Product Details

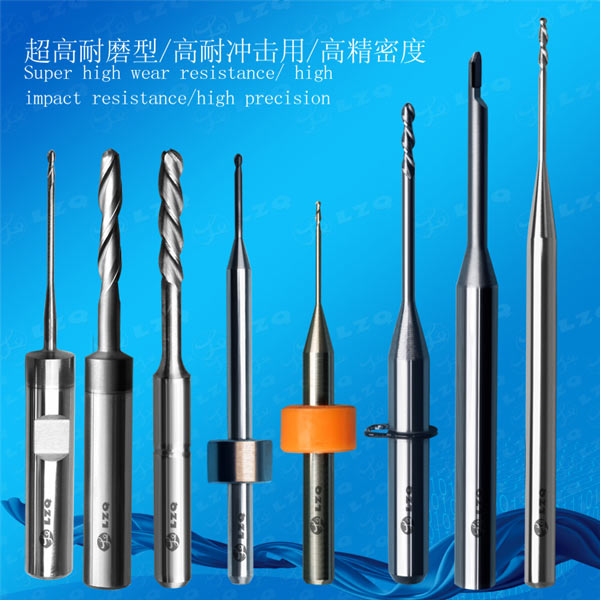

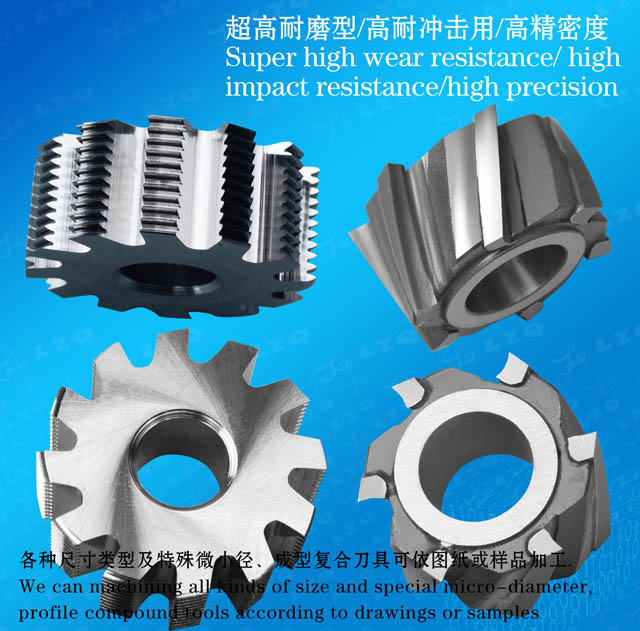

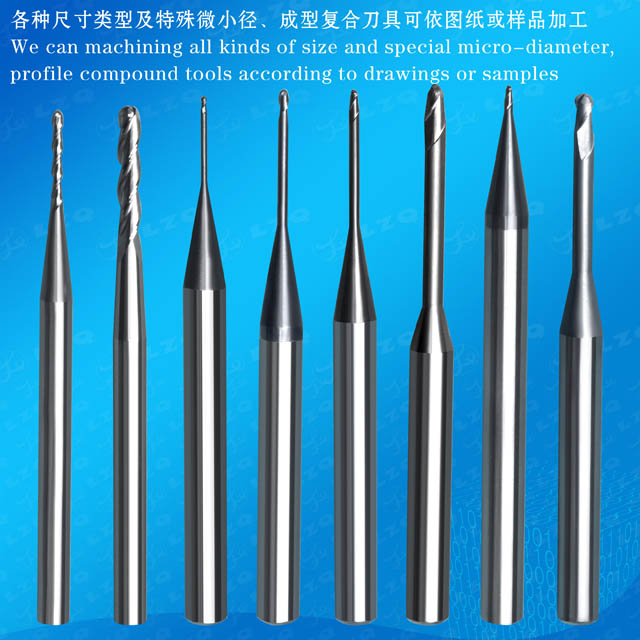

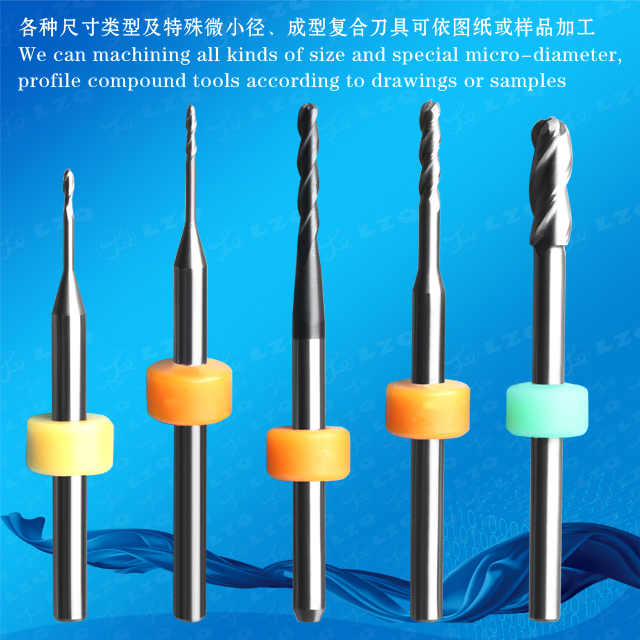

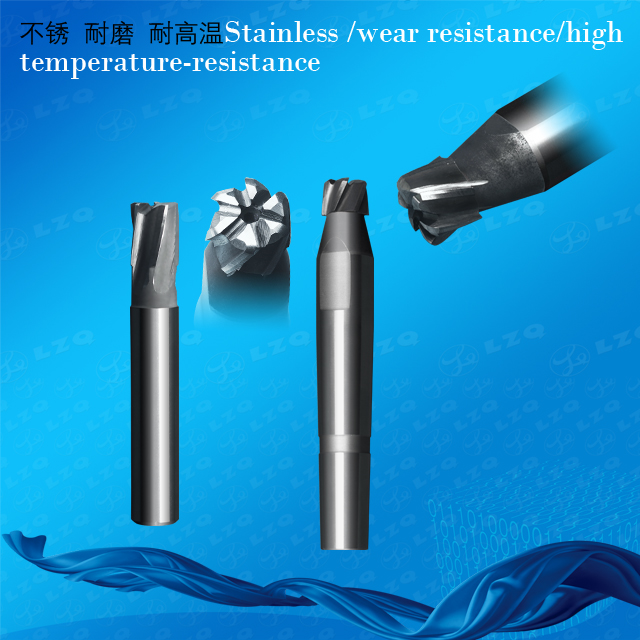

Material: Carbide

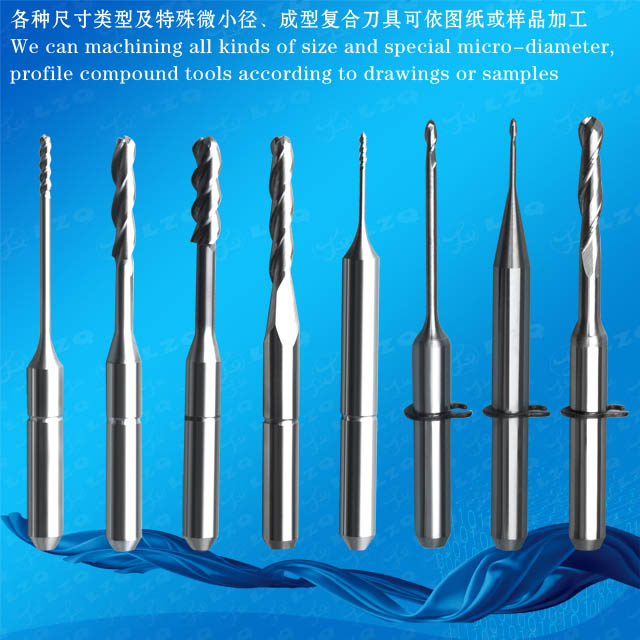

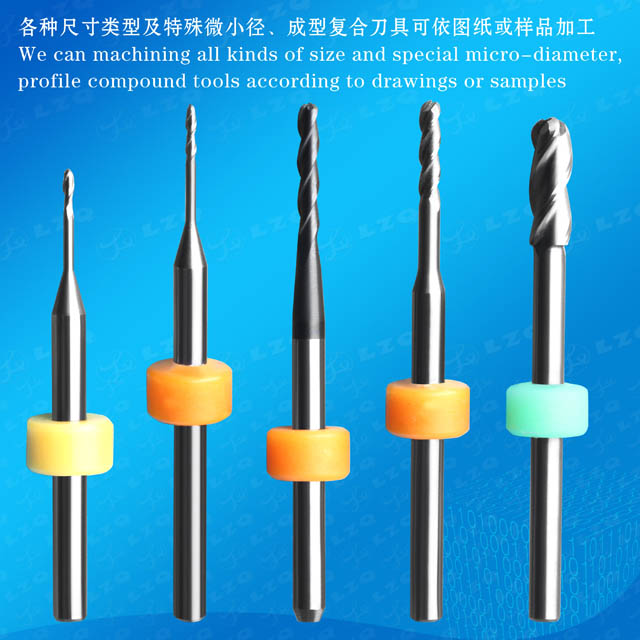

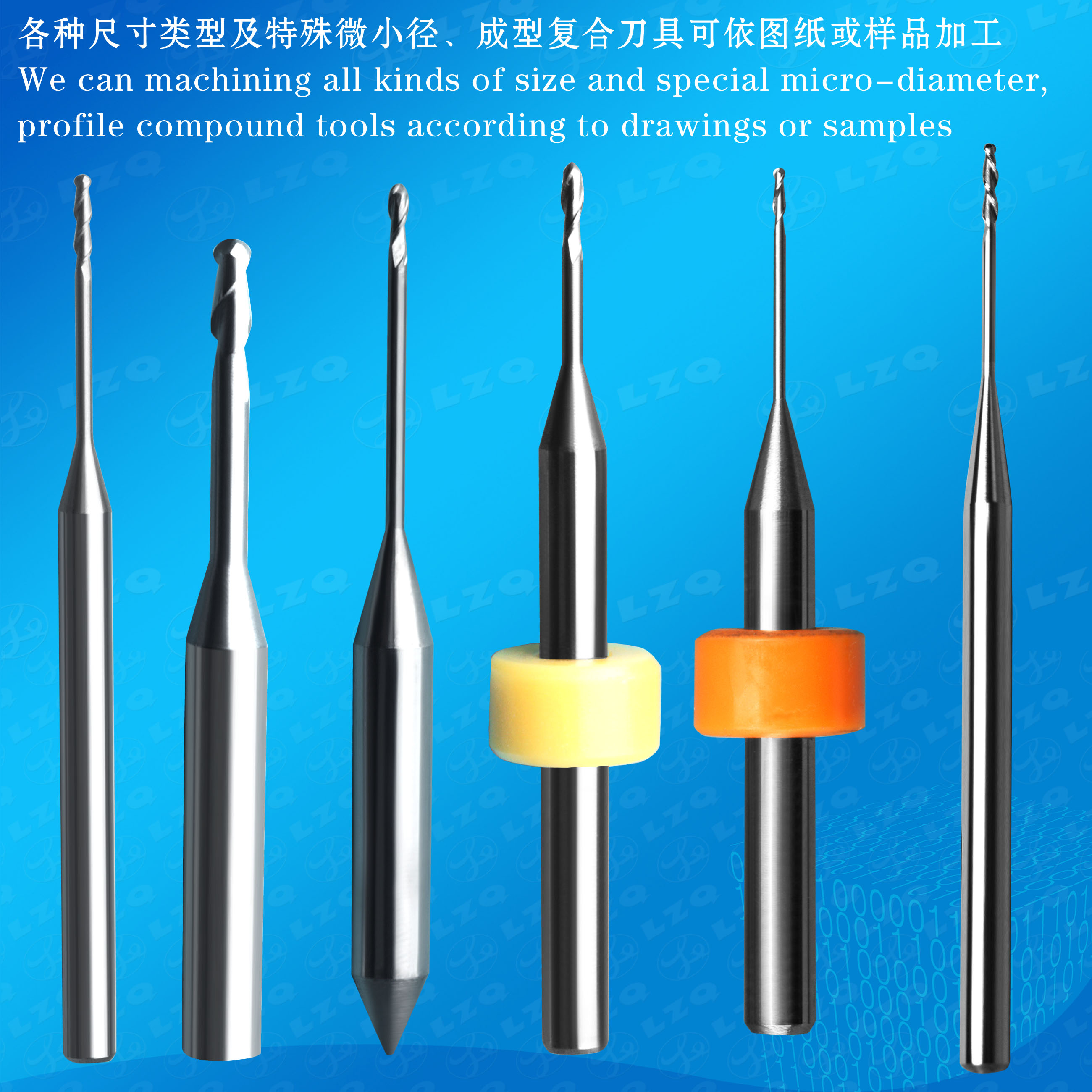

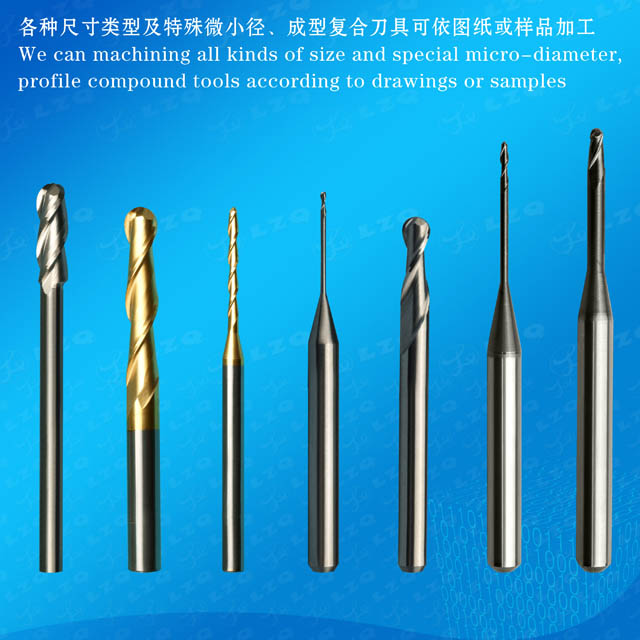

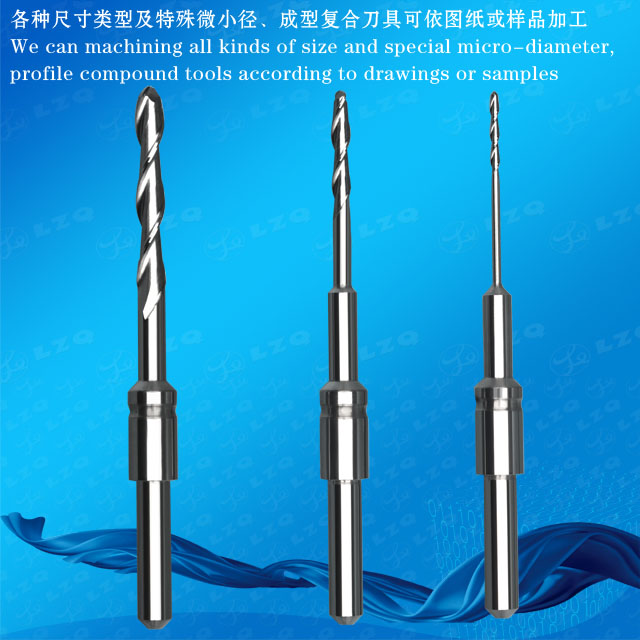

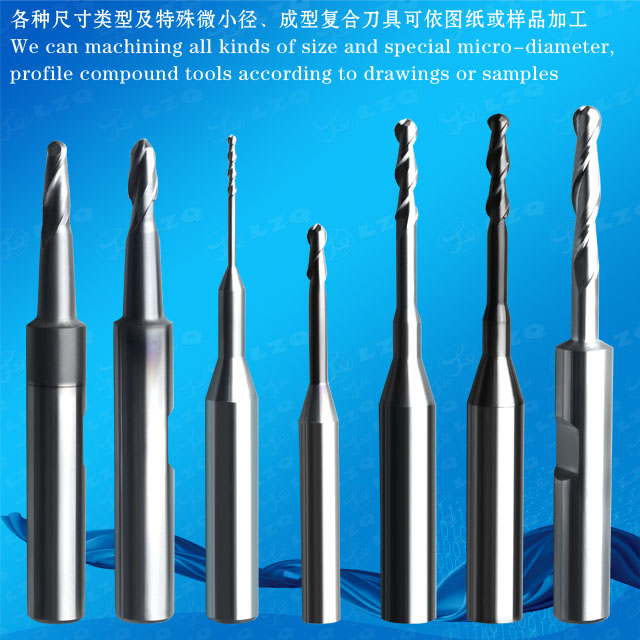

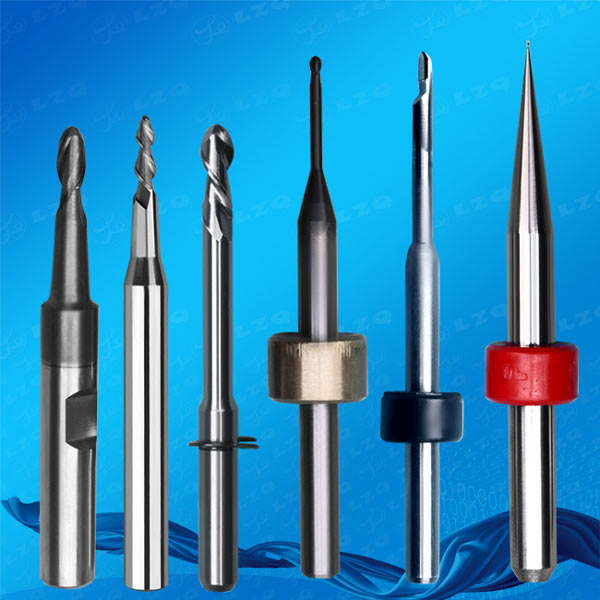

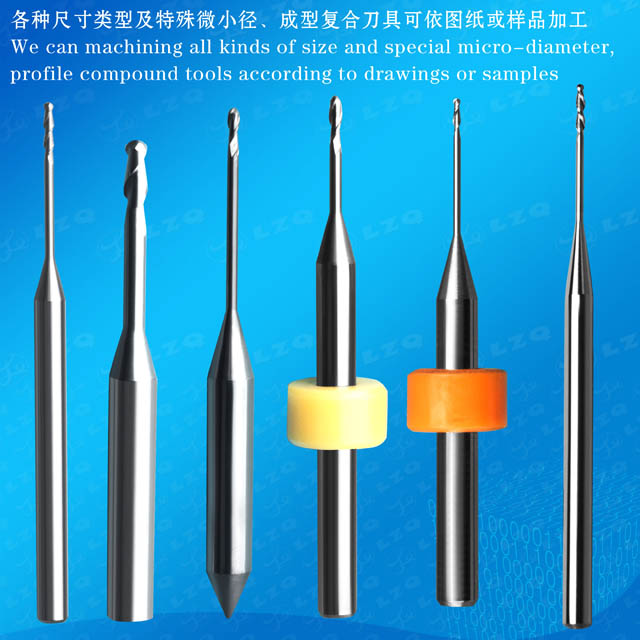

