Description

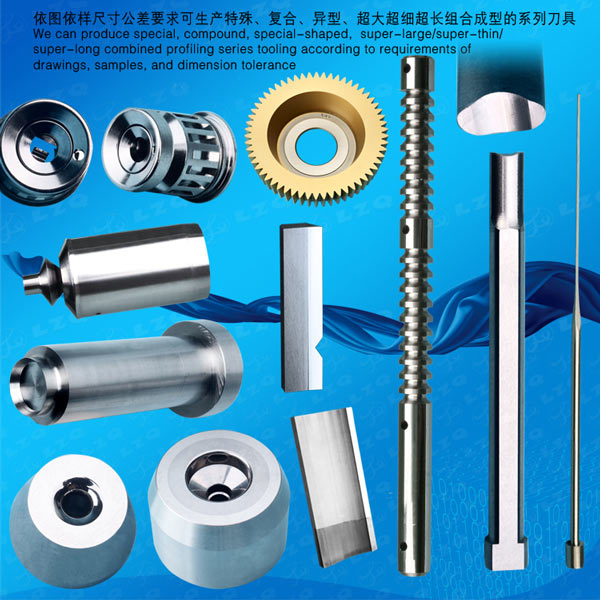

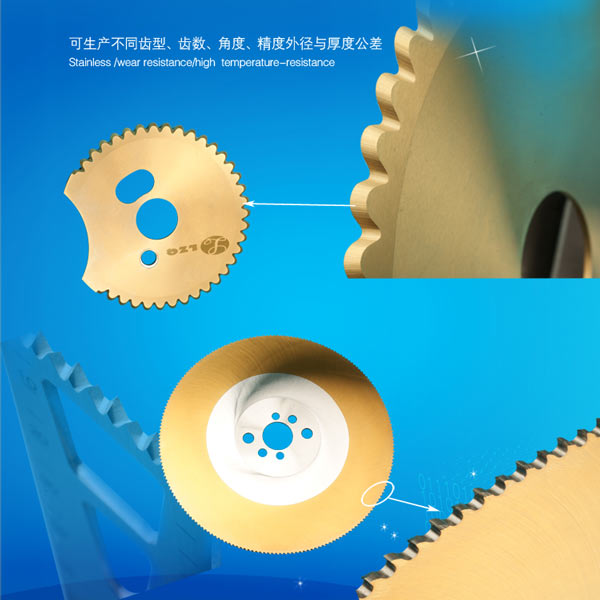

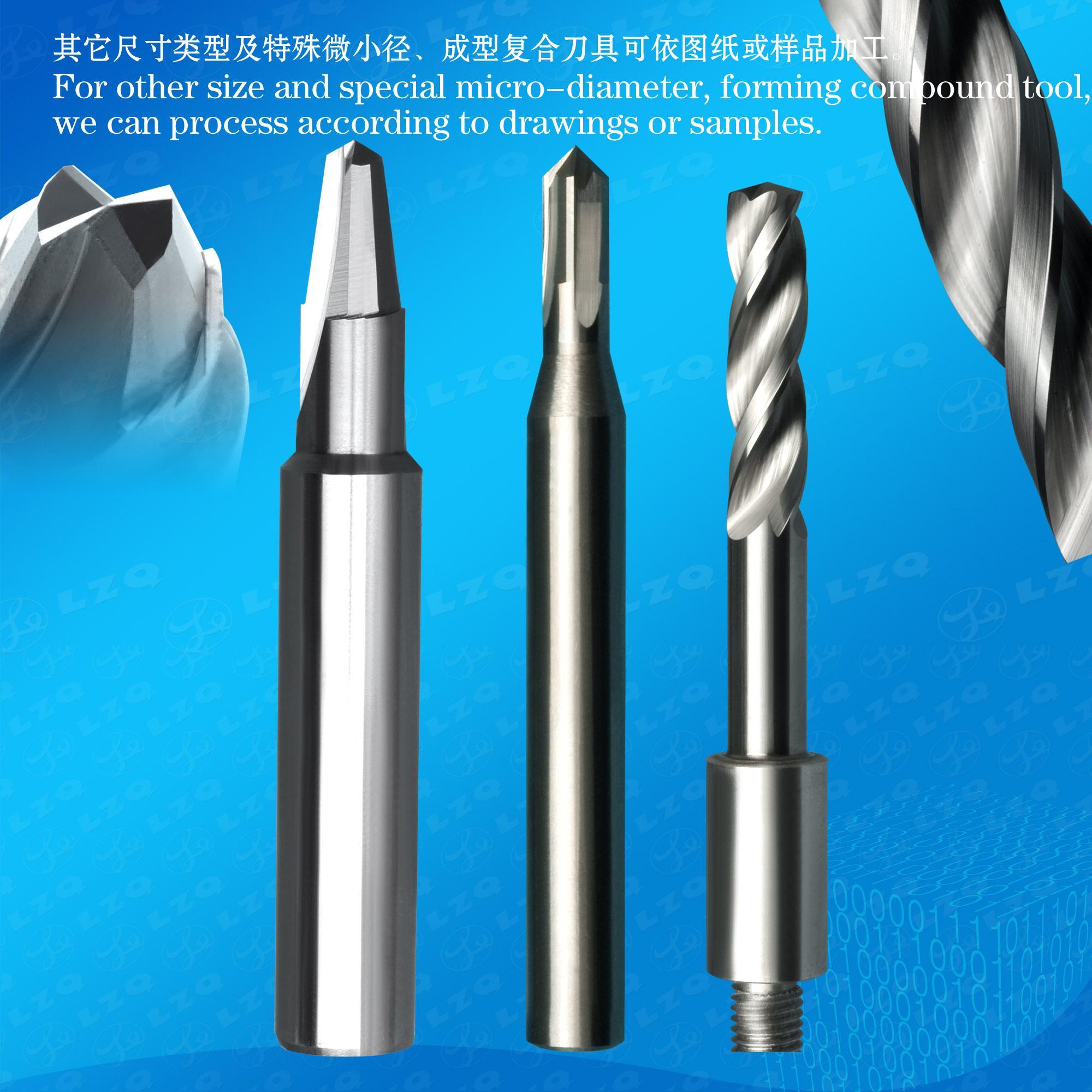

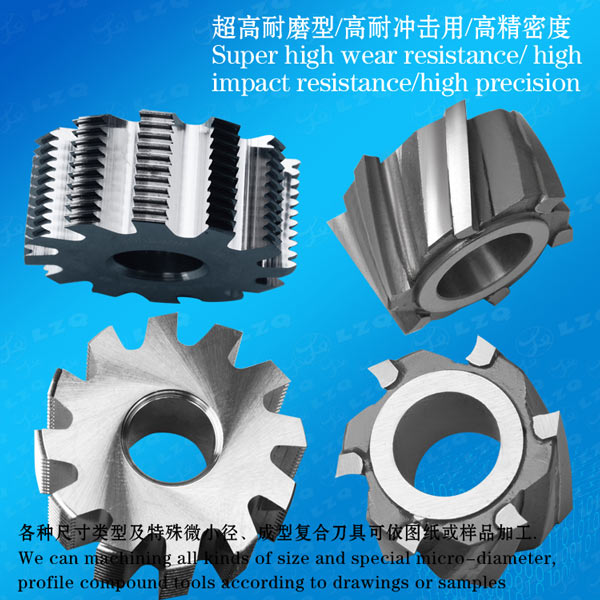

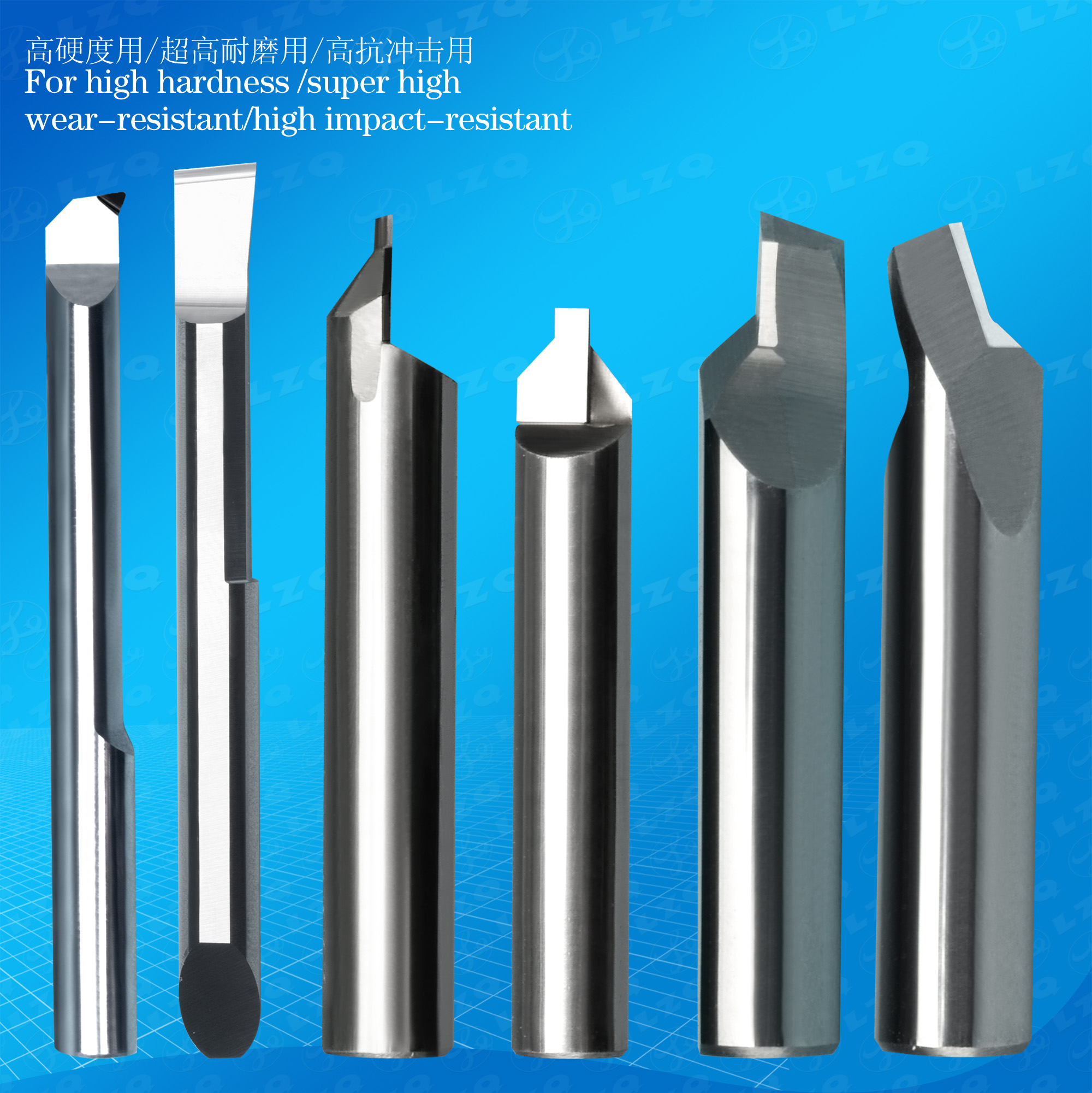

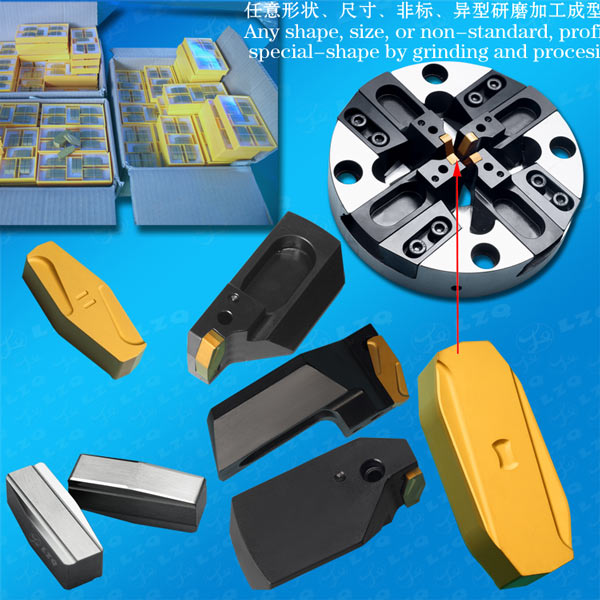

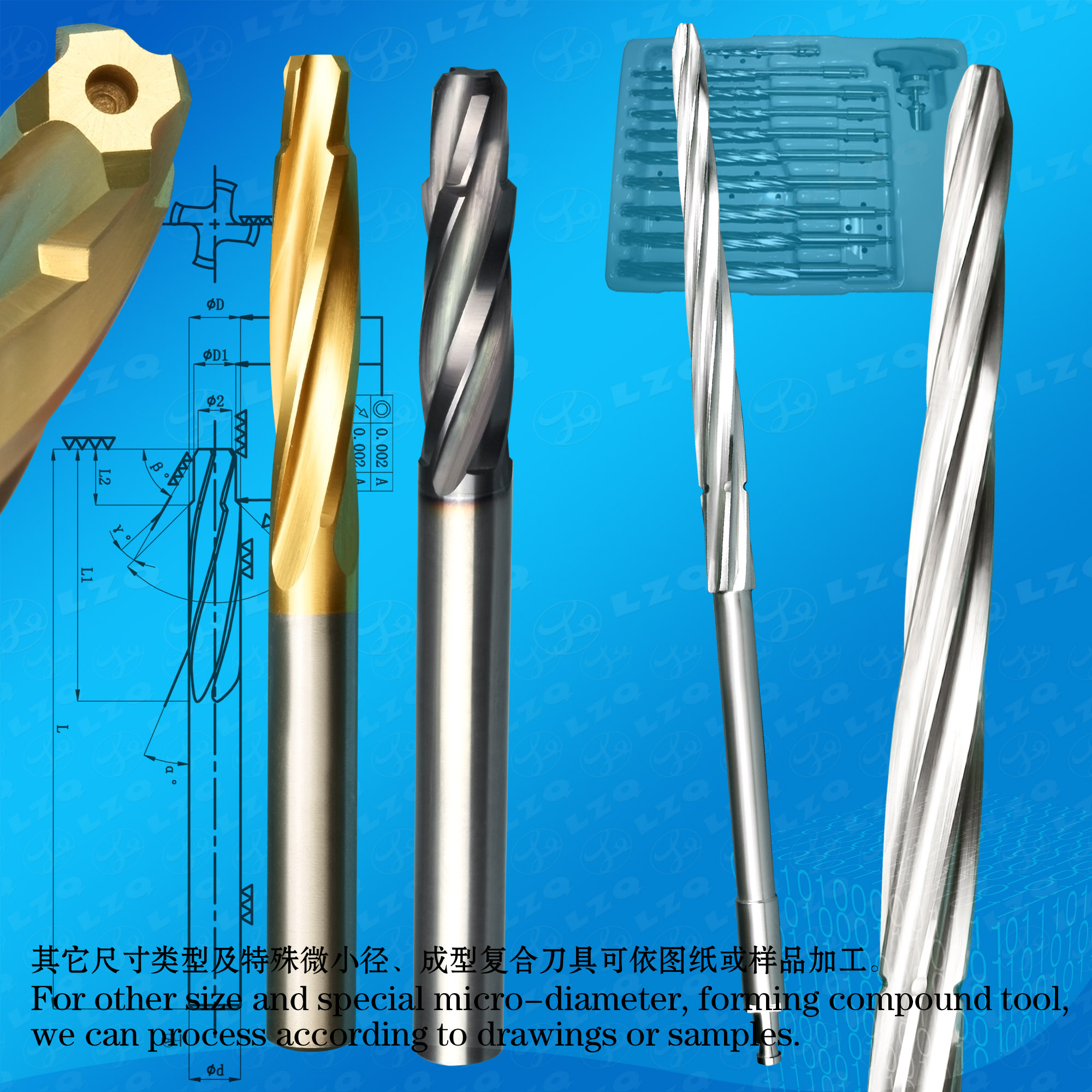

