Description

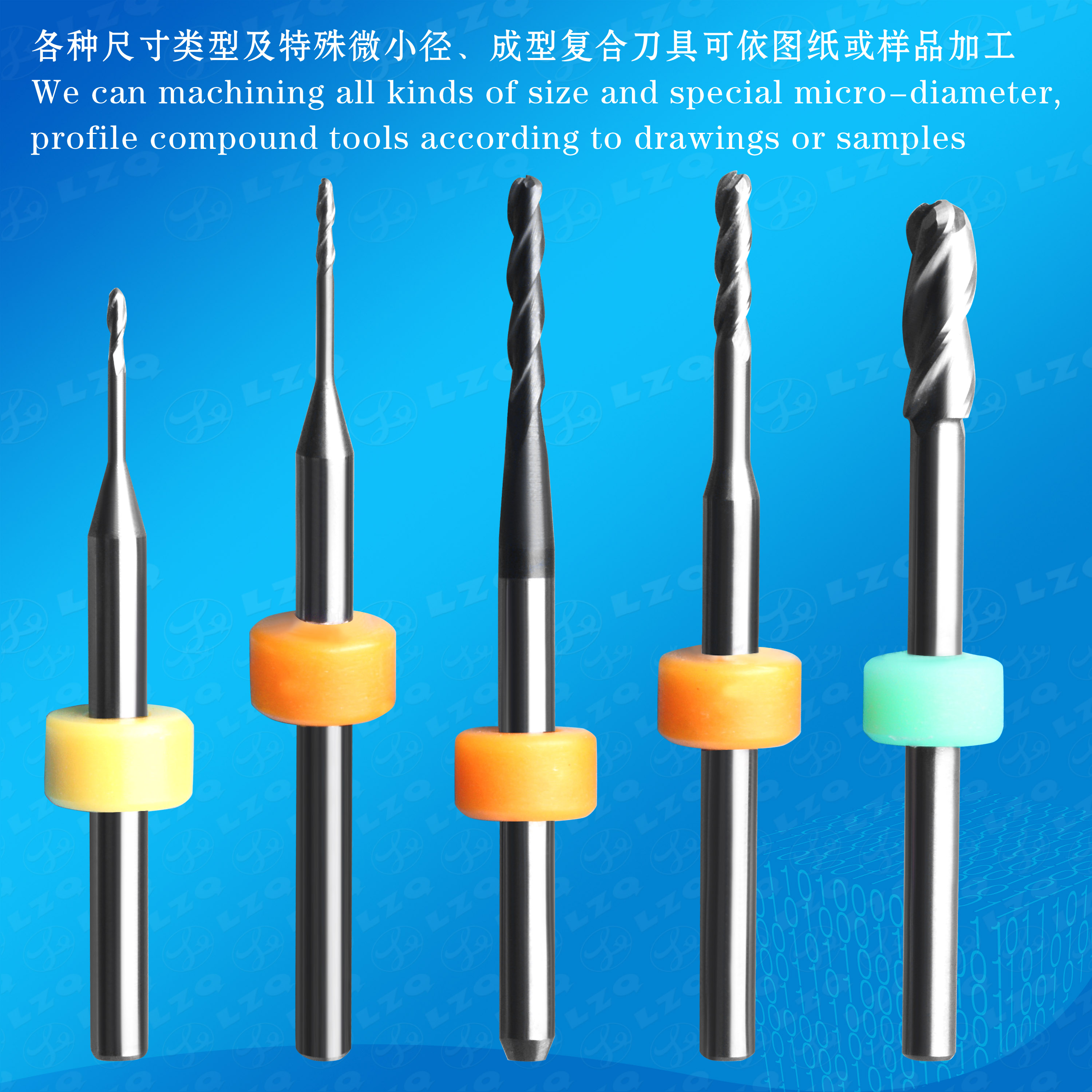

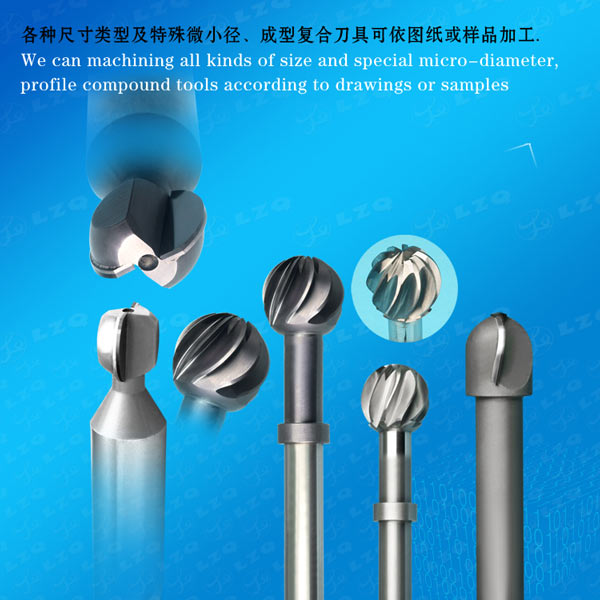

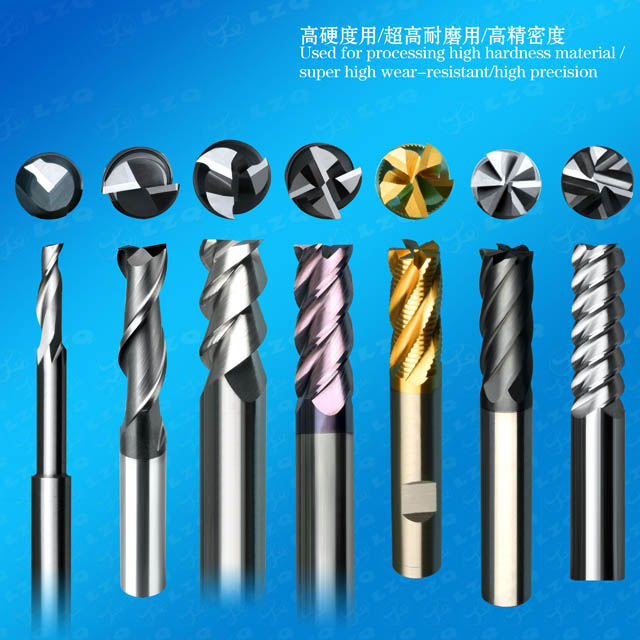

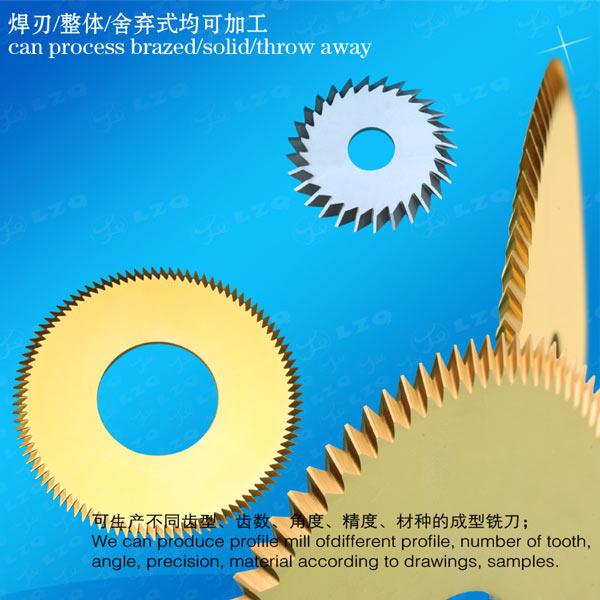

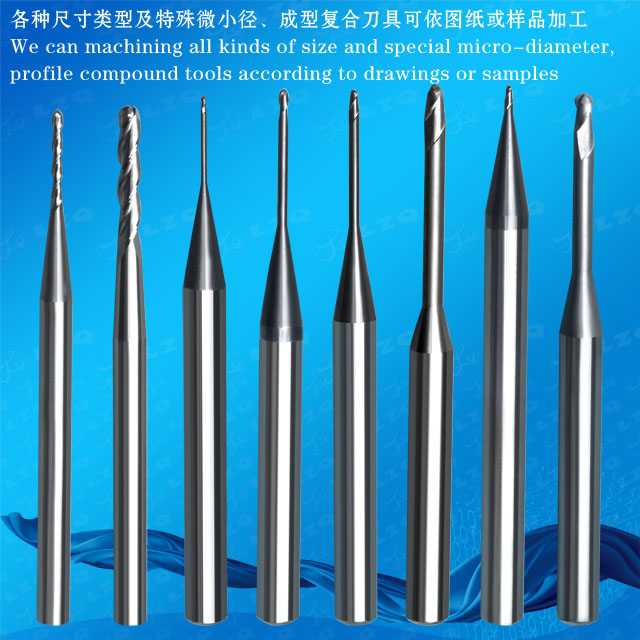

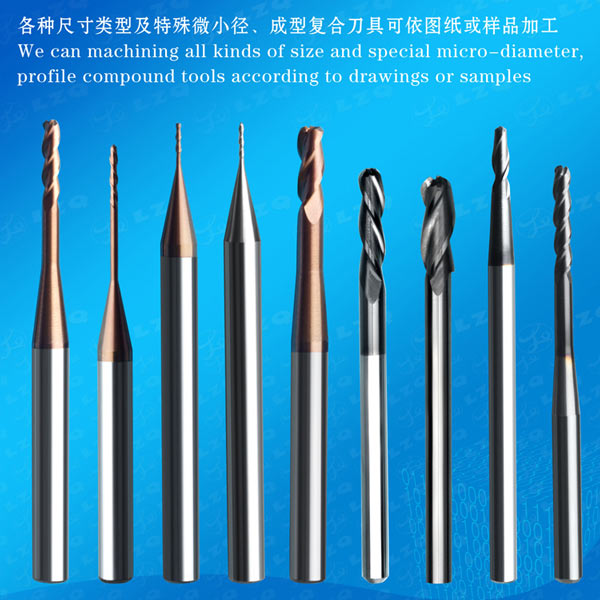

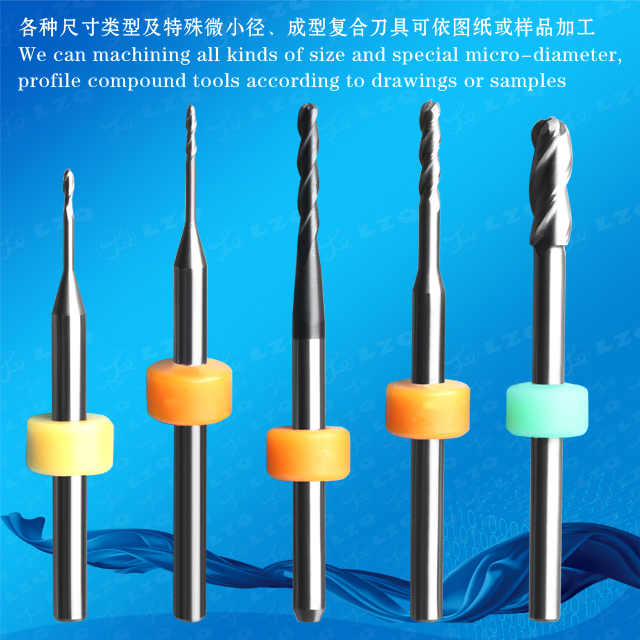

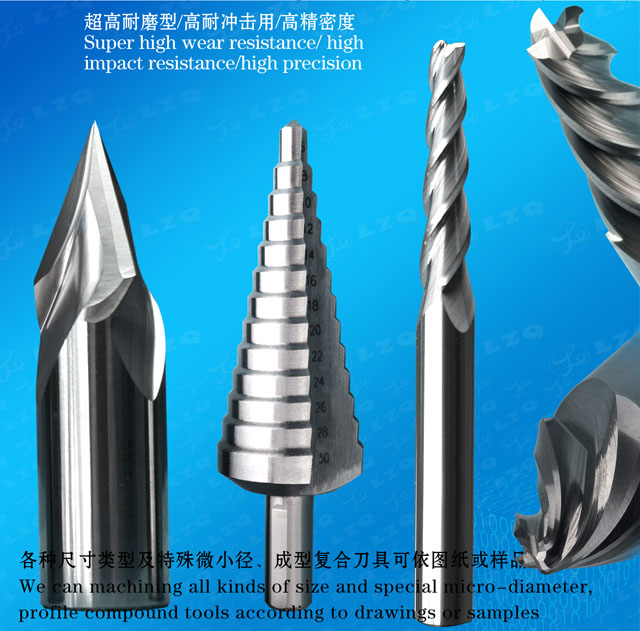

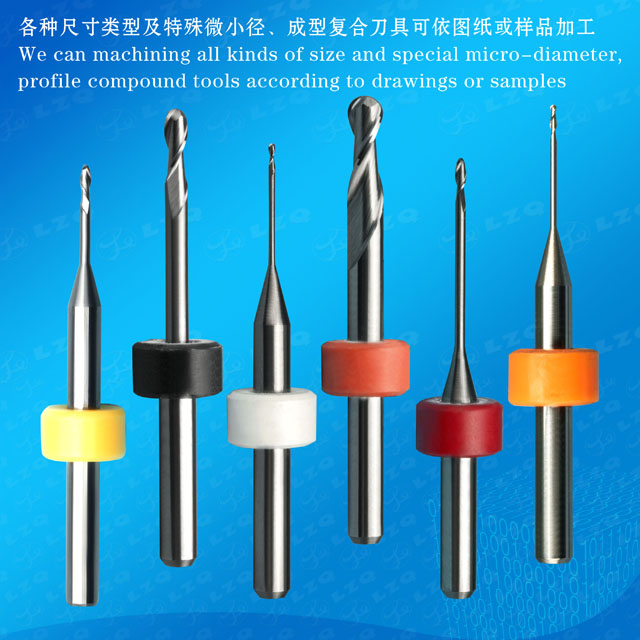

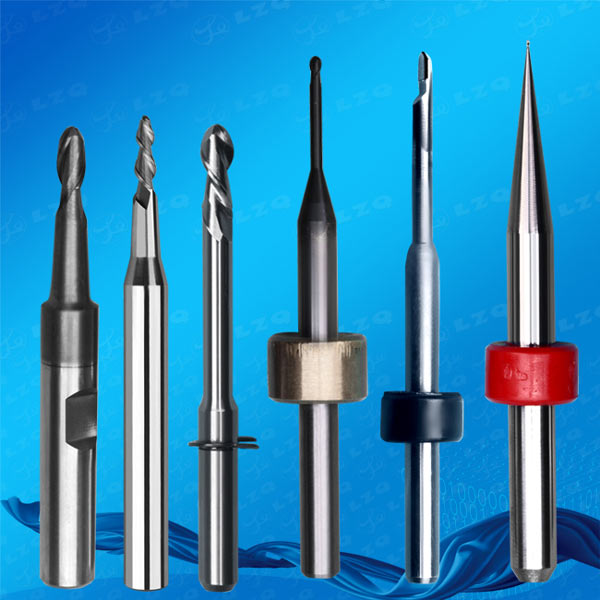

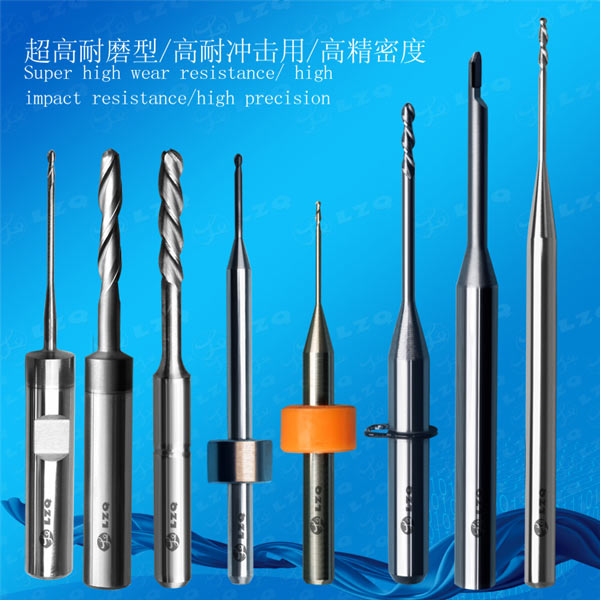

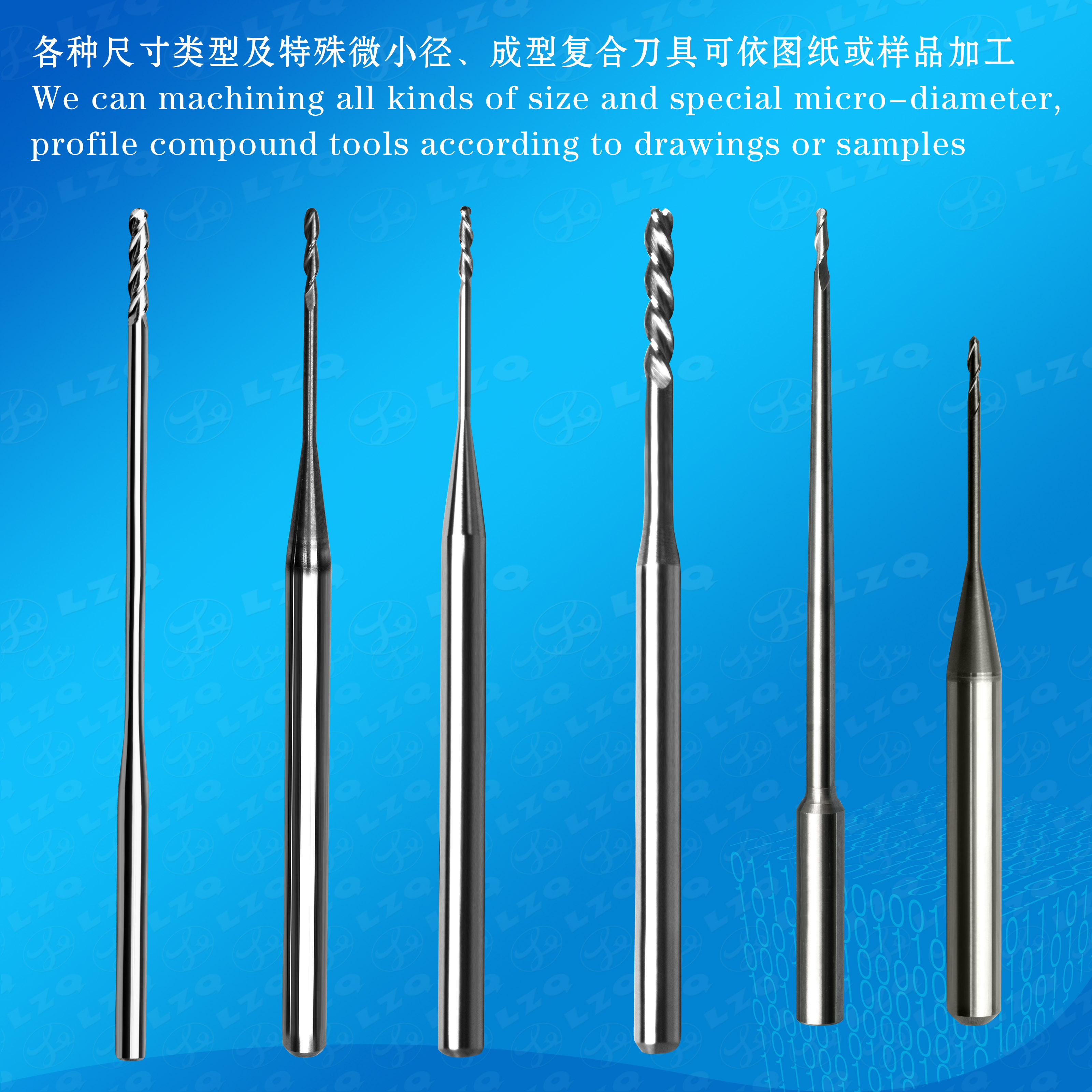

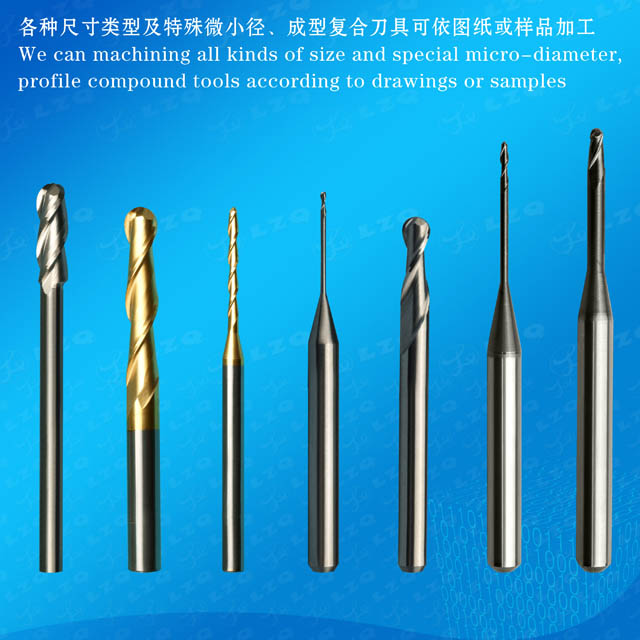

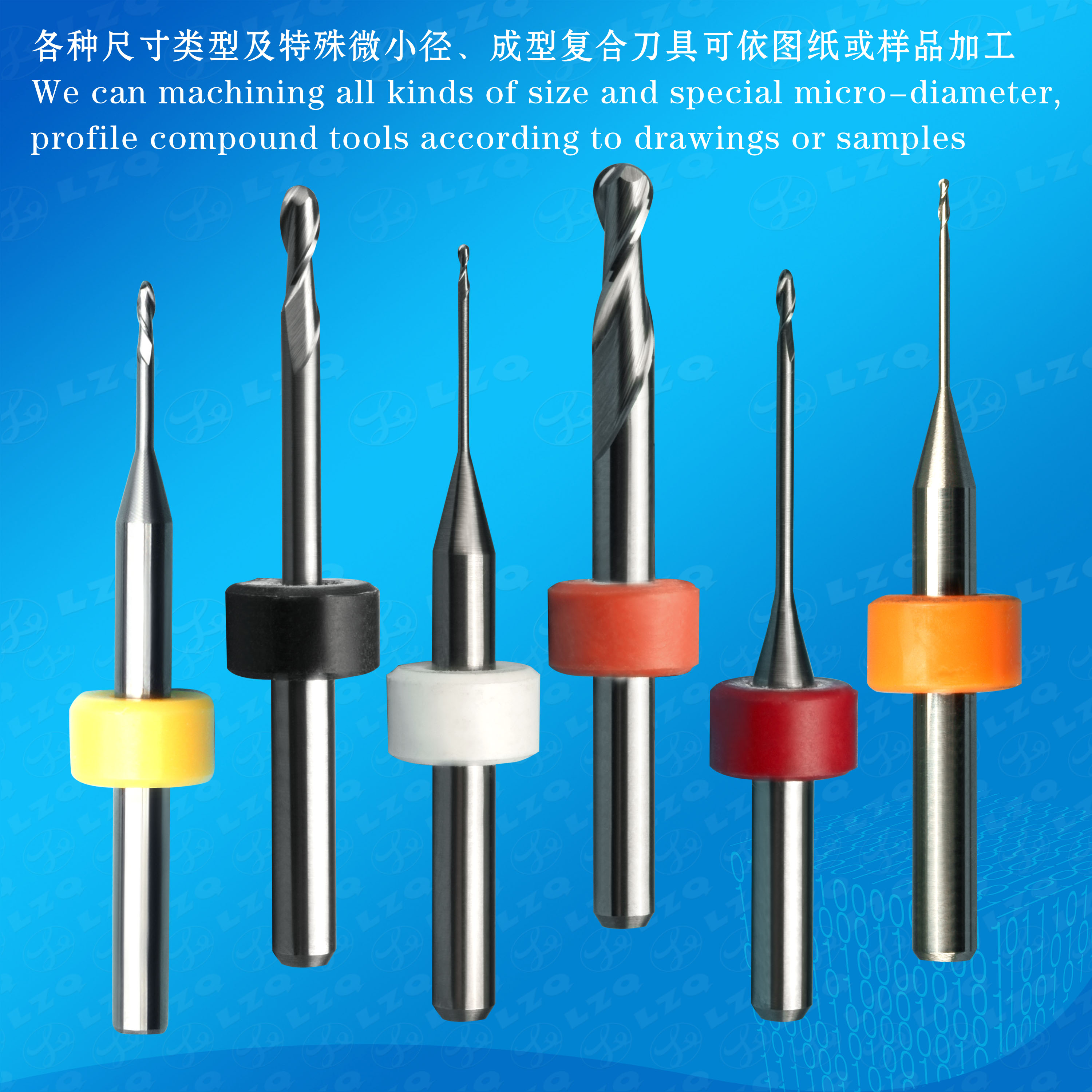