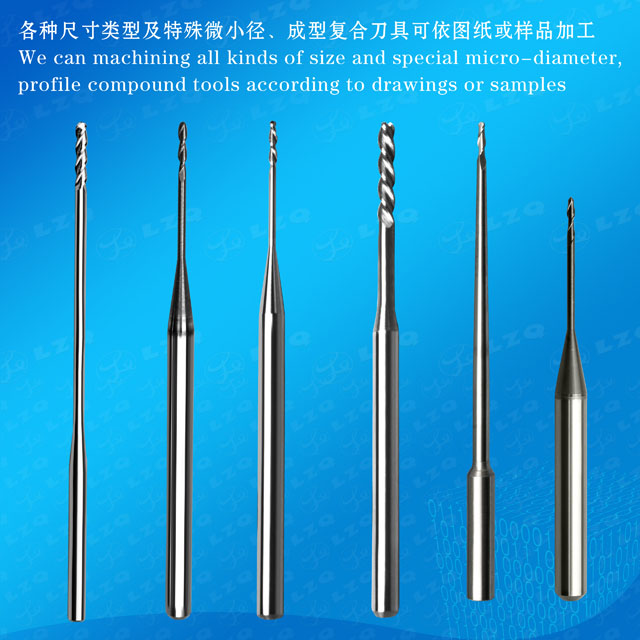

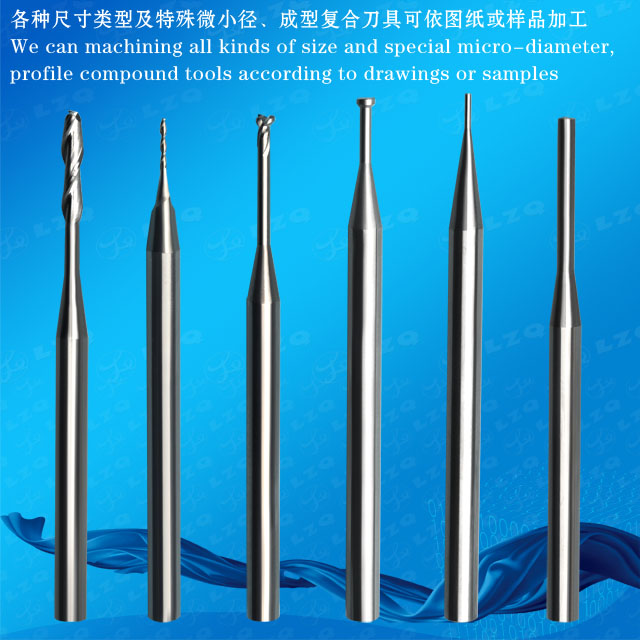

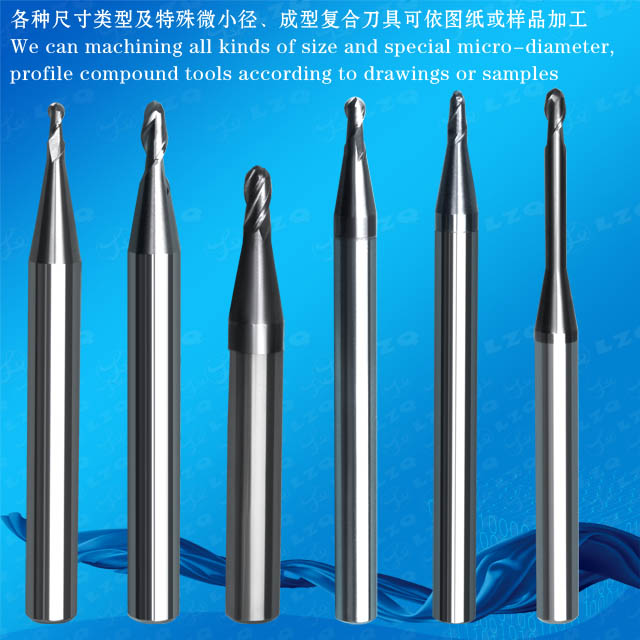

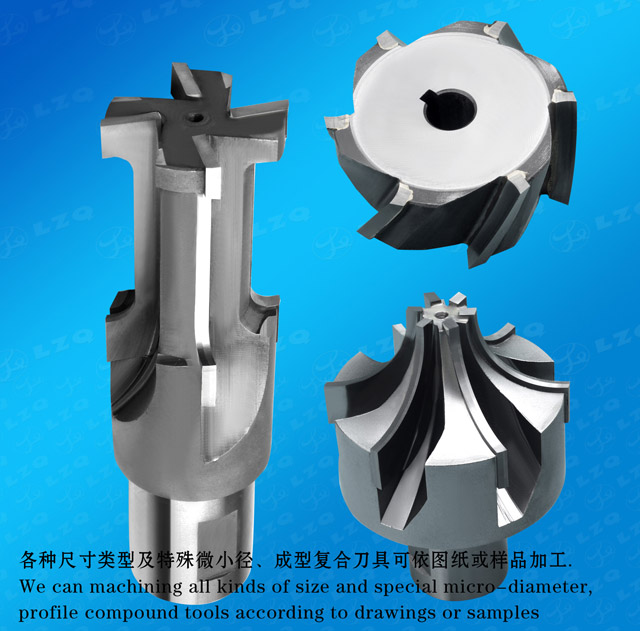

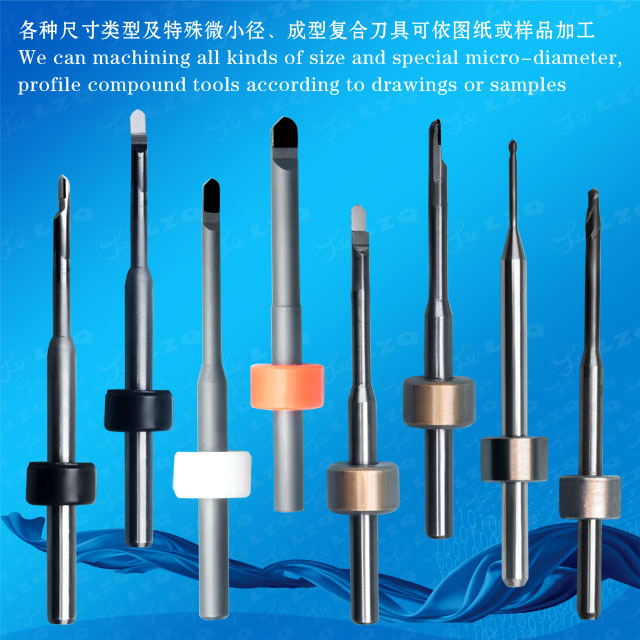

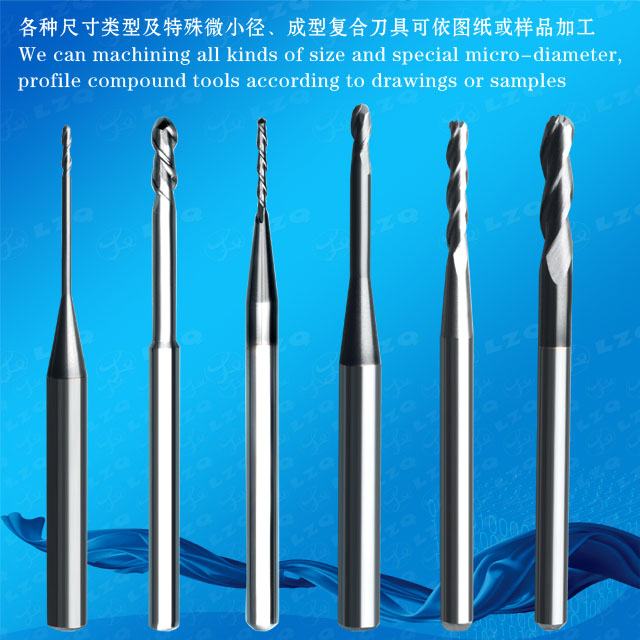

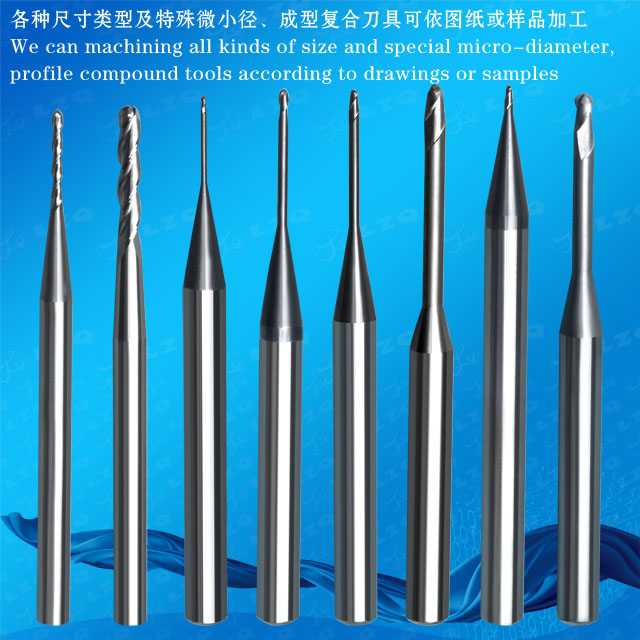

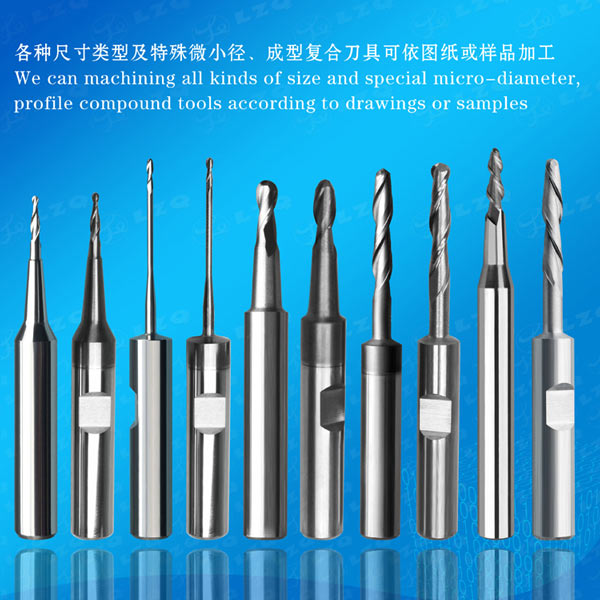

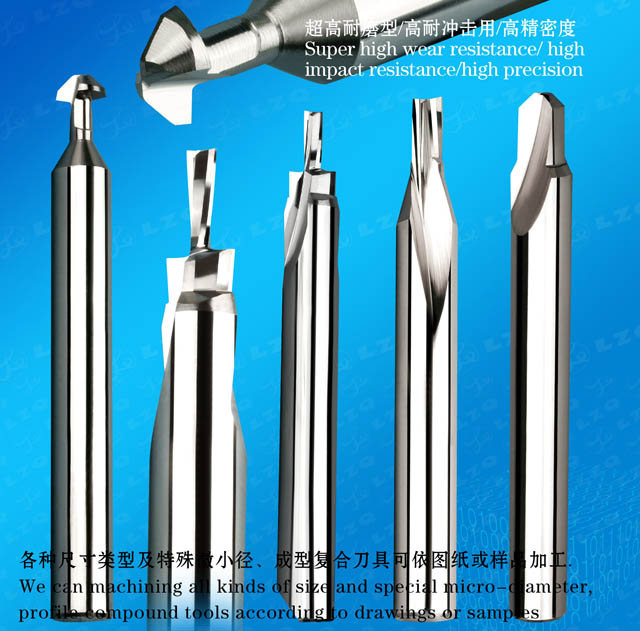

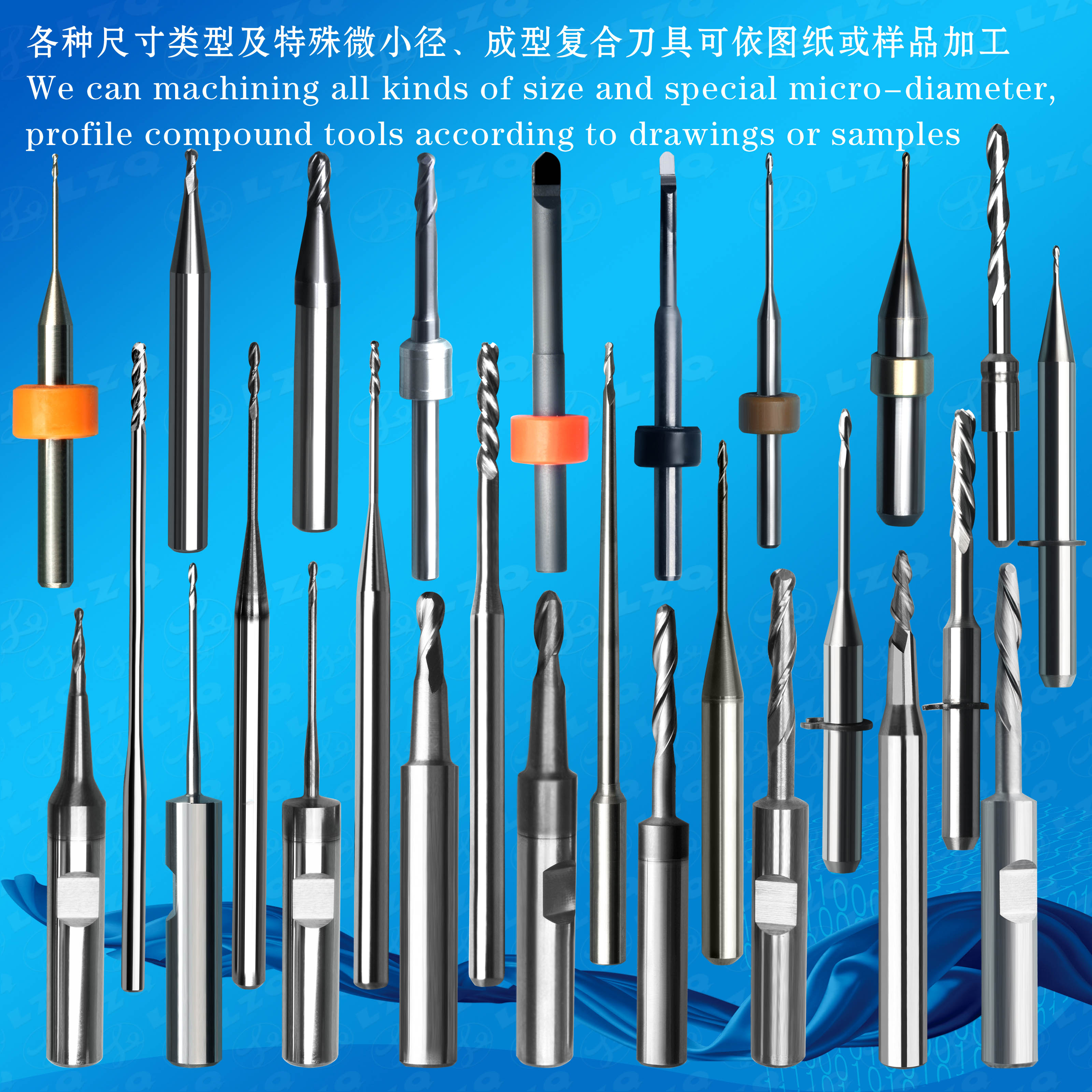

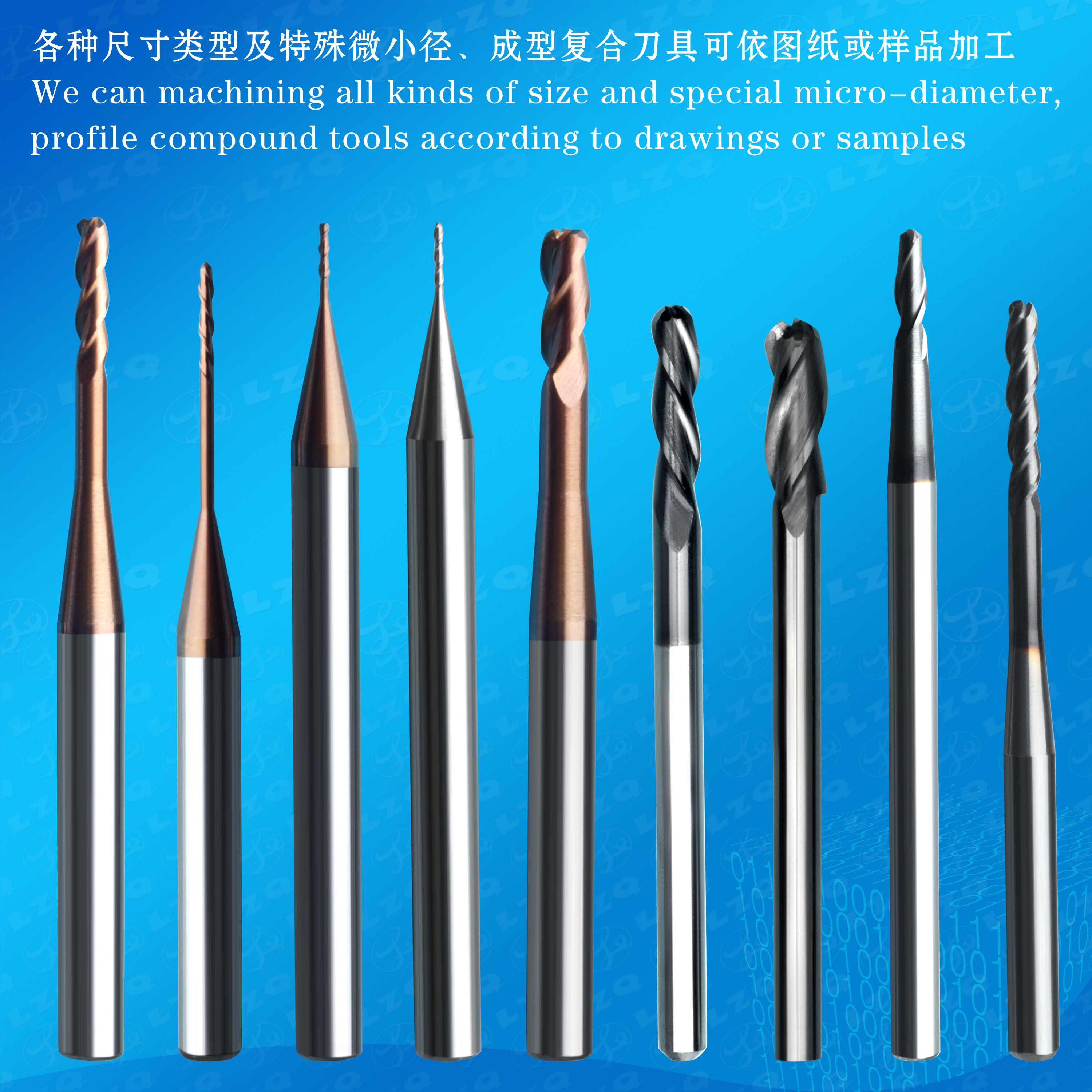

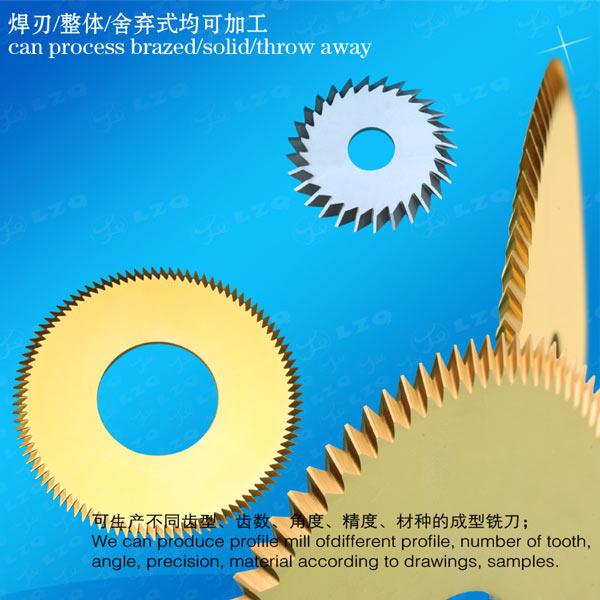

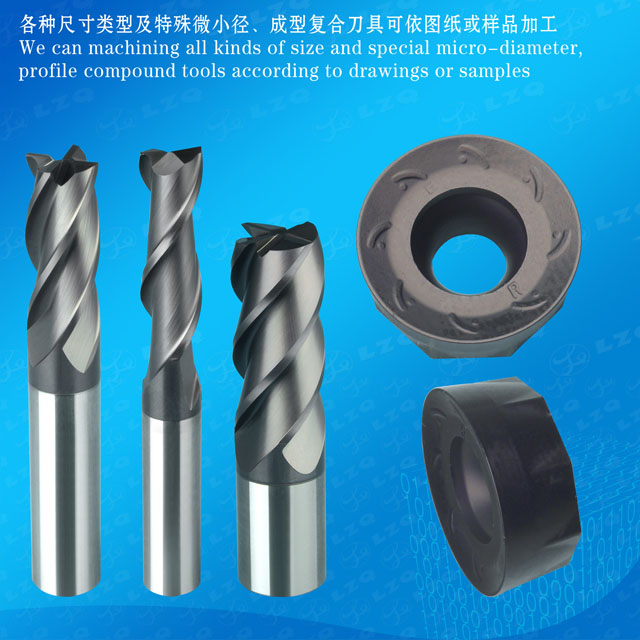

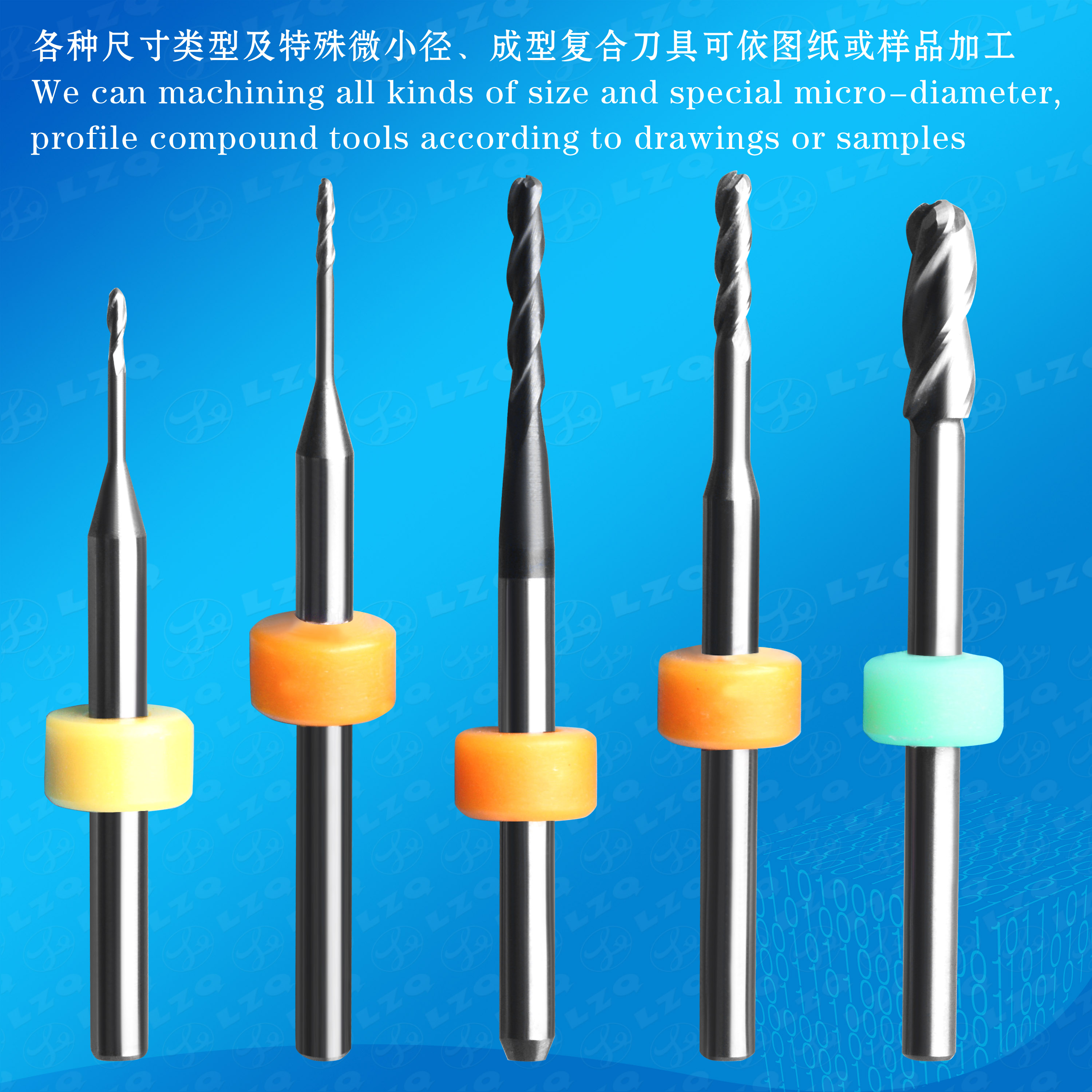