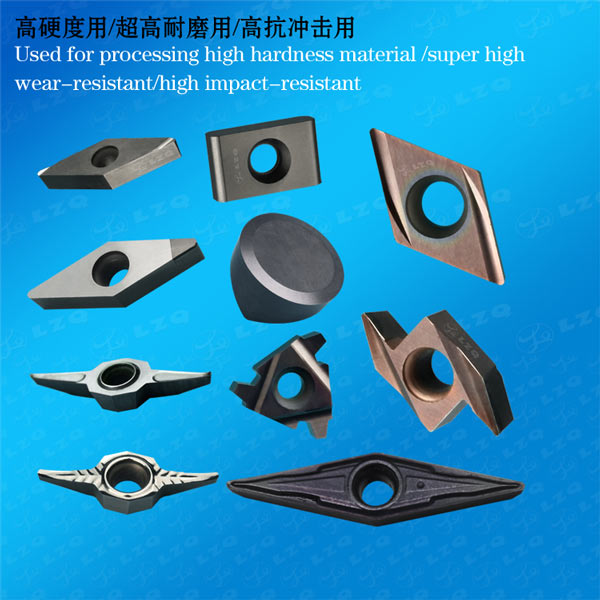

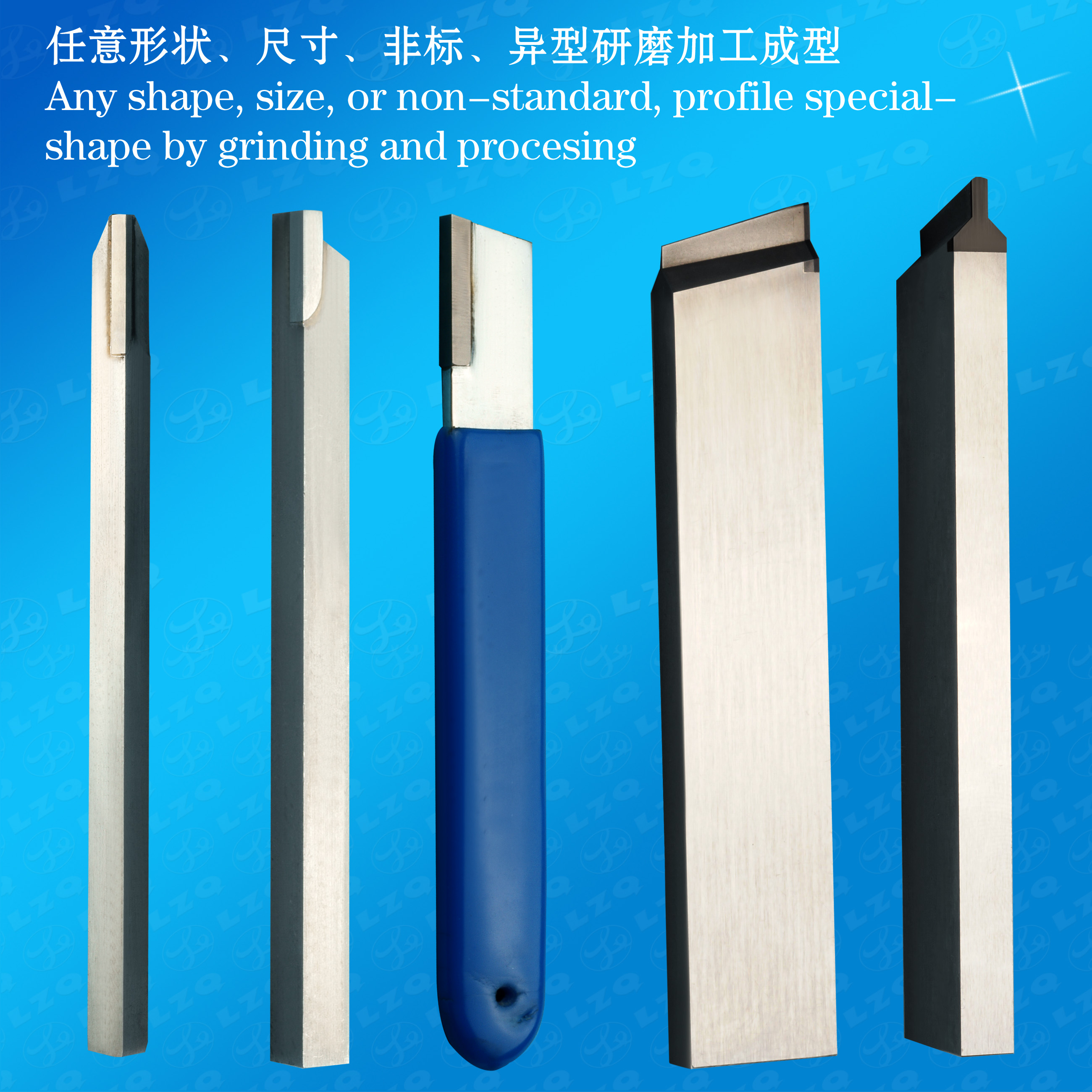

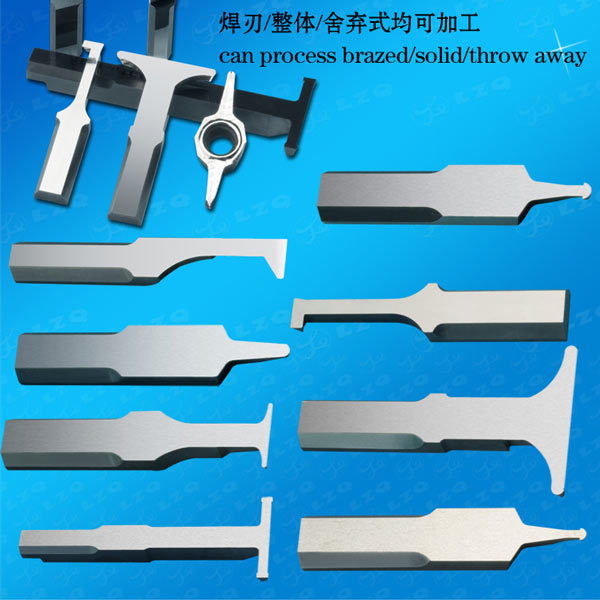

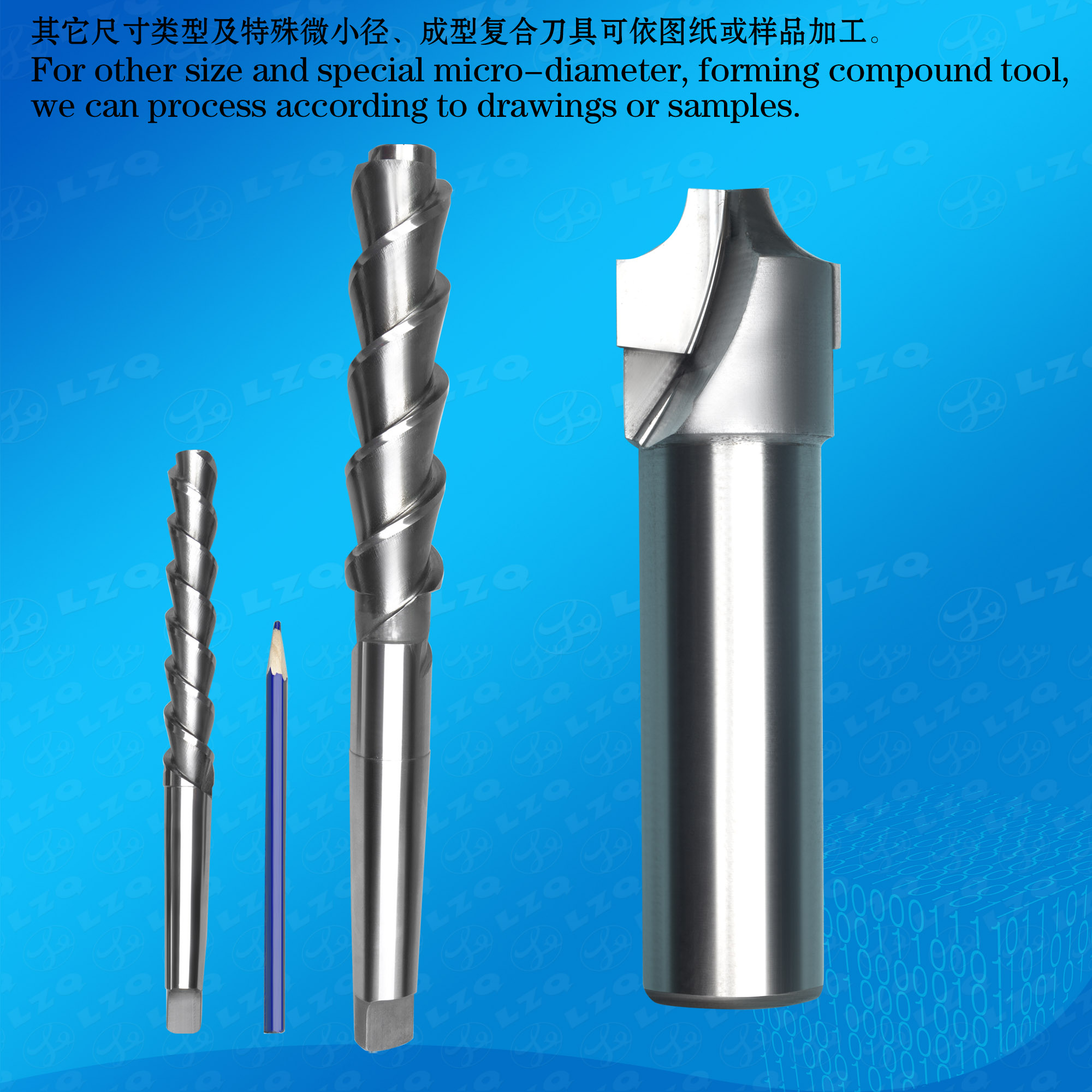

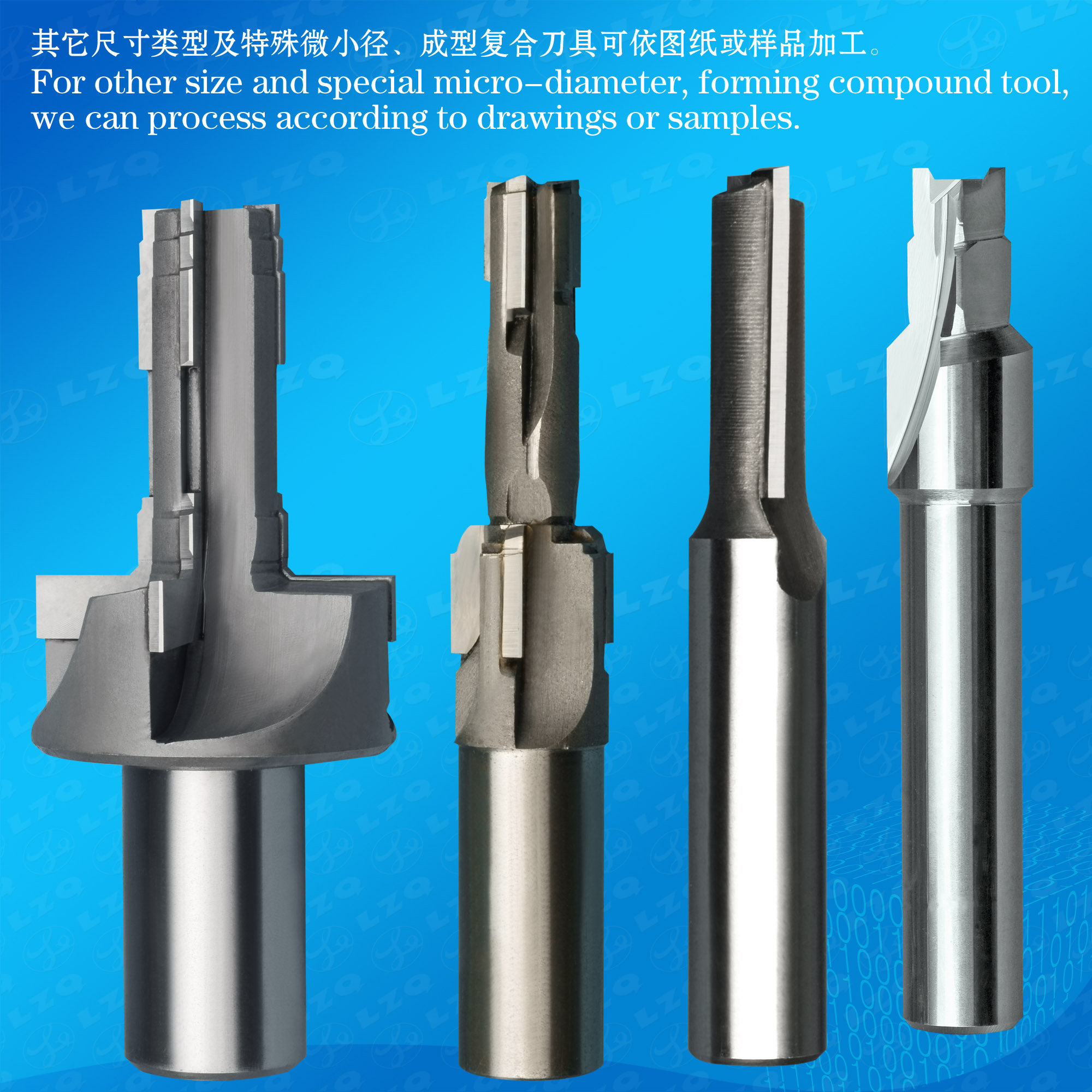

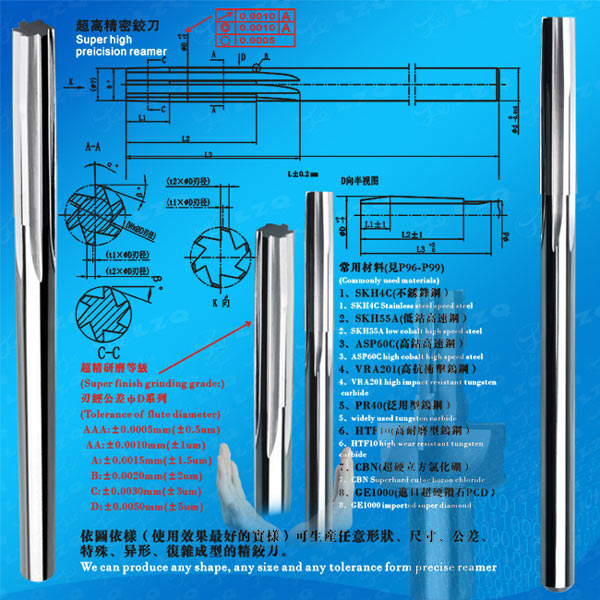

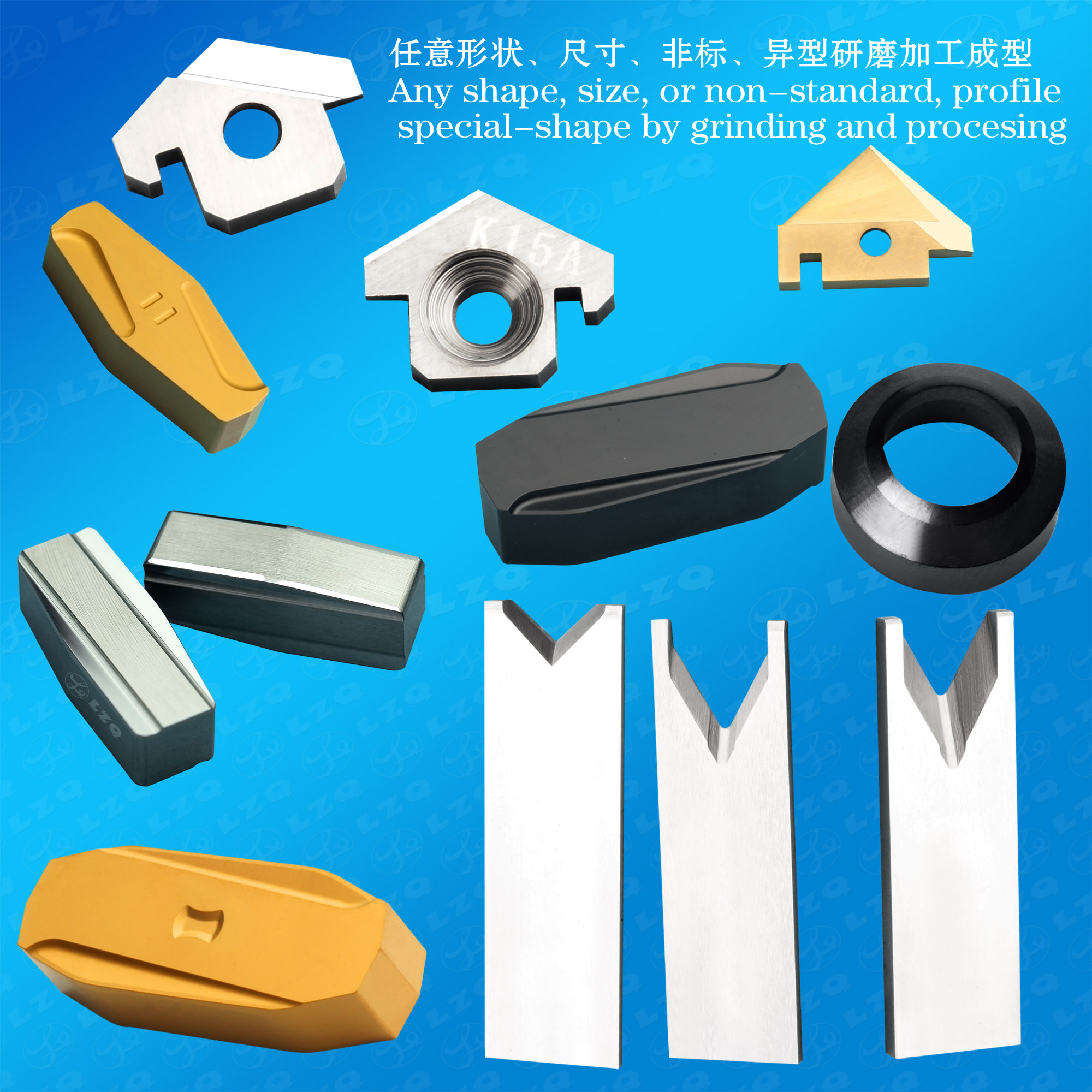