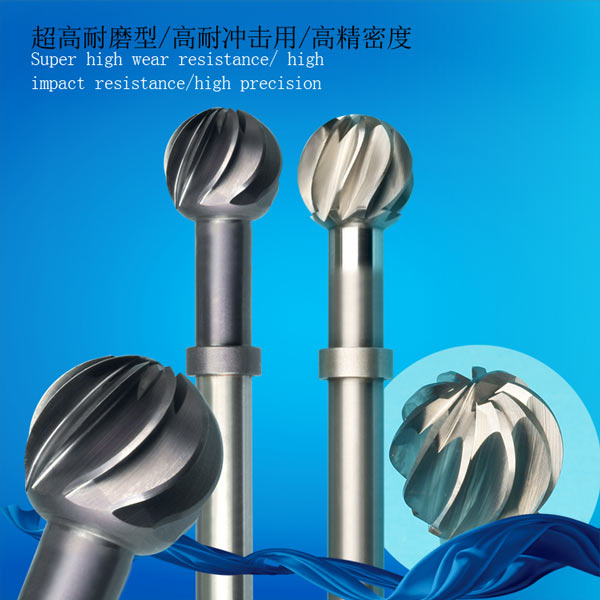

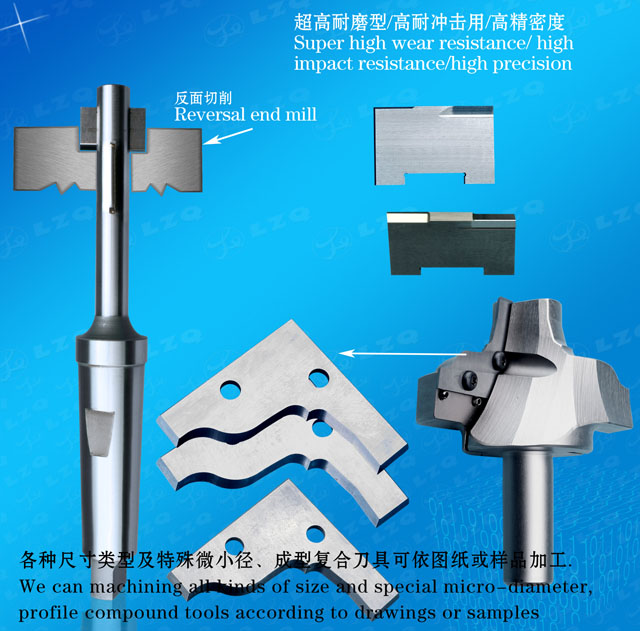

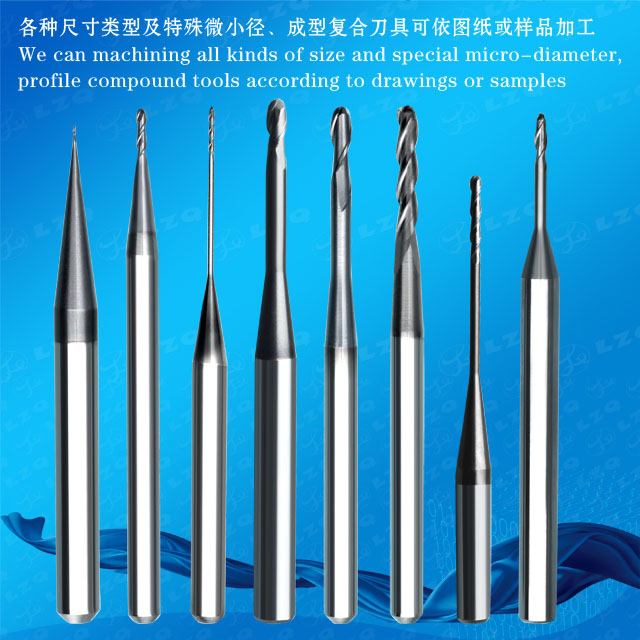

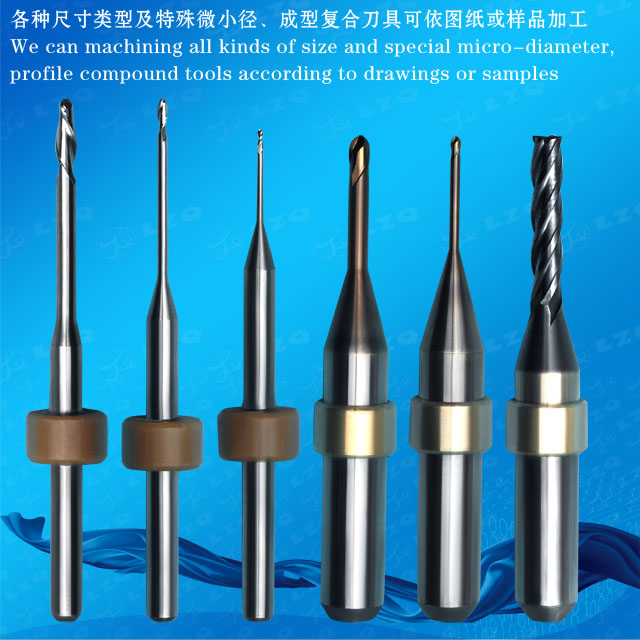

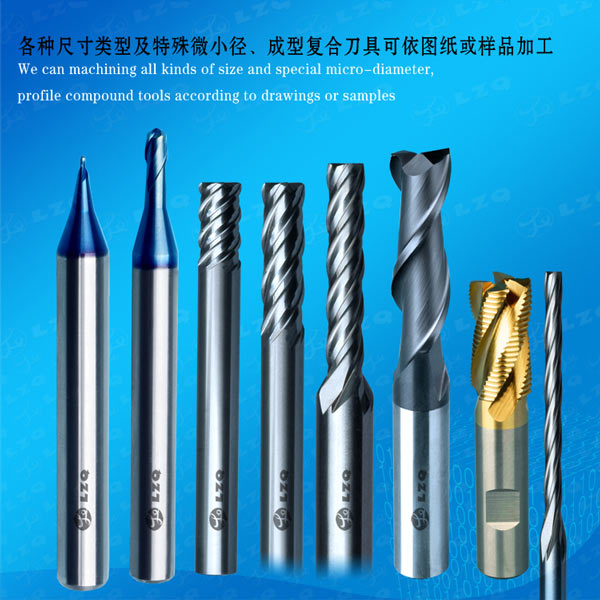

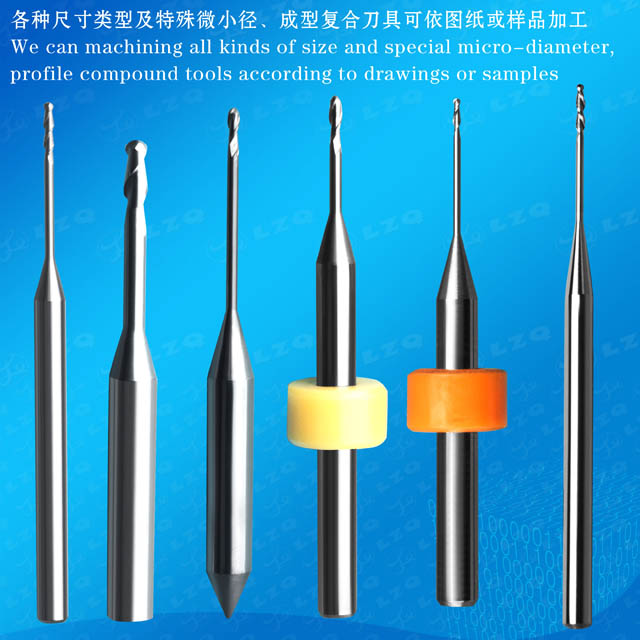

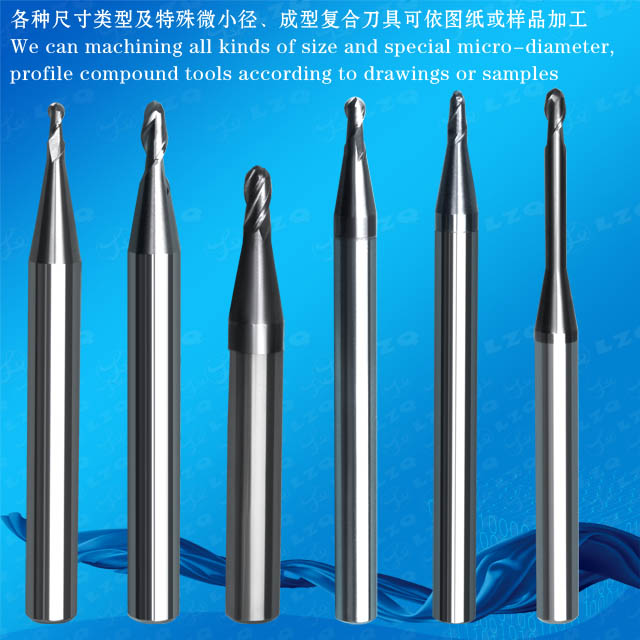

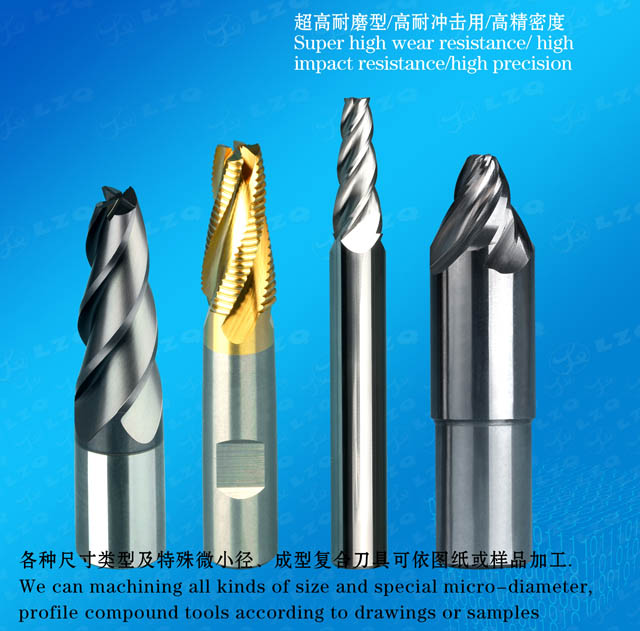

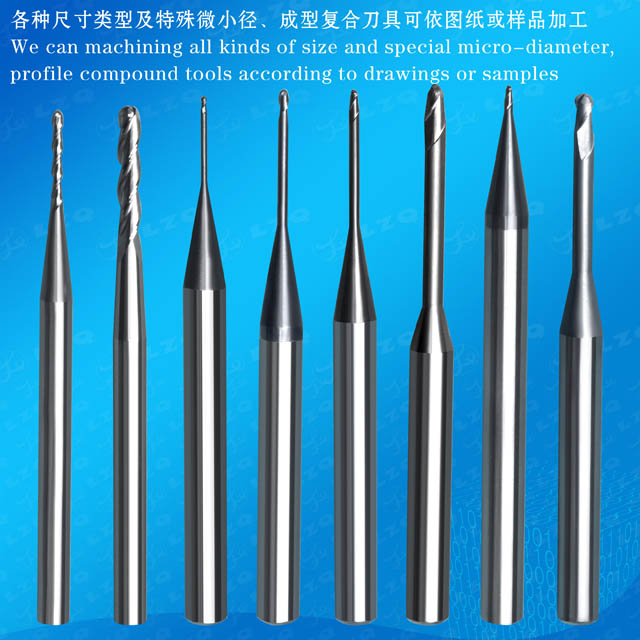

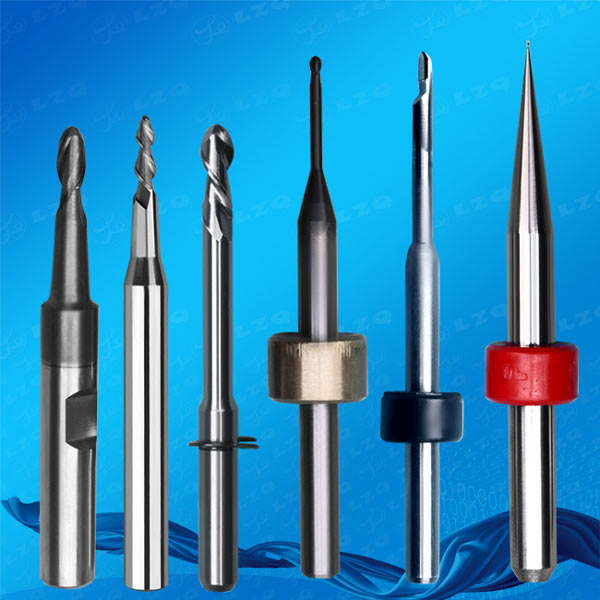

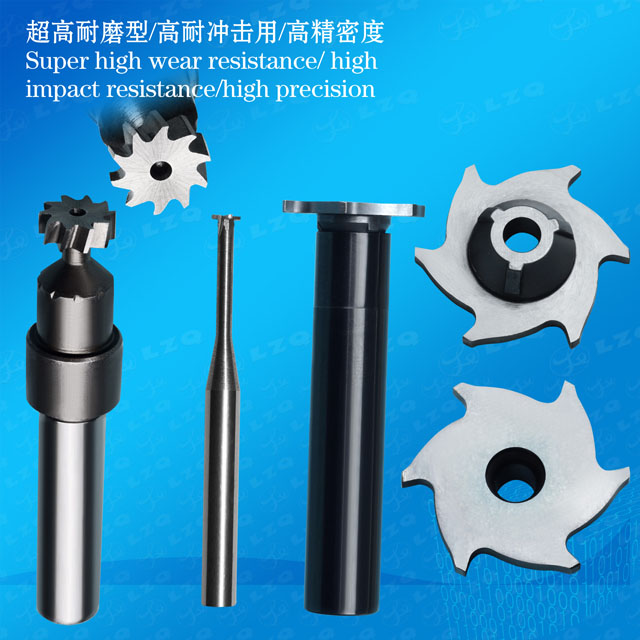

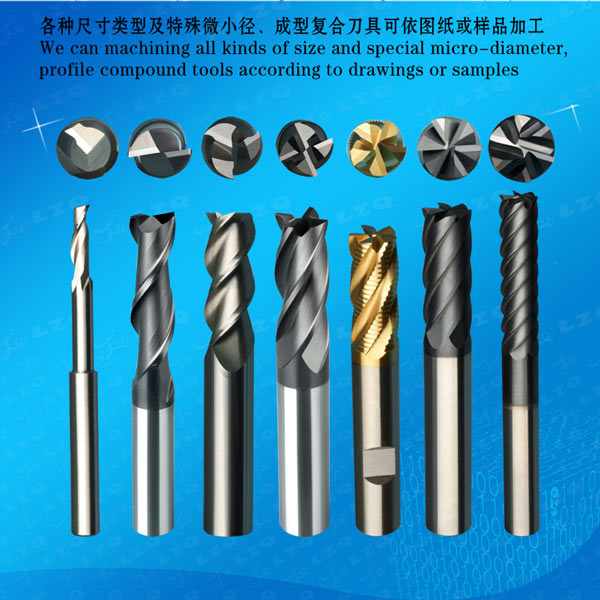

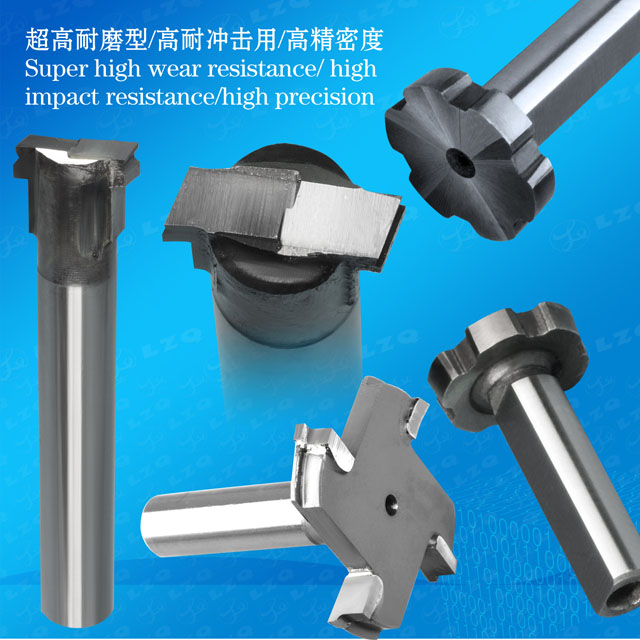