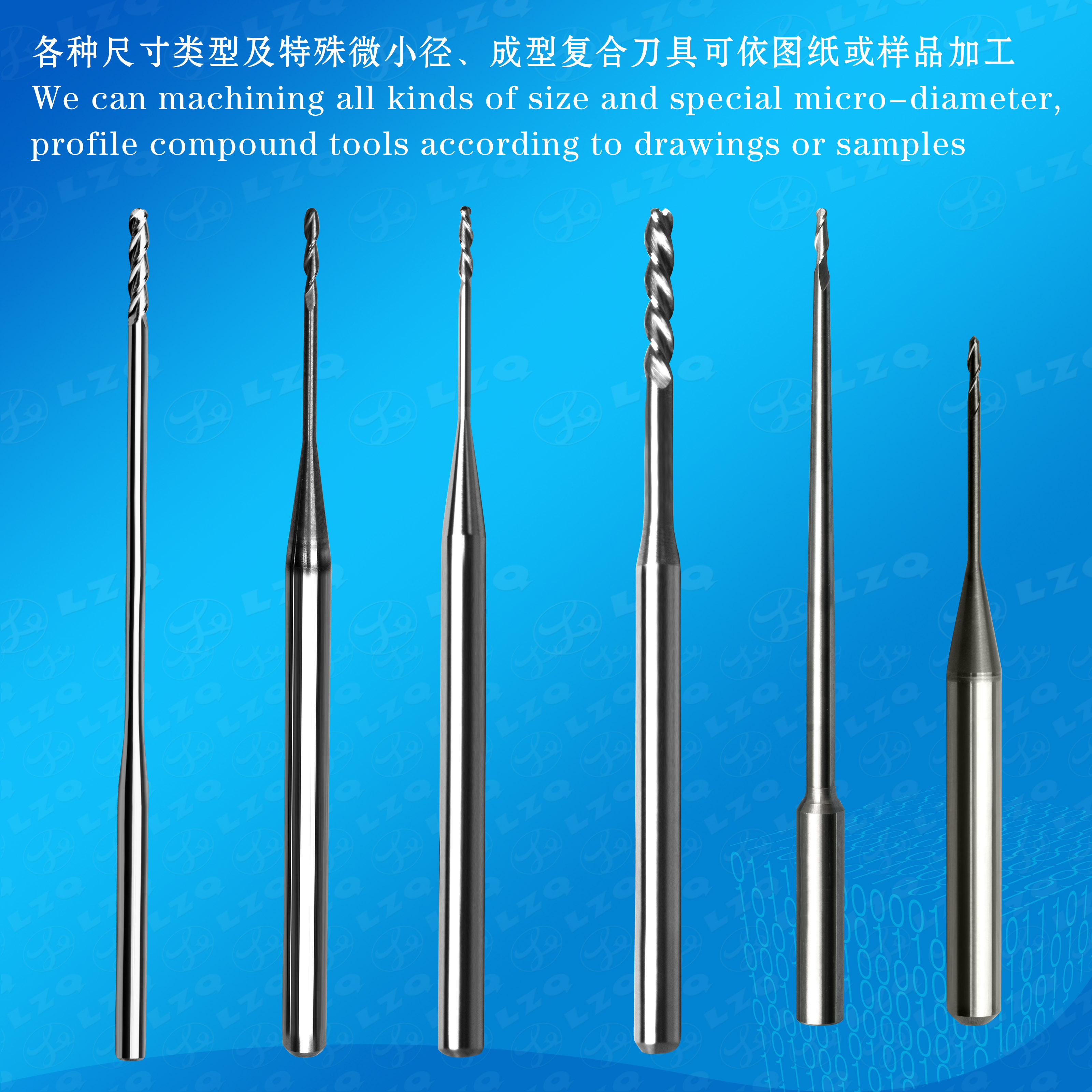

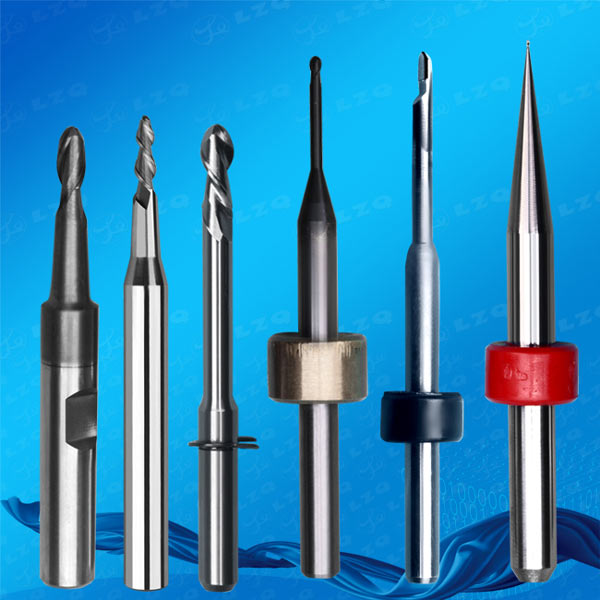

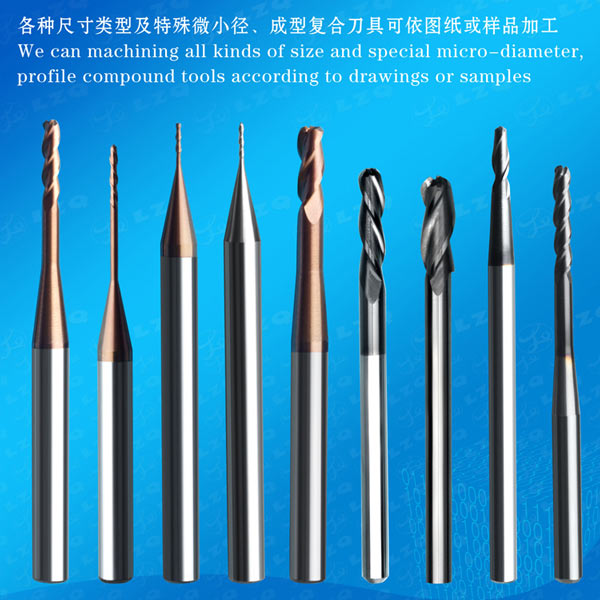

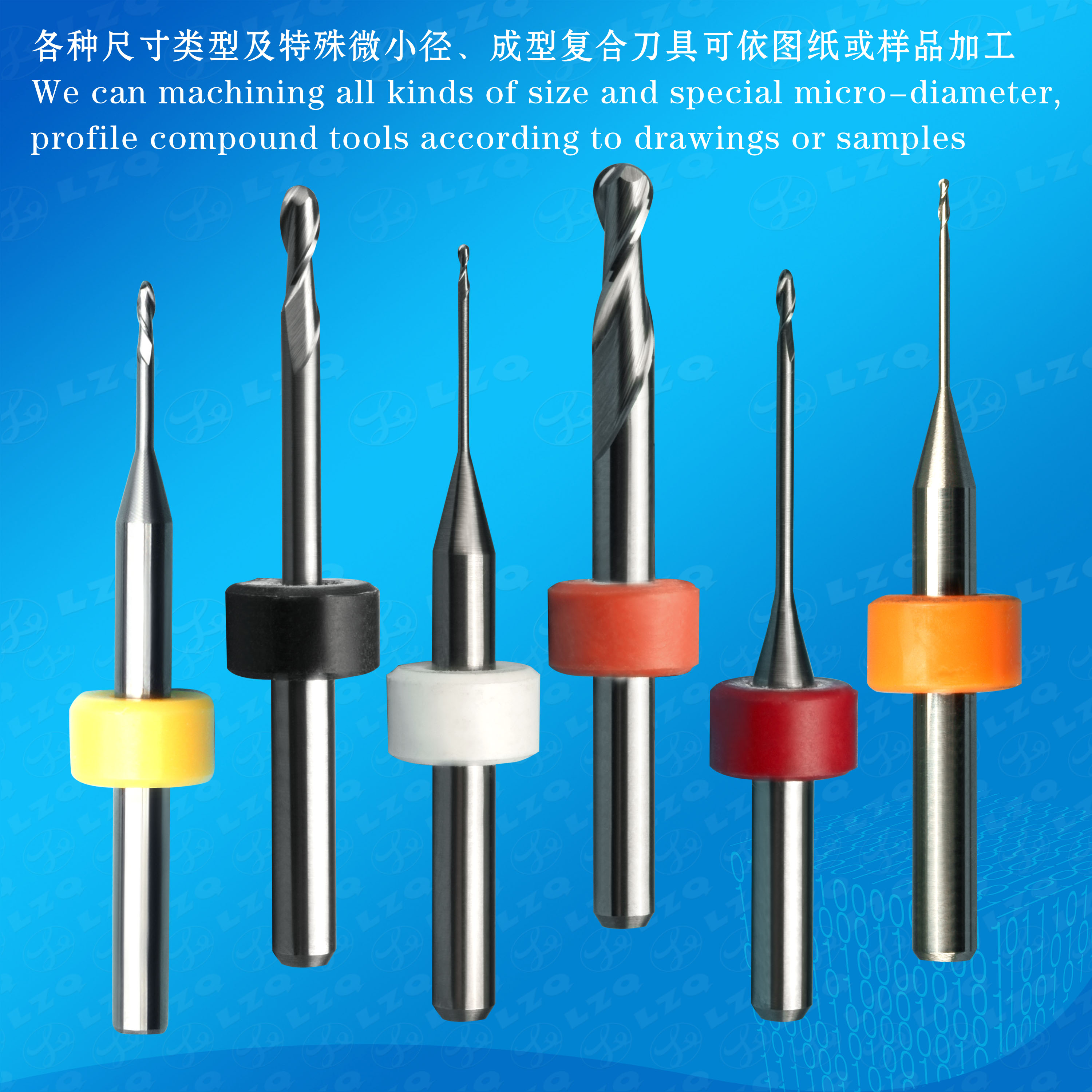

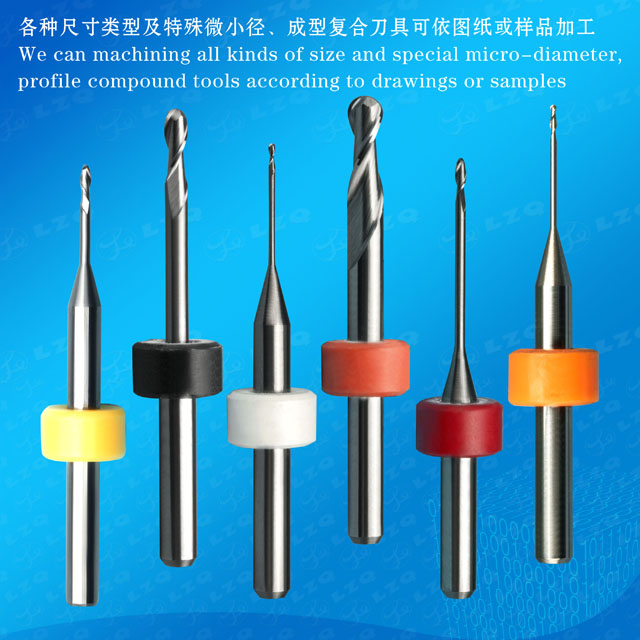

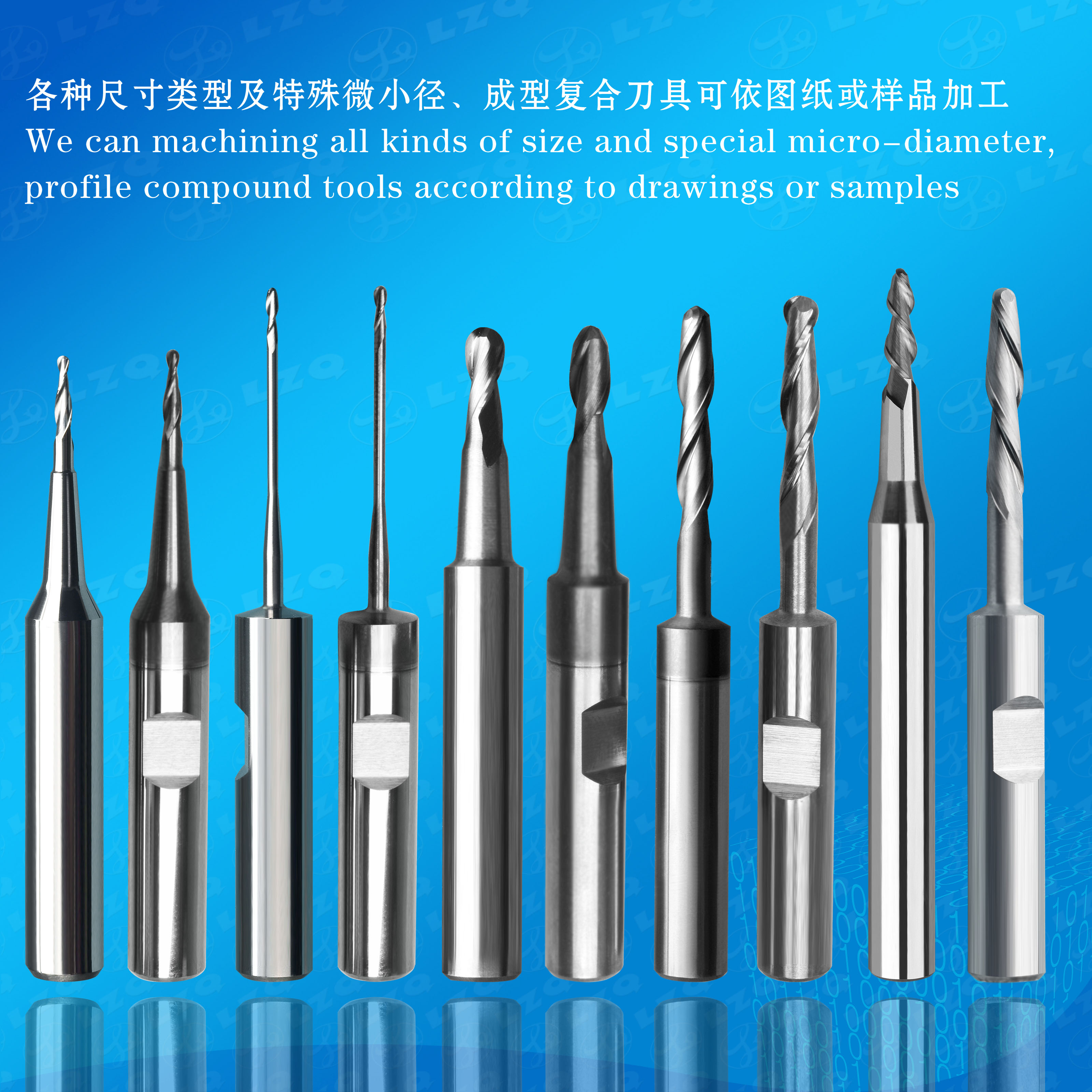

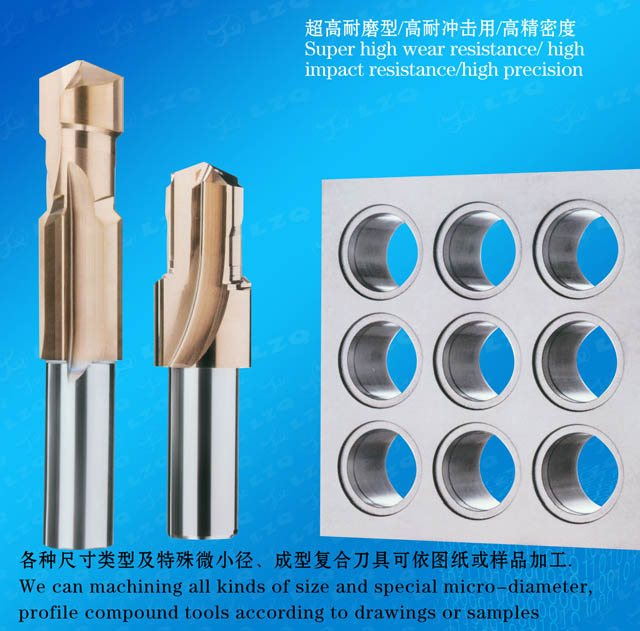

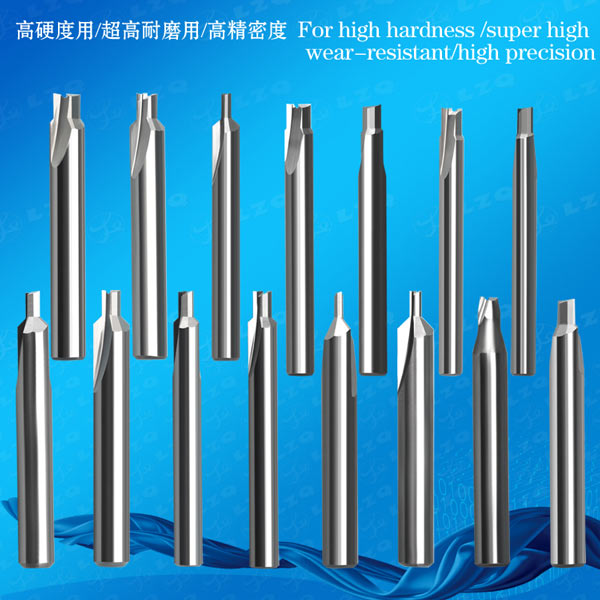

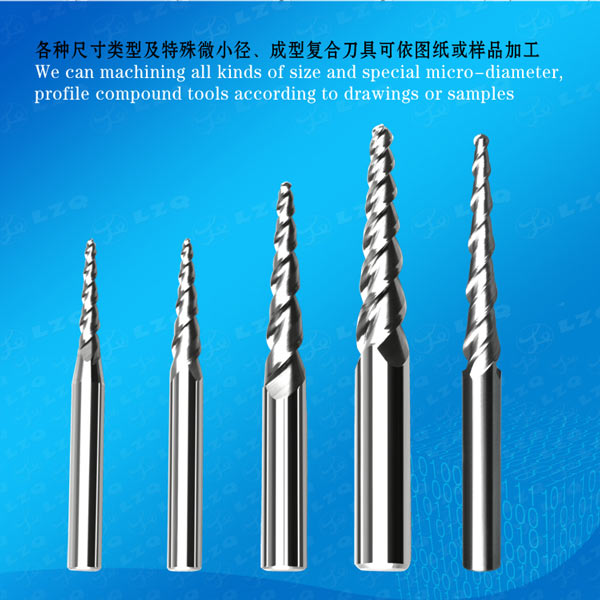

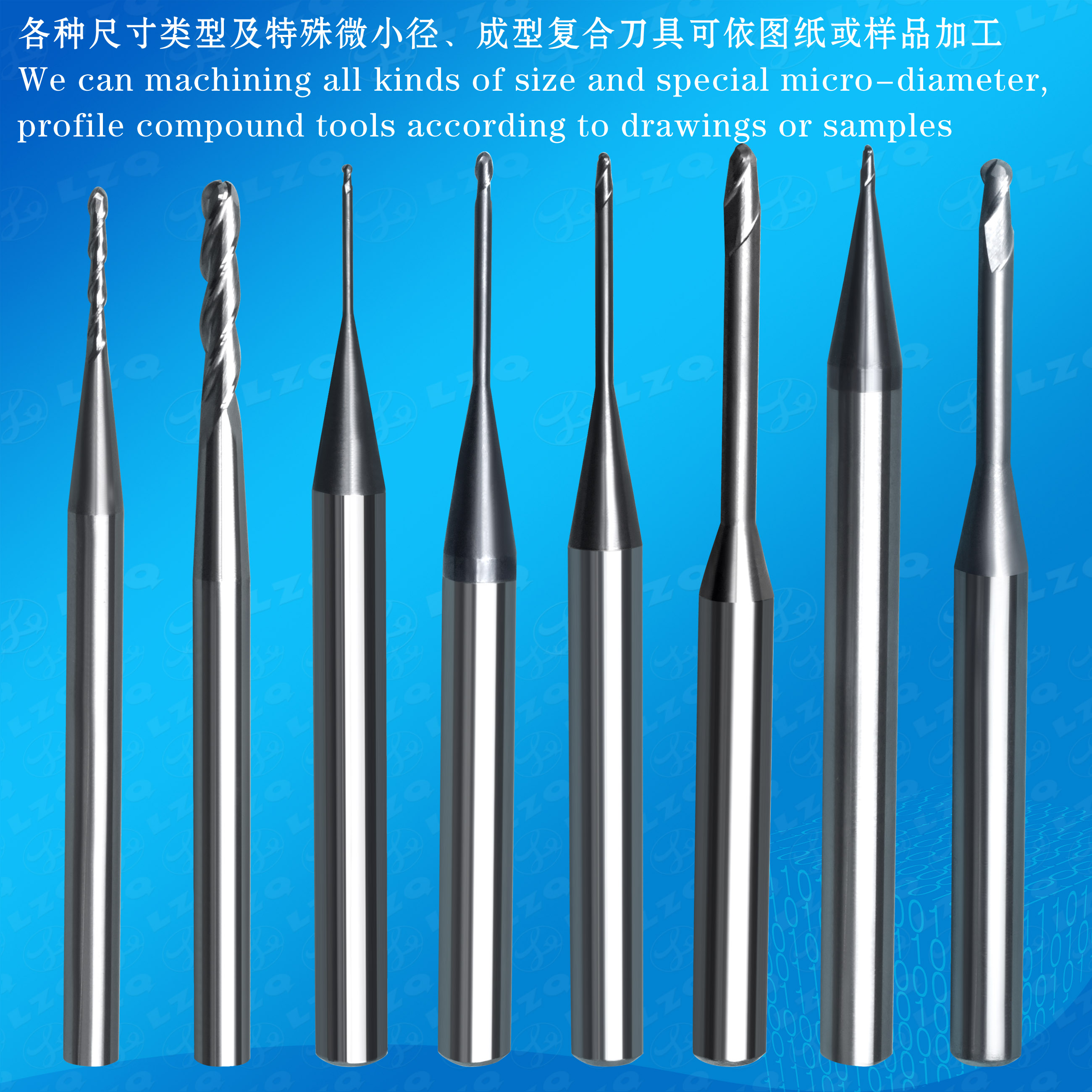

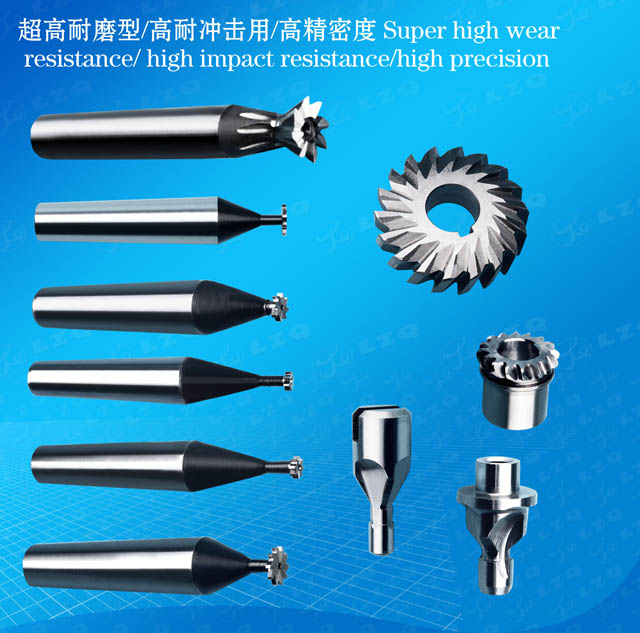

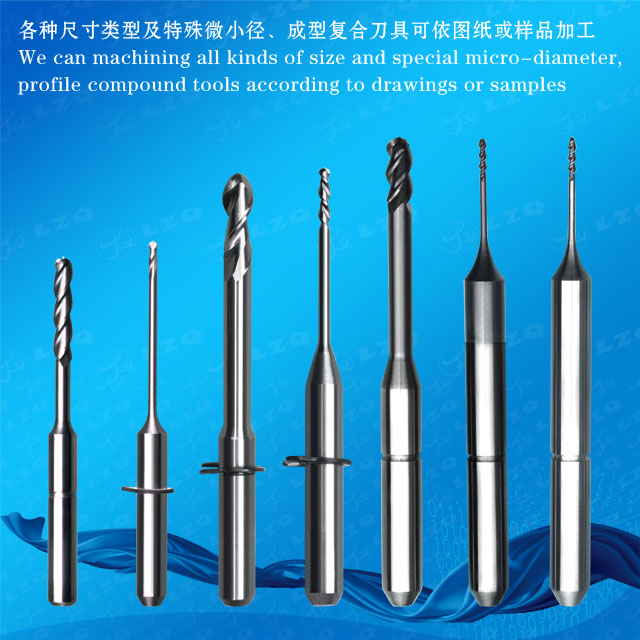

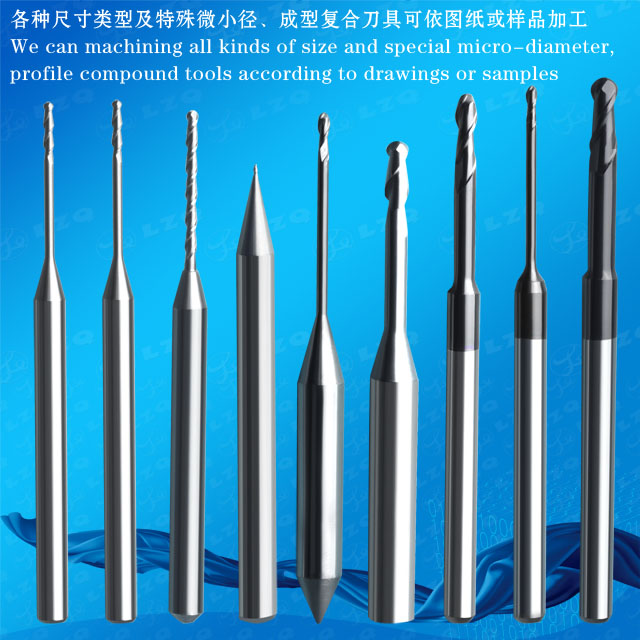

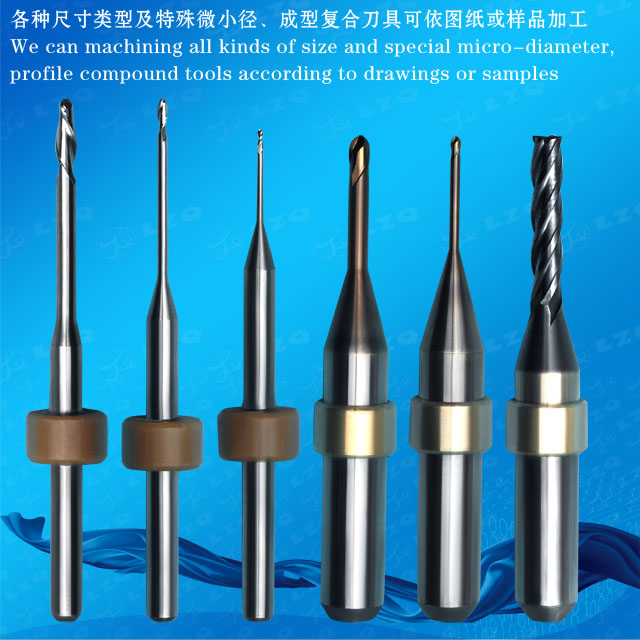

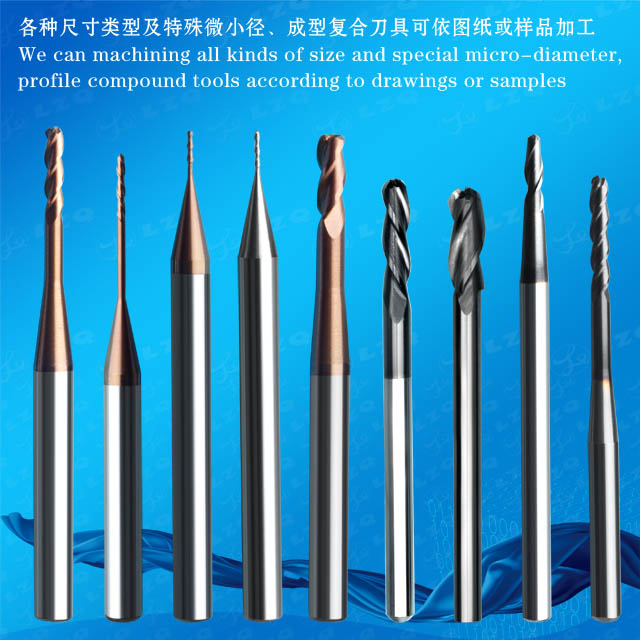

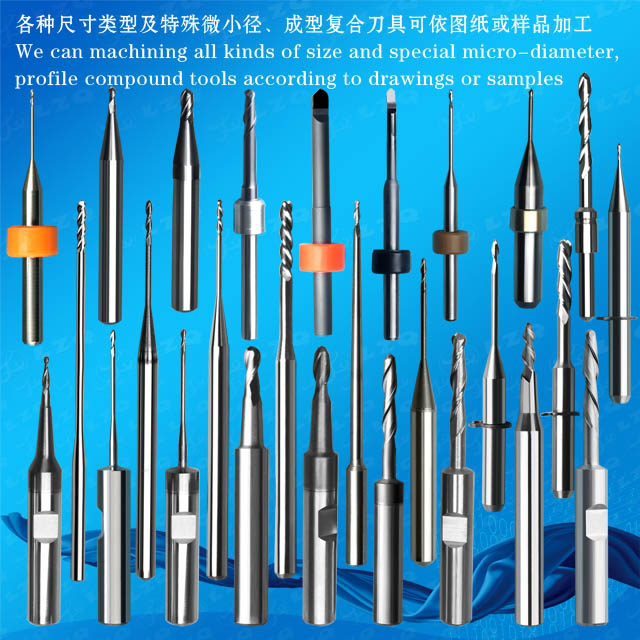

LZQ is an OEM factory for all kinds of Smart card Milling cutters, such as ABS Milling Tools, SIM card Milling Reamer, PVC Milling Cutter, RFID Card mills, telecom card Milling cutter, bank card Milling cutter and Plastic card Milling Tools, etc. We can also produce Smart card Milling cutter of any sizes just according to your requirement.

Referencing Referencing to the page footer, please provide your detailed drawing and samples (Samples should be with the best performance) and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency,when you make inquiry. What is the processed material and its HRC?

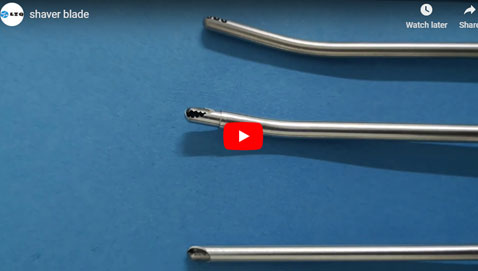

Workpiece drawing and notes, and please supply us new and old best-performed samples. And note clearly about samples: Is it easy to blunt or break or easy to break the edge? Or blunt after using some while( or how long tools will get blunt). LZQ is possessed of the cutting-edge & comprehensive production system, as well as rich producing & machining capability with different precision technology.

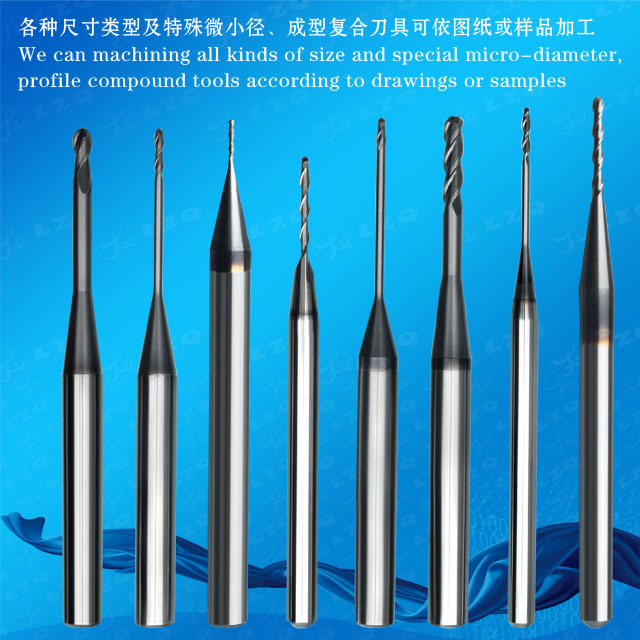

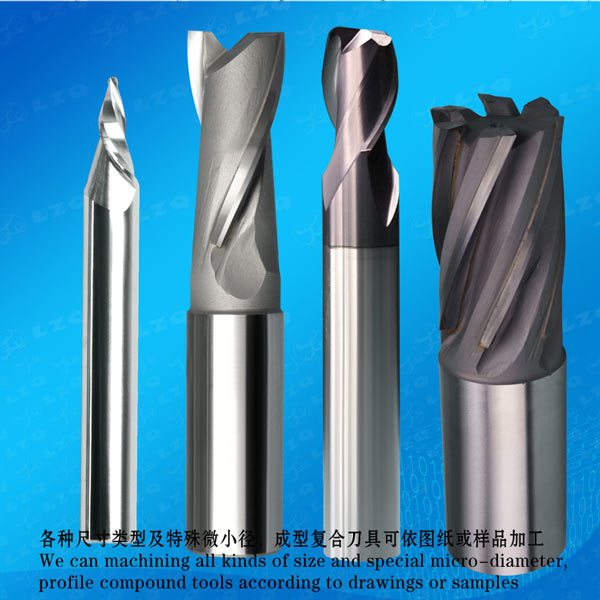

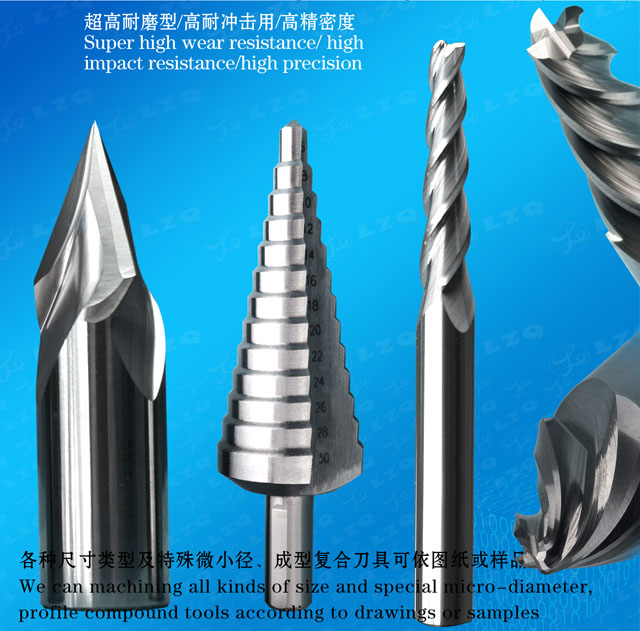

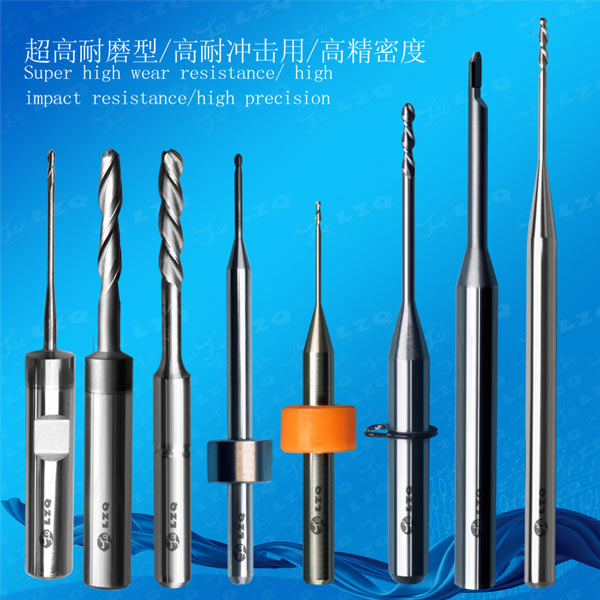

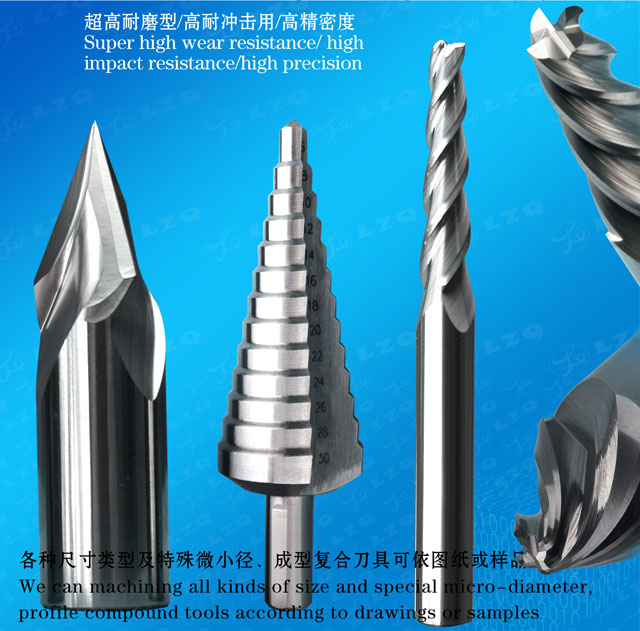

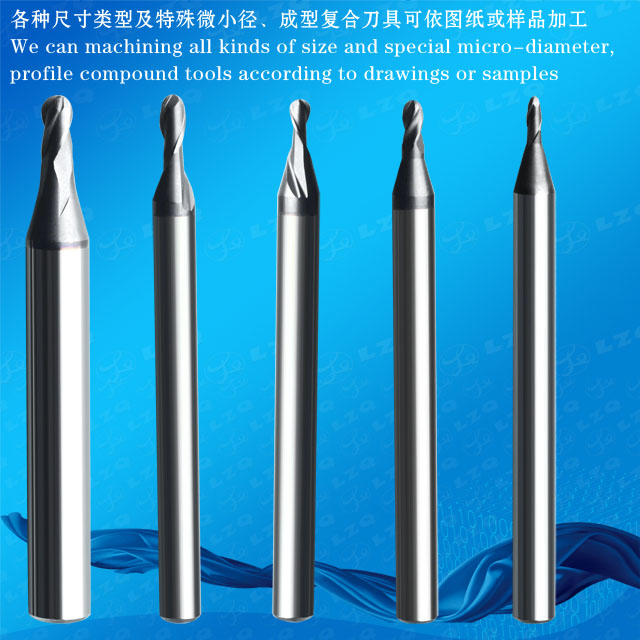

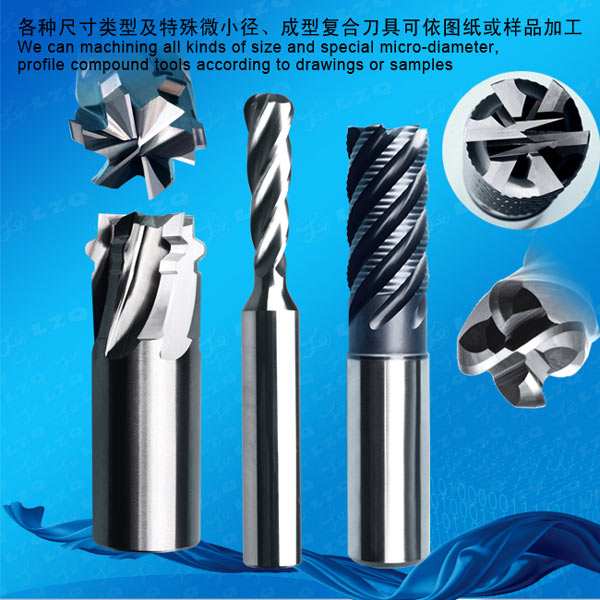

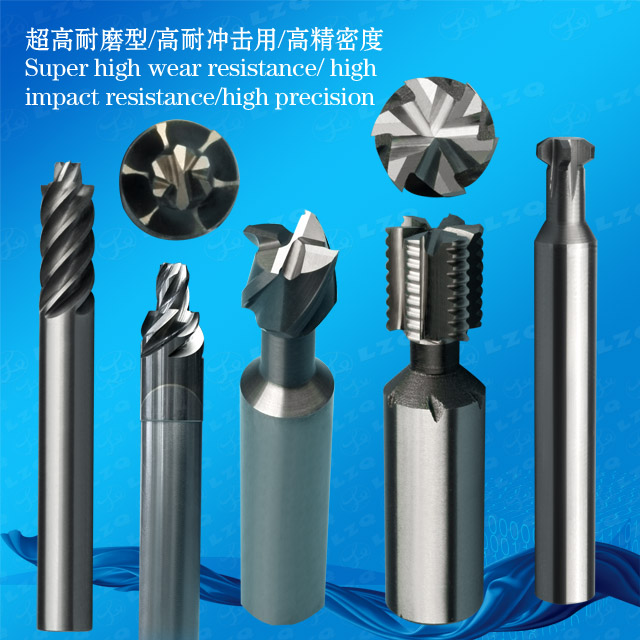

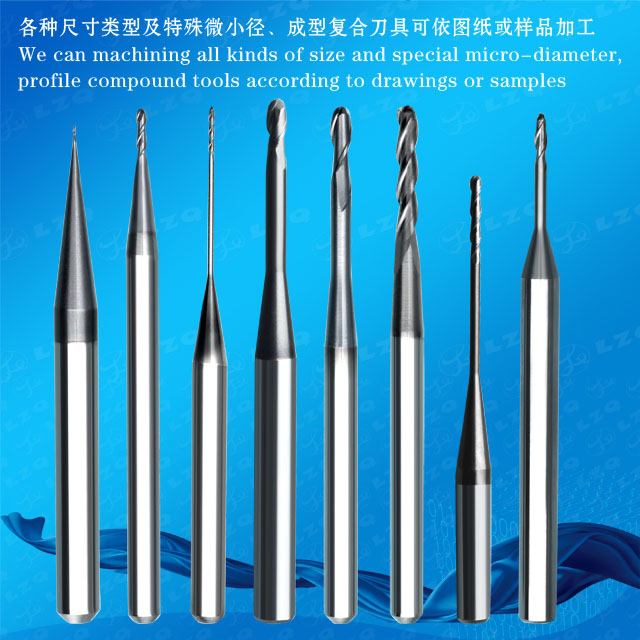

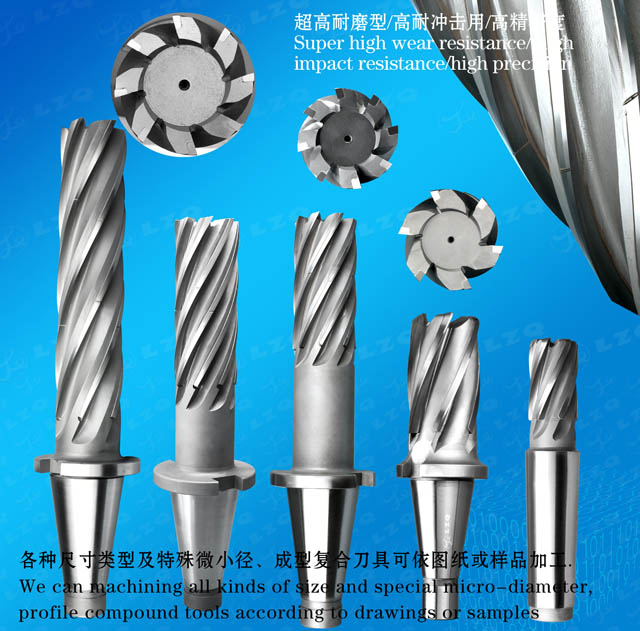

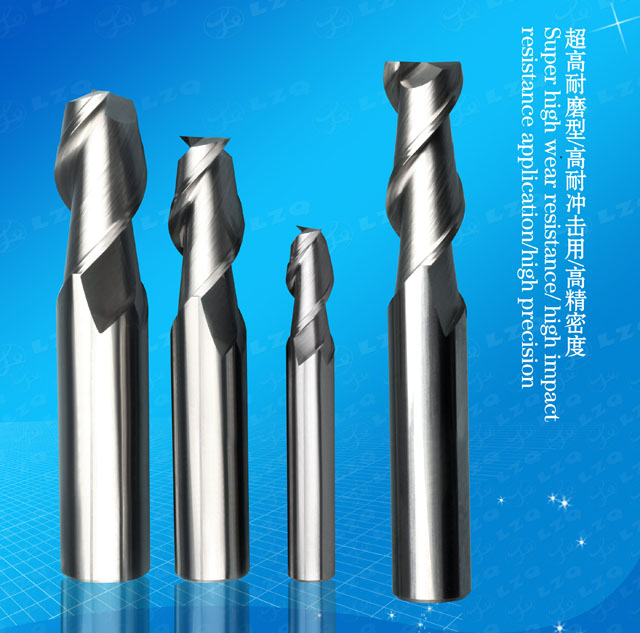

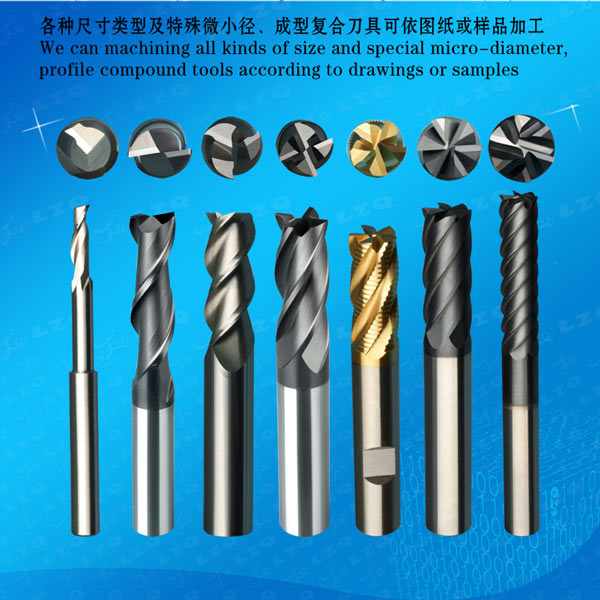

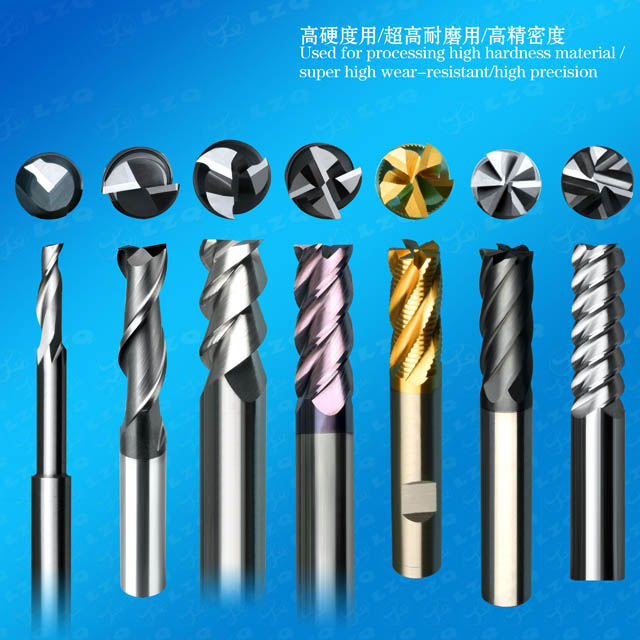

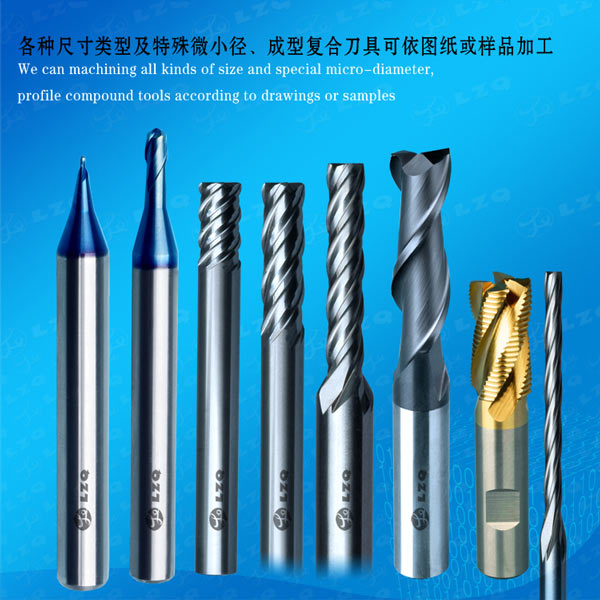

Flutes/teeth: The flutes of the milling bit are the deep helical grooves jogging up the cutter, while the sharp blade alongside the area of the flute is regarded as the tooth. The tooth cuts the material, and chips of this fabric are pulled up the flute through the rotation of the cutter. There is nearly always one tooth per flute, however, some cutters have two teeth per flute. Often, the phrases flute and tooth are used interchangeably. Milling cutters can also have from one to many teeth, with 2, three and four being most common. Typically, the extra tooth a cutter has, the greater swiftly it can put off material. So, a 4-tooth cutter can take away cloth at twice the rate of a 2-tooth cutter.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

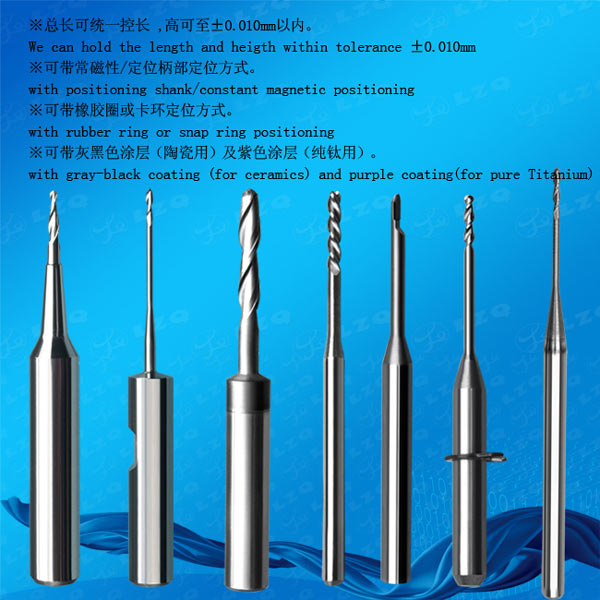

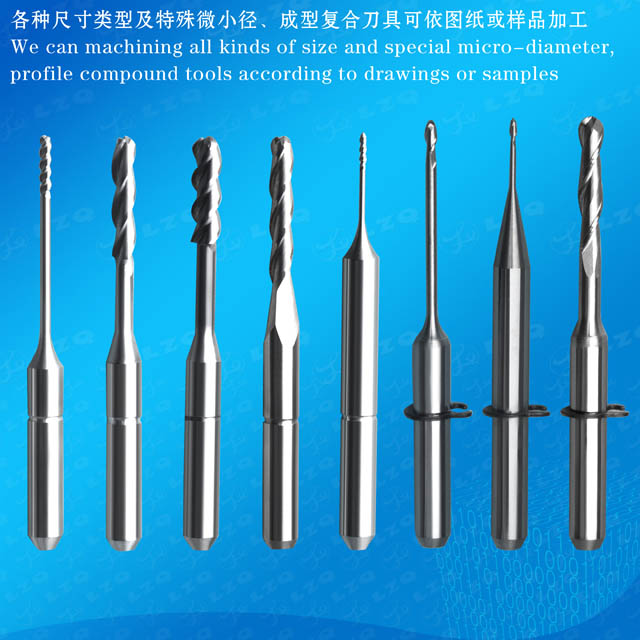

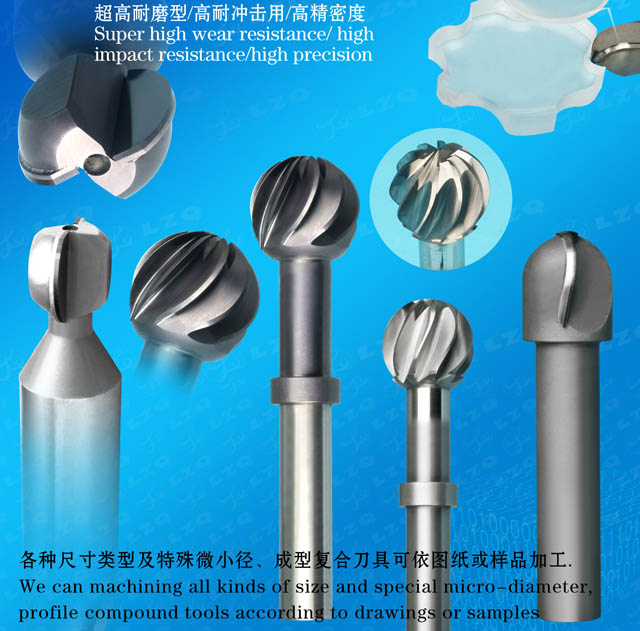

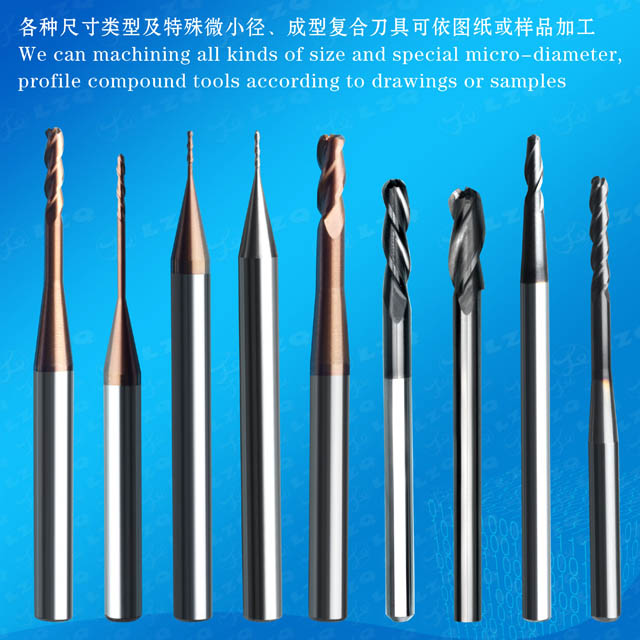

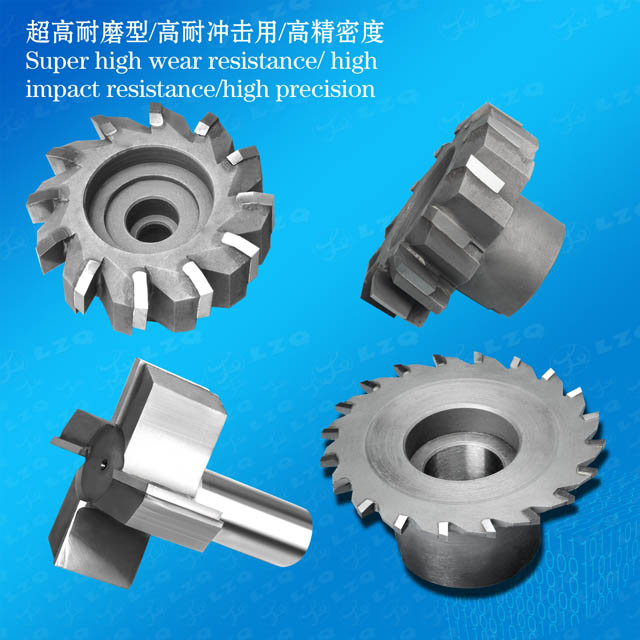

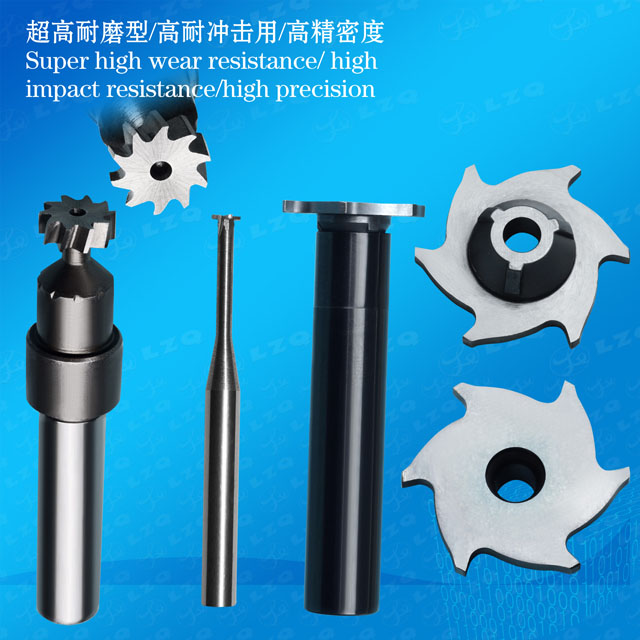

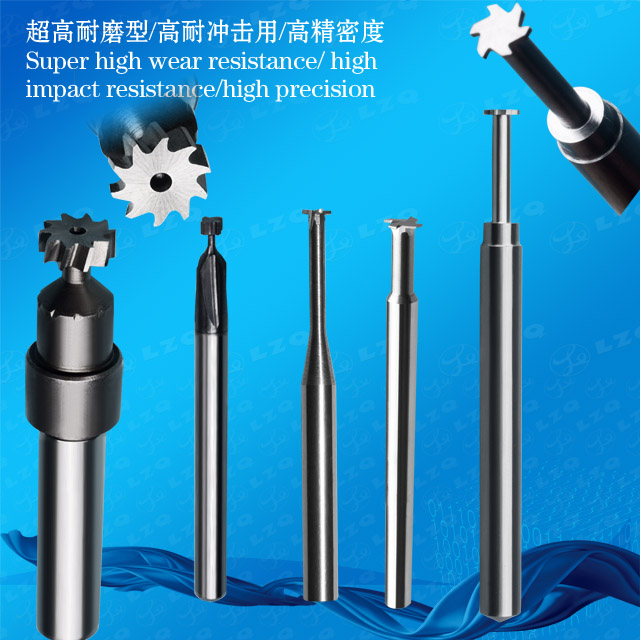

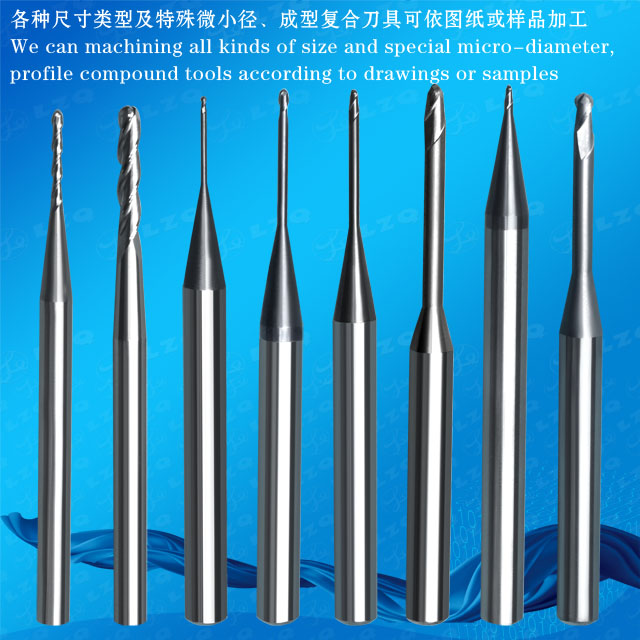

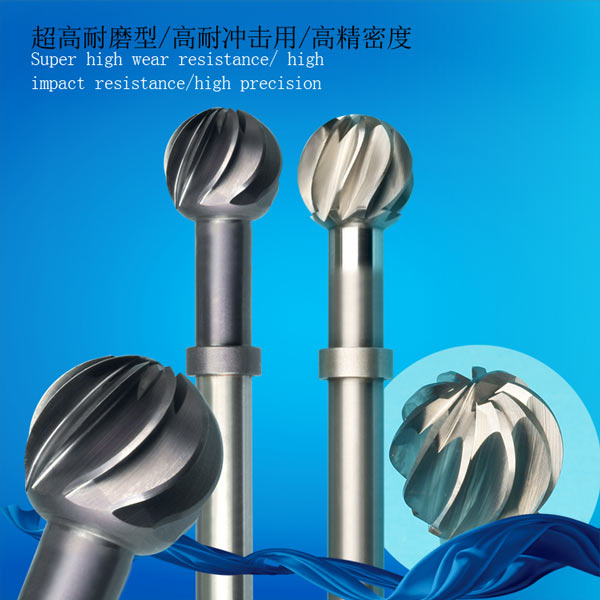

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

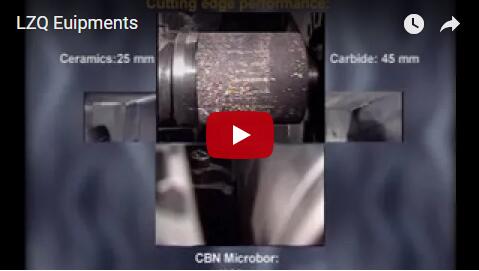

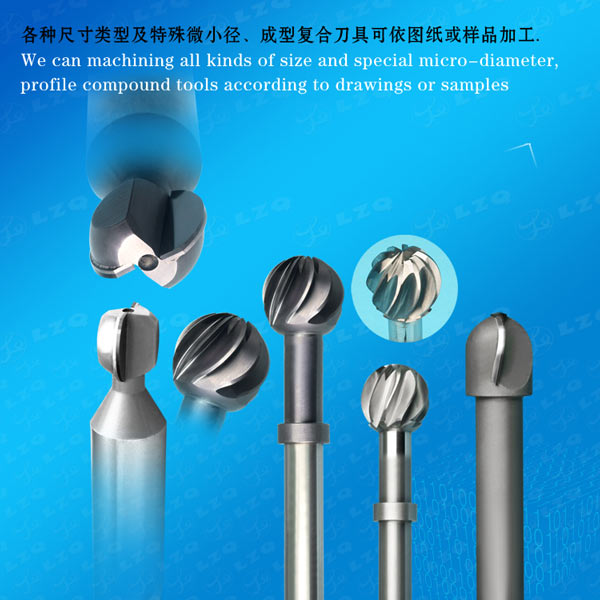

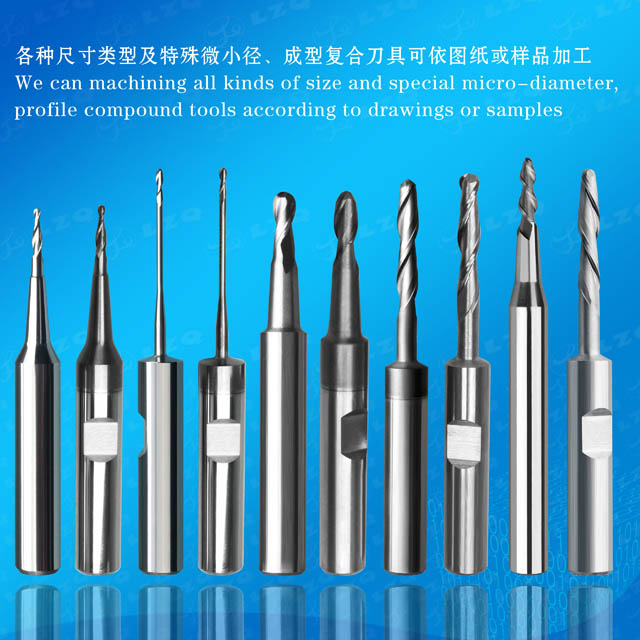

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

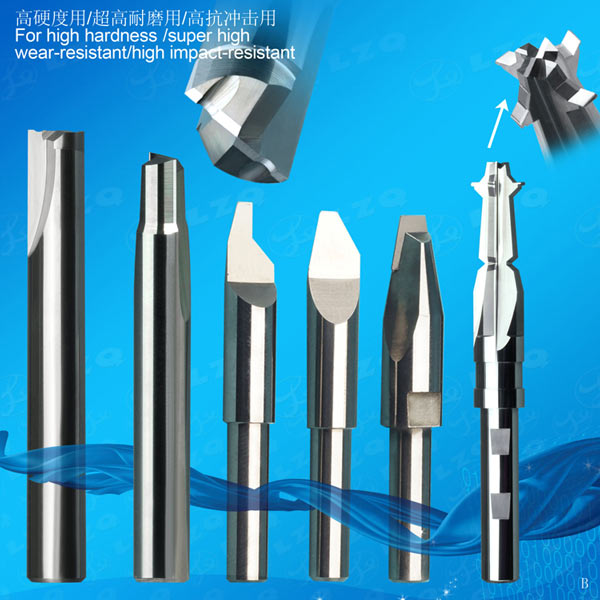

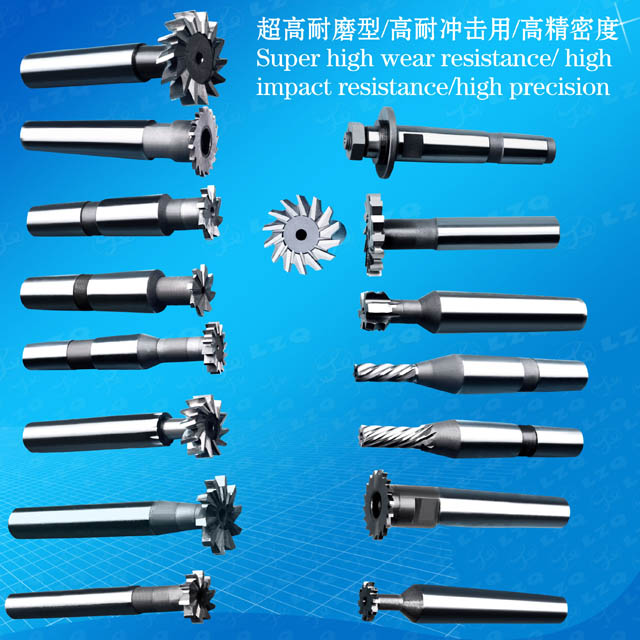

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

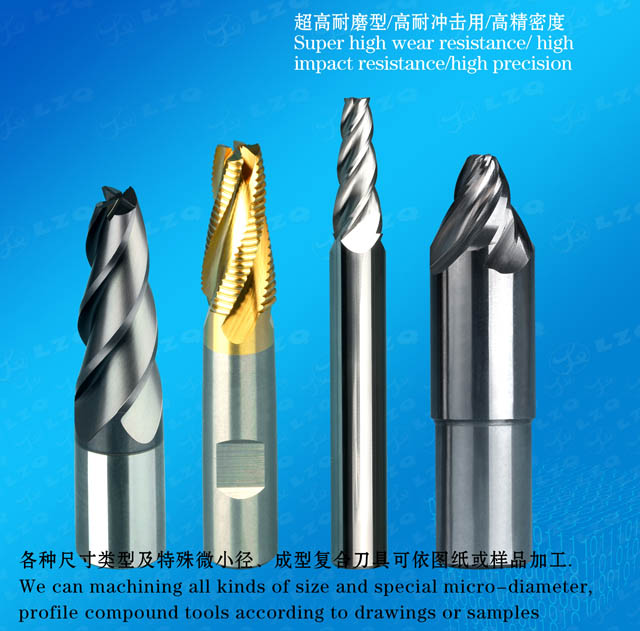

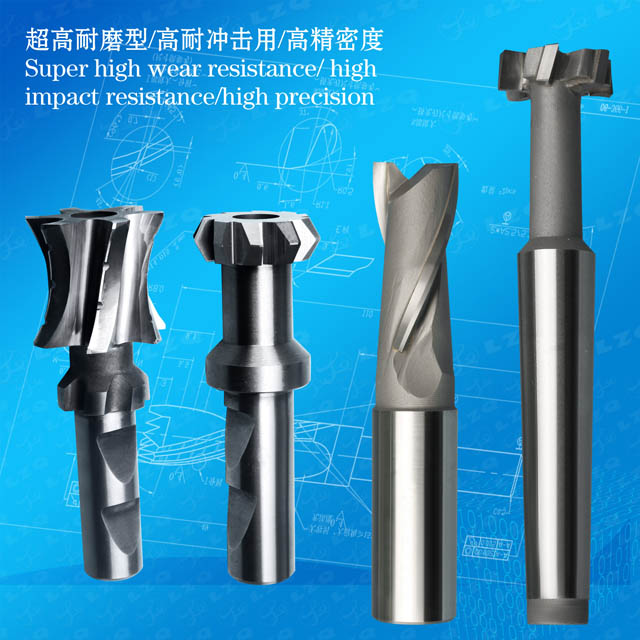

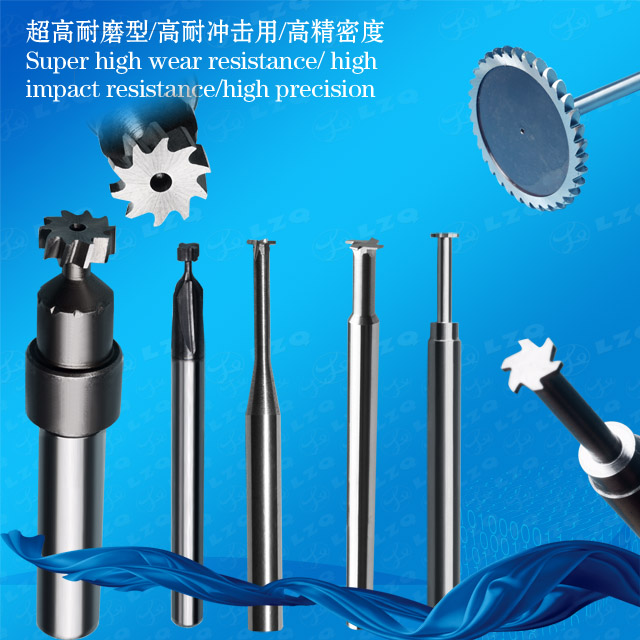

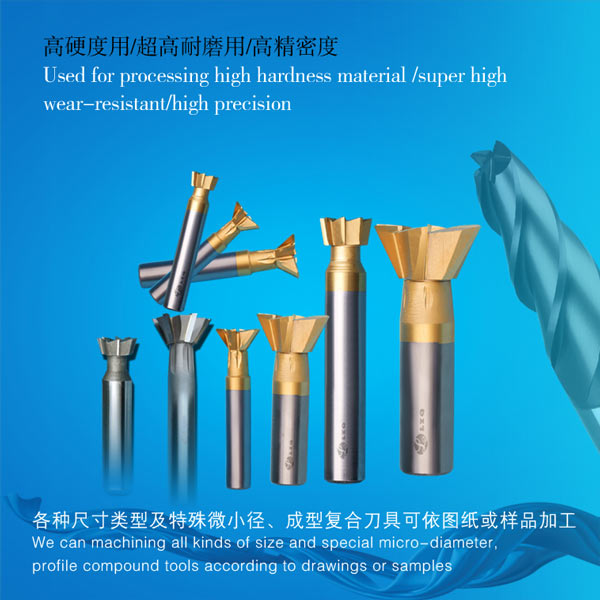

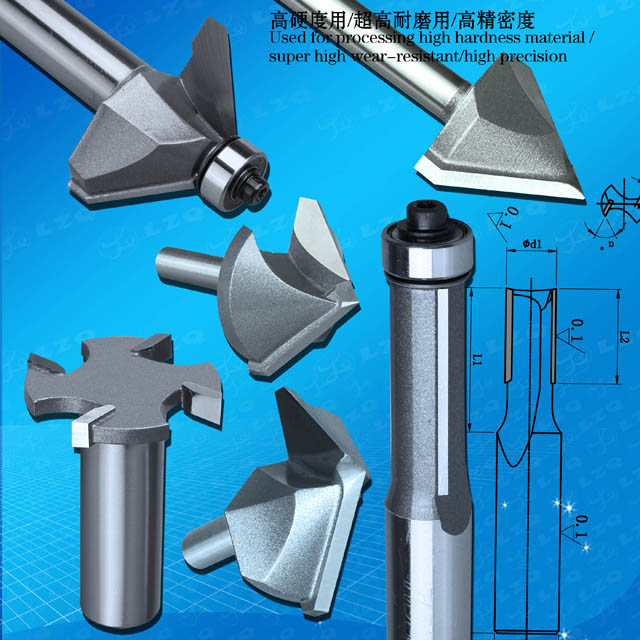

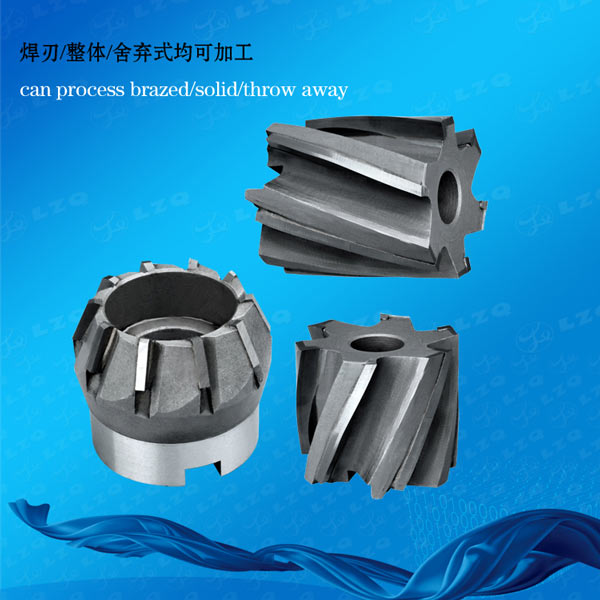

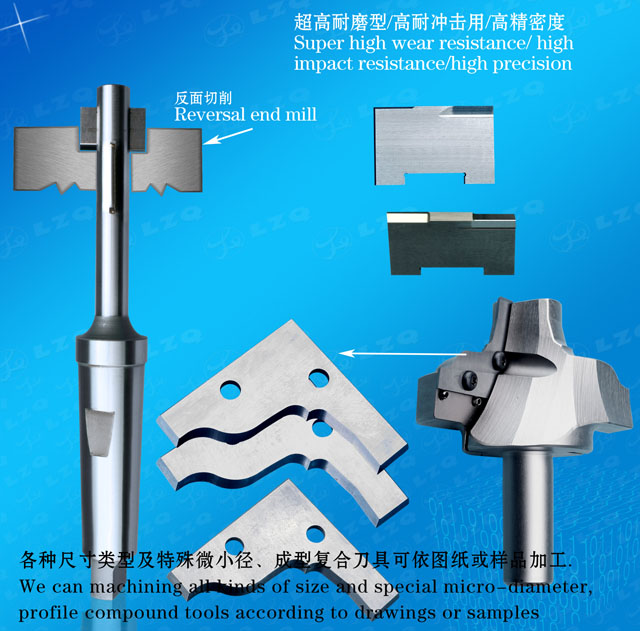

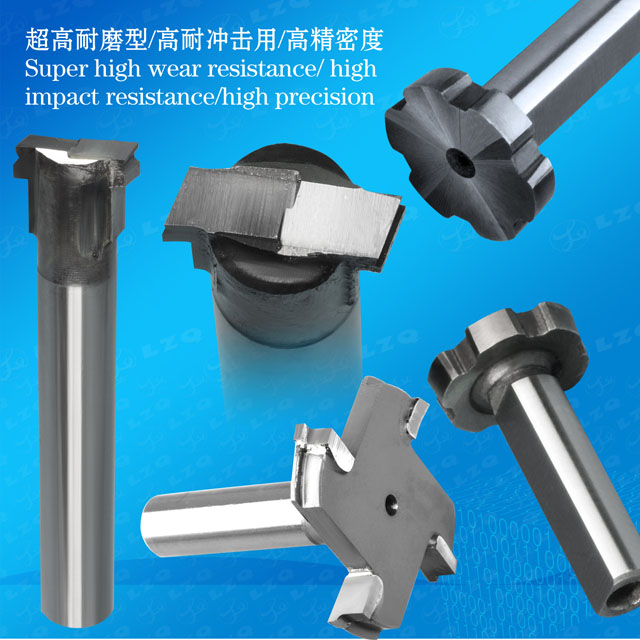

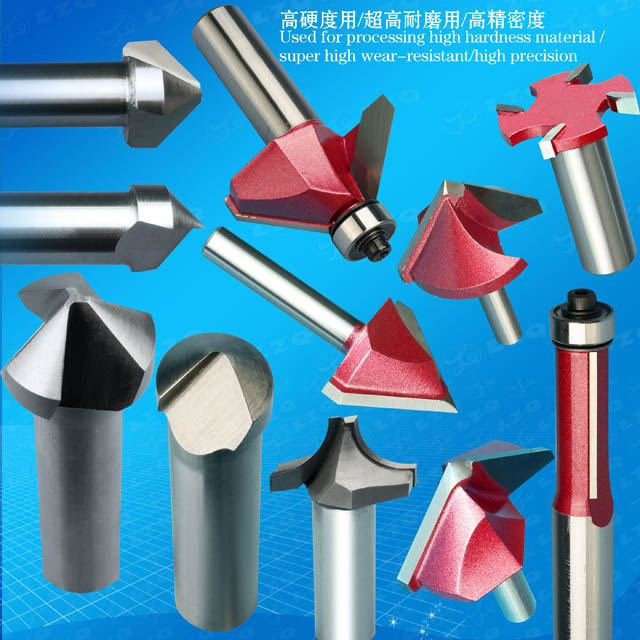

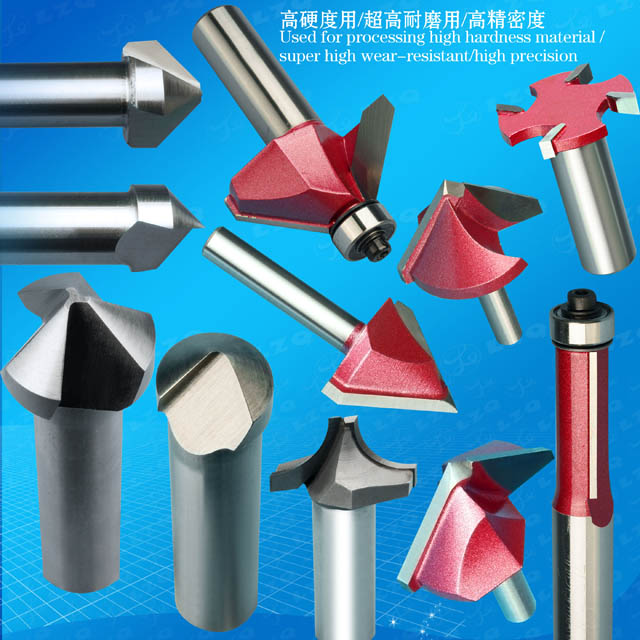

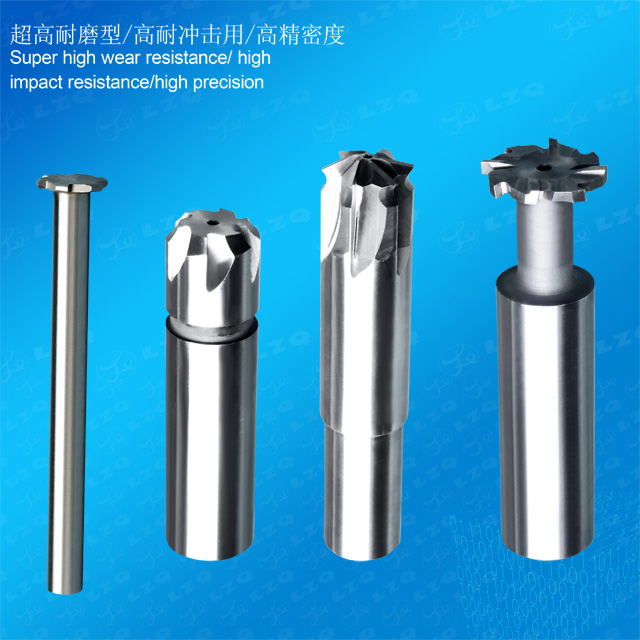

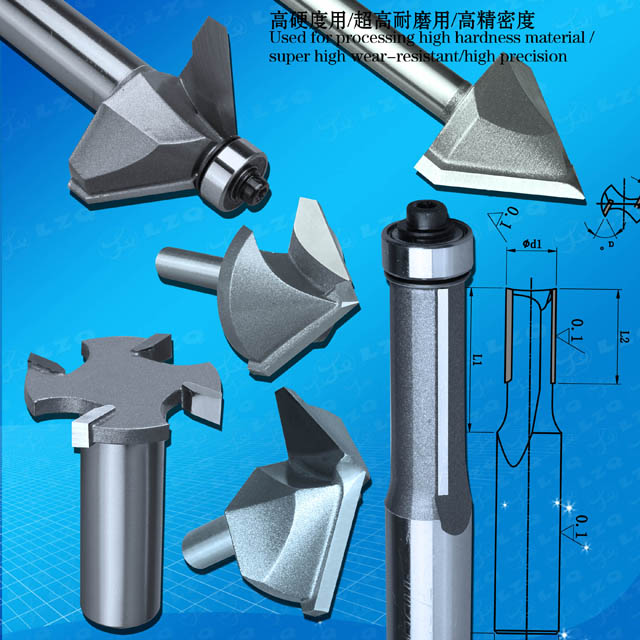

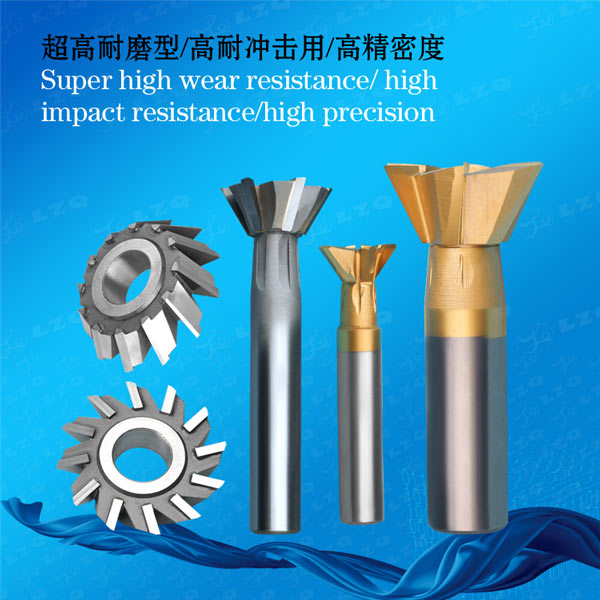

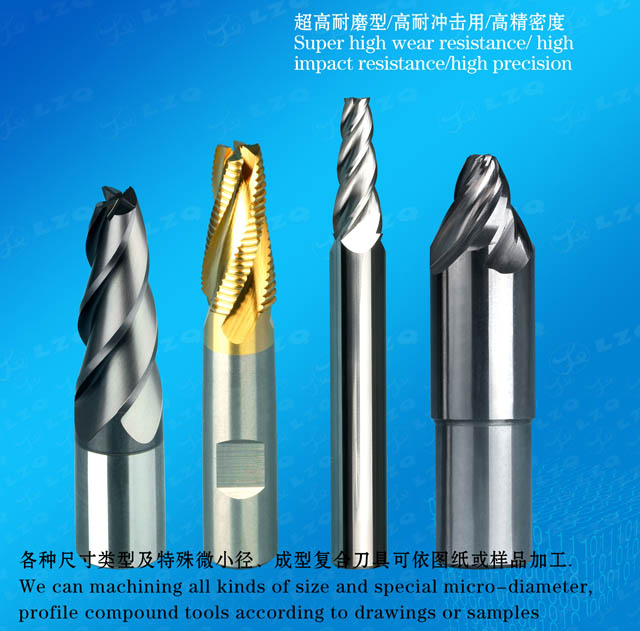

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

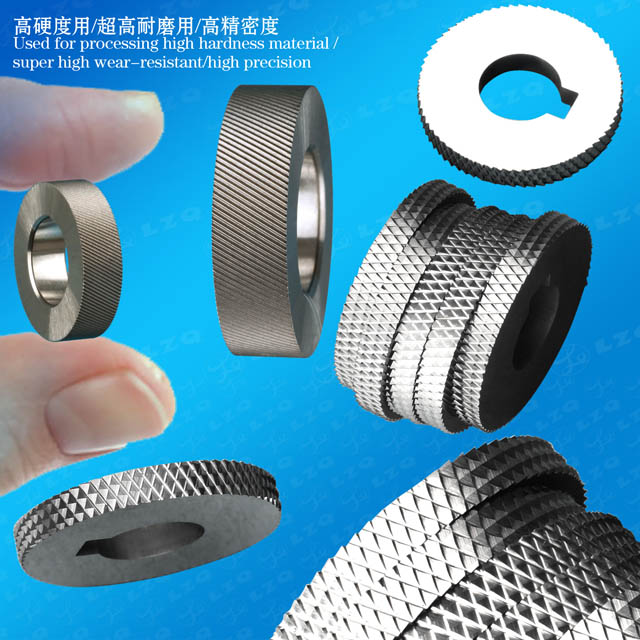

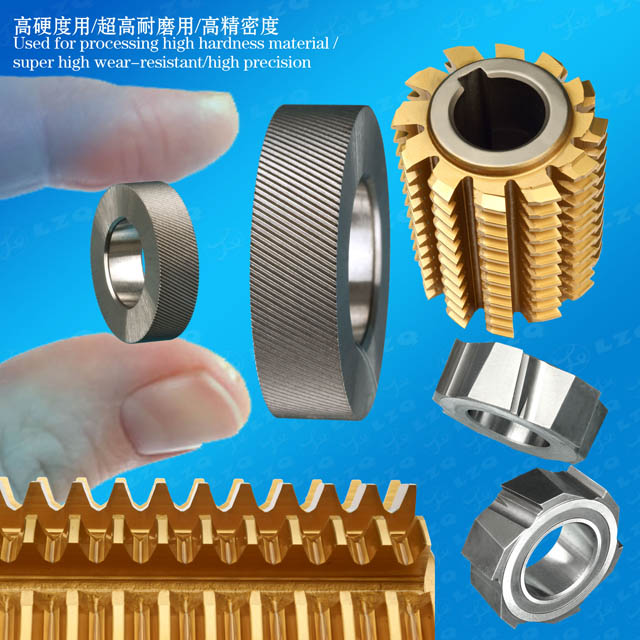

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.