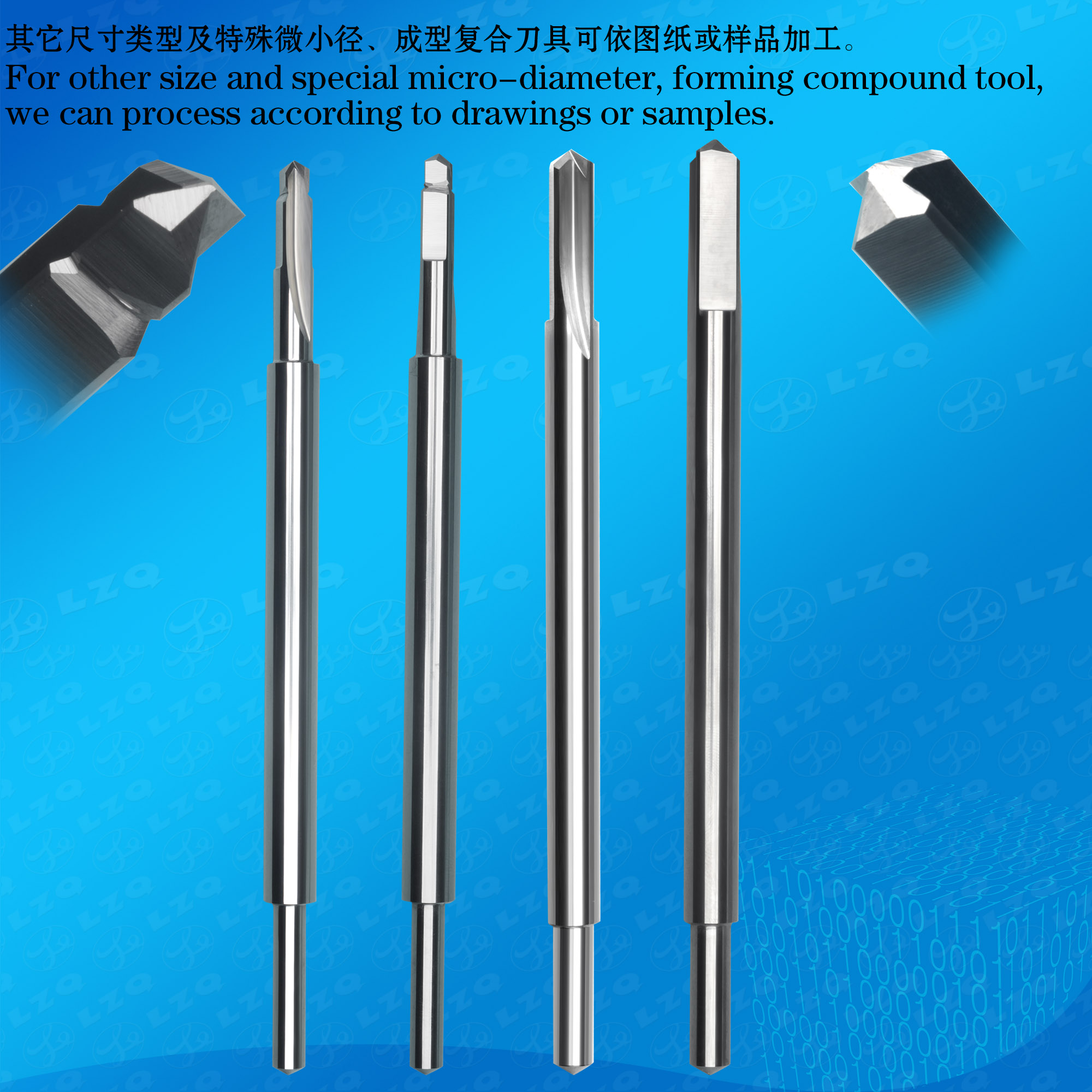

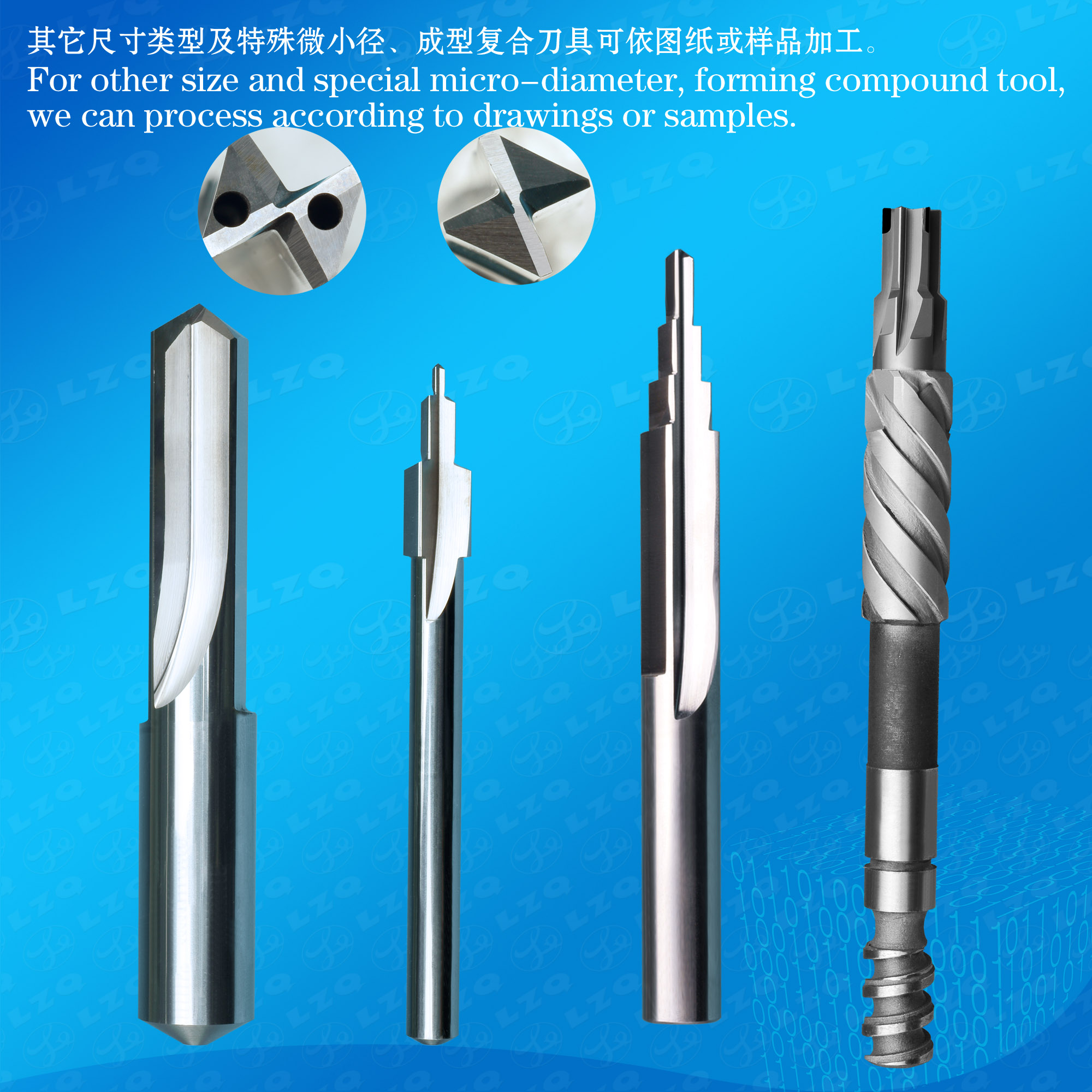

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material ,semi-products, finished products in ordinary year, we are capable to produce according to drawing or sample provided by customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory.