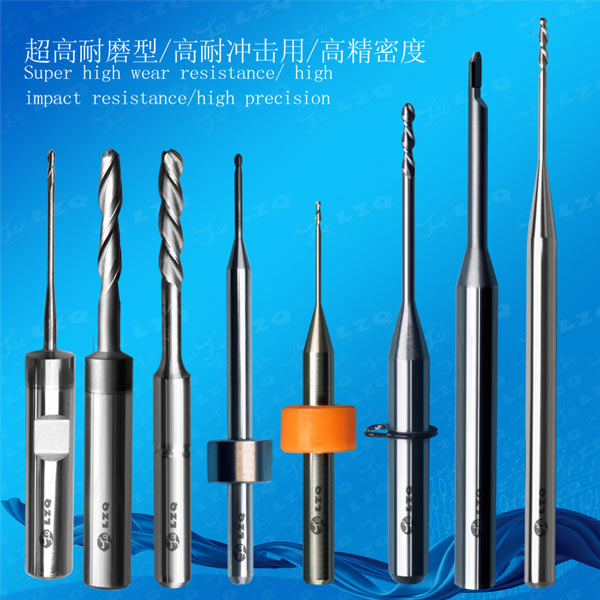

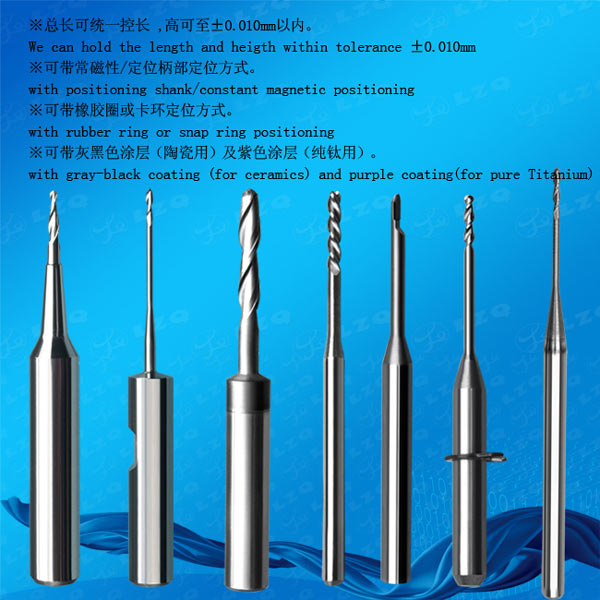

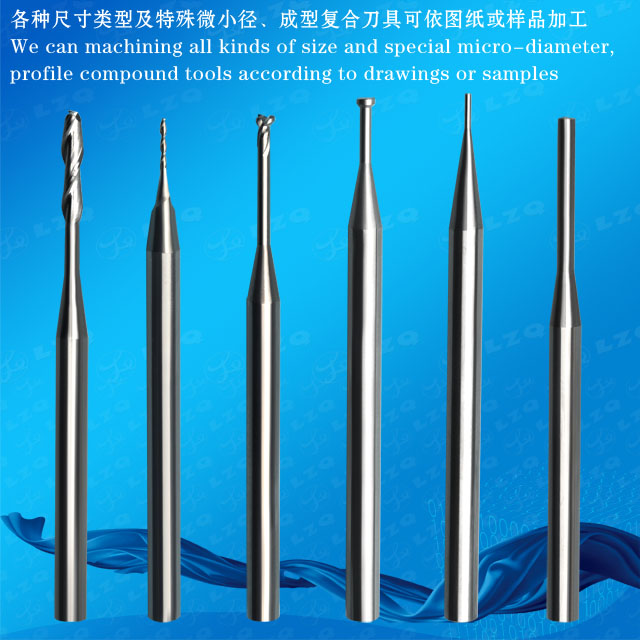

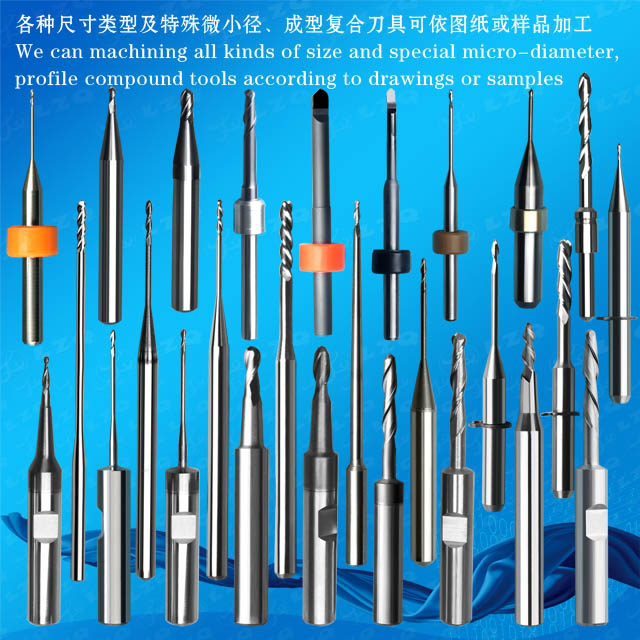

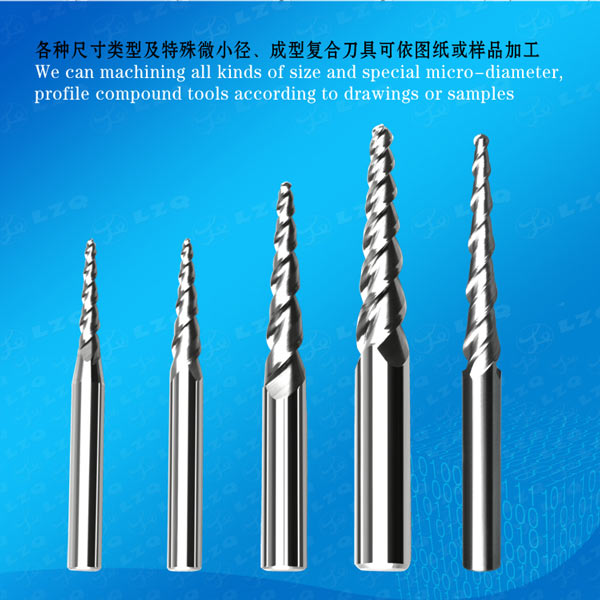

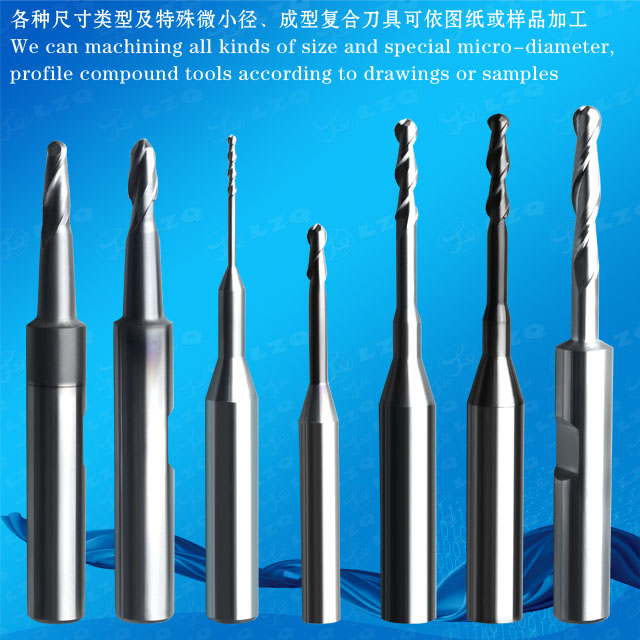

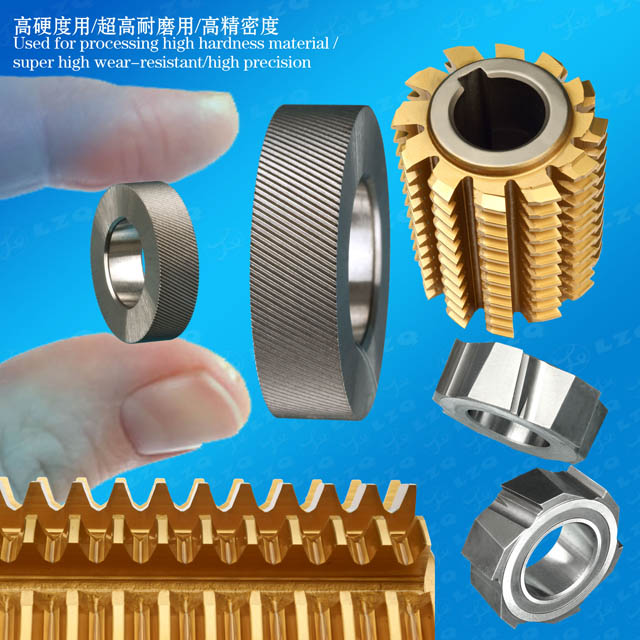

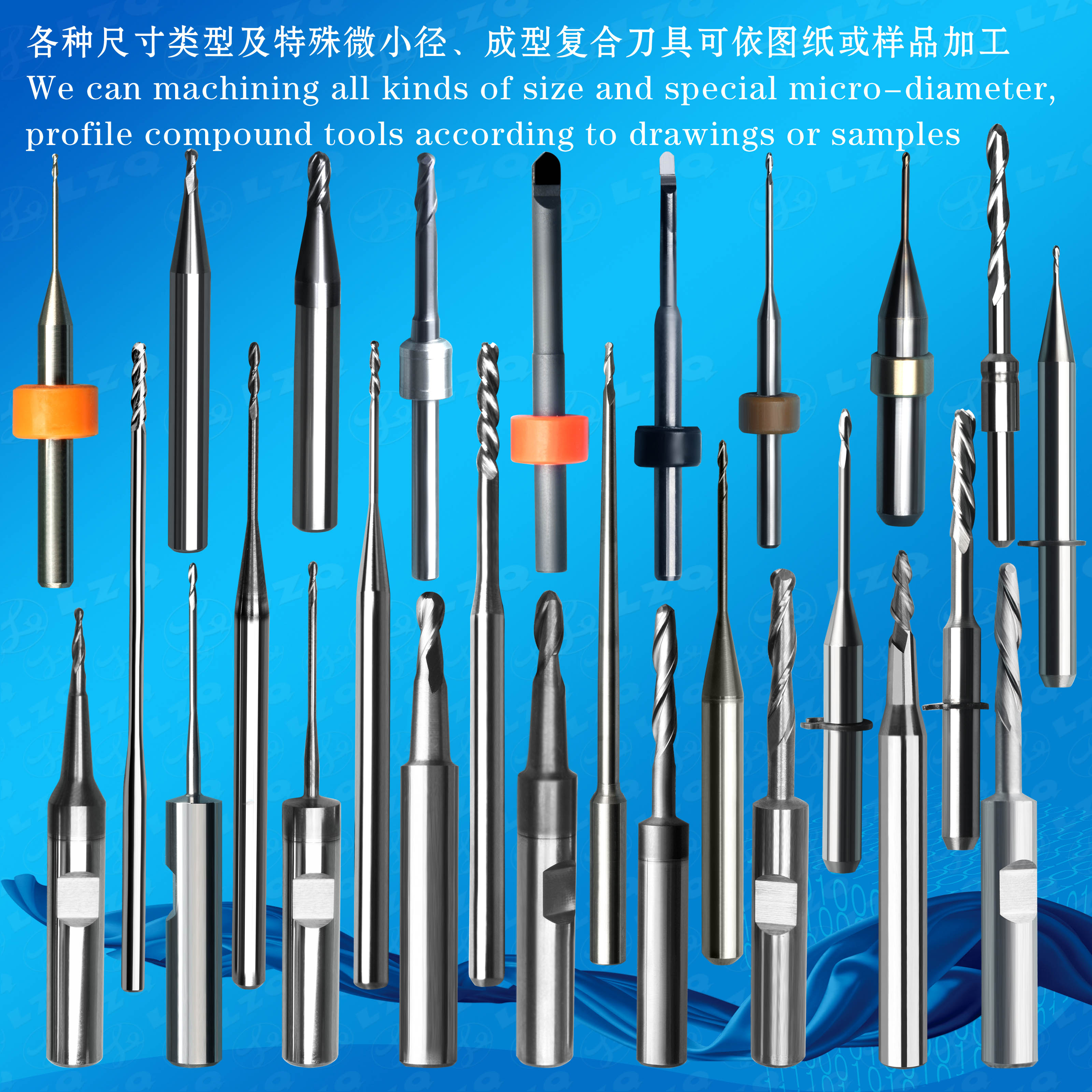

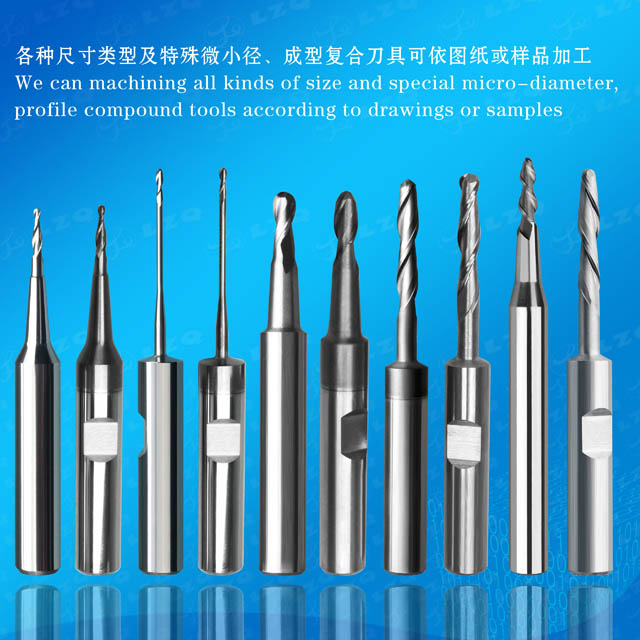

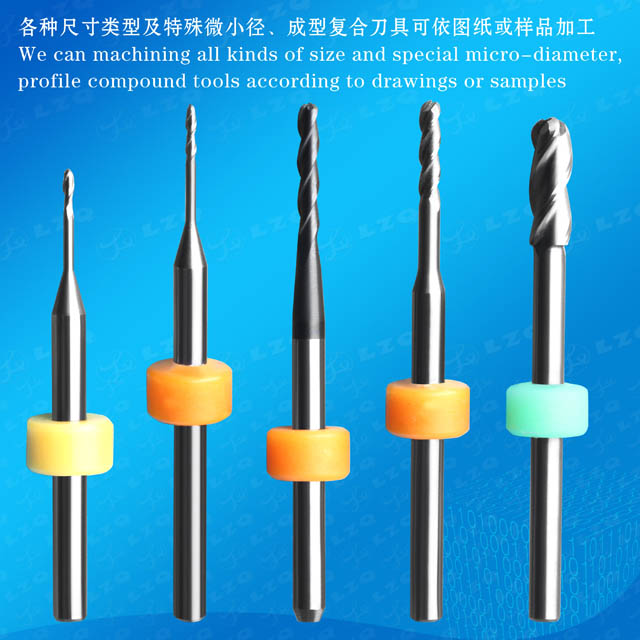

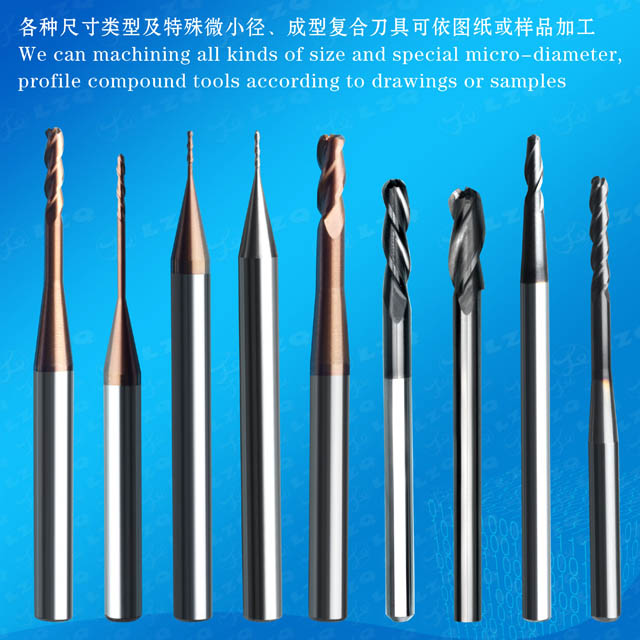

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material, semi-products, finished products in an ordinary year, we are capable to produce according to drawing or sample provided by the customer, so as to present you a favourable cost-performance ratio…Welcome to visit our factory.

Product Details

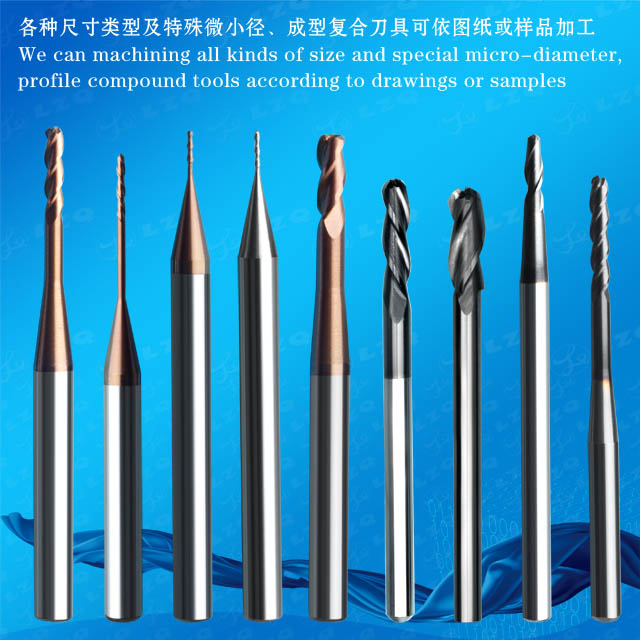

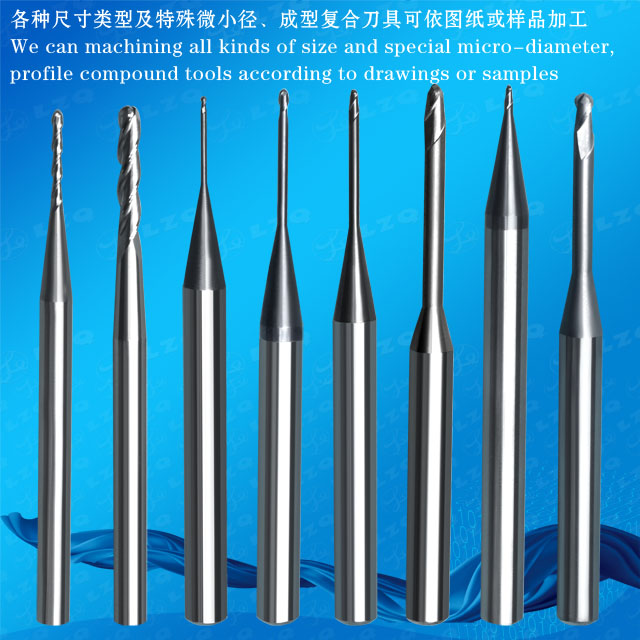

End mills are sold in each imperial and metric shank and cutting diameters. In the USA, the metric is quite simply available, but it is solely used in some machine shops and now not others; in Canada, due to the country's proximity to the US, much the identical is true. In Asia and Europe, metric diameters are standard.

Geometry and tools

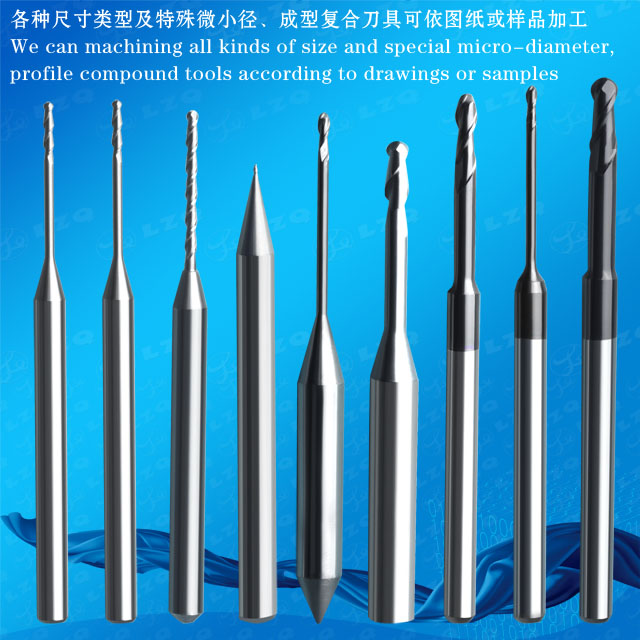

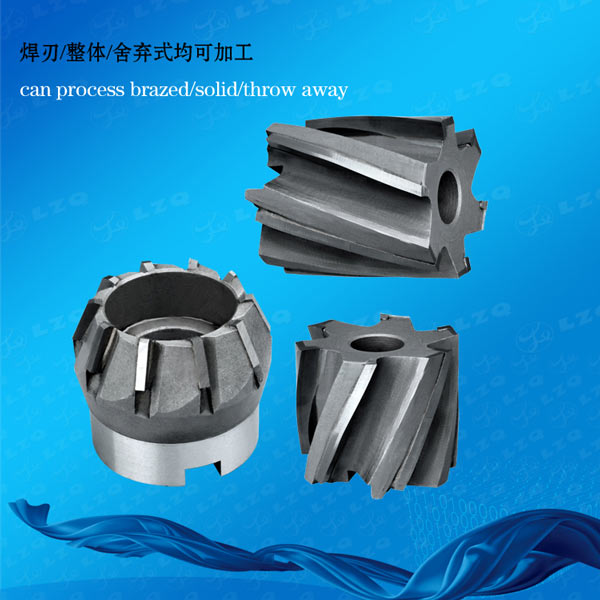

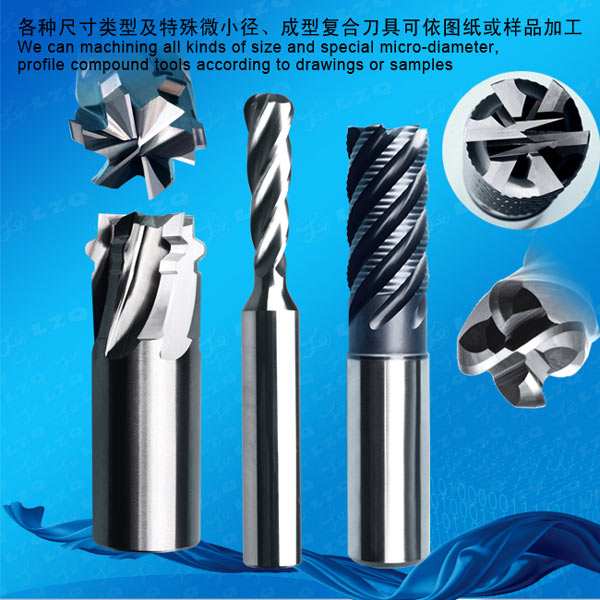

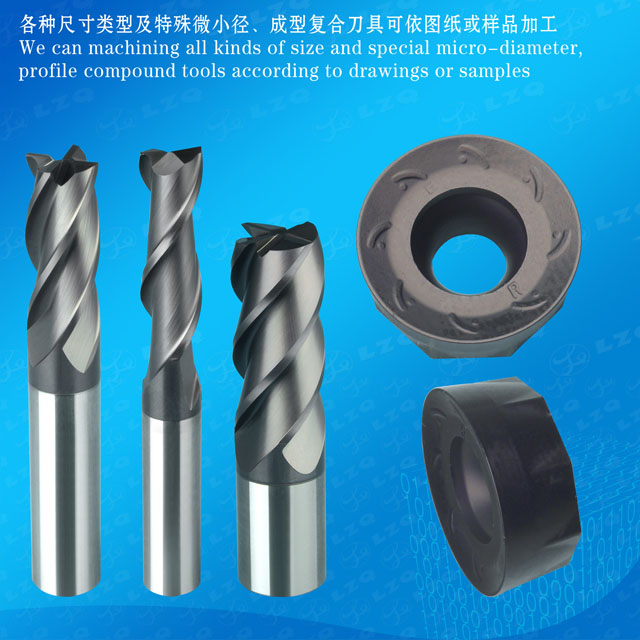

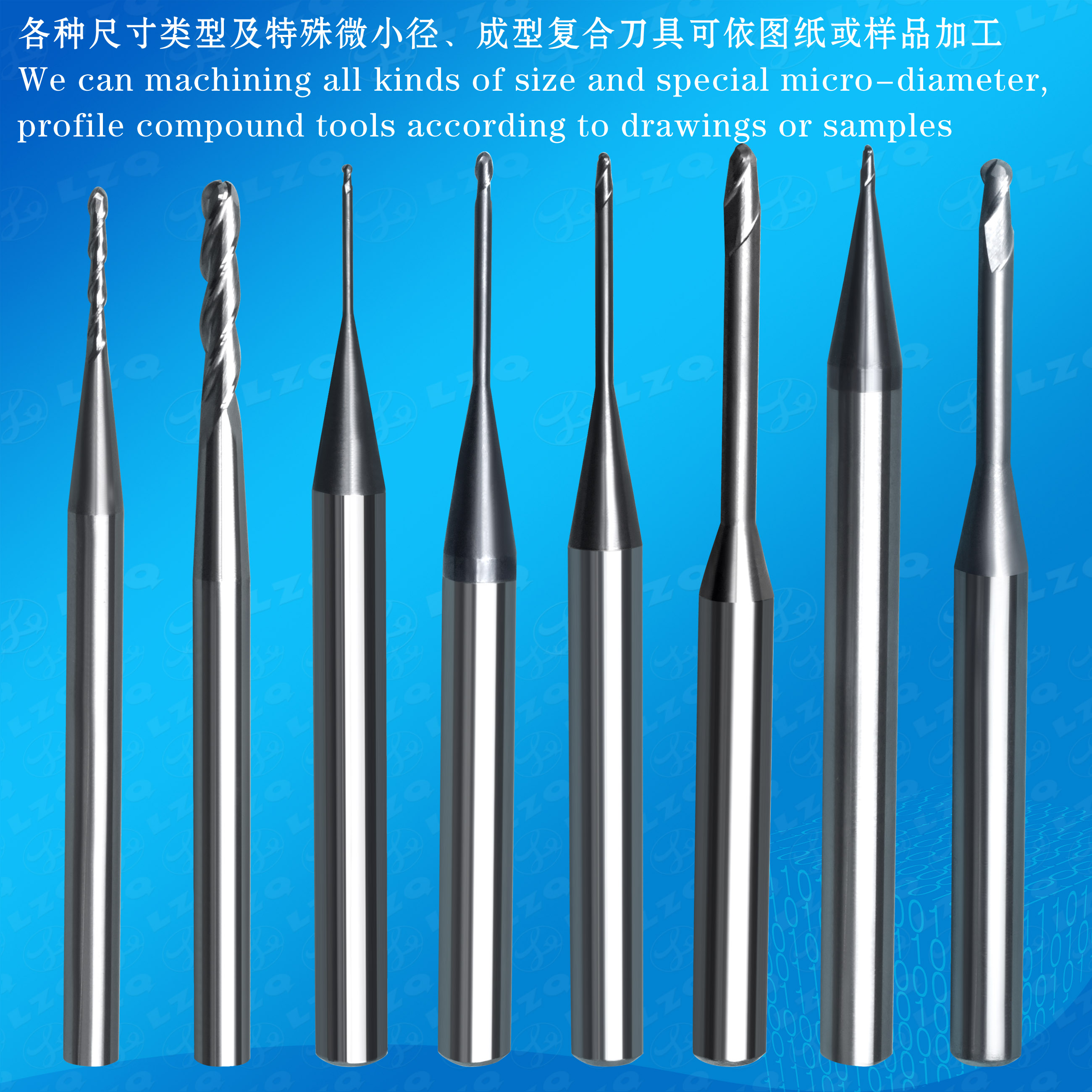

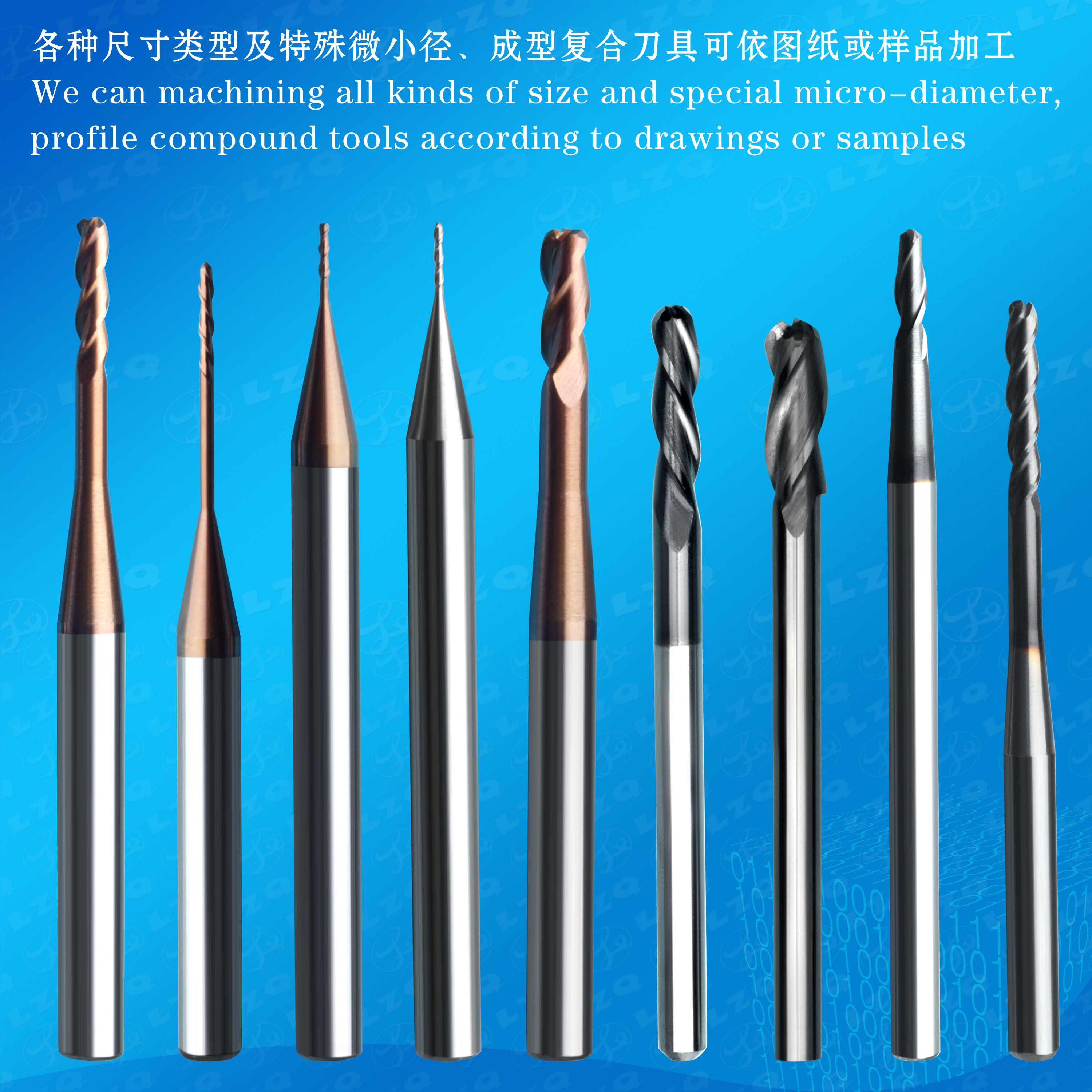

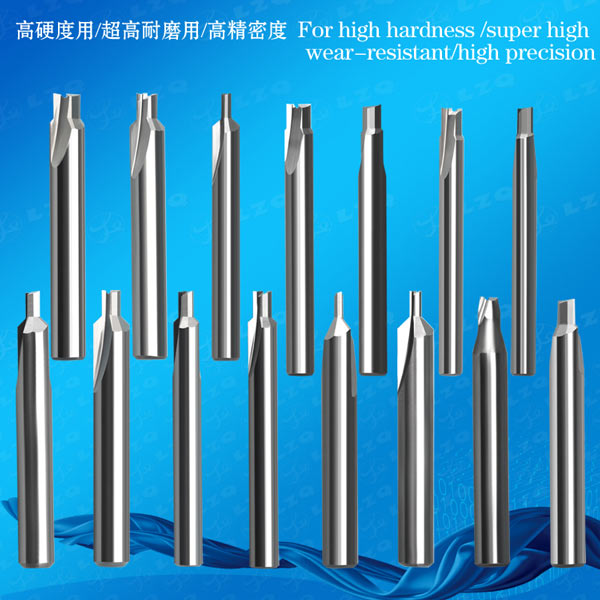

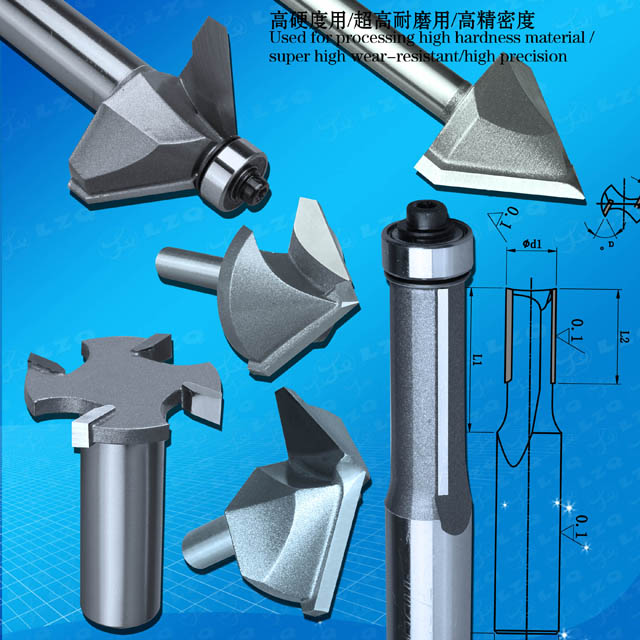

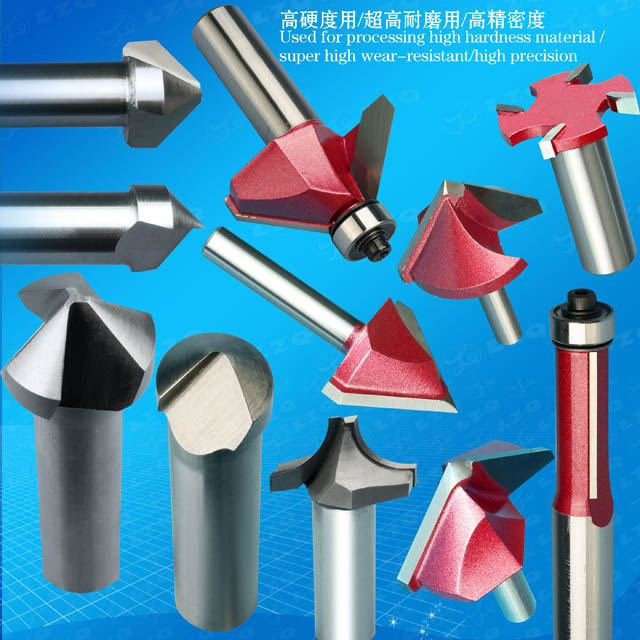

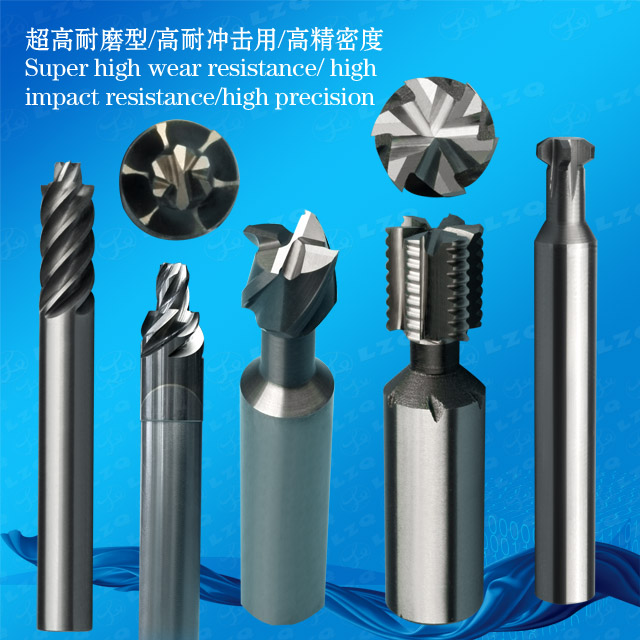

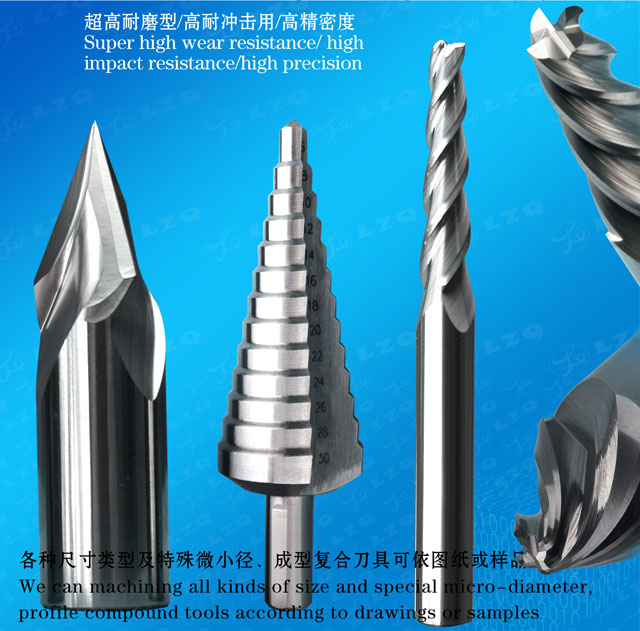

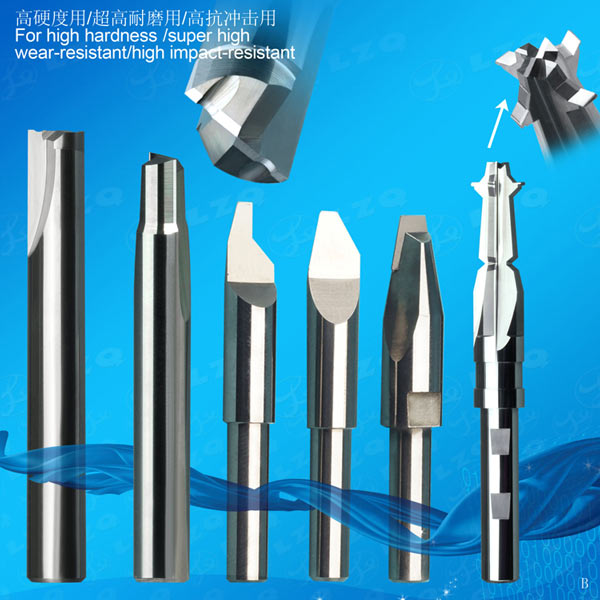

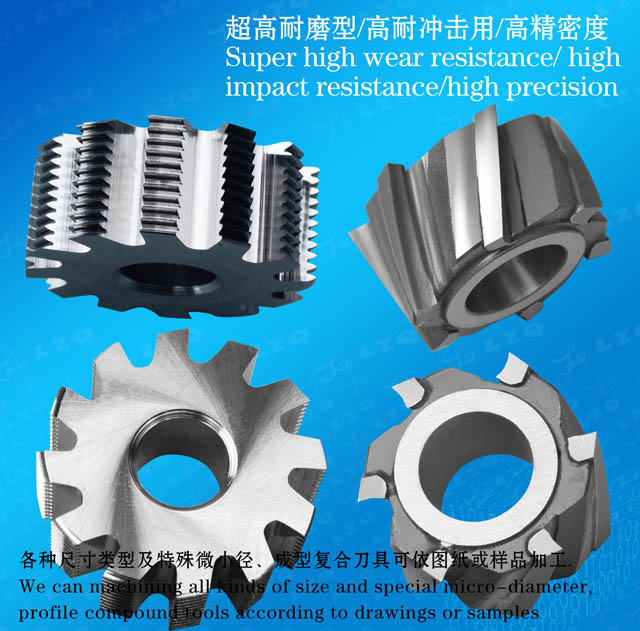

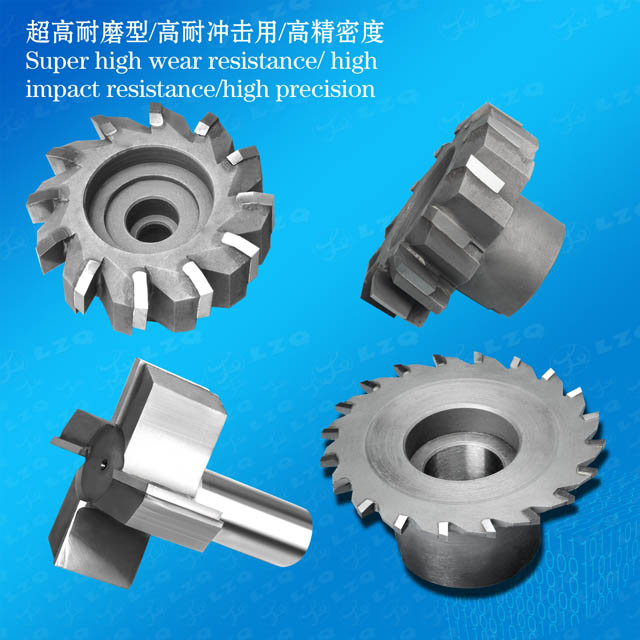

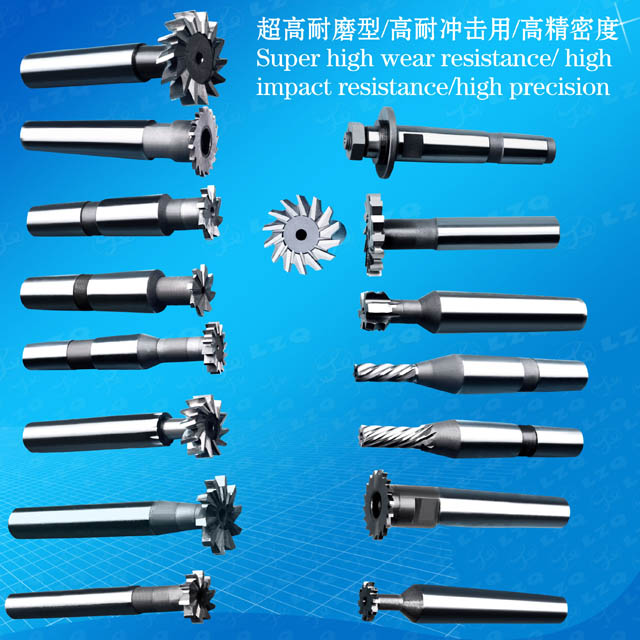

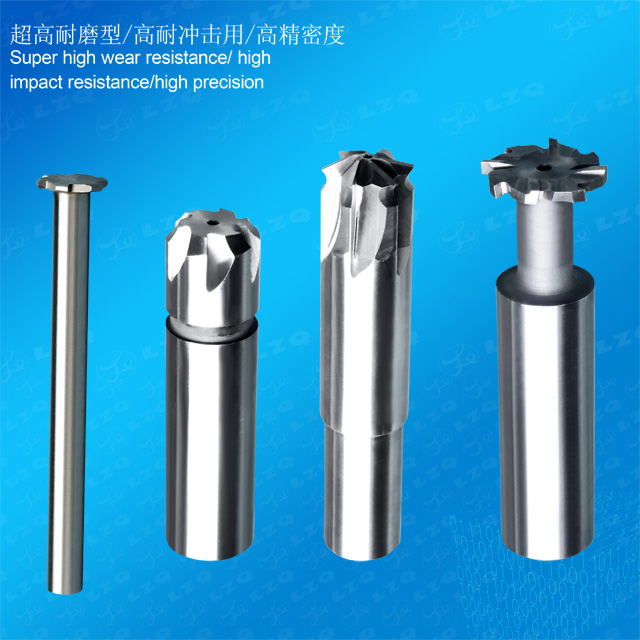

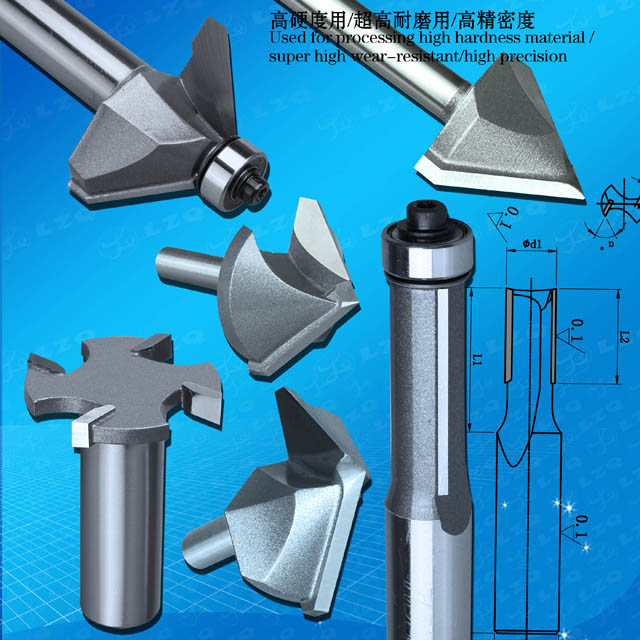

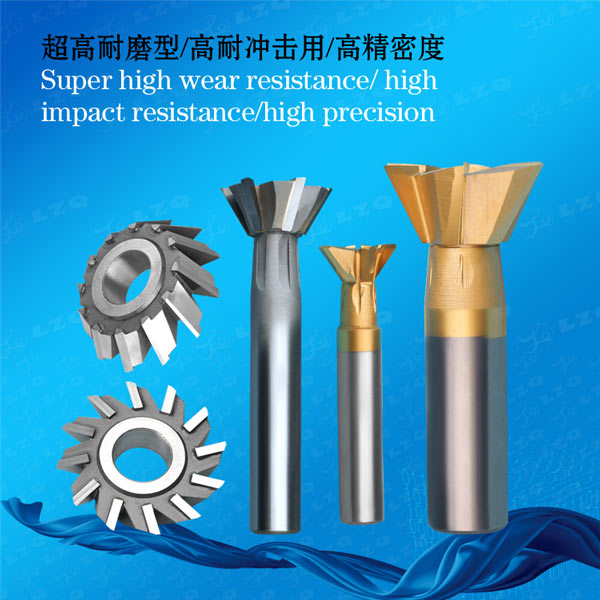

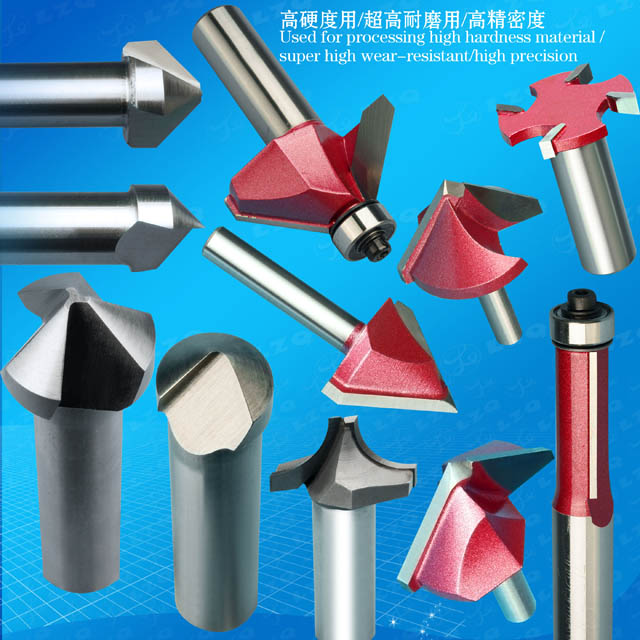

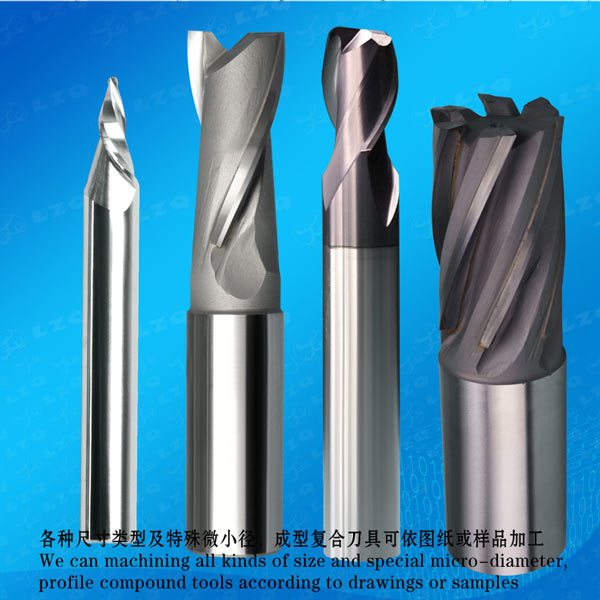

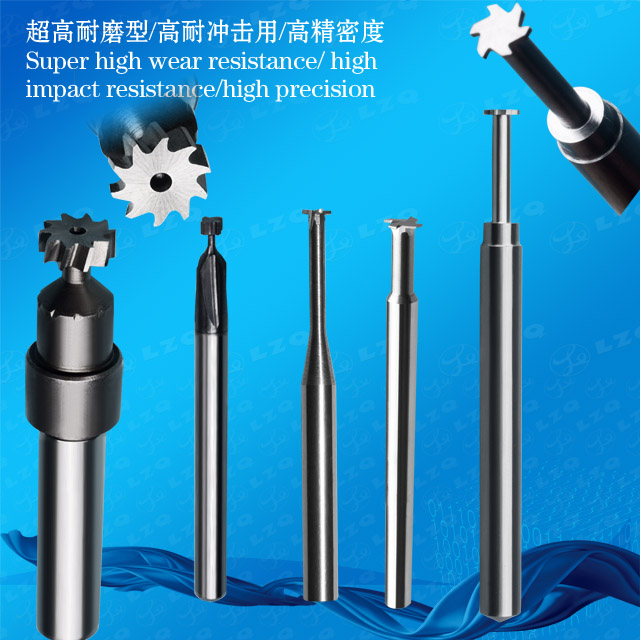

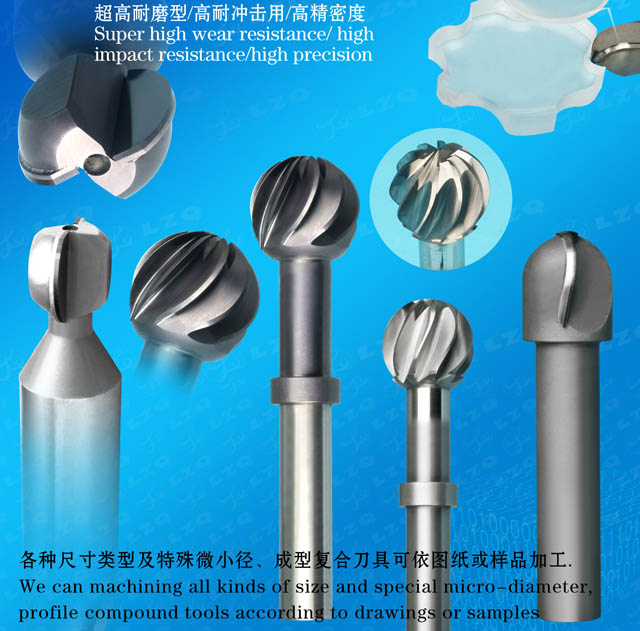

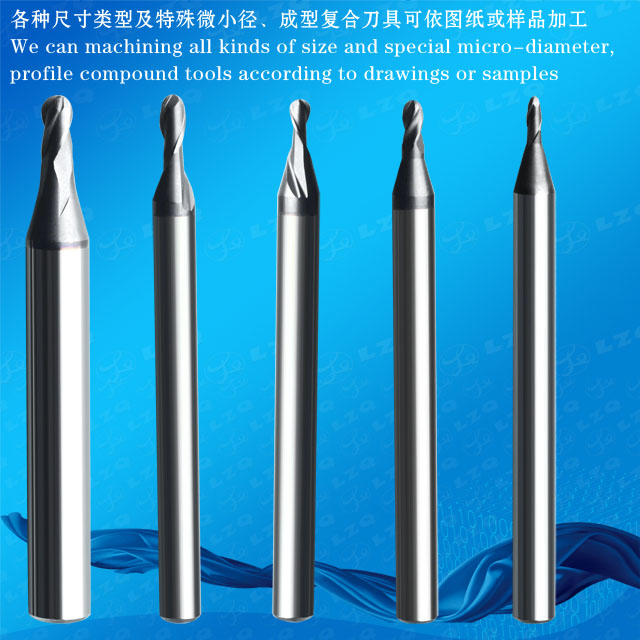

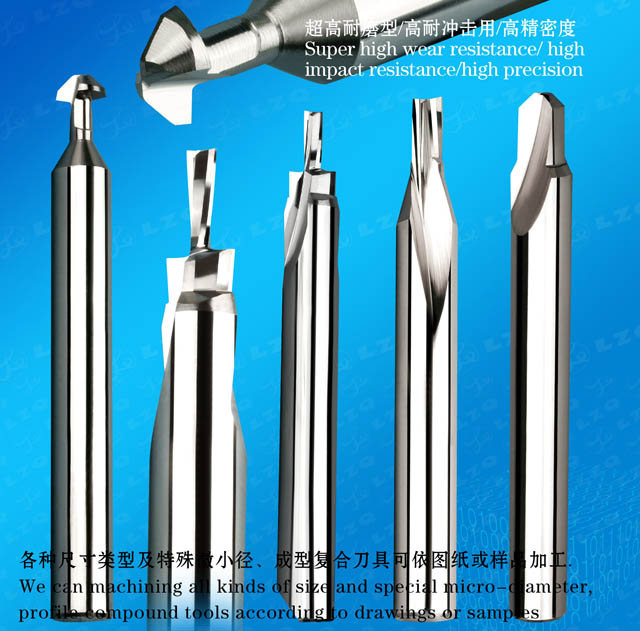

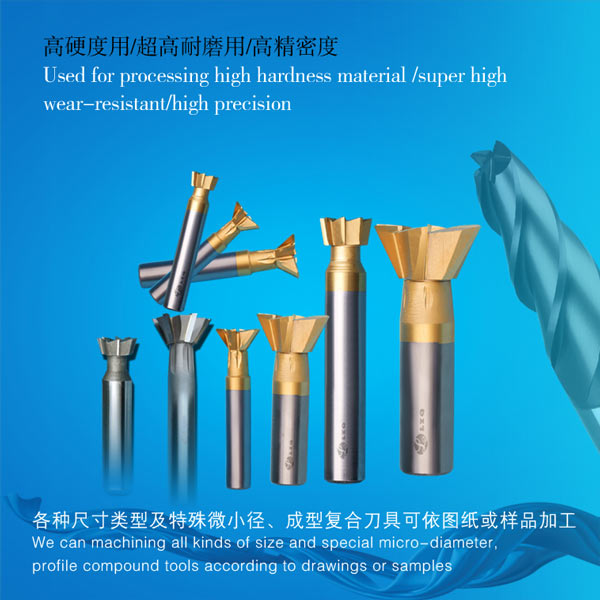

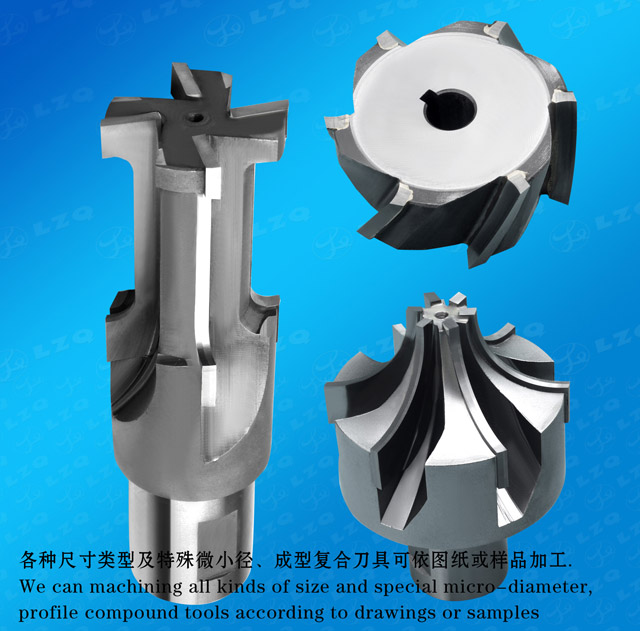

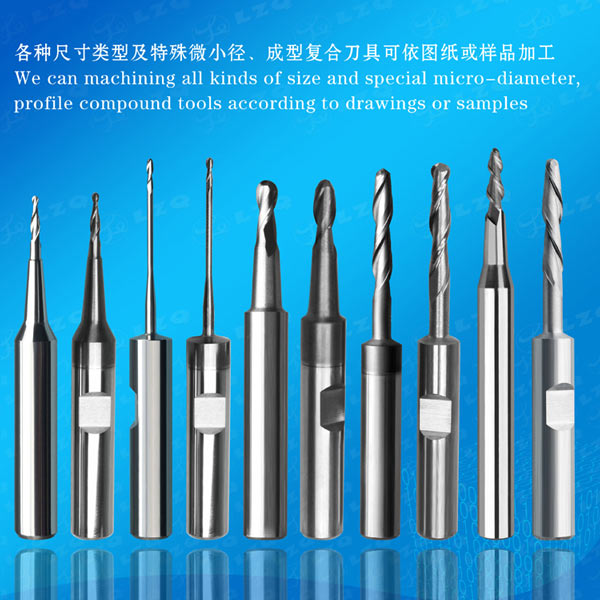

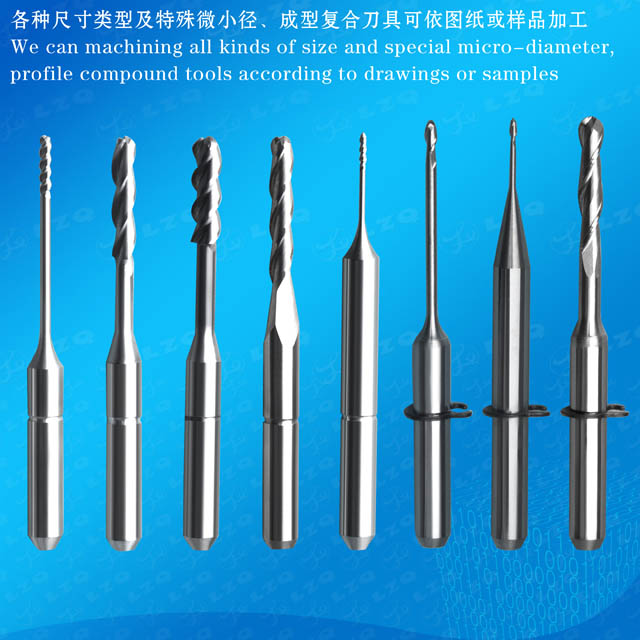

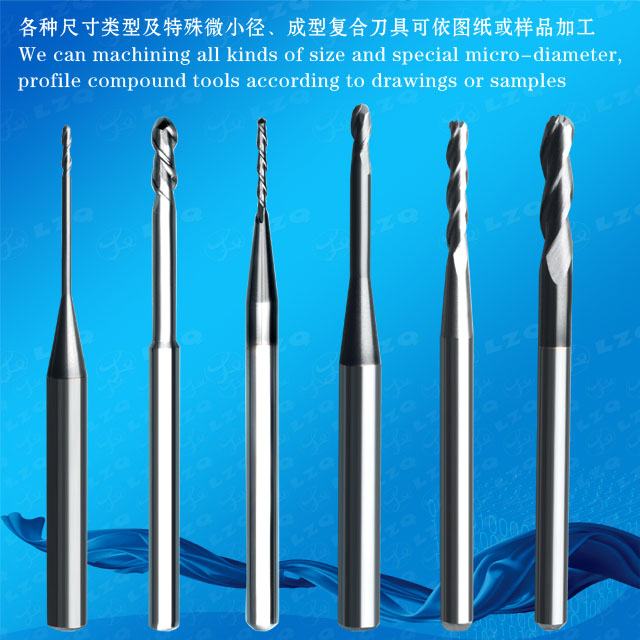

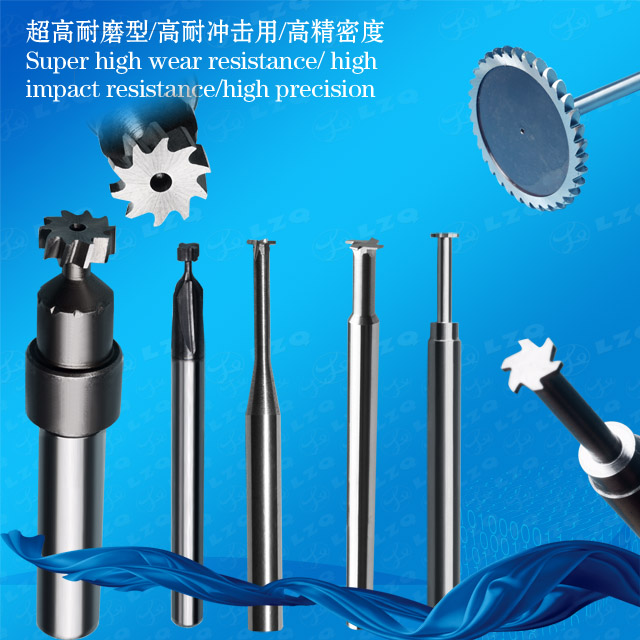

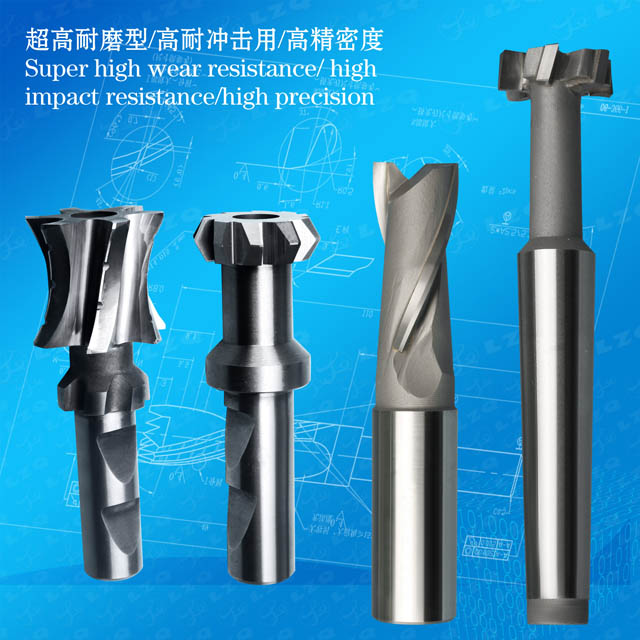

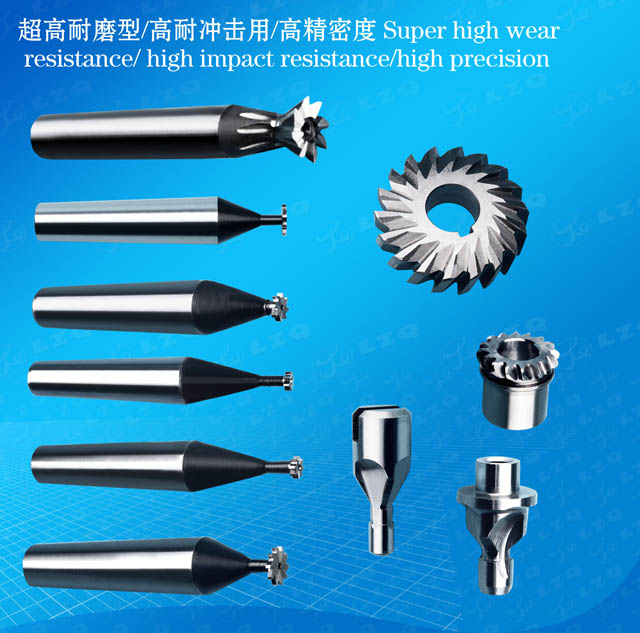

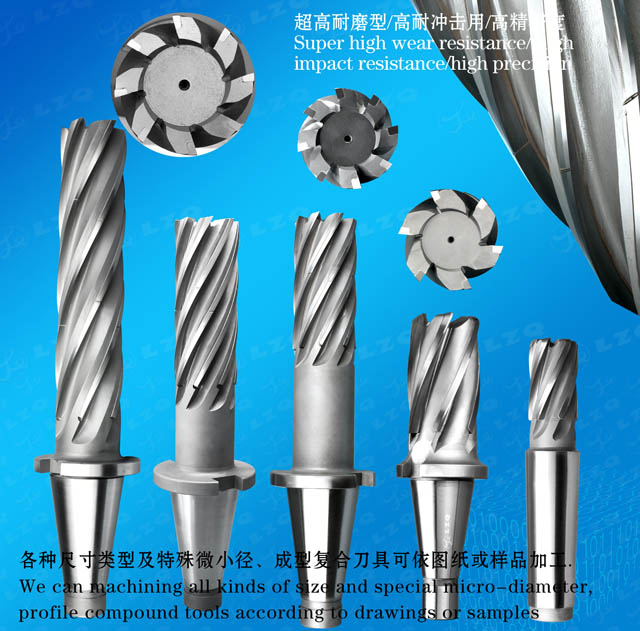

A variety of grooves, slots, and pockets in the work-piece may additionally be produced from a variety of device bits. Common tool bit kinds are: rectangular give up cutters, ball stop cutters, t-slot cutters, and shell mills. Square stop cutters can mill square slots, pockets, and edges. Ball cease cutters mill radiused slots or fillets. T-slot cutters mill exactly that: T-shaped slots. Shell give up cutters are used for large flat surfaces and for perspective cuts. There are versions of these device kinds as well.

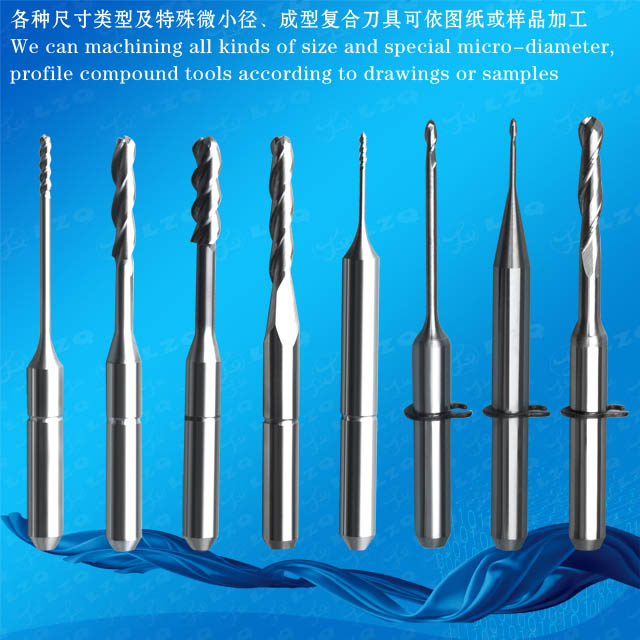

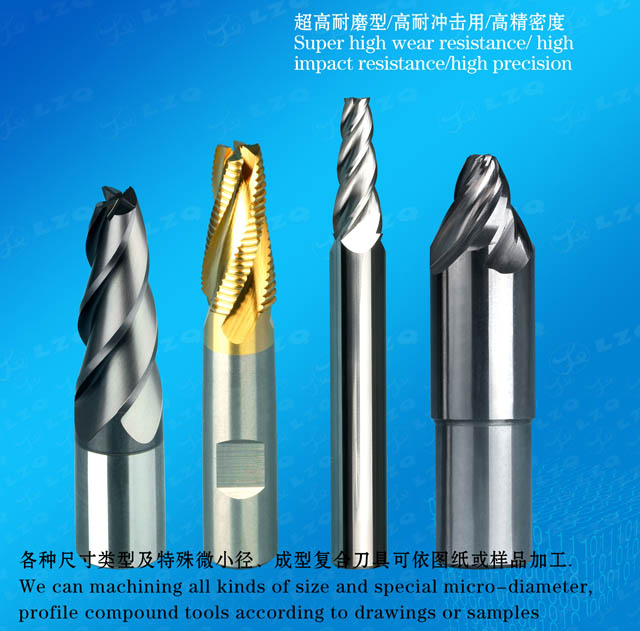

There are 4 necessary angles of each slicing tool: stop cutting edge angle, axial relief angle, radial comfort angle, and radial rake angle. Depending on the material being milled, and what undertaking need to be performed, exceptional tool sorts and geometry may be used. For instance, when milling a cloth-like aluminium, it may also be positive to use a device with very deep, polished flutes, a very sharp cutting side and high rake angles. When machining a tough material such as stainless steel, however, shallow flutes and a squared-off slicing part will optimize cloth removal and device life.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

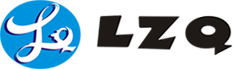

Medical Instrument

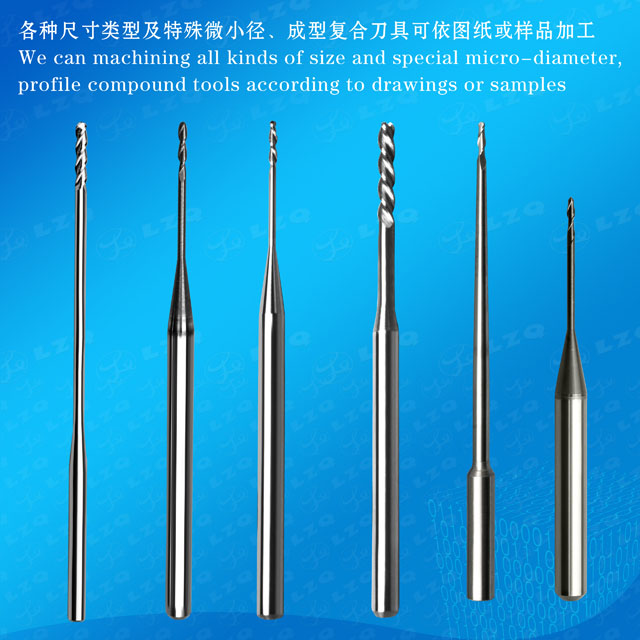

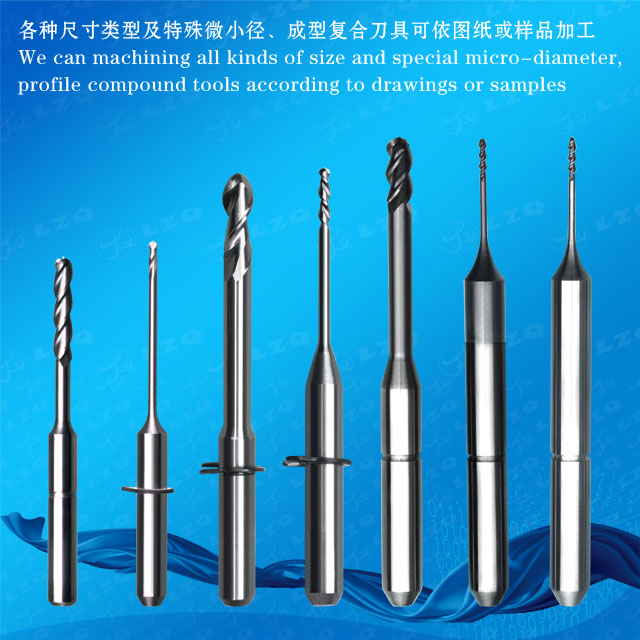

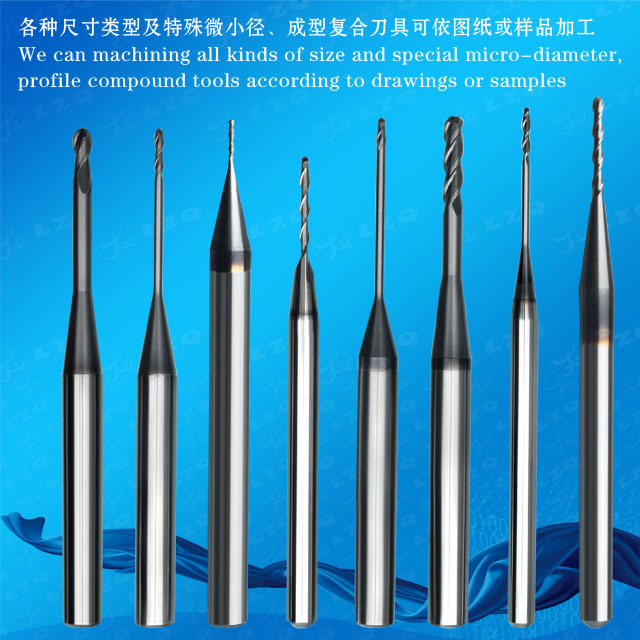

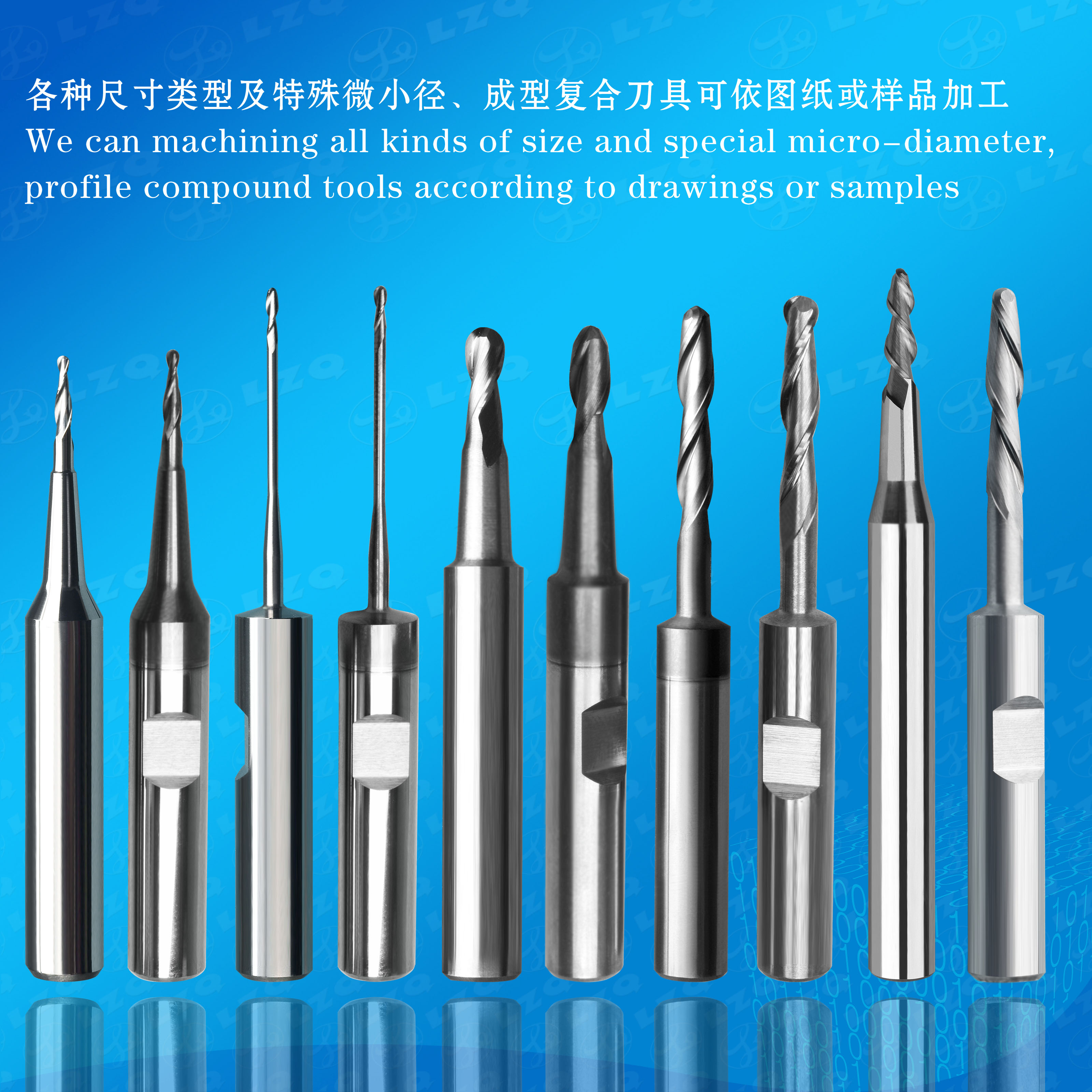

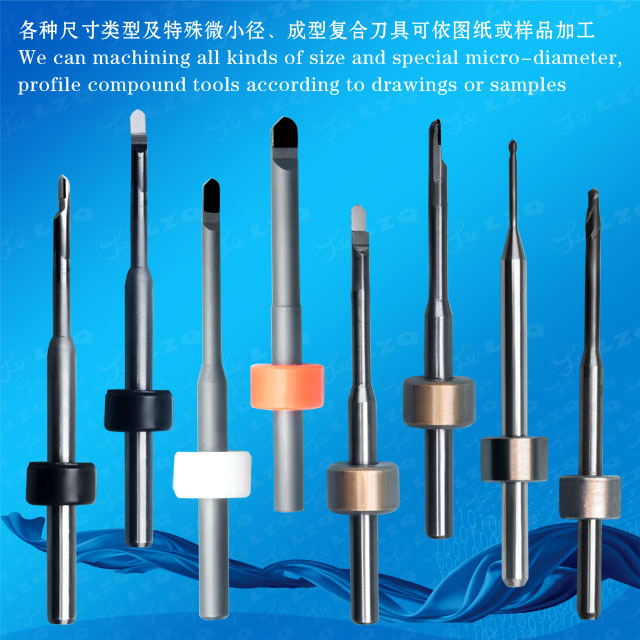

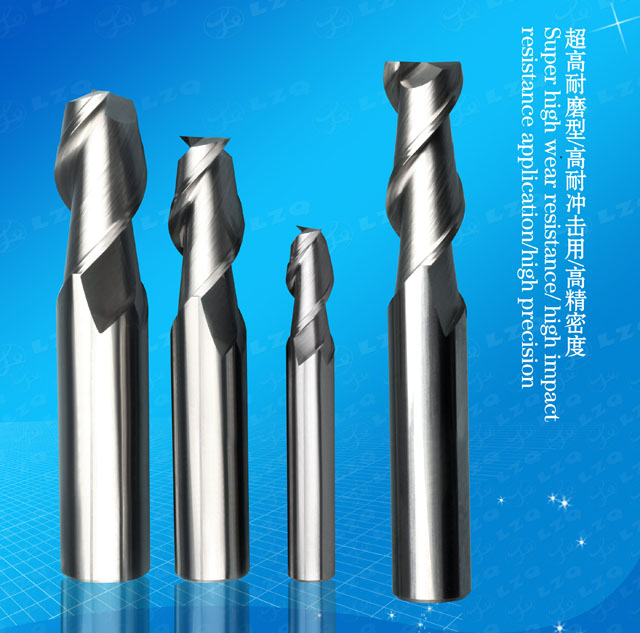

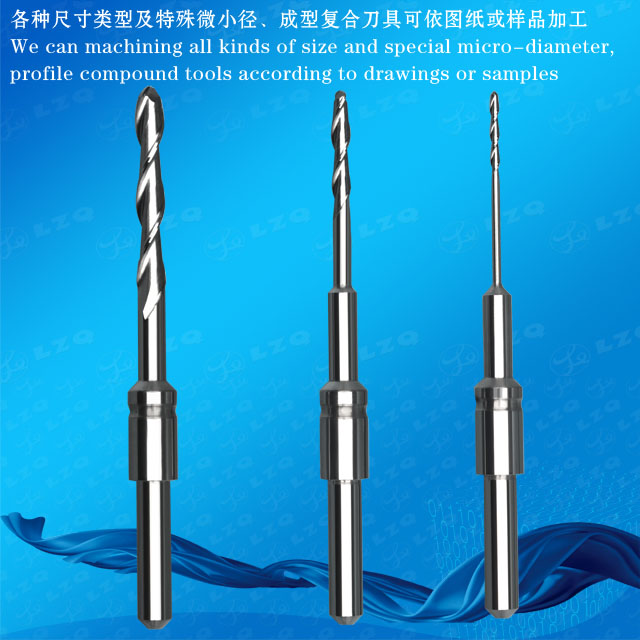

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

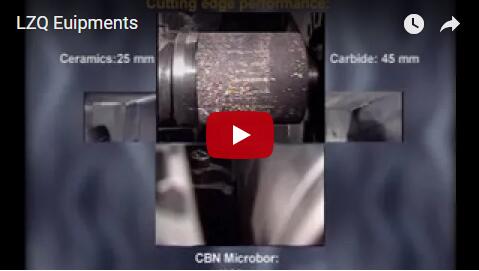

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

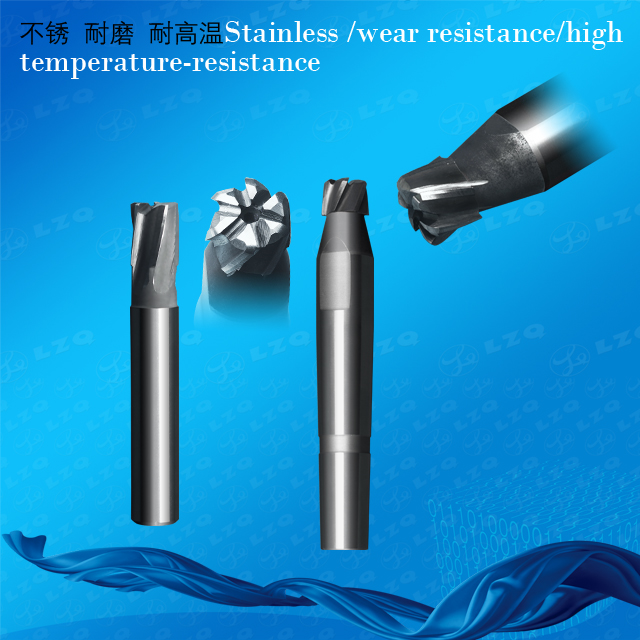

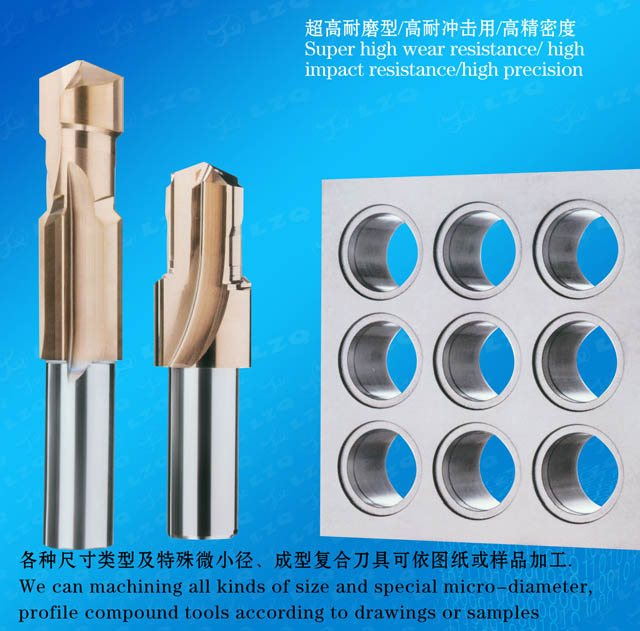

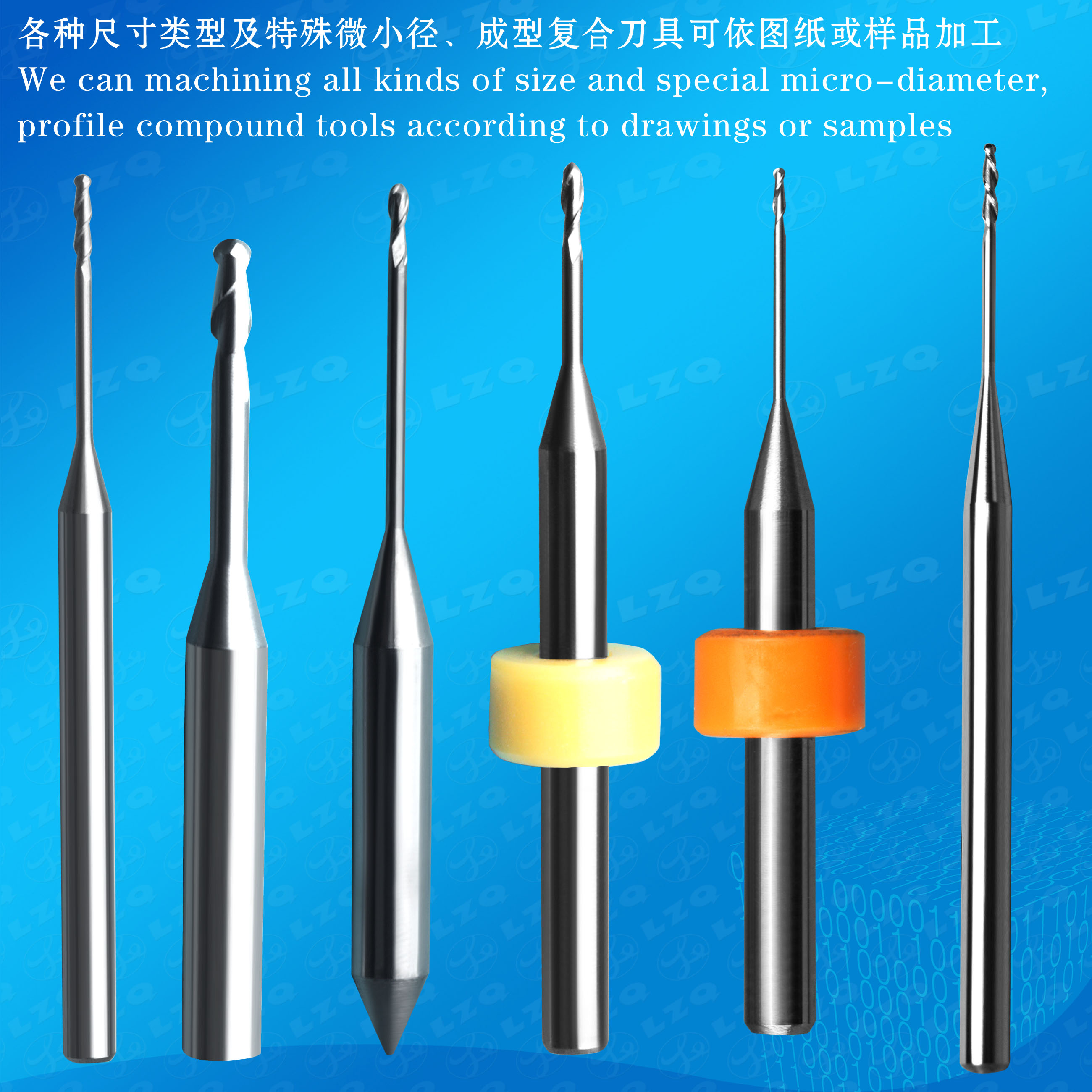

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

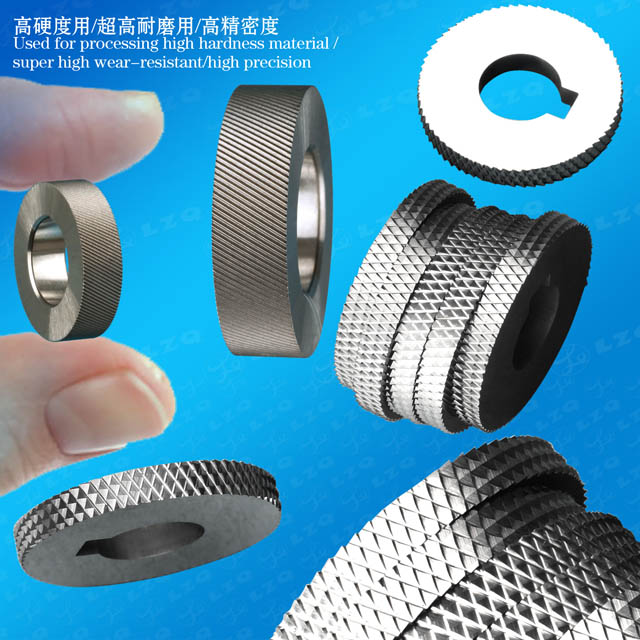

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.