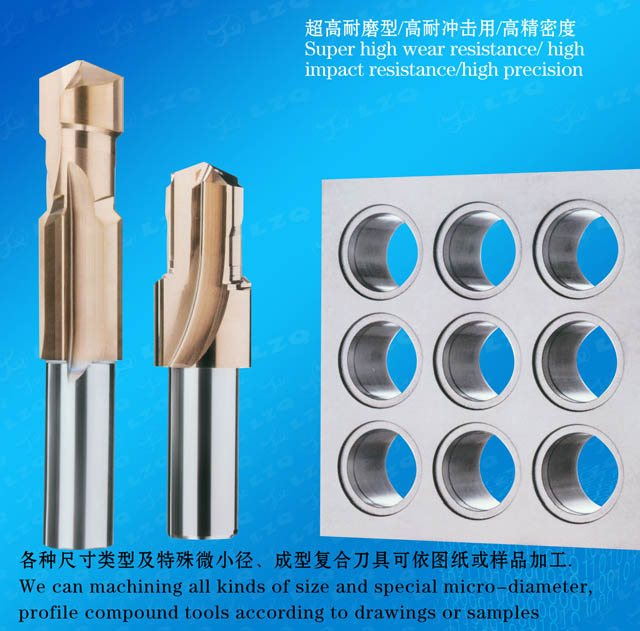

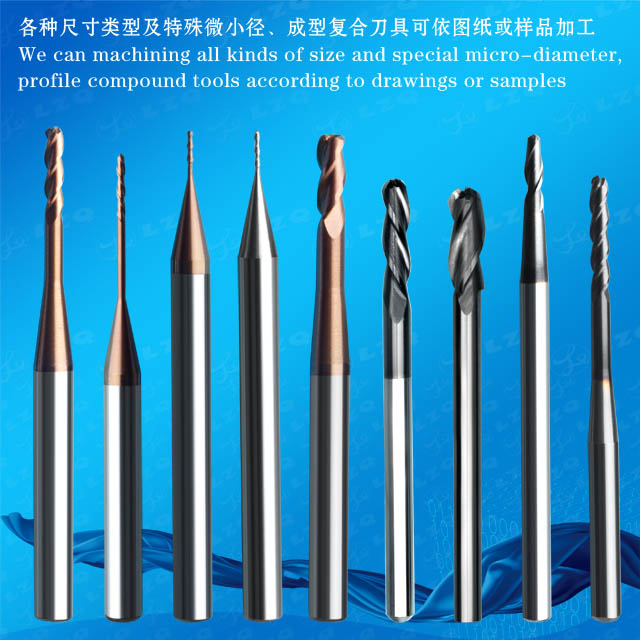

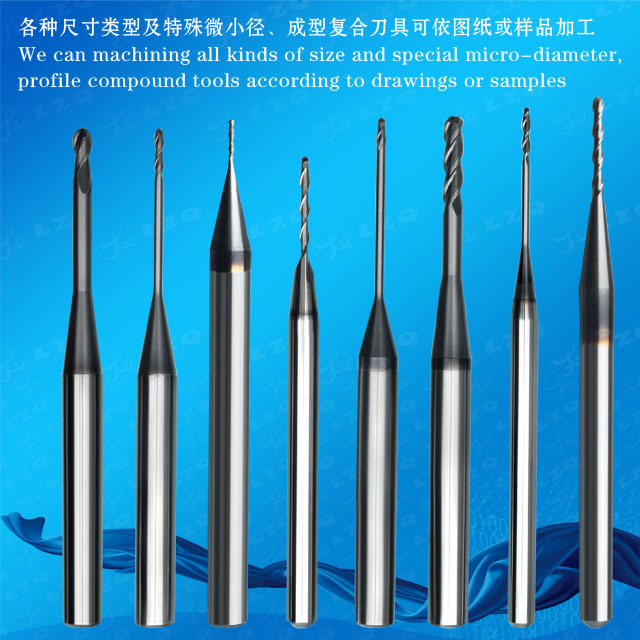

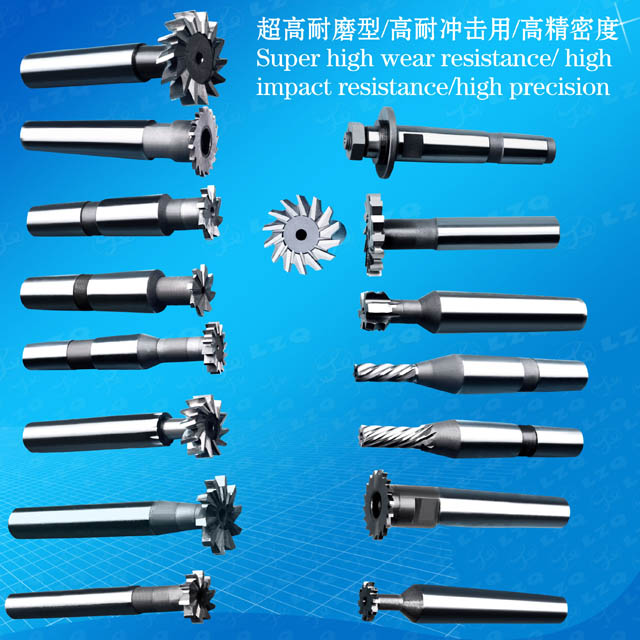

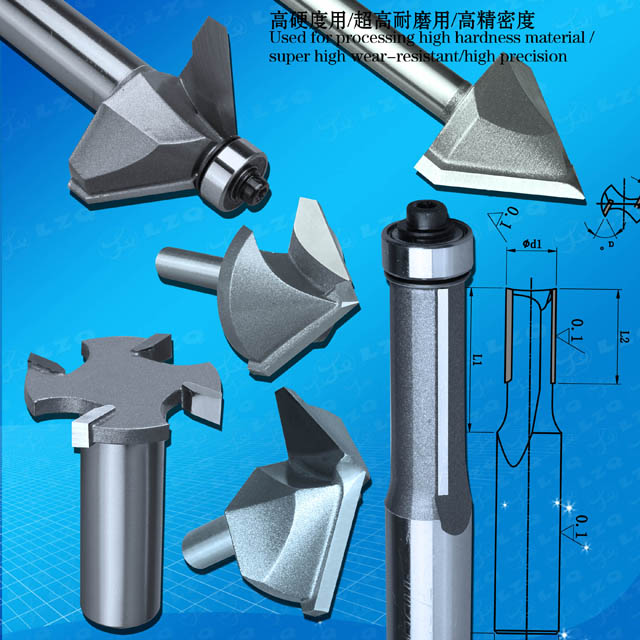

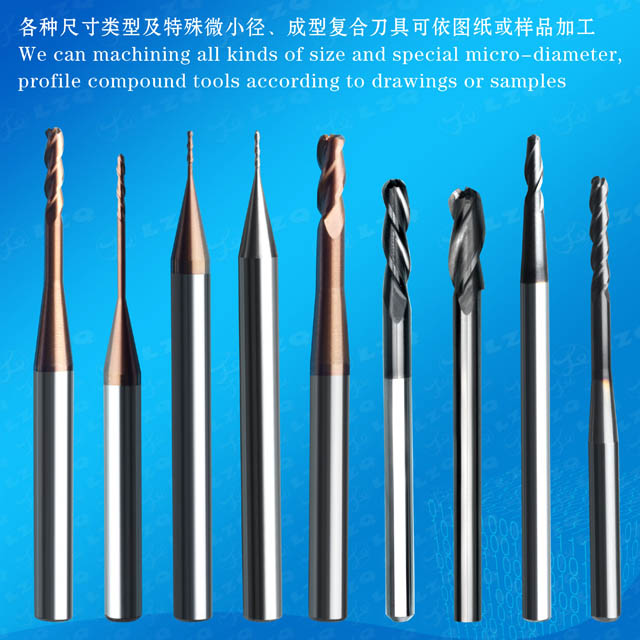

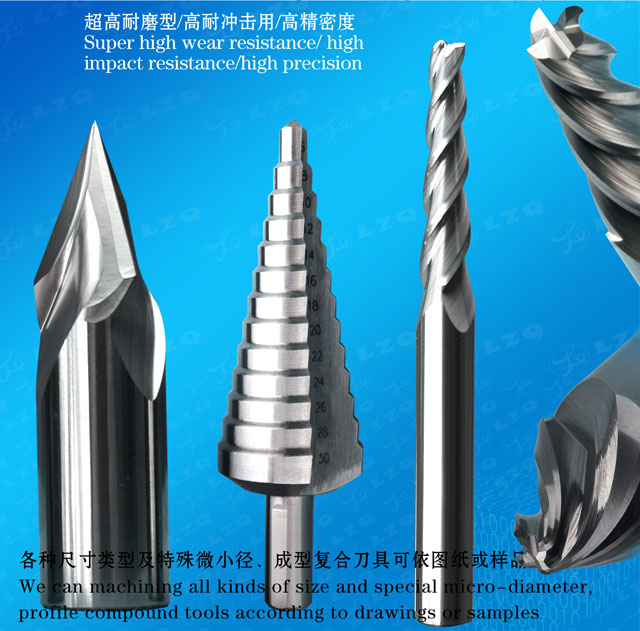

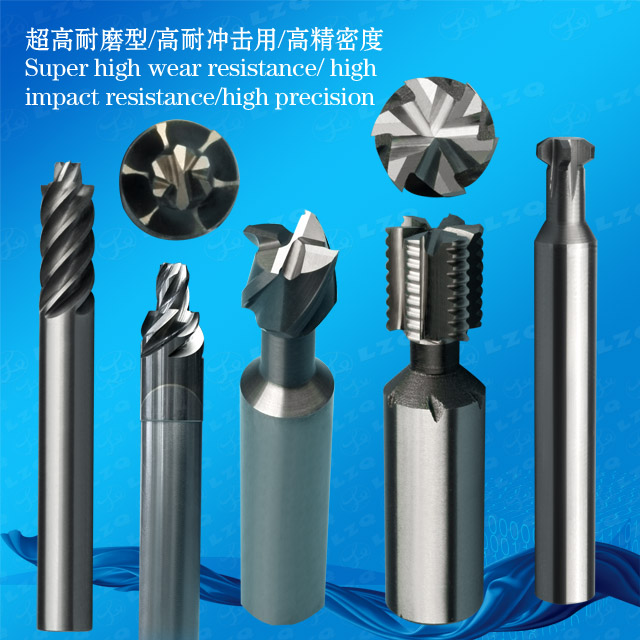

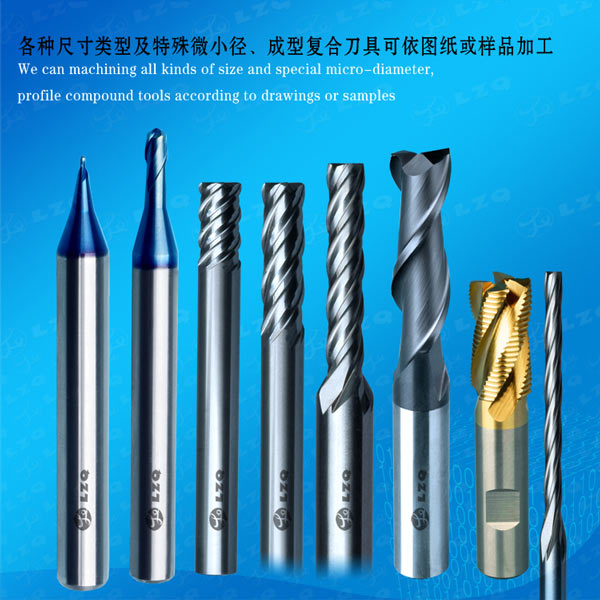

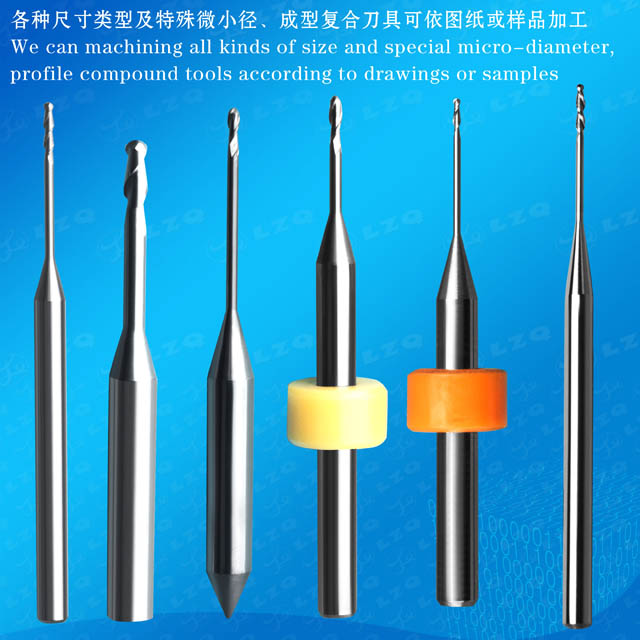

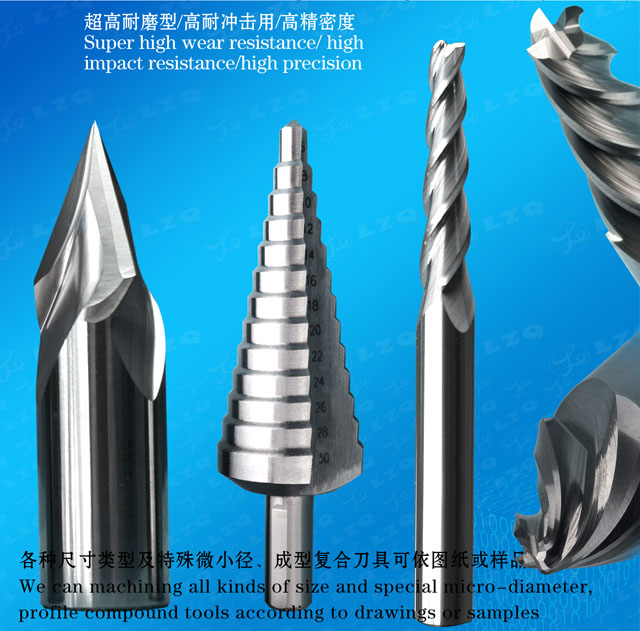

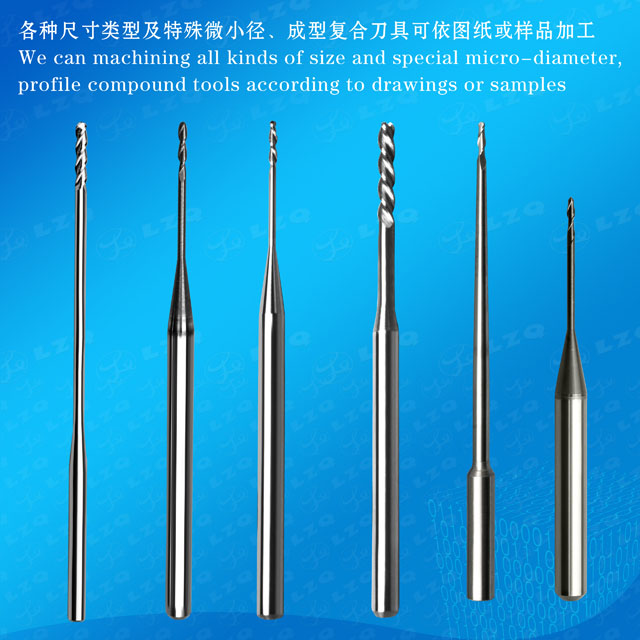

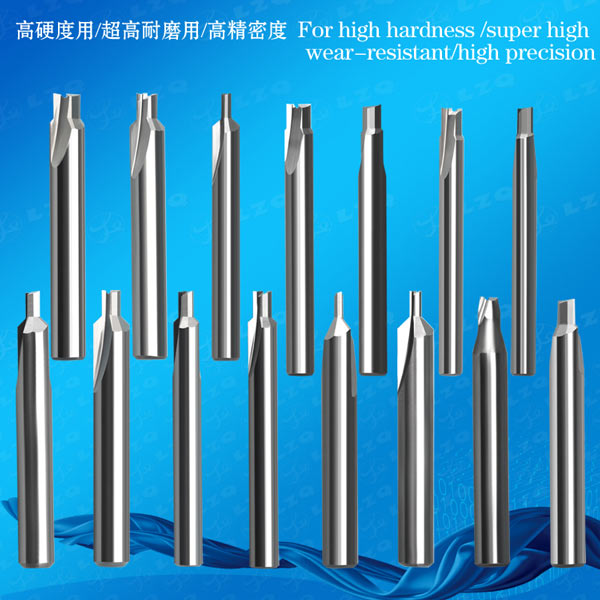

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material, semi-products, finished products in an ordinary year, we are capable to produce according to drawing or sample provided by the customer, so as to present you a favourable cost-performance ratio…Welcome to visit our factory.

Product Details

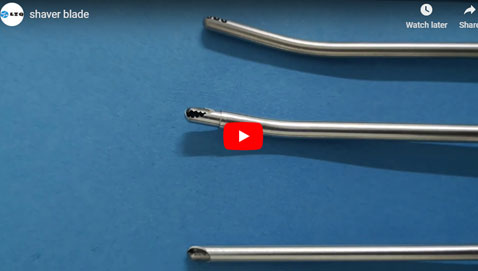

Process

Face milling method (cutter rotation axis is vertical - 0° inclination relative to tool axis) Milling is a reducing process that makes use of a milling cutter to cast off the cloth from the floor of a workpiece. The milling cutter is a rotary reducing tool, often with more than one reducing points. As adversarial to drilling, where the device is superior alongside its rotation axis, the cutter in milling is normally moved perpendicular to its axis so that reducing happens on the circumference of the cutter. As the milling cutter enters the workpiece, the slicing edges (flutes or teeth) of the device persistently reduce into and exit from the material, shaving off chips (swarf) from the workpiece with every pass. The reducing motion is shear deformation; cloth is pushed off the workpiece in tiny clumps that grasp together to a higher or lesser extent (depending on the material) to shape chips. This makes steel slicing truly exceptional (in its mechanics) from cutting softer substances with a blade.

The milling method eliminates cloth by performing many separate, small cuts. This is performed with the aid of the use of a cutter with many teeth, spinning the cutter at high speed, or advancing the material through the cutter slowly; most frequently it is some aggregate of these three approaches. The speeds and feeds used are diverse to swimsuit a combination of variables. The pace at which the piece advances thru the cutter is referred to as feed rate, or simply feed; it is most often measured in length of material per full revolution of the cutter.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

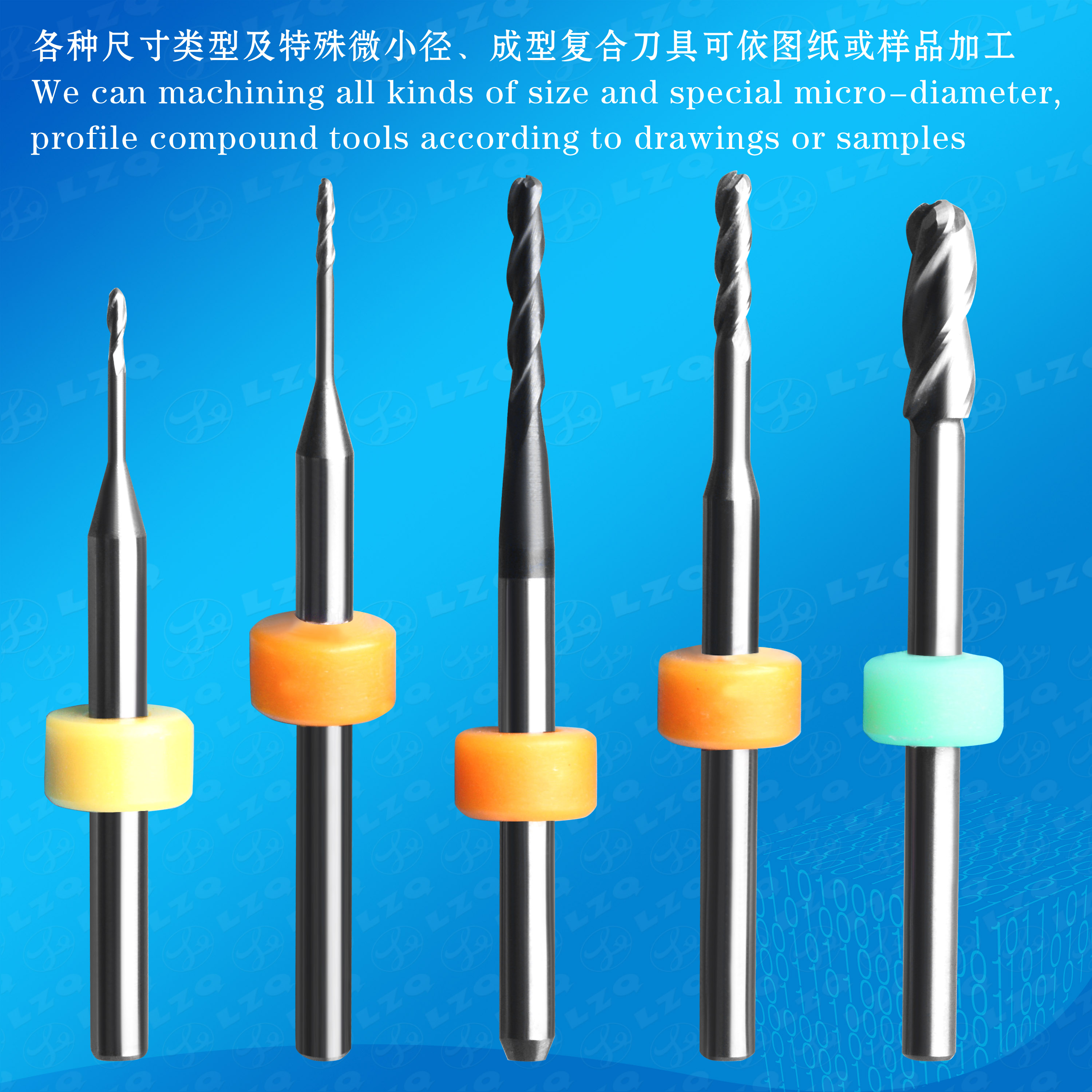

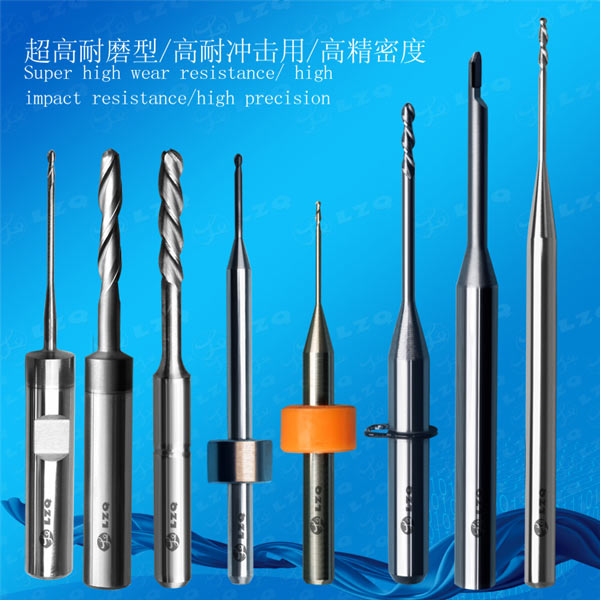

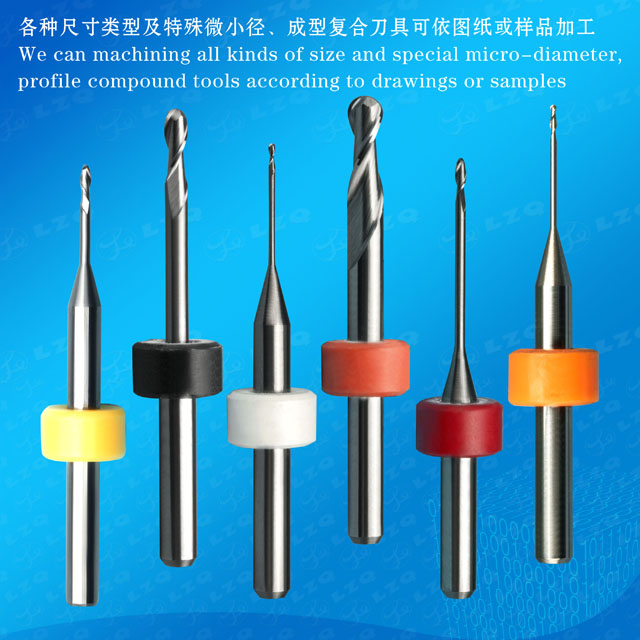

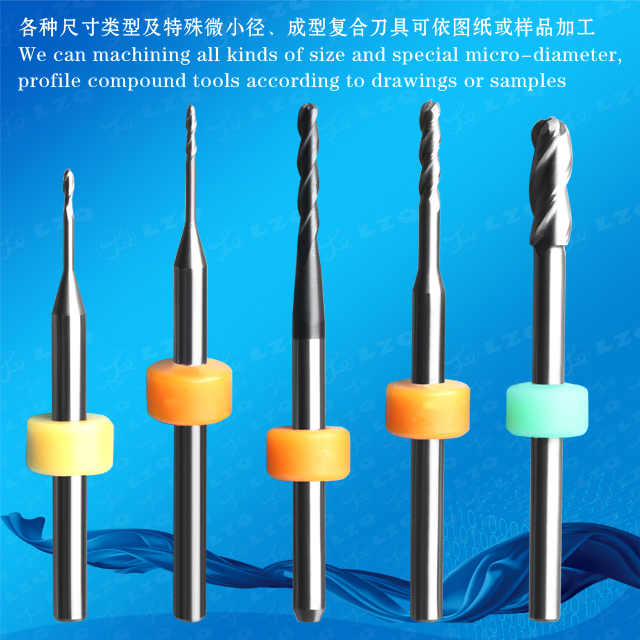

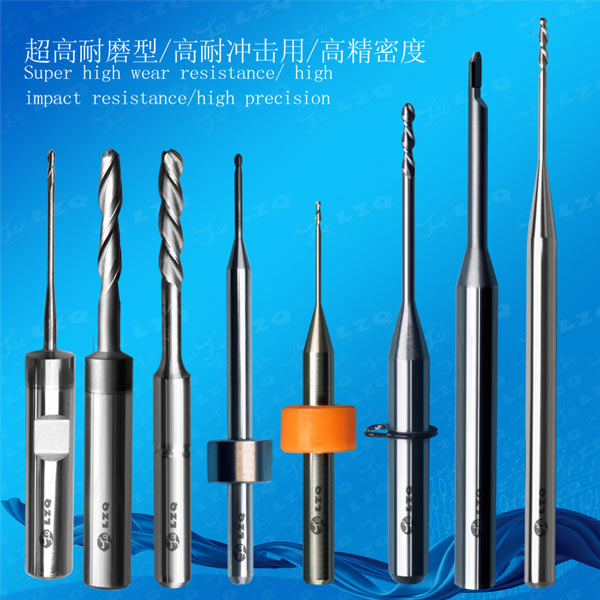

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

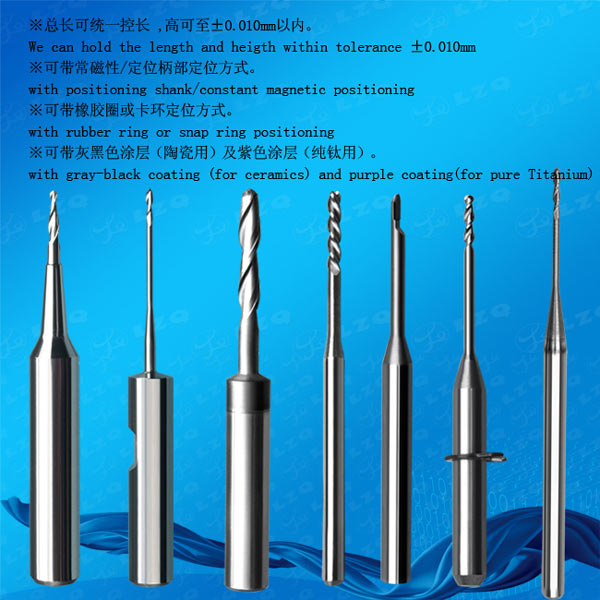

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

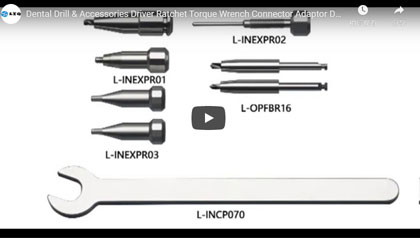

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

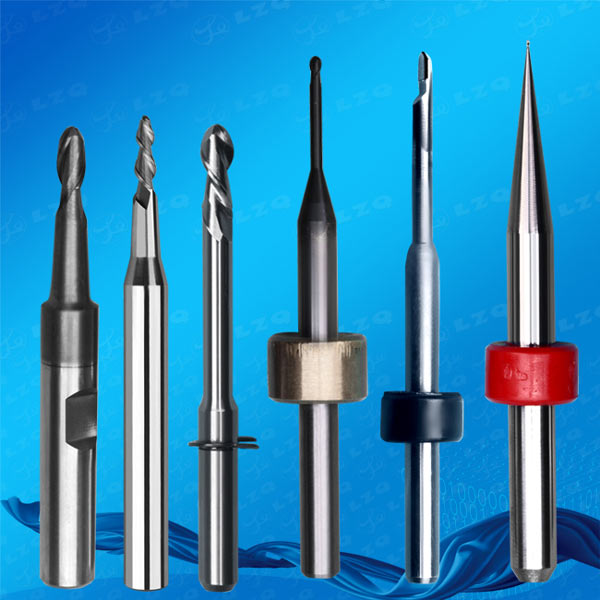

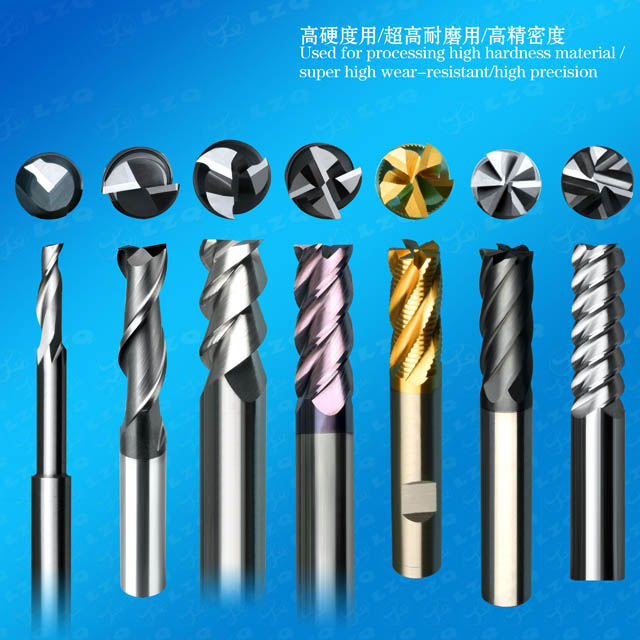

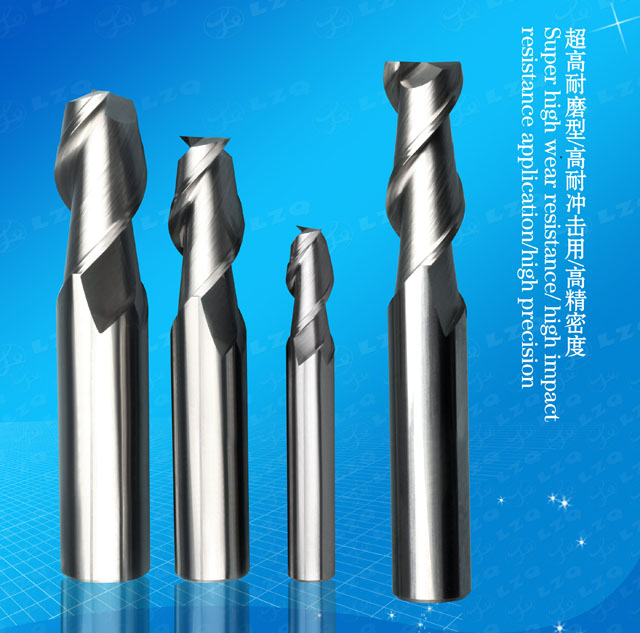

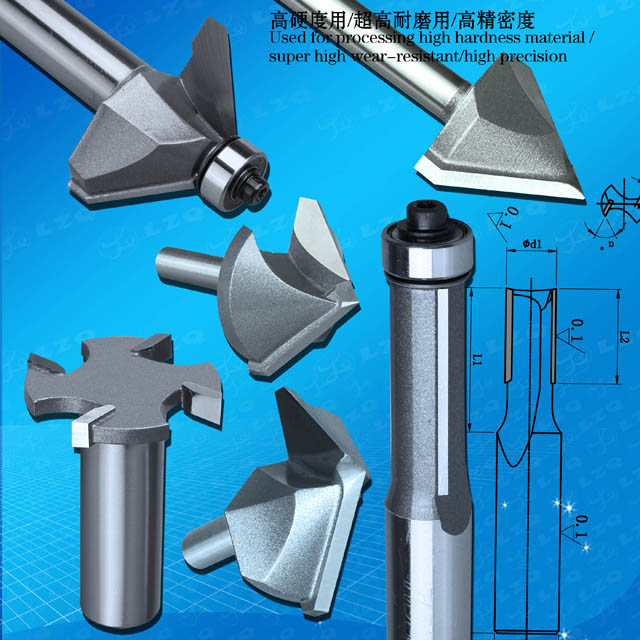

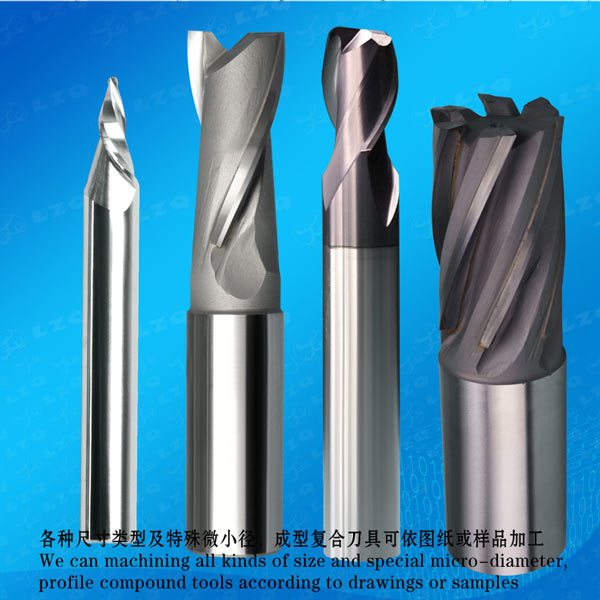

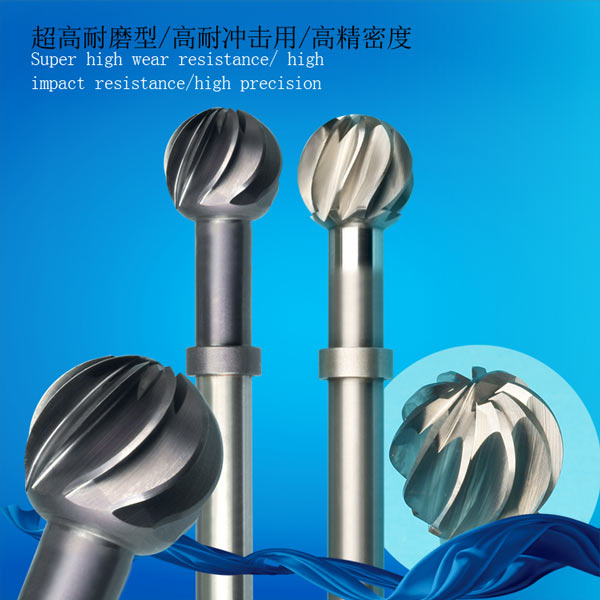

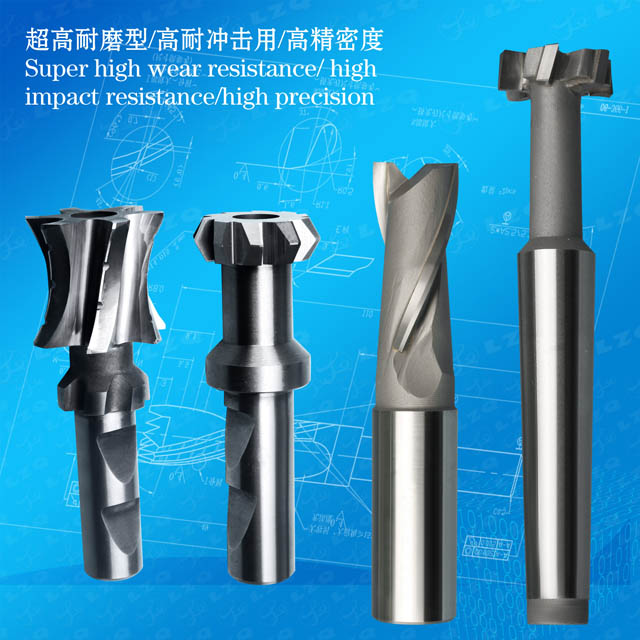

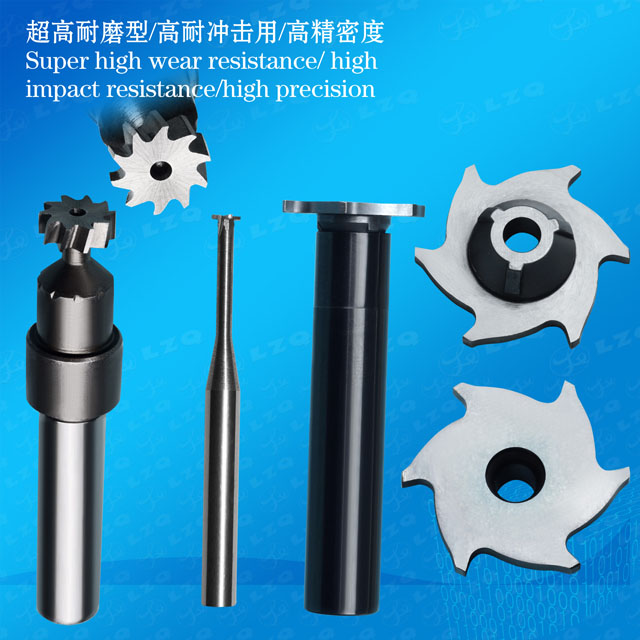

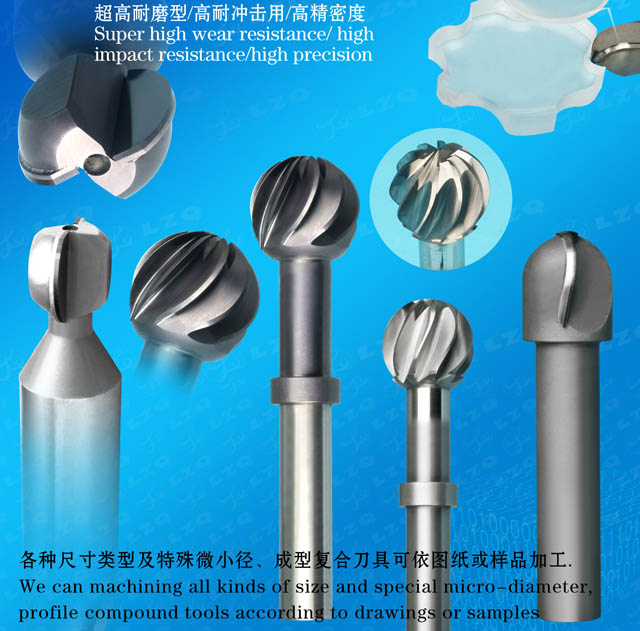

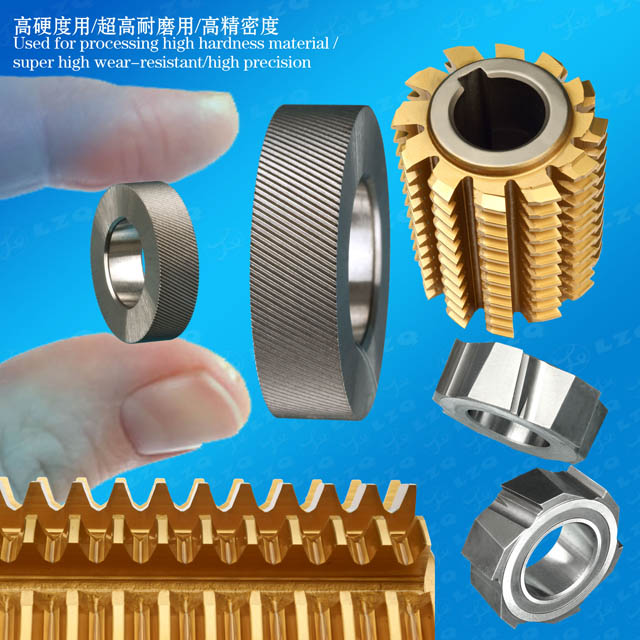

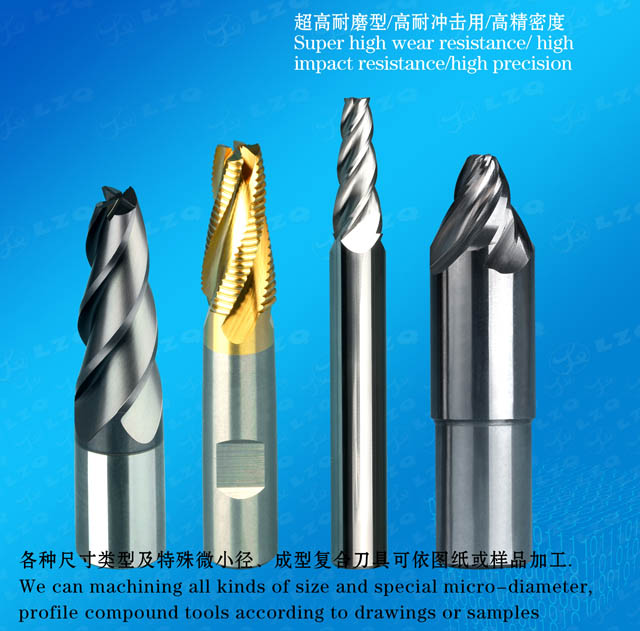

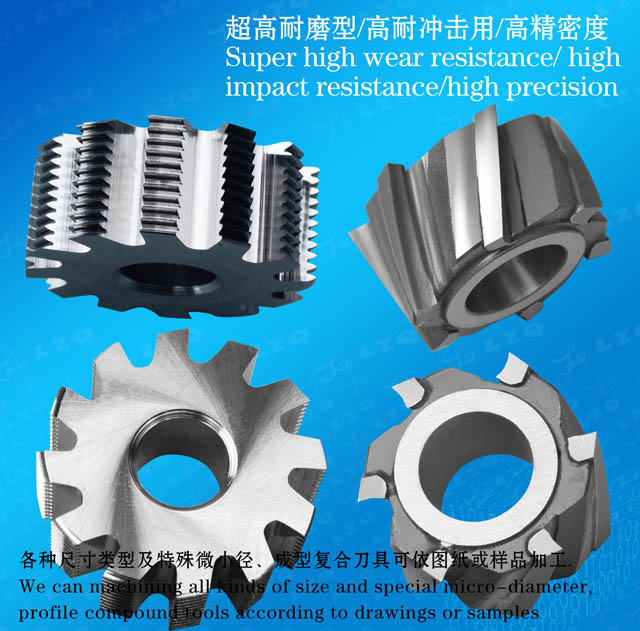

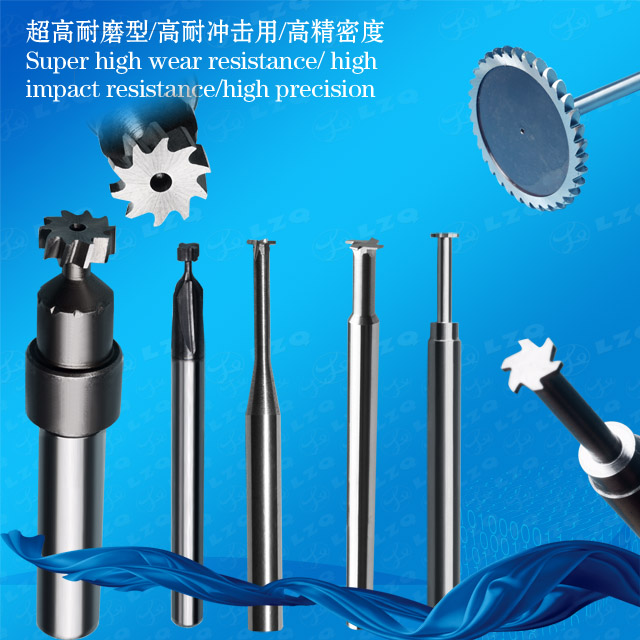

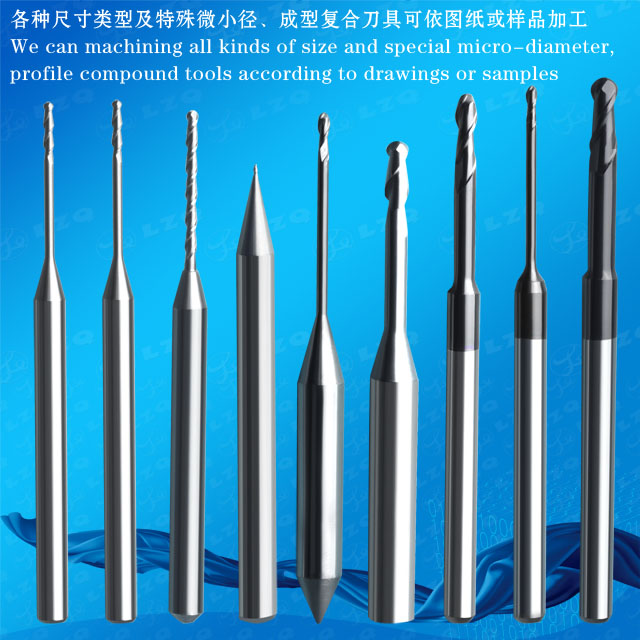

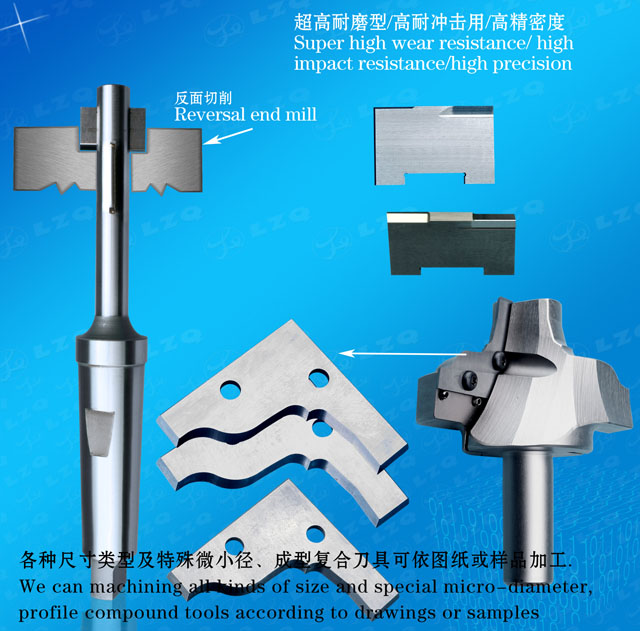

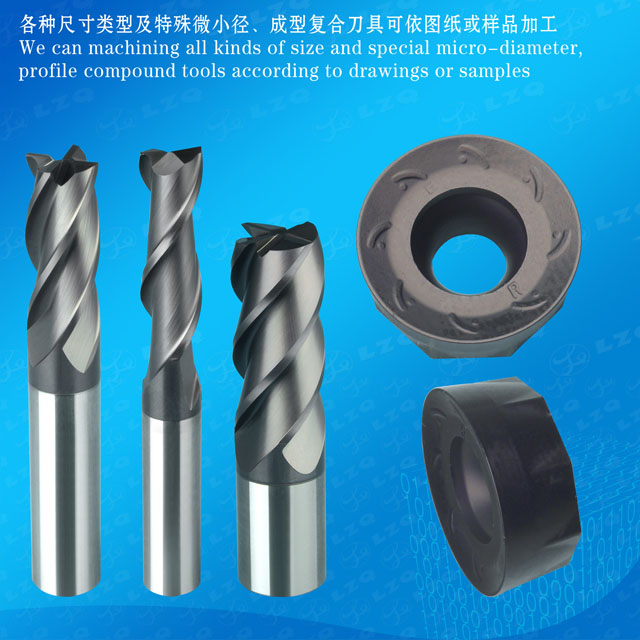

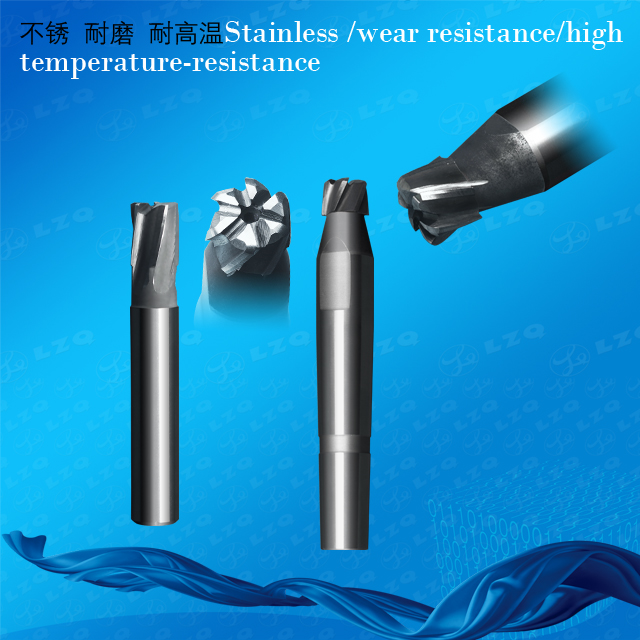

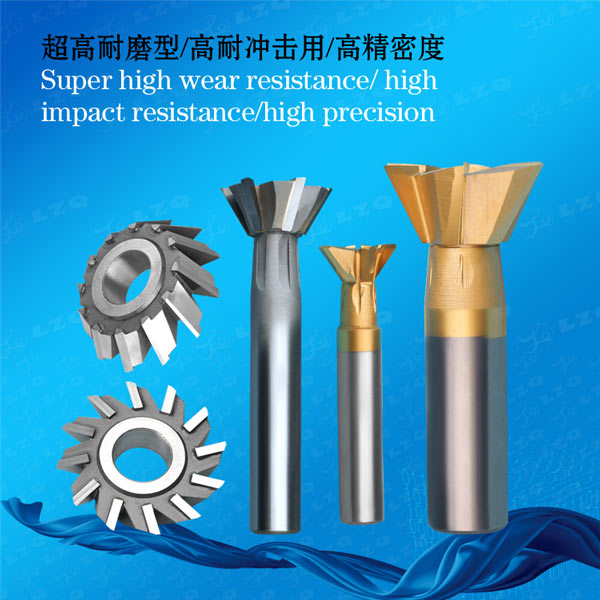

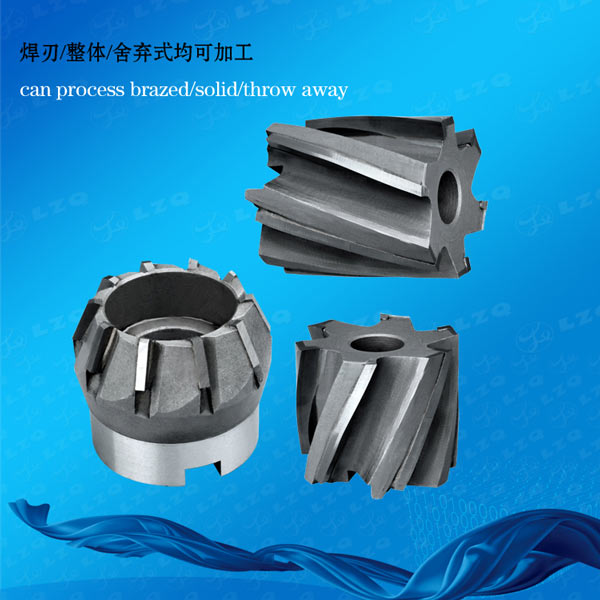

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

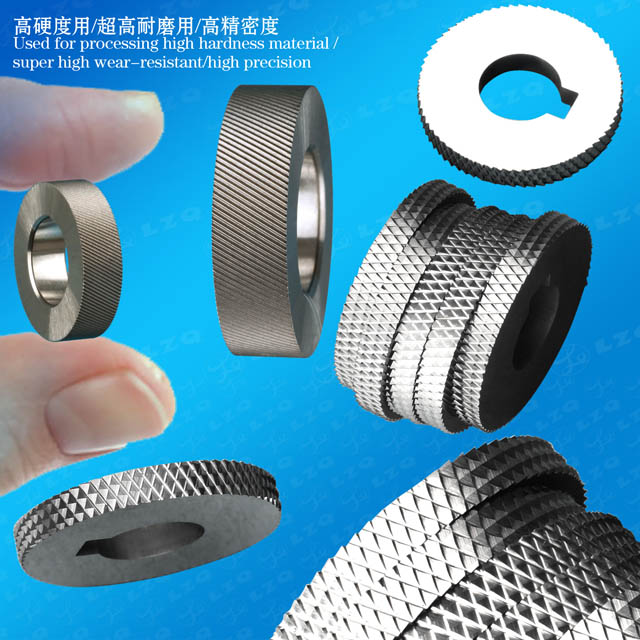

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.