Product Details

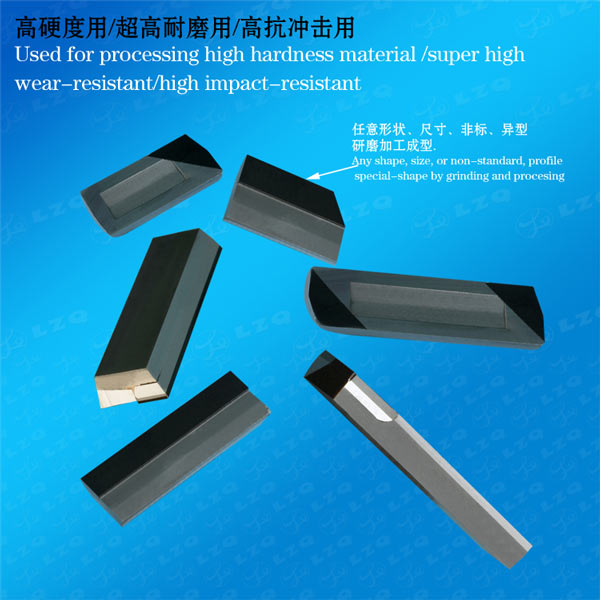

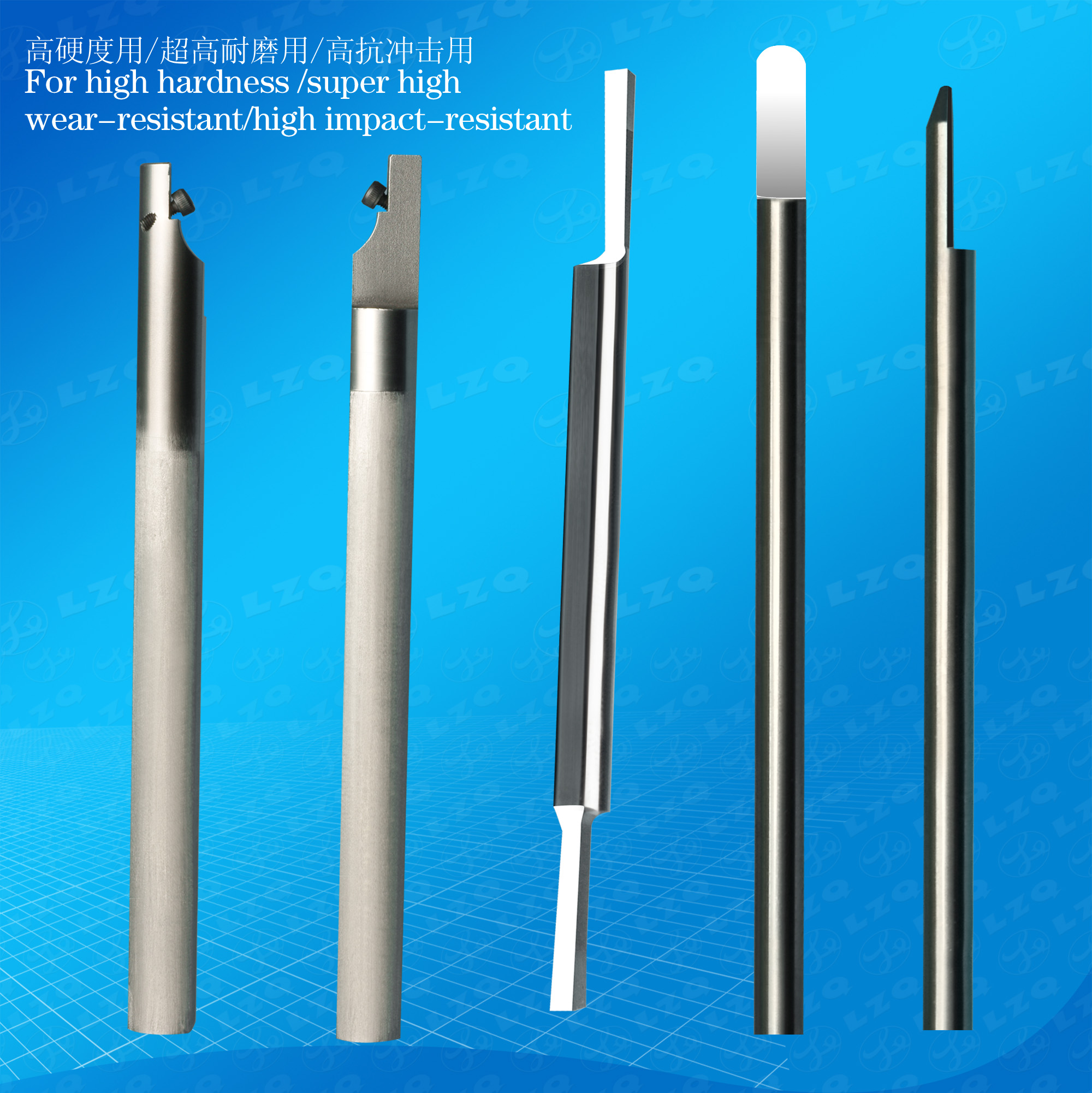

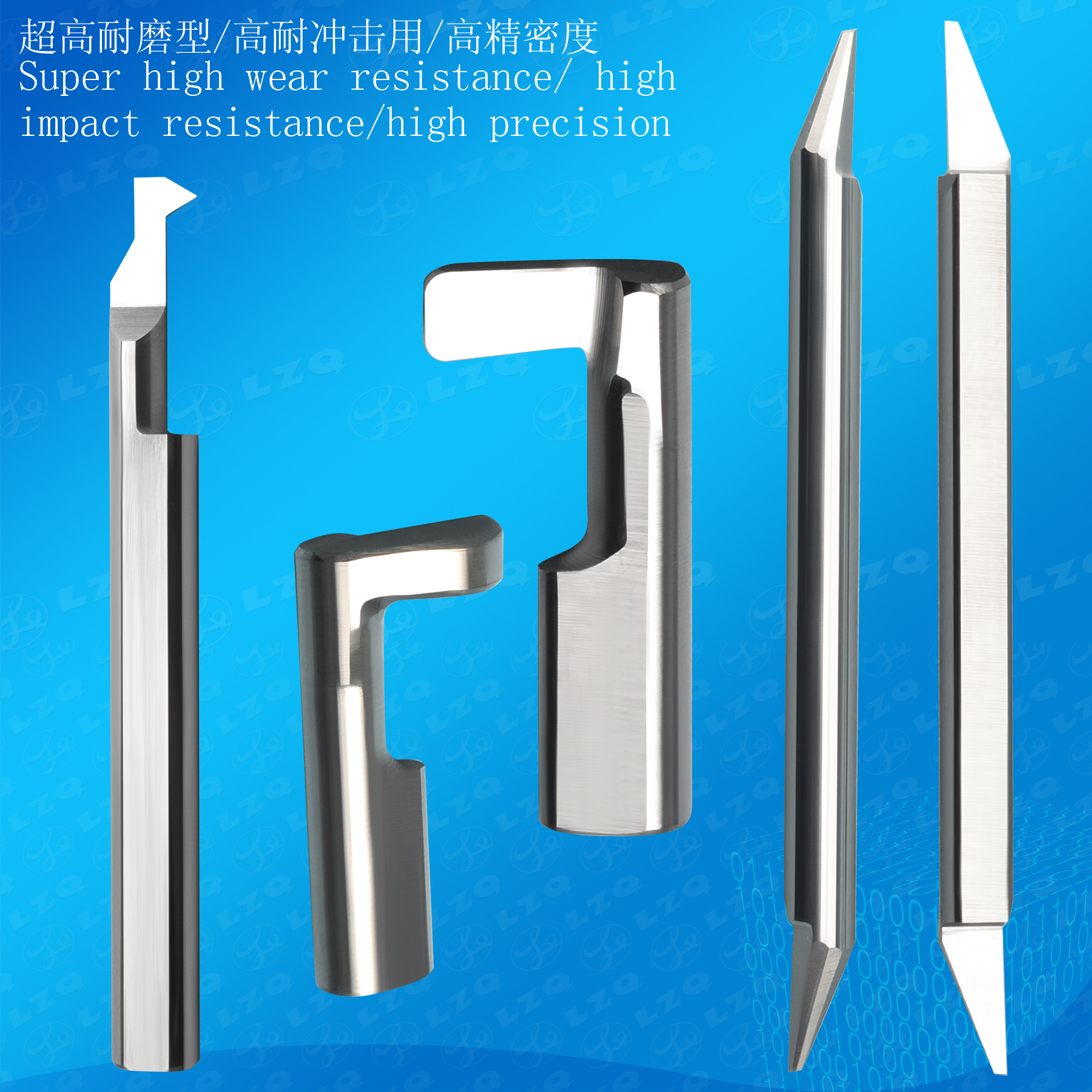

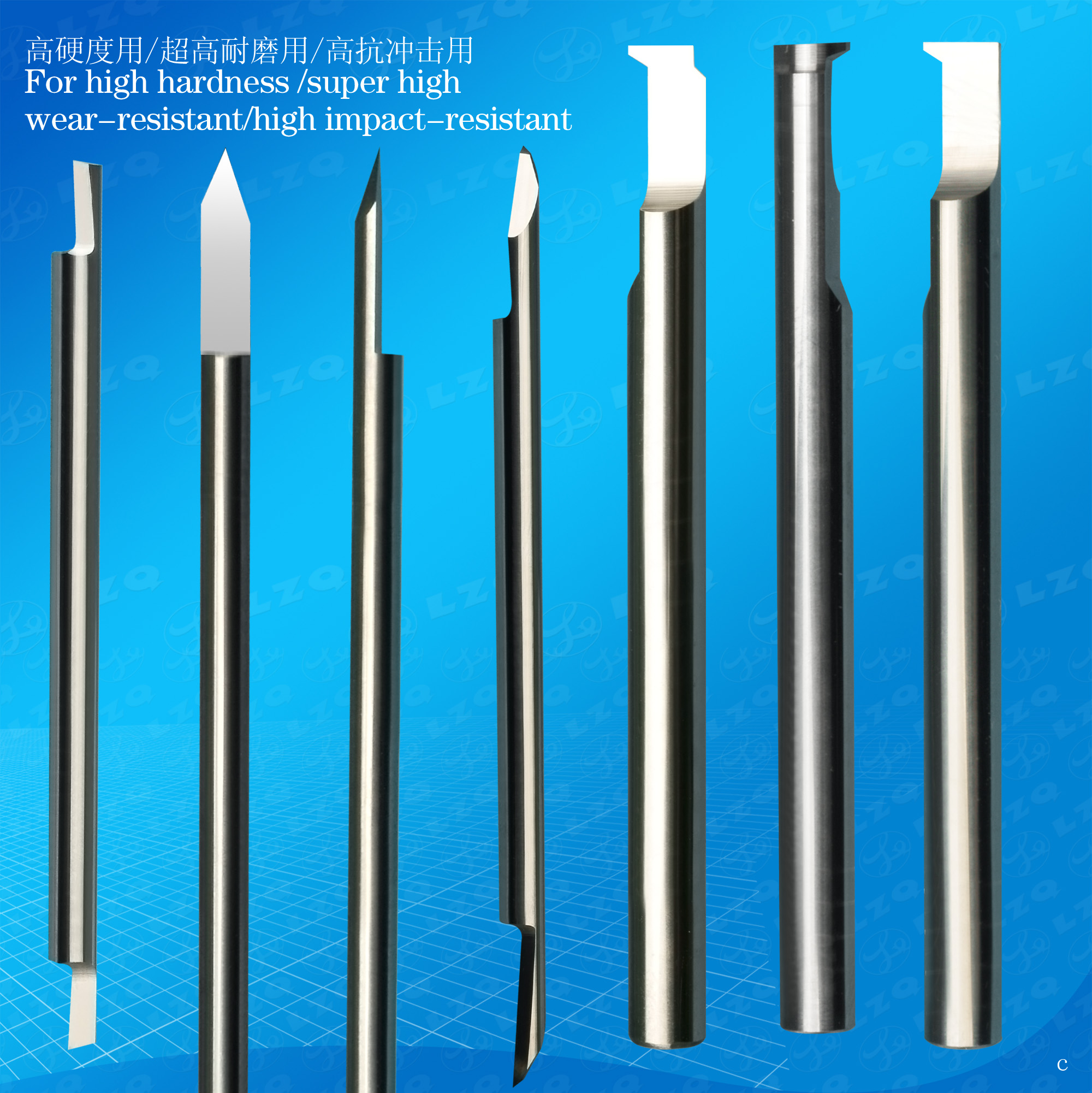

We can make any oval shape, round shape and other various shapes, stepsby super hard and super finish grinding. We can make any concave and convex shape and chip removal groove by mirror surface finish grinding. Punch,special-shape punch,high precision punch. CNC super finish grinding(complicated) profile punch die, finish shaft&wear resistant spare parts

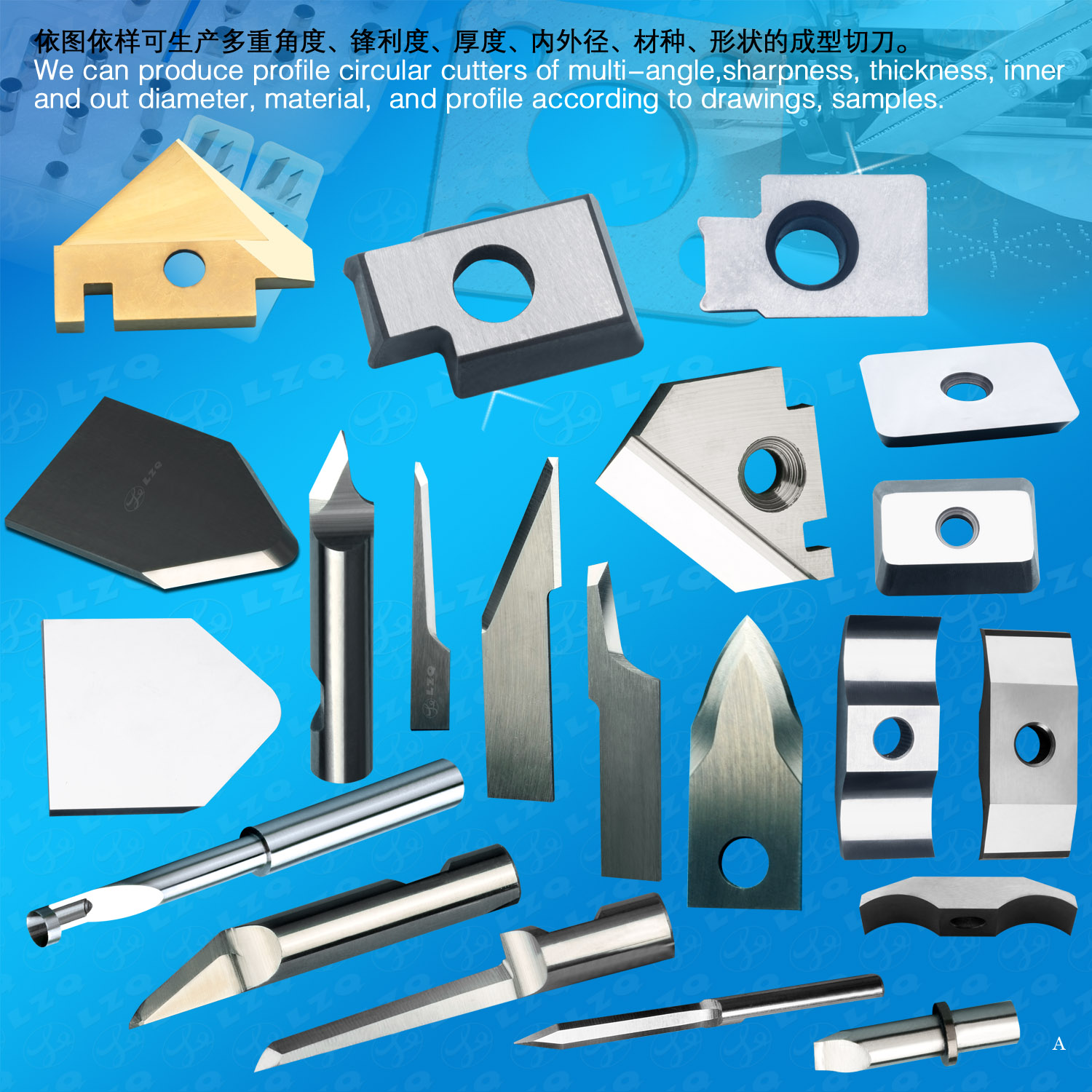

Knives are sharpened in various ways. Flat floor blades have a profile that tapers from the thick spine to the sharp aspect in a straight or convex line. Seen in pass section, the blade would structure a long, skinny triangle, or where the taper does not prolong to the back of the blade, a lengthy thin rectangle with one peaked side. Hollow floor blades have concave, beveled edges. The ensuing blade has a thinner edge, so it might also have higher cutting capacity for shallow cuts, but it is lighter and less durable than flat ground blades and will tend to bind in deep cuts. Serrated blade knives have a wavy, scalloped or saw-like blade. Serrated blades are more well acceptable for tasks that require aggressive 'sawing' motions, whereas simple area blades are higher acceptable for tasks that require push-through cuts (e.g., shaving, chopping, slicing).

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

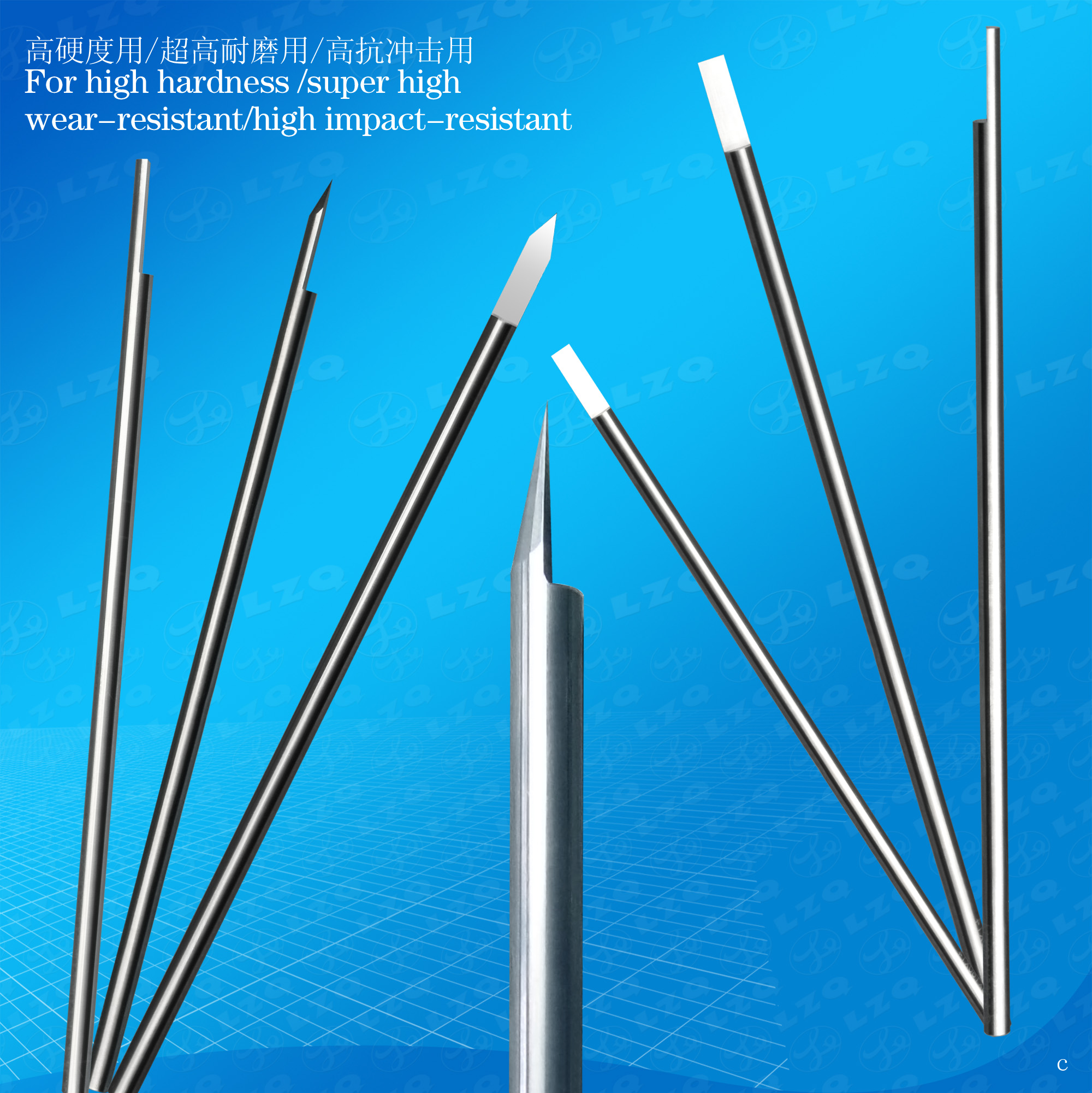

Medical Instrument

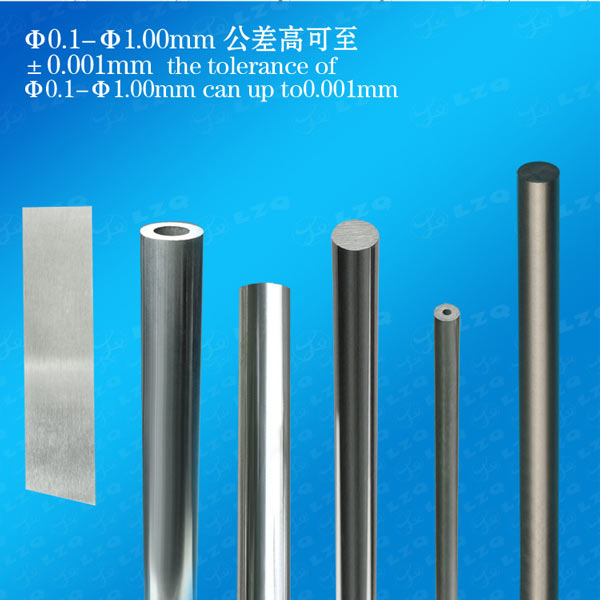

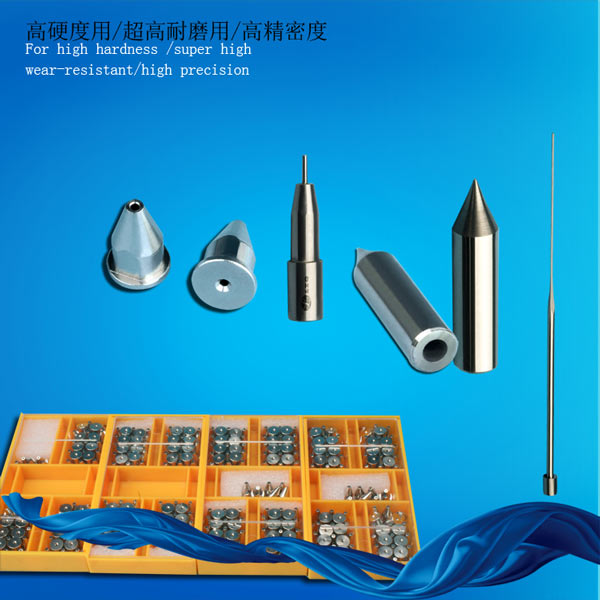

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

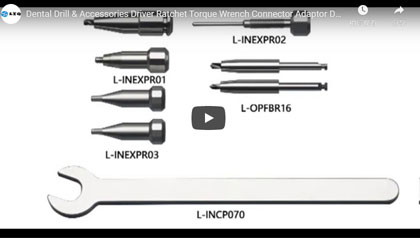

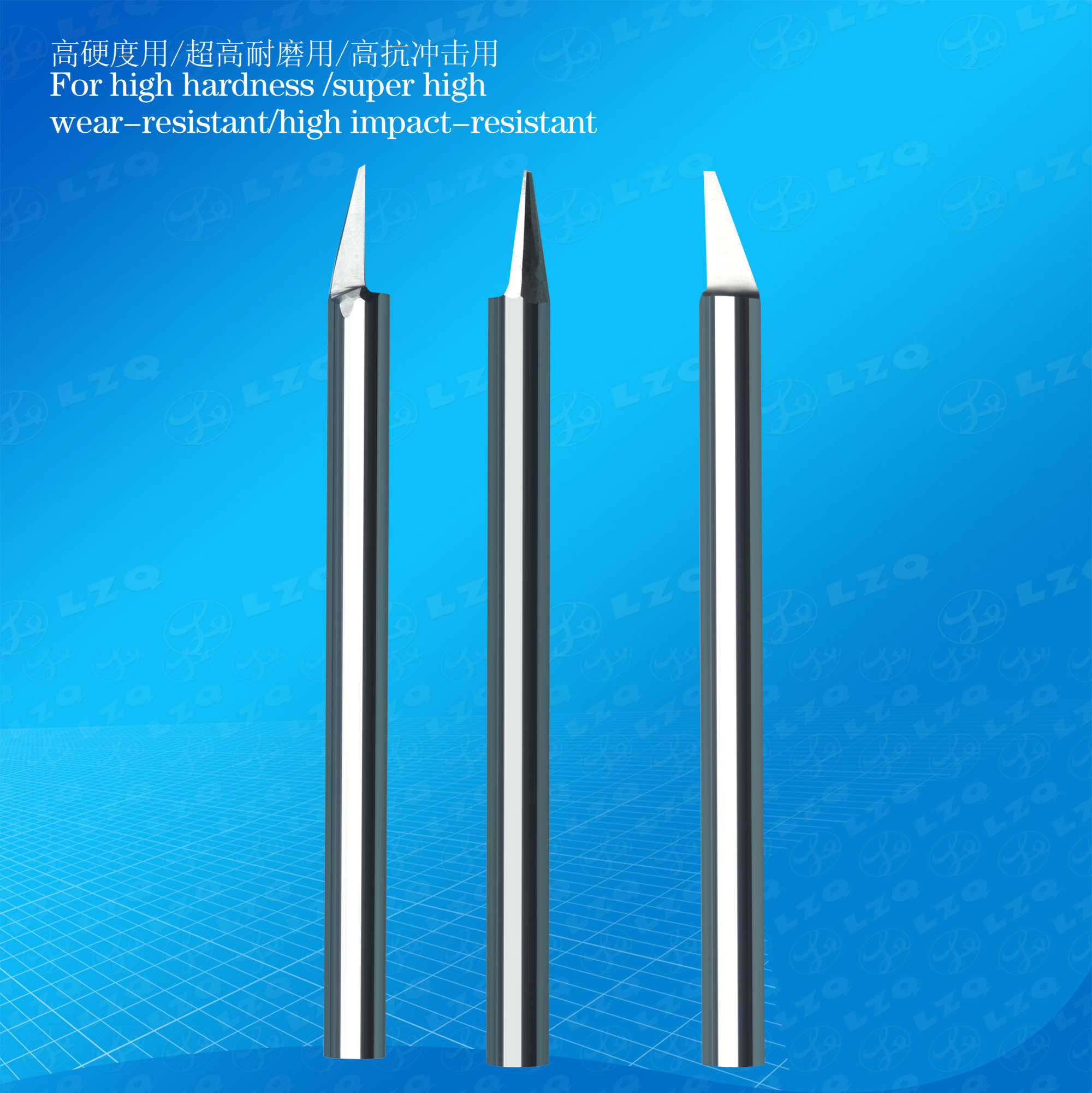

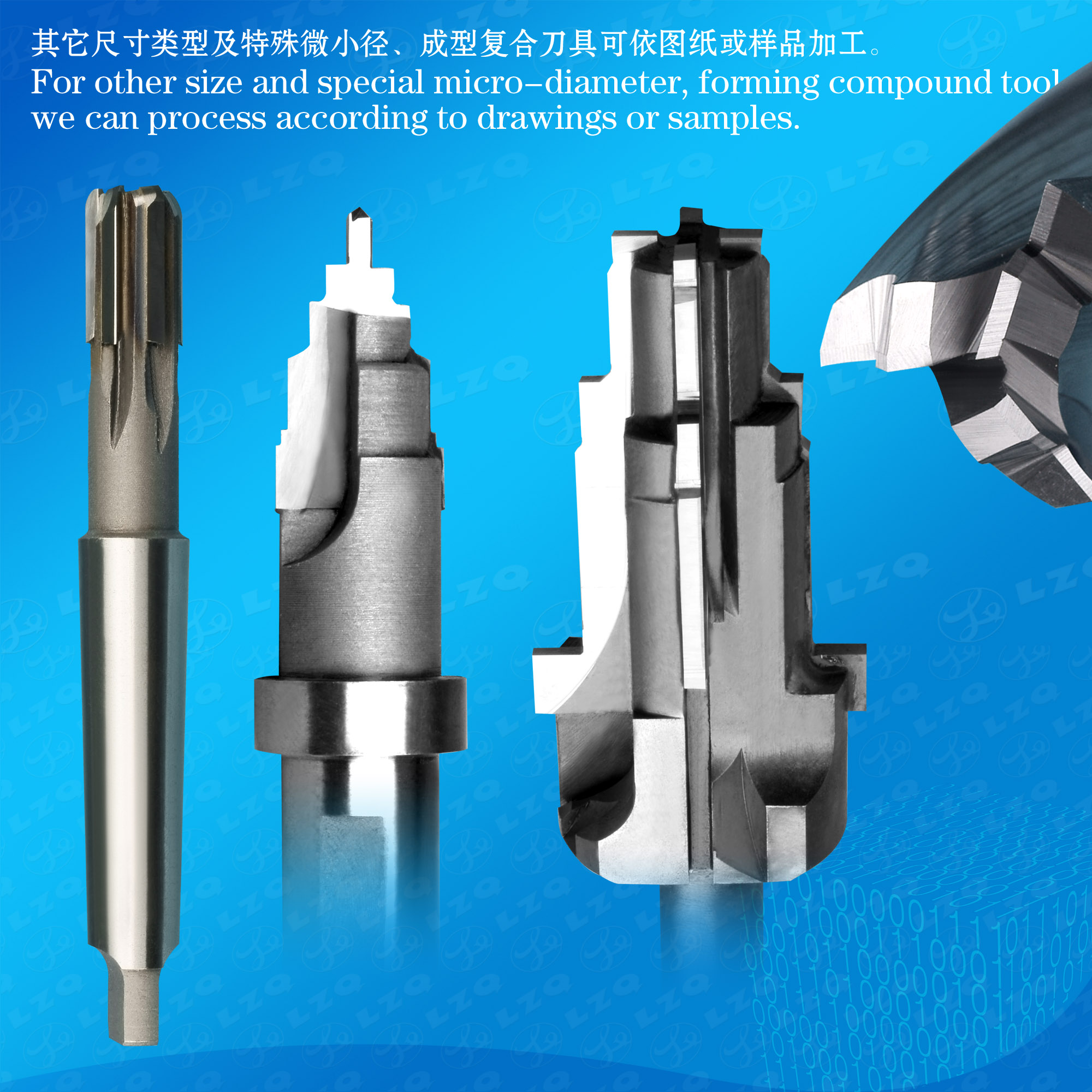

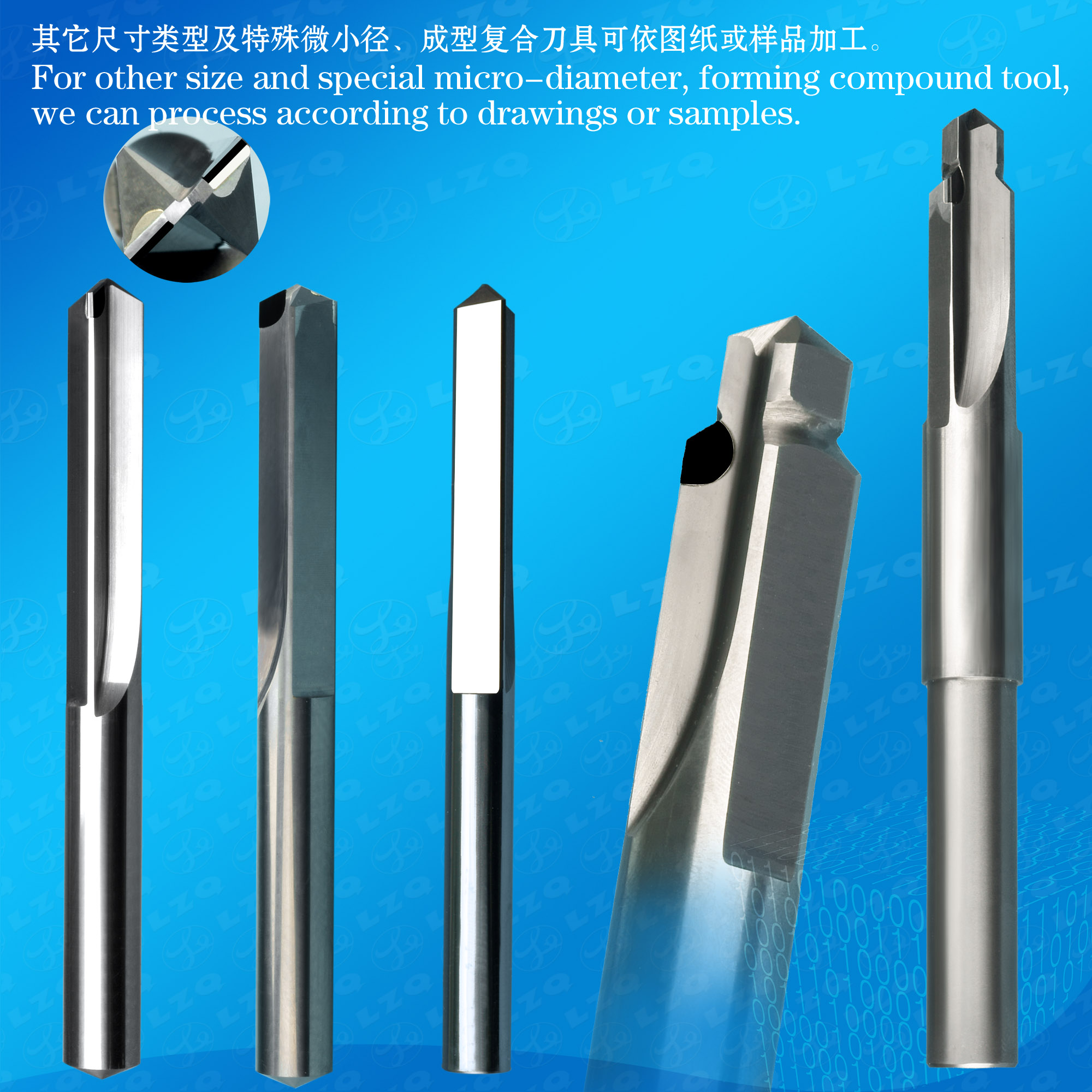

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

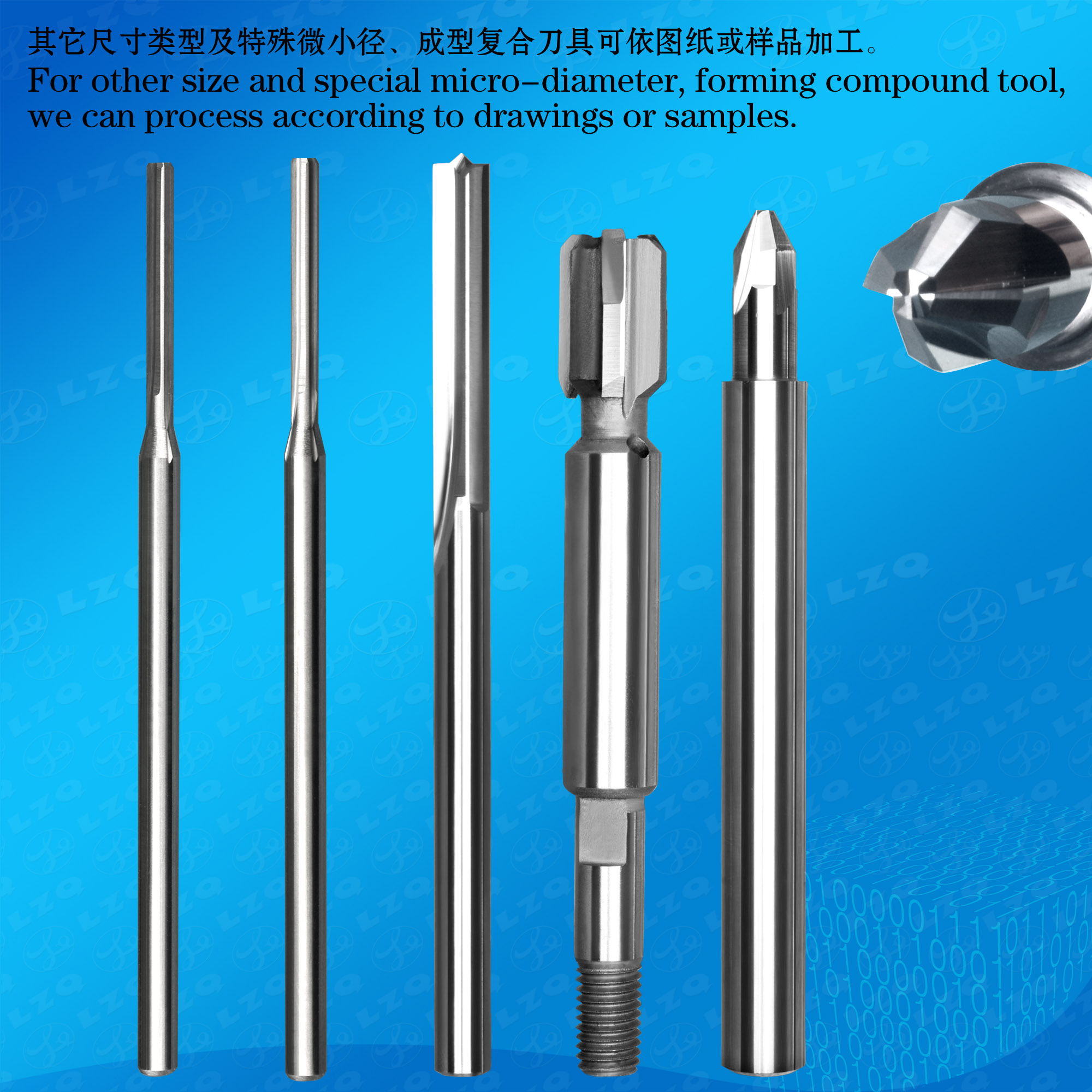

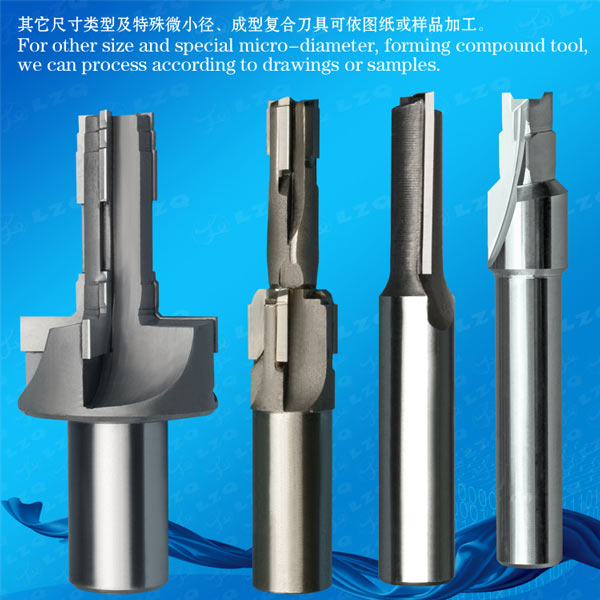

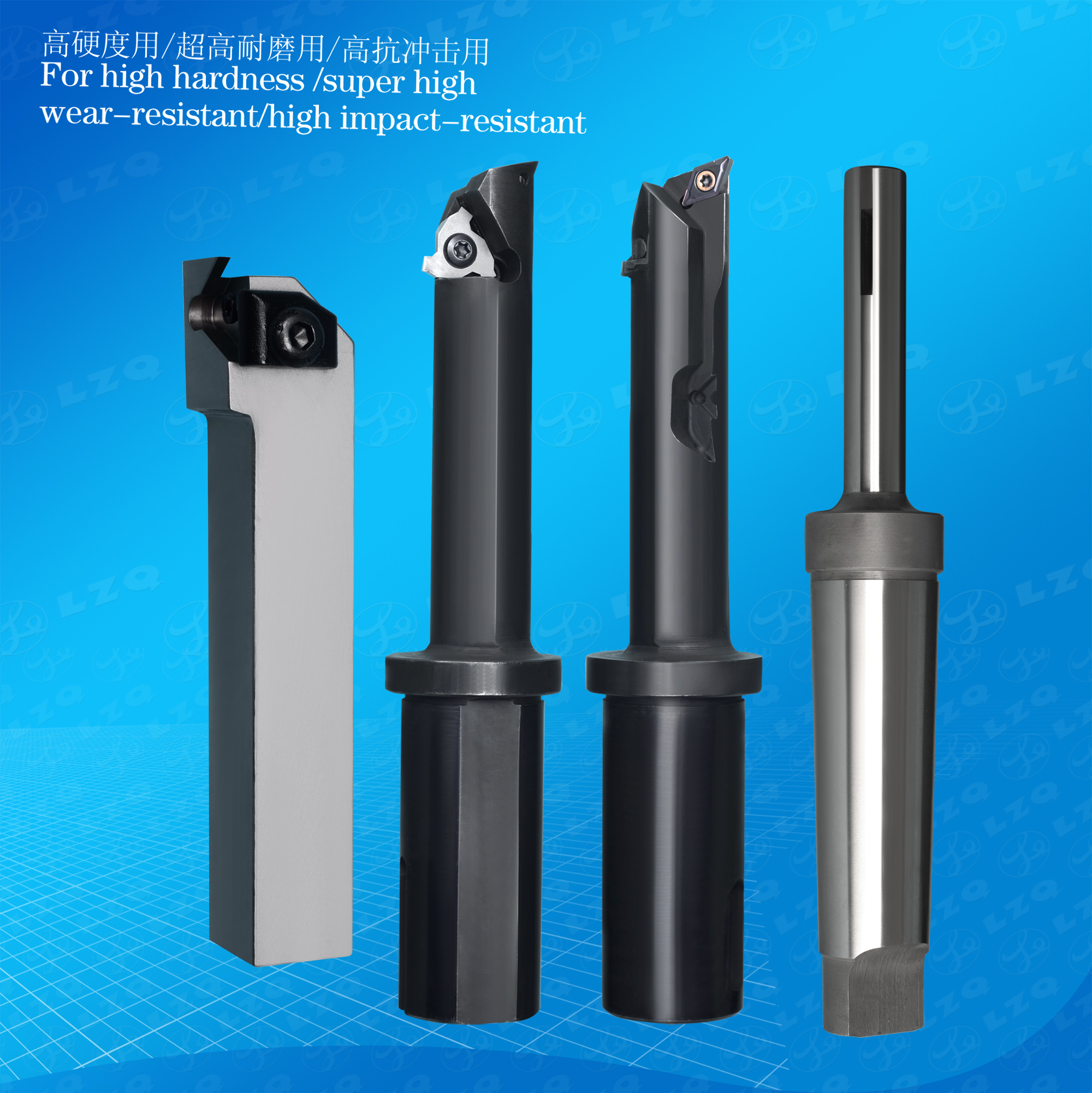

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

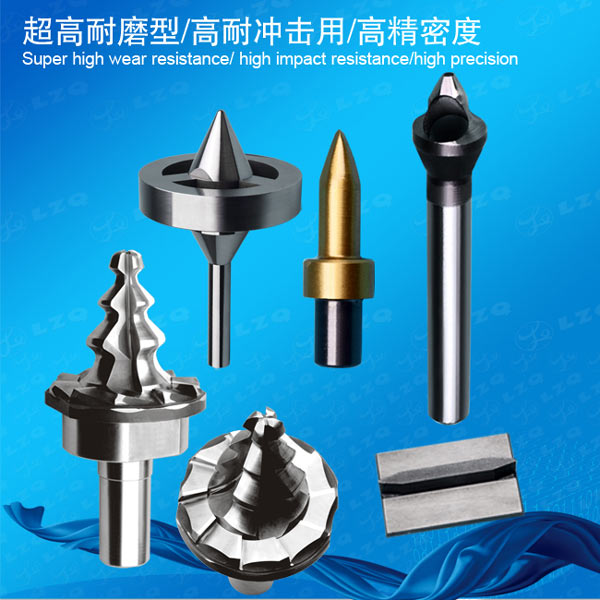

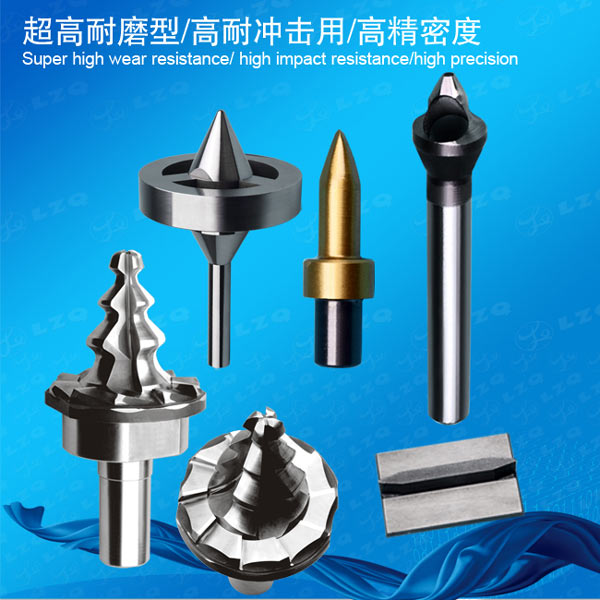

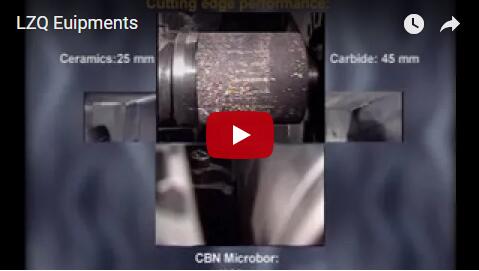

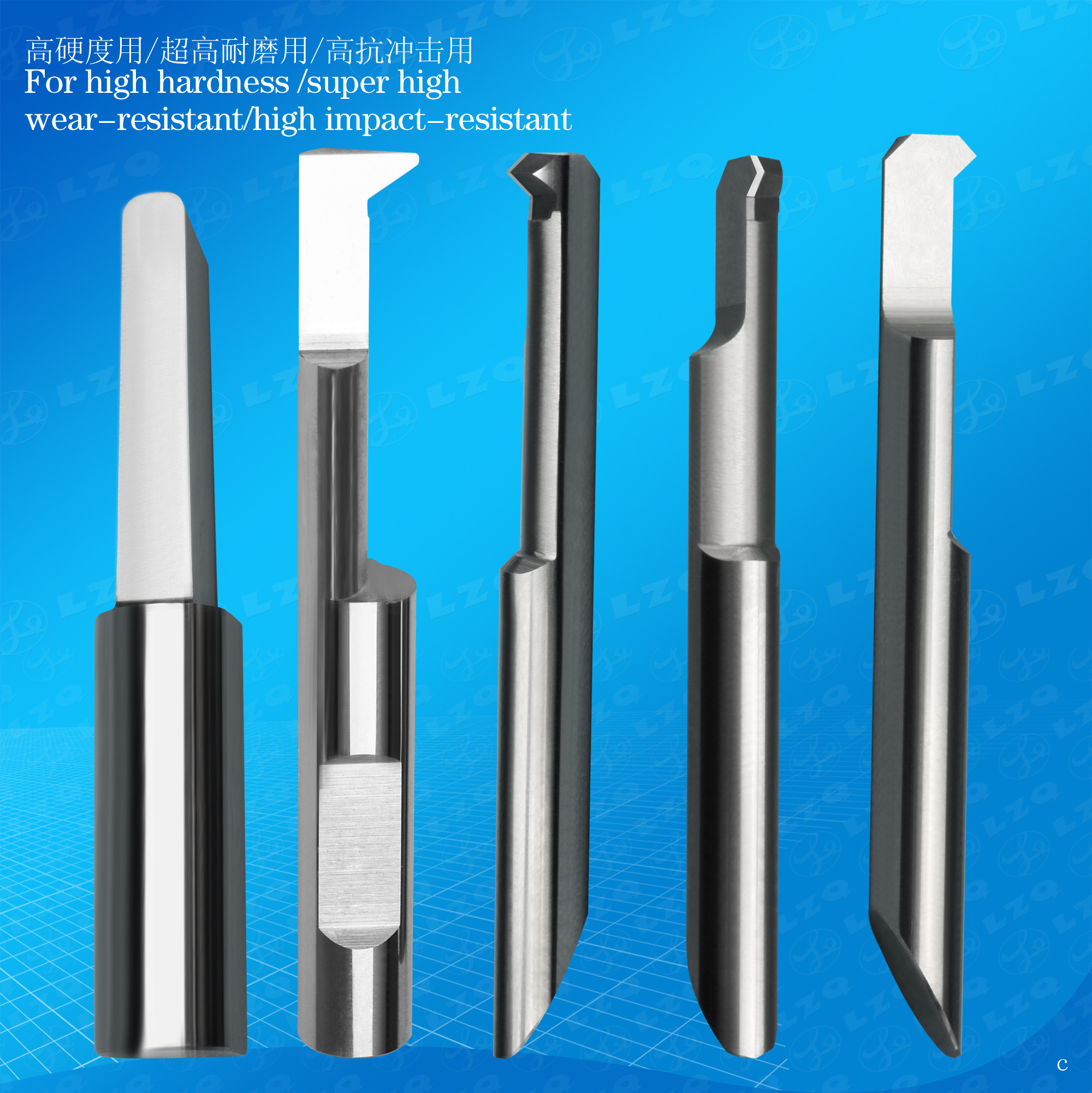

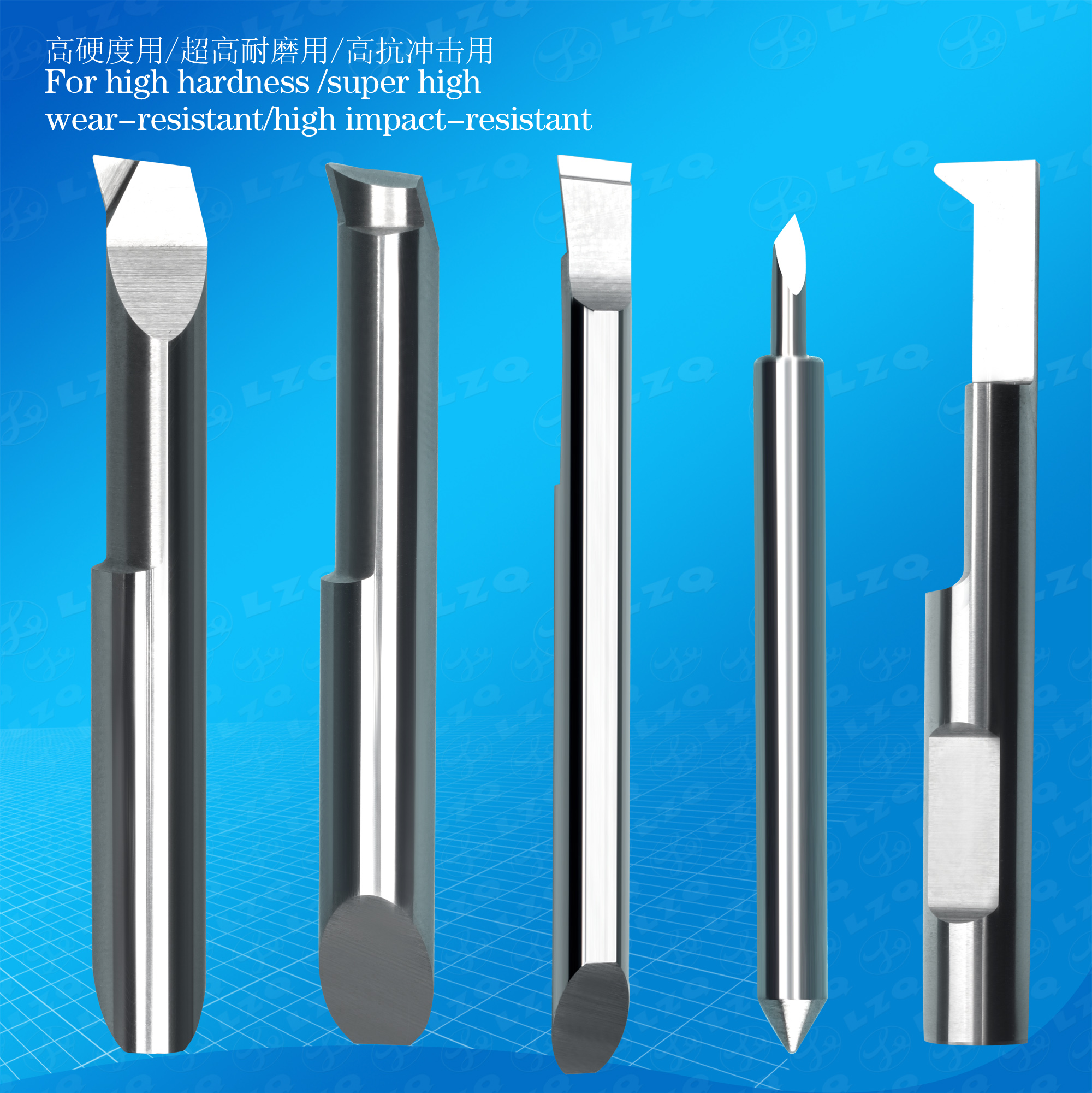

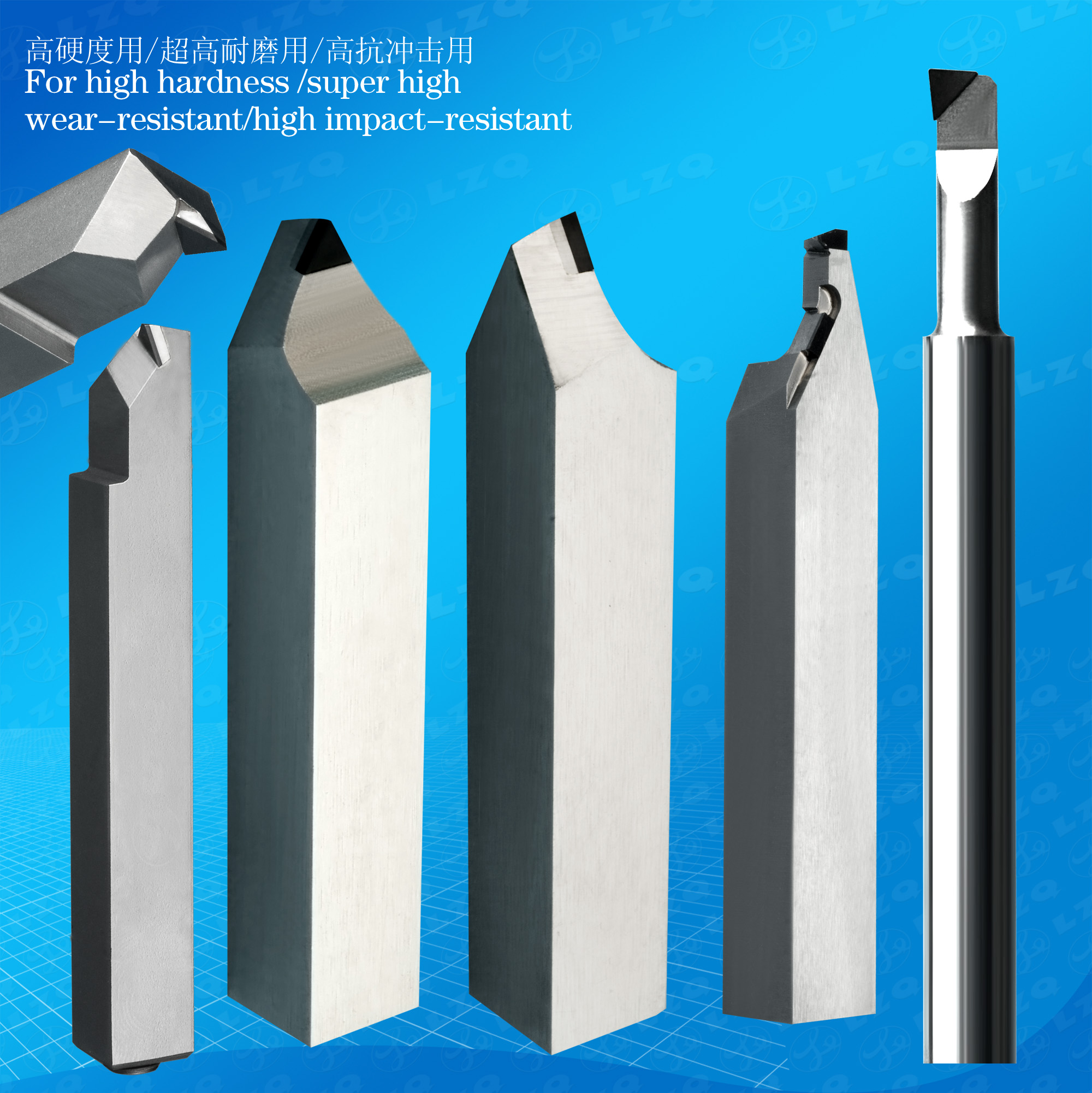

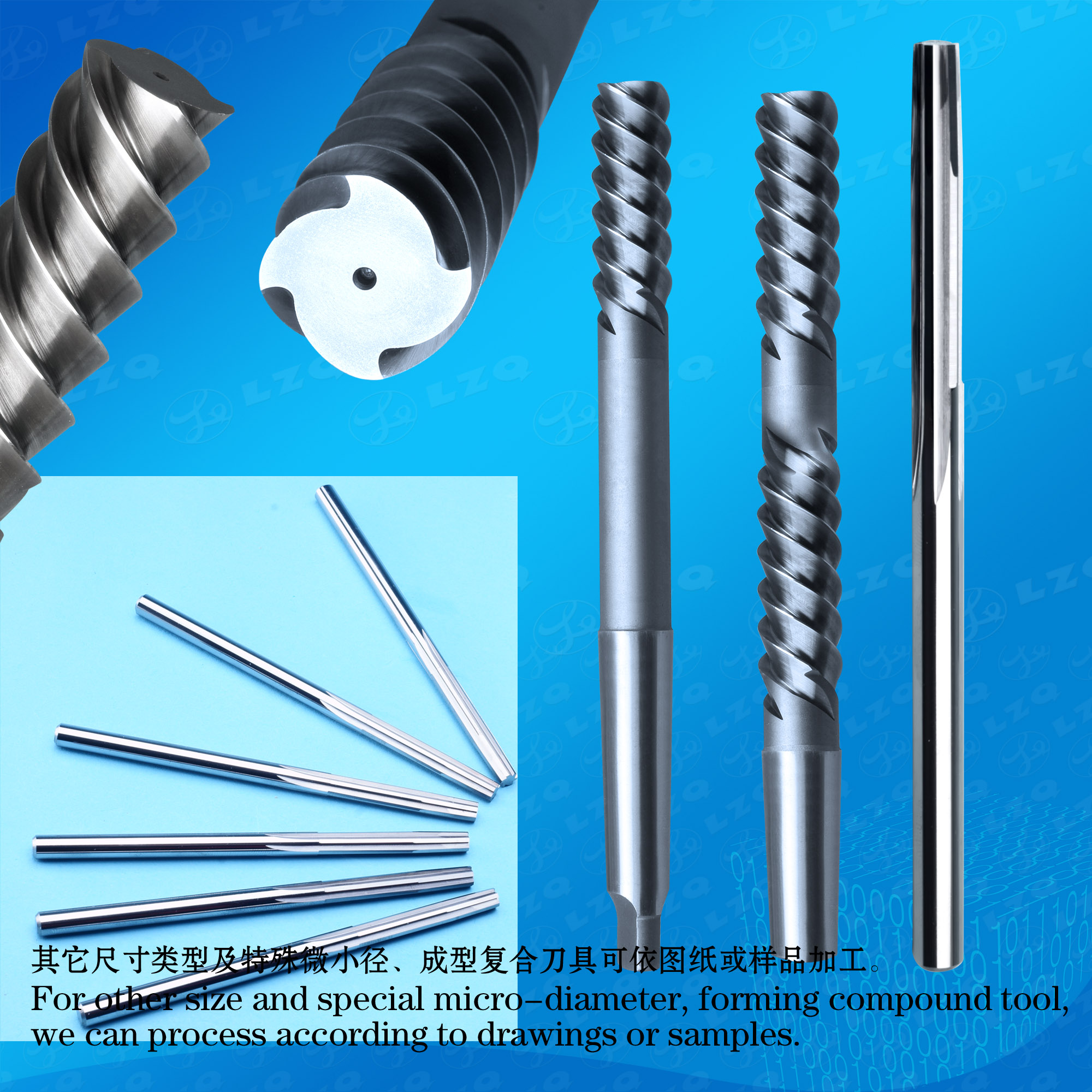

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

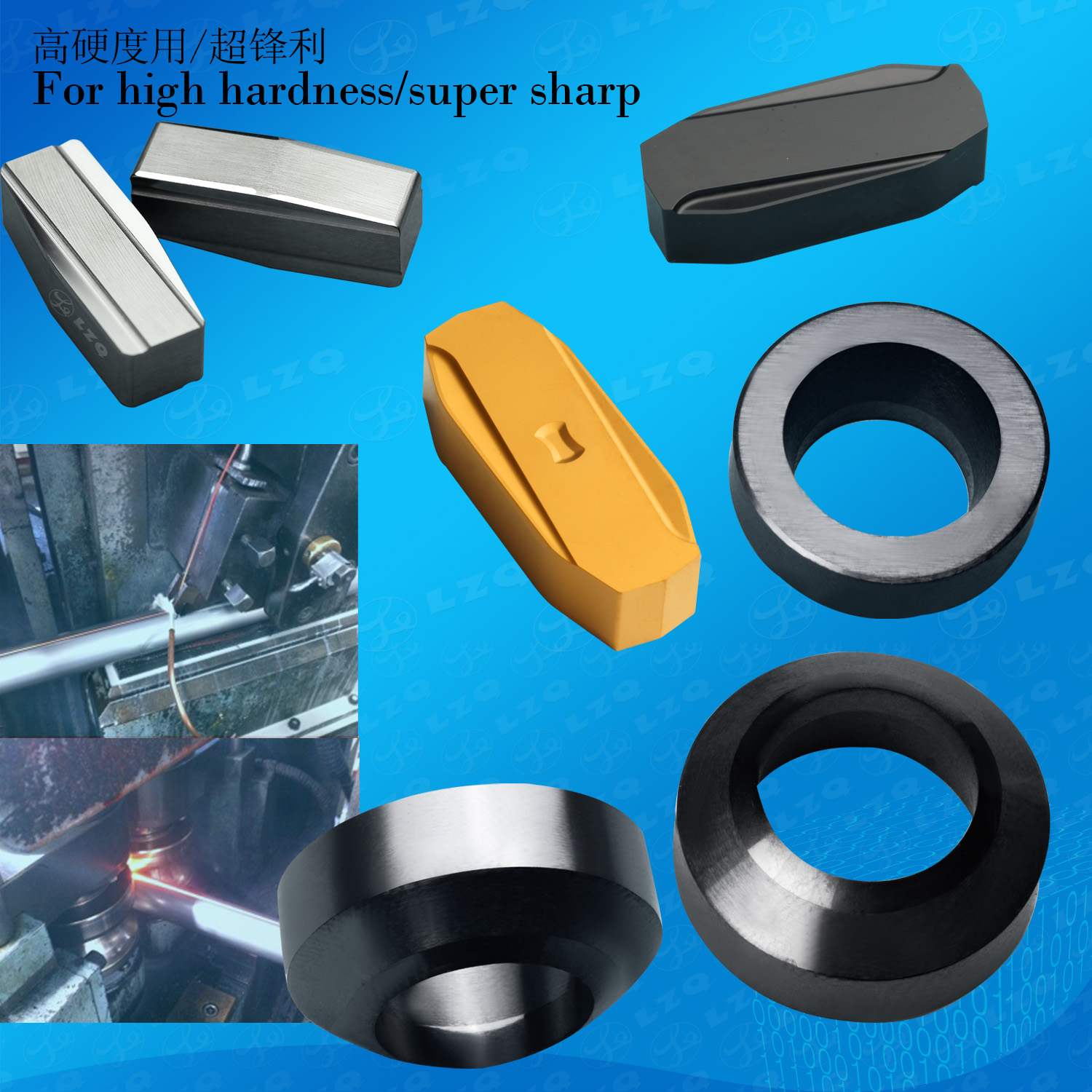

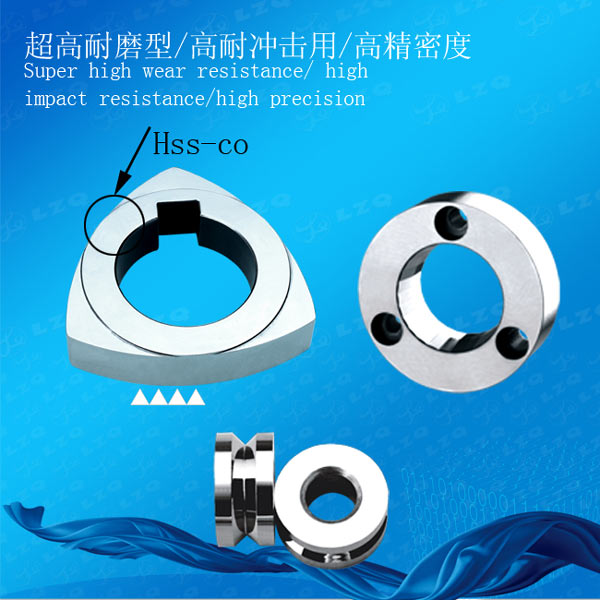

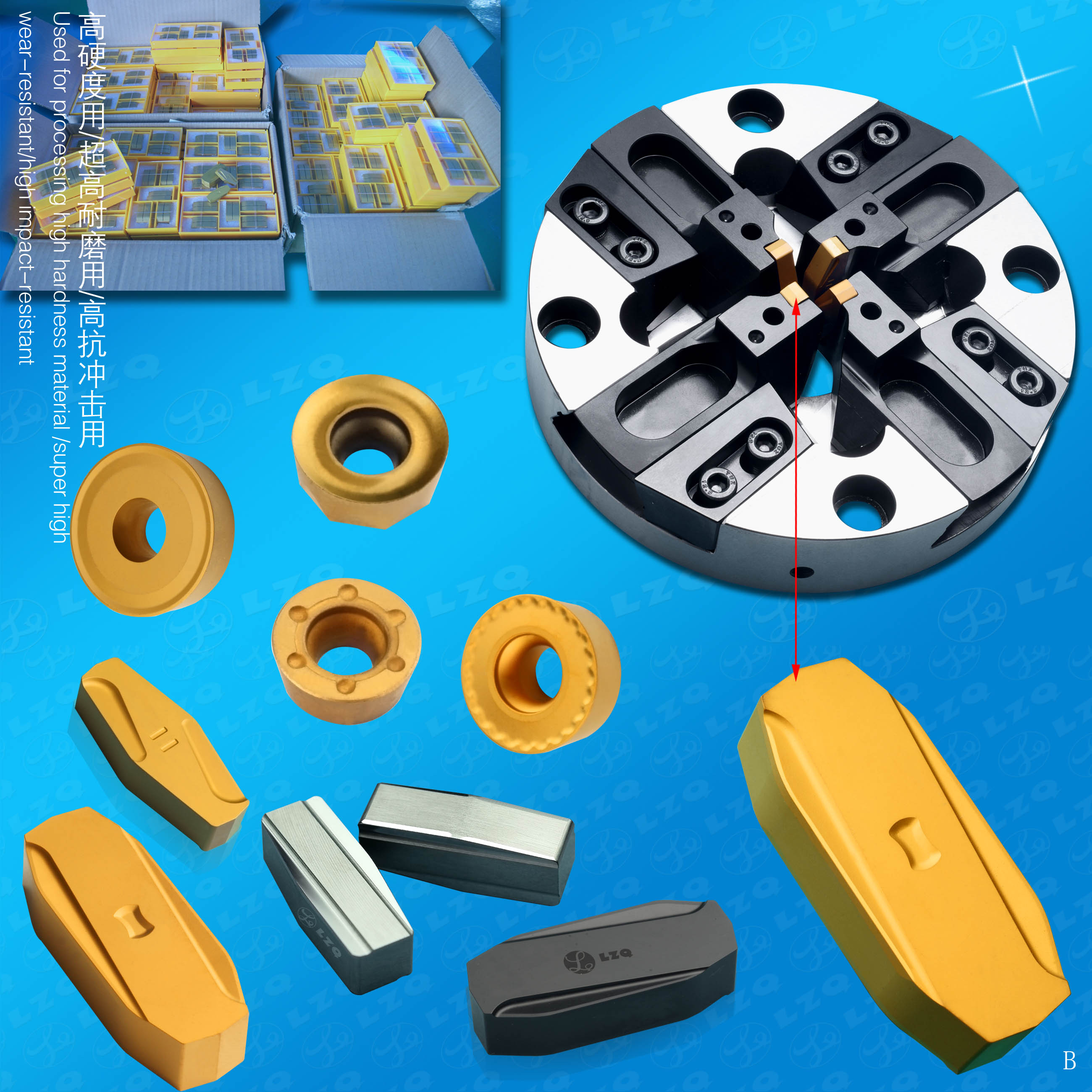

